Table of Contents

隐藏

For global wholesale buyers and engineering‑focused procurement teams, how to cut galvanized steel sheet is not a workshop tip. It directly influences corrosion resistance, dimensional accuracy, service life and warranty outcomes. When thousands of galvanized components go into outdoor cabinets, telecom housings, vending machines or farm equipment, the stability of the cutting process determines the long‑term reliability of your products—and your customer’s perception of quality.

Most online guides explain how to cut galvanized sheet metal with hand tools for home projects. Those resources do not address coating integrity, batch consistency, industrial tolerances or the supply chain risks wholesale buyers face. This article shifts the focus to the real concerns of B2B sourcing: coating protection, production repeatability, downstream fabrication impact and the ability to evaluate suppliers who claim they can cut galvanized steel effectively.

Our goal is to help you read quotations with greater technical clarity, verify capability more confidently and select partners who manage cutting as a controlled process—not an improvised step.

Quick Overview — How Professionals Cut Galvanized Sheet Metal in Production

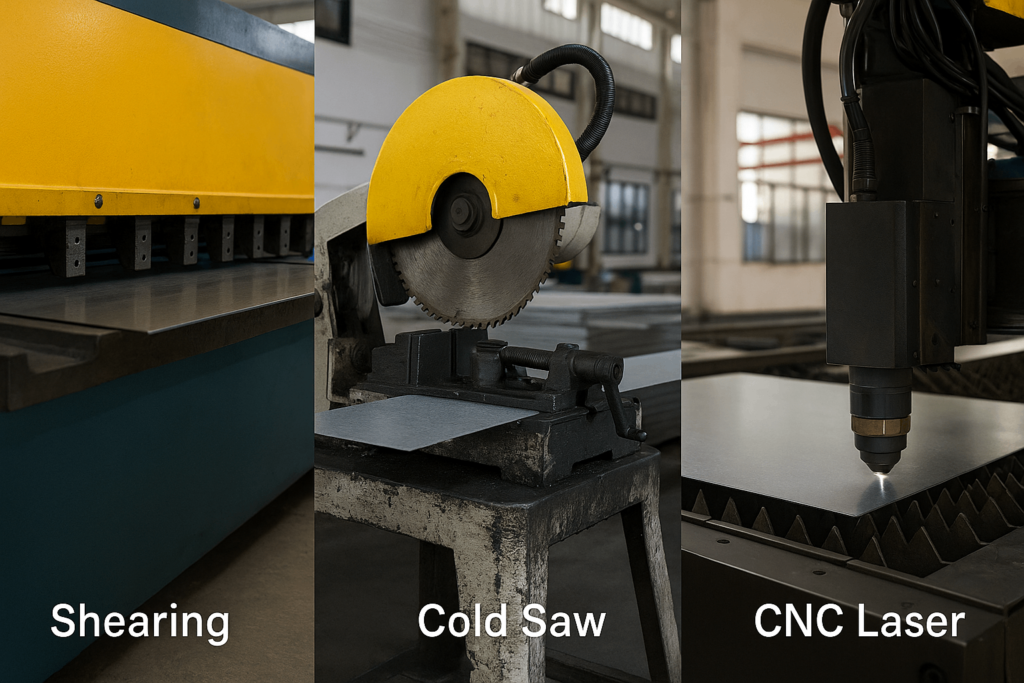

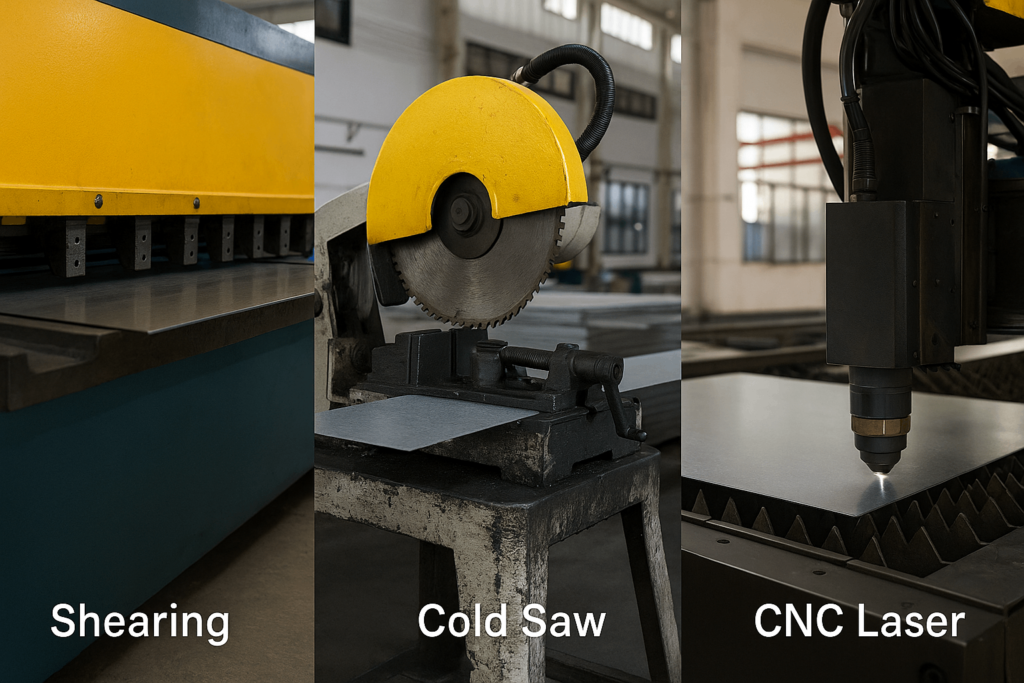

Industrial cutting follows a structured workflow. Sheets are supported on rigid tables, clamped at fixed intervals and aligned using laser guides or digital layouts. Straight cuts typically rely on mechanical shears or cold‑cut saws that minimise heat and protect the zinc layer. For curves, slots or complex internal features, CNC punching or laser cutting is introduced. Edges are cleaned, deburred and treated with zinc‑rich coatings when required. Dimensional checks follow before parts move into bending, welding or surface preparation. For wholesale buyers, this professional workflow answers the practical question of how to cut galvanized steel sheet at scale without sacrificing coating life or production consistency.Understanding How Galvanized Steel Behaves During Cutting

