Introduction: Why Industrial Buyers Should Care About Aluminum Printing

In high-volume industrial procurement, printing on aluminum sheets is not a cosmetic concern—it’s a functional specification. For buyers in sectors like electrical enclosures, vending systems, HVAC control panels, and med-tech, the printed layer impacts compliance, brand integrity, readability, and even system diagnostics. A misaligned or worn print mark could delay assembly, increase error rates, or fail certification audits.

Aluminum sheet printing is not plug-and-play. Variations in base metal, surface finish, ink chemistry, and environmental exposure create hidden risks. This article reframes printed aluminum not as a “nice to have” but as a strategic lever in lean manufacturing, traceable QA, and lifecycle cost control.

At YISHANG, a 26-year specialist in custom metal components, we’ve integrated industrial printing into sheet metal production SOPs across 50+ global markets. This guide outlines exactly what industrial buyers need to know—beyond aesthetics.

Aluminum Isn’t a Material—It’s a Spec System

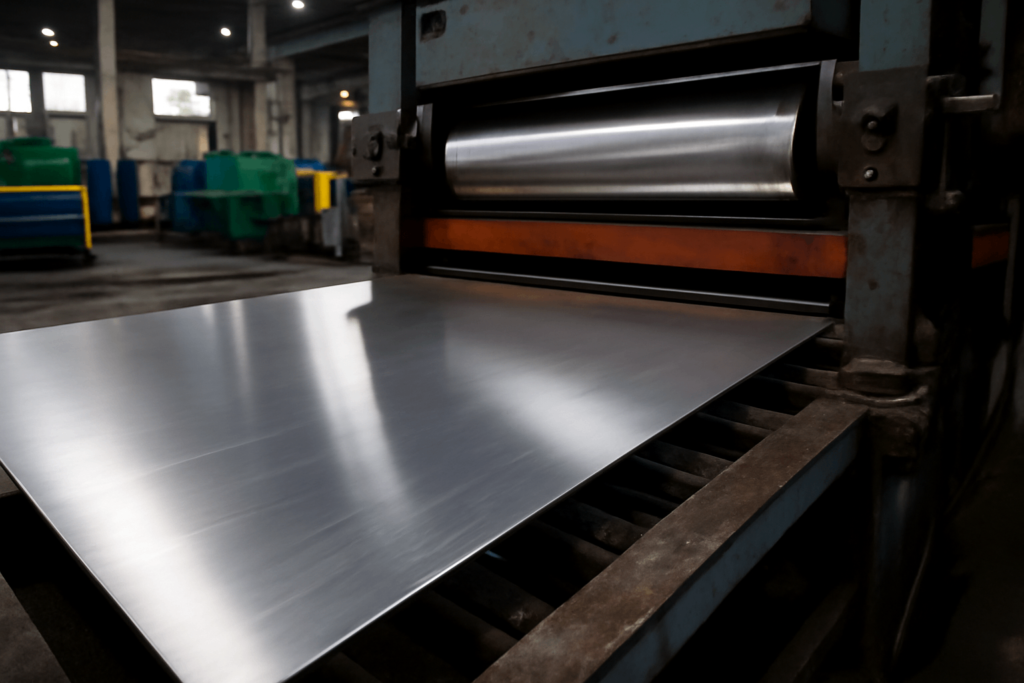

Alloy, Temper, and Sheet Gauge: Your Print Base Matters

Every printed part starts with substrate selection. 6061-T6, 5052-H32, and 1100 aluminum all offer different trade-offs:

- 6061-T6: Strong, corrosion-resistant, but harder, requiring aggressive pre-treatment to accept ink.

- 5052-H32: Ideal for parts needing both durability and print clarity, and supports post-print forming.

- 1100: Softer, better printability, but limited structural performance.

For printed nameplates, control panels, or data plates, mismatch here results in ink cracking during forming or insufficient clarity post-curing.

Buyer Tip: For foldable components, verify the alloy’s elongation rate. A printed panel that cracks at the bend is a rejected part.

Surface Finish and Surface Energy (Dyne Level)

Whether the aluminum is mill-finish, brushed, anodized, or coated affects adhesion dramatically. Surface energy—measured in dyne/cm—must be ≥38 for consistent ink bonding. Lower values risk spotty print, ghosting, or early flaking.

Use dyne pens or corona discharge testing before every print batch. YISHANG records surface energy for each production lot to ensure traceability.