Metallurgical Behaviour During Cutting

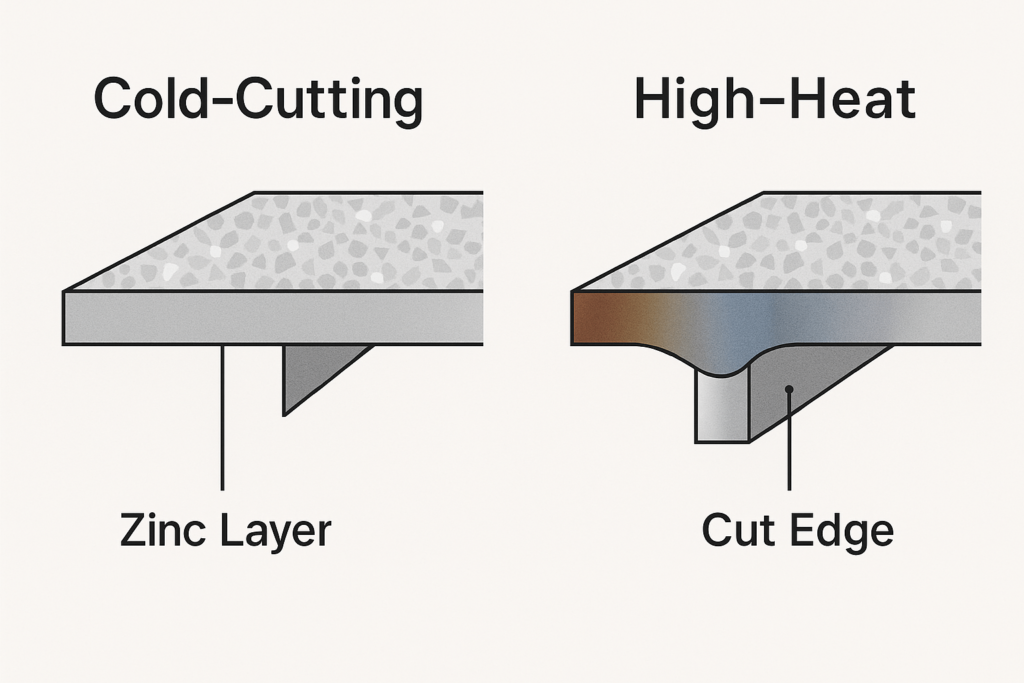

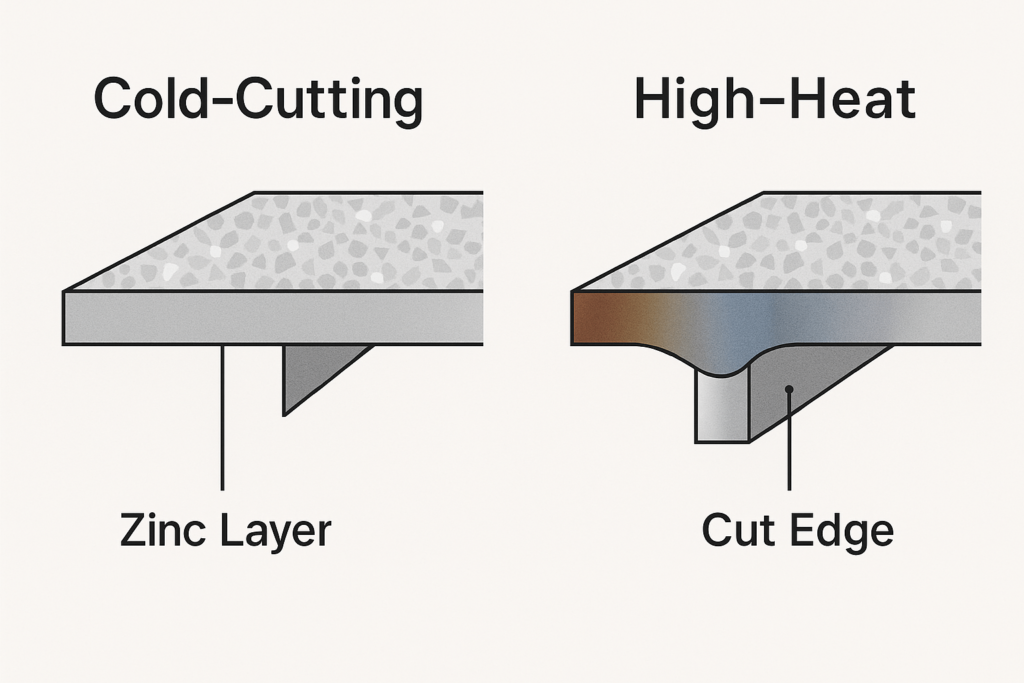

Galvanized steel combines a strong steel substrate with a zinc layer that provides sacrificial corrosion protection. Zinc melts at about 420°C, far lower than steel. When cutting generates excessive heat, the zinc layer softens, smears or vaporises. Even minor coating disruption exposes the edge to corrosion, which becomes visible in the field. Tests on 1.0–1.5 mm galvanized sheet consistently show that abrasive cutting introduces wide heat‑affected zones, while cold‑cut shears or saws preserve more than 95% of coating thickness. For buyers supplying outdoor and long‑life products, coating retention is directly linked to service life and maintenance costs.Internal Tension and Coating Variability