Match Substrate + Print Type to Application Conditions

Outdoor aluminum tags face UV, humidity, salt spray. Printed control panels on factory lines endure chemical wipes and thermal stress. Use this rule:

- High UV exposure → Ink must pass ASTM G154

- Corrosive environments → Substrate + primer must pass ASTM B117

- Mechanical wipe-down → Ink must pass ISO 2409 adhesion tests

Poor substrate selection isn’t cosmetic—it’s operational risk.

Before the First Drop of Ink: Surface Engineering Essentials

Industrial Cleaning Protocols

A clean substrate is non-negotiable. Residual oil, oxidation, or particulate matter causes print inconsistencies or peel-off. YISHANG uses:

- Dual-phase cleaning: IPA + deionized water

- Pre-bake at 65°C to release surface moisture

- Light acid etching (if needed) to boost dyne rating

Skipping this step caused up to 18% failure in third-party cross-hatch tests.

Primer Systems and Functional Coatings

Printing on aluminum without primer works—for short-lived, indoor-only parts. For field durability, pair ink chemistry with primer class:

- UV inks → urethane primers

- Solvent inks → epoxy primers

Always require test data from suppliers: ISO 2409 adhesion ratings, ASTM B117 corrosion cycles, humidity aging tests.

Engineering Note: For high-speed wipe-down zones, ask for abrasion resistance results using Taber or Crockmeter testing.

Where Printing Fits in the Assembly Line

Should printing occur before or after forming? Both options carry risks:

- Pre-form printing: risk of ink fracture during bending

- Post-assembly printing: risk of contamination from assembly fluids

At YISHANG, we print after metal forming but before mechanical fastening, using CNC-aligned jigs to maintain ±0.2mm print placement.

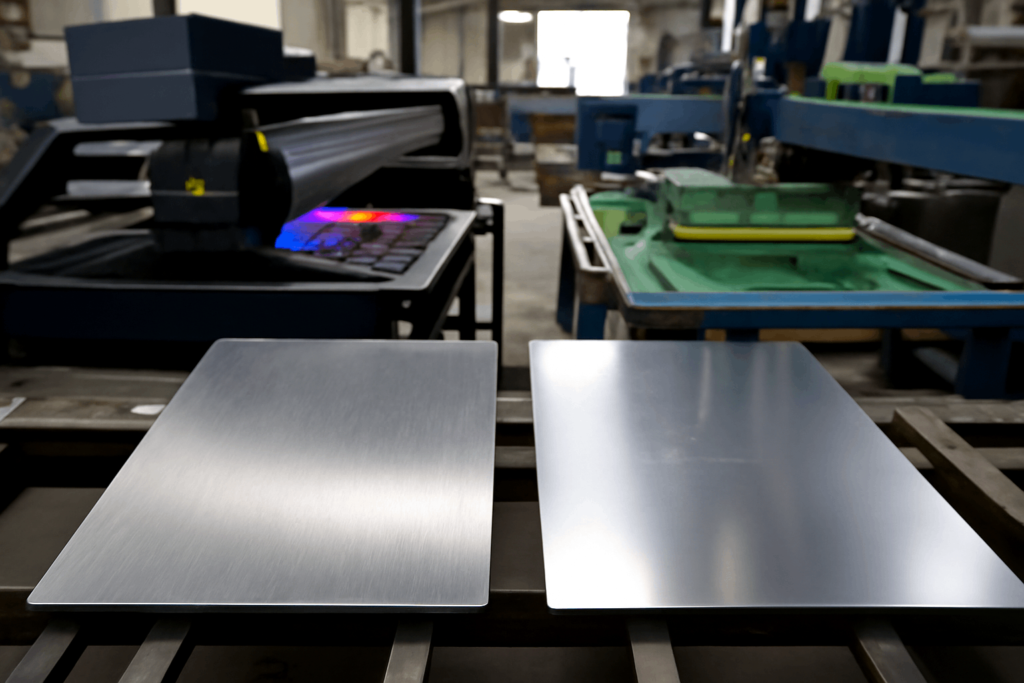

Which Printing Method Is Best for Your Specs?

UV Digital: Agile But Limited

- Best for: short runs, variable data, rapid prototyping

- Pros: low setup cost, flexible graphics

- Cons: lower durability, weak solvent resistance

Use case: Internal serial labels, instructional overlays

Screen Printing: Rugged and Scalable

- Best for: >500 pcs, outdoor or industrial parts

- Pros: high ink deposit, chemical/UV resilience

- Cons: requires screen tooling

Use case: Machinery panels, vending faceplates

Sublimation: High Visuals, Low Toughness

- Requires: polyester-coated aluminum blanks

- Pros: full-color photo-quality

- Cons: weak UV/solvent resistance

Use case: Decorative panels, office signage—not for OEM parts

Hybrid and Precision Methods

Advanced OEMs now mix:

- Laser + ink fill for serialized plates

- Pad print + clear coat for IP-rated enclosures

Buyer Tip: If serial traceability is needed, confirm print legibility after salt spray and chemical wipe.

Will It Survive the Field? Test Before You Print at Scale

Environmental and Chemical Durability

Mandate suppliers test to these benchmarks:

| Test Standard | Purpose | Min. Requirement |

|---|---|---|

| ASTM G154 | UV resistance | 500hr exposure |

| ASTM B117 | Salt spray corrosion | 240hr with <15% delam |

| ISO 2409 | Adhesion | ≤Grade 1 |

YISHANG logs all these values per batch for QA traceability.

Mechanical Interference and Print Wear

Problems arise near bends, rivets, or screw holes. Follow spacing rules:

- Leave ≥8× sheet thickness from print to bend line

- Avoid placing print over stress-bearing contours

- Allow ≥24h full cure before packing to prevent smearing

Real Case: One client saw a 90% defect drop after re-spacing prints post-bend.

Transit and Shelf-Life Protection

Even perfect prints fail if poorly packed:

- Use PE protective films

- Foam interleaf between panels

- Export-grade cartons with moisture barrier

YISHANG Packaging SOP: Zero movement per box, <2% shipping abrasion loss.

Print Integration into OEM Production SOPs

Inline Traceable Printing

YISHANG aligns print operations with your SOP:

- Fixture-guided positioning

- Inline optical QC

- Batch-lot ink certification

Outcome: 98.7% first-pass yield in a 10,000-pc lot for EV charger panels.

CAD-Driven Print Zones

DFM starts at the drawing stage. CADs should include:

- No-print and ink-safe zones

- Barcode/QR code specs

- Ink class and finish type

Our engineers co-develop DFM-compatible prints with procurement teams for lower defect rates.

Full QA Traceability Packs

Auditable print lots include:

- Ink batch + expiration

- Cure data log

- Surface energy (dyne test) record

- Print location / jig setup ID

Critical for: Medtech, EV, Aerospace, UL-marked goods

Buyer’s Checklist: What to Confirm Before Placing Orders

Before sending a PO for printed aluminum sheets, get answers to these:

- Is the alloy compatible with my forming needs?

- Has surface energy been validated (≥38 dyne/cm)?

- What primer system is in use?

- Which print method fits my lifecycle needs?

- Can supplier align to my assembly SOP?

- Are ASTM/ISO test reports included?

- What’s the MOQ and tooling lead time?

Pro tip: Ask for a functional sample under your exact assembly & cleaning conditions.

FAQ: What Industrial Buyers Ask About Printed Aluminum

Q1: What’s the MOQ for industrial aluminum printing?

Typically 300–500 pcs for screen print; digital as low as 50 pcs. MOQ varies by print size & substrate.

Q2: Can printed aluminum survive chemical exposure?

Yes, with correct primer + ink + overcoat. Always request ISO 2409 and ASTM B117 data.

Q3: Can prints resist UV fading outdoors?

With UV-rated inks and proper substrate prep, yes. Look for ASTM G154 ratings ≥500 hrs.

Q4: Can my barcode or serial number be printed inline?

Yes, via digital or pad printing with CAD-defined zones. Add verification steps in QC SOP.

Q5: How long is the print durable post-shipment?

With correct curing, handling, and packaging, up to 5–10 years depending on environment.

Conclusion: Printing is Not Decoration—It’s a Supply Chain Spec

Printed aluminum parts aren’t about design—they’re about performance. From UV and salt spray to barcode traceability and assembly alignment, printing on aluminum requires an engineered approach.

At YISHANG, printing is not a final step—it’s a built-in process, integrated with forming, QA, and traceability. That means reduced return rates, faster SOP onboarding, and better end-user reliability.

Talk to Our Print Engineering Team

Let YISHANG help you define the right printing workflow for your application. From alloy selection to test data to inline setup, we build print solutions—not just prints.

📩 Reach out now to align your specs with real-world performance.