Coating thickness varies across the sheet due to cooling differences during galvanizing. Some regions hold more tension or bond slightly differently. These variations influence how the sheet responds to cutting forces. Operators familiar with these effects adjust feed speed and pressure; inexperienced teams often push through and create random coating failures. For large‑volume orders, small inconsistencies multiply. Understanding how suppliers manage tension, clamping and process tuning helps you assess their ability to deliver consistent quality.Edge Quality Matters More Than Nominal Thickness

Two sheets of the same gauge can behave differently depending on edge quality. Smooth edges with preserved zinc resist corrosion far longer than edges damaged by heat or vibration. Accelerated corrosion tests show up to 30% fewer corrosion pits on cleanly cut edges compared with heat‑affected ones. Buyers should include edge requirements—straightness, deburring, cosmetic expectations and visibility—in drawings. This ensures cutting choices align with real‑world performance goals.Define Cutting Requirements Before Selecting Any Method

Align Cutting Strategy With Performance Requirements

Durability, accuracy and throughput form the core priorities of most industrial projects. Outdoor housings and construction components demand strong coating protection. Precision assemblies—such as medical cabinets or telecom racks—require tight tolerances. High‑volume programmes emphasise speed and repeatability. Clear priorities guide suppliers toward the right cutting strategy. Without them, default decisions often prioritise speed over coating stability, increasing long‑term risk.Risks When Zinc Coating Is Compromised

Damaged edges begin oxidising immediately. If those areas are later welded or bent, zinc irregularities lead to porosity, cracking or poor coating adhesion. Powder‑coated parts with heat‑damaged zinc frequently show blistering or flaking. For buyers shipping into varied climates, each compromised edge raises the likelihood of premature failure. Explicitly stating coating protection and edge treatment requirements prevents avoidable defects.How Experienced Fabricators Choose Cutting Strategy

Skilled teams evaluate four elements: edge visibility, post‑cut operations, tolerance requirements and production volume. This structured approach ensures the cutting process matches your application. Suppliers who ask these questions demonstrate process understanding; those who do not may rely on generic, unstable workflows.Choosing the Right Cutting Method for Production

Protecting the Coating for Harsh Environments

Mechanical shears, CNC punching and cold‑cut saws minimise heat and protect the zinc layer. These methods deliver durable edges suited for outdoor cabinets, agricultural equipment and construction hardware. When reviewing quotes, ask suppliers why they chose a specific method and how they control coating protection.Ensuring Precision in High‑Fit Applications

Telecom, medical and vending systems require tight fits and stable tolerances. Guided saws, CNC cutters and multi‑point clamping maintain accurate, repeatable results. Buyers should request sample tolerance data and verify calibration practices.Balancing Throughput and Quality for Mass Production

Large orders require both volume and consistency. Controlled feed rates, heat management and tool temperature monitoring preserve the zinc layer while meeting delivery targets. Examine how suppliers balance speed with coating integrity.Managing Curves, Slots and Internal Features

Complex geometries introduce coating stress. Combining narrow‑kerf blades, CNC lasers and mechanical shears spreads the load across methods, protecting the zinc layer while achieving design accuracy.High‑Control Cutting Workflow in Professional Production

Managing Tension and Stability

Residual tension affects sheet behaviour. Professional shops support sheets across their length and clamp every 300–400 mm. This reduces vibration and prevents coating cracks during cutting.Accurate and Durable Marking Techniques

Heat‑resistant scribes, punches, layout pens and laser projection ensure cut lines remain visible. For repeat orders, CAD‑to‑CNC data transfer ensures consistent part geometry.Three Variables That Determine Edge Quality

Feed speed, cutting angle and edge temperature govern cut performance. Operators monitor vibration, sound and spark colour to maintain edge temperatures below zinc’s melting point.Safety and Fume Control

Zinc fumes pose health risks when overheated. Professional shops use extraction systems, PPE and controlled processes. Suppliers who manage fumes effectively tend to control heat input more precisely—protecting coating quality.Strategic Post‑Cut Edge Treatment

Deburring and zinc‑rich touch‑up coatings significantly extend corrosion resistance. Salt spray tests confirm longer life when edges receive proper treatment.Flatness Checks to Support Assembly

Flatness inspections prevent downstream assembly issues and reduce rework. Buyers should confirm that suppliers include flatness checks before packing.What Wholesale Buyers Should Evaluate in a Supplier

Consistency Across Shipments

Perfect prototypes can hide weak processes. Ask suppliers about tool maintenance schedules, parameter records and in‑process inspections to assess reliability across large orders.Matching Tool Choice to End‑Use Market

Telecom and medical applications prioritize cosmetic edges; agricultural and industrial parts prioritise durability. Experienced suppliers adapt methods accordingly.Evidence‑Based Quality Control

Cross‑section images, salt spray data and dimensional reports strengthen technical trust. Quality‑driven suppliers share objective evidence of edge integrity.Tool Options and Their Coating Impact

Mechanical Shears

Shears provide cold, clean cuts with minimal coating disturbance—ideal for long, straight sections.Cold‑Cut Circular Saws

Controlled chip formation prevents overheating. These saws suit thicker sheet and structural parts.CNC Laser Cutting

Lasers deliver precise geometry but require heat‑control strategies to protect zinc. Buyers should ask how suppliers manage heat and post‑cut treatment.Abrasive Cutting Tools

Abrasive wheels generate high heat and should not be the primary method for visible, outdoor parts.Common Hand Tools

Tin snips, reciprocating saws and angle grinders appear in many how to cut galvanized sheet metal searches. These tools are suitable for small adjustments but not for industrial batches.Troubleshooting Cutting Issues

Burr Formation

Burrs indicate dull tools, incorrect feed speed or poor fixturing. Repeated burr issues suggest unstable processes.Micro‑Cracks in the Zinc Layer

Fine cracks accelerate corrosion. They result from heat, vibration or unsupported cutting. Buyers should confirm suppliers’ preventive measures.Dimensional Drift

Drift causes assembly problems. Guided systems and calibrated equipment minimise this risk.Integrating Cutting Into the Full Fabrication Chain

Cutting, Bending and Welding Interaction

Damaged edges worsen bend quality and create weld porosity. Integrated process planning prevents downstream failures.Coating Preparation and Edge Protection

Post‑cut priming ensures strong adhesion for paints and powder coatings.Export‑Ready Packaging and Transport

Edge protection, separators and corrosion‑control packaging prevent transit damage.FAQs

What is the best tool to cut galvanized sheet metal in production? For long, straight cuts on panels and strips, mechanical shears or cold cut circular saws are usually the best balance of coating protection, accuracy and throughput. For complex shapes, CNC lasers and punching can be added while controlling heat and protecting edges.

Can you cut galvanized steel sheet with tin snips? Tin snips and aviation snips work well on thin gauges and small cuts, especially for on site adjustment or low volume work. For large batches or thicker material they become inefficient and hard to control, so industrial buyers generally prefer mechanical or CNC methods. Is it safe to cut galvanized steel with an angle grinder? Angle grinders are common in maintenance work but they generate high temperatures and zinc fumes. In controlled, well ventilated environments they can be used for non critical edges. For primary production or visible edges, low heat cutting methods are safer for both coating performance and operator health. How do I specify cutting quality in drawings or purchase documents? Include thickness, edge visibility, straightness tolerance, requirement for deburring, need for zinc rich edge touch up and any flatness expectations on key dimensions. These details guide the supplier toward an appropriate choice of how to cut galvanized steel sheet for your project. Do I need different cutting approaches for indoor and outdoor products? Yes. Indoor applications with mild environments may tolerate slightly more cosmetic imperfections. Outdoor or industrial products benefit from stricter control of coating damage, more careful edge treatment and more robust packaging during shipment.