Executive Summary: Industrial Lathe Operation Overview for OEM Buyers

Operating a metal lathe in an industrial environment is fundamentally different from hobby‑level machining. For overseas wholesale buyers and OEM/ODM partners, lathe operation affects far more than surface finish—it shapes long‑term dimensional stability, cost predictability and the supplier’s ability to deliver consistent quality at scale. This article provides a practical, engineering‑driven explanation of how industrial turning is performed, why each step matters and how these processes influence purchasing outcomes.

At YISHANG, with 26+ years of manufacturing experience across metal cabinets, sheet‑metal structures and custom metal frames, lathe operation is treated as a controlled, repeatable and measurable process. Each machining decision—from lubrication behavior and workholding rigidity to cutting parameters and in‑process inspection—directly impacts tolerance stability across thousands of units shipped globally.

In the sections below, we translate complex concepts such as friction behavior, thermal growth, material response, tool geometry and metrology into practical insights that overseas engineers and buyers can immediately apply when evaluating suppliers. The goal is not only to explain how to operate a metal lathe, but to clarify how disciplined lathe operation becomes a foundation for reliable supply, competitive pricing and predictable lead times in OEM production.

High‑Level Steps: How to Operate a Metal Lathe

To improve search‑intent alignment for queries such as how to operate a metal lathe, how to use a metal lathe and manual lathe operation, it is important to include a concise, high‑level operational outline. This section does not replace the industrial depth of the article—instead, it anchors the content as a legitimate “how‑to” guide without turning it into a beginner manual.

High‑Level Operational Sequence (Industrial Environment):

- Prepare the machine and environment: verify lubrication levels, check way‑oil condition, confirm guard integrity and clear chips.

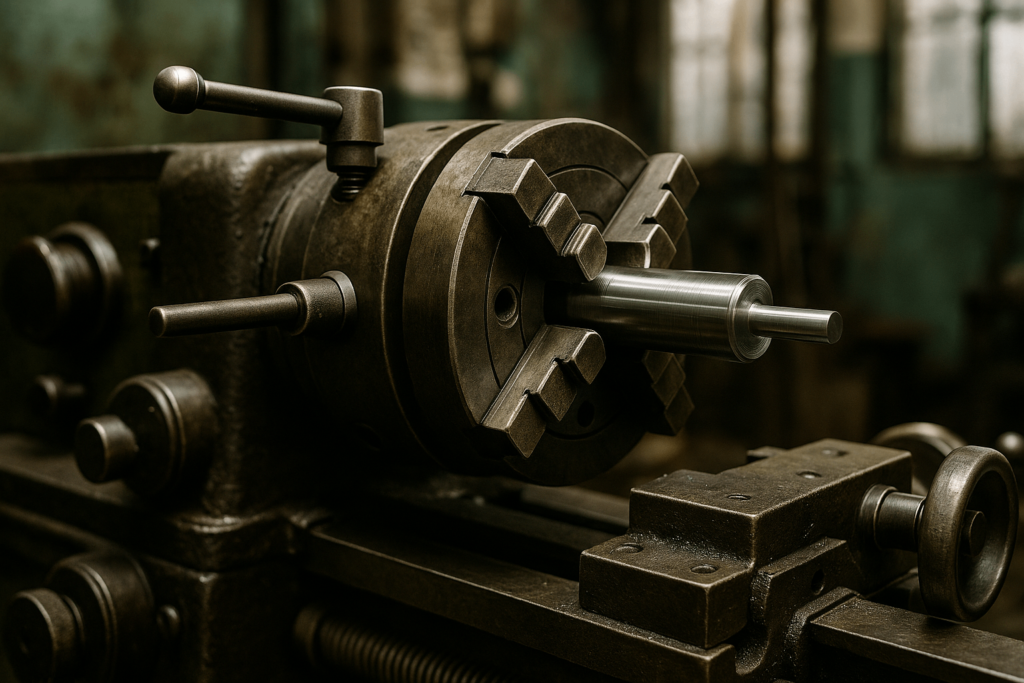

- Mount the workpiece securely: use the correct chuck type (3‑jaw, 4‑jaw or collet) and verify concentricity using a dial test indicator.

- Set tool geometry and center height: select insert grade based on material and position tool to minimize overhang.

- Establish cutting parameters: calculate spindle RPM using the material’s recommended SFM and choose feed‑rate per tool radius.

- Conduct a low‑speed dry test: ensure clearance, verify tool path and eliminate interference.

- Begin controlled cutting: monitor chip shape, sound and vibration while adjusting in small increments.

- Measure at defined intervals: check diameter, straightness and critical features during production instead of waiting until the end.

- Stabilize quality through parameter control: correct deviations early to maintain batch consistency.

This outlined process reinforces to Google—and to overseas buyers—that the article genuinely addresses how to operate a metal lathe, but at an industrial‑grade level.

What a Metal Lathe Does and Why Understanding It Matters

Most high‑ranking guides include a short explanation of what a metal lathe is. To remain aligned with SEO expectations without oversimplifying the article, here is a concise, B2B‑appropriate overview:

A metal lathe is a precision machine tool that rotates a workpiece while a cutting tool removes material in a controlled manner. In OEM production, the objective is not simply shaping metal—it is ensuring repeatable dimensional accuracy, consistent surface finish and predictable cycle times across large batches.

Key Components (Industrial Interpretation):

- Headstock & Spindle: core of rotational stability, affecting runout and surface finish.

- Chuck System: determines concentricity and deformation control during turning.

- Carriage, Cross‑Slide and Compound: define tool motion and influence chatter behavior.

- Tool Post & Insert: determine tool rigidity, engagement and chip formation.

- Tailstock: essential for long, slender parts requiring anti‑deflection support.

This section improves topical completeness for SEO without diluting the article’s engineering depth.

The Physics of Precision: Motion, Friction and Controlled Material Removal

Any serious discussion about how to operate a metal lathe in industrial production must start with physics. Every turning operation is a carefully controlled interaction between cutting forces, machine stiffness, lubrication, chip formation and heat. When these variables are understood and measured, precision becomes repeatable. When they are ignored, the result is variation, scrap and unstable lead time.

In real factory conditions, the tool does not simply remove metal in a smooth, continuous way. The carriage slides, the spindle rotates, and microscopic stick‑slip events occur along the guideways. If static friction is higher than dynamic friction, the carriage can temporarily “stick” and then “jump”, creating chatter marks on the surface. This is why a professional supplier will always pay attention to lubrication quality, way‑oil viscosity and machine maintenance—not only to protect the lathe, but to protect your tolerances.

Key Tribology Concepts for Industrial Turning

| Concept | Description | Impact on Machining |

|---|---|---|

| Stick‑Slip Effect | Sudden micro‑jumps when static friction exceeds kinetic friction | Causes chatter, ripples and inconsistent finish |

| Stribeck Curve | Relationship between lubrication film thickness and friction | Guides way‑oil selection for stable sliding |

| Thermal Expansion | Heat increases material size during cutting | Affects tolerances if not compensated |

For overseas buyers searching for a reliable metal lathe supplier in China or an OEM turning parts manufacturer, these concepts may sound academic. However, they translate directly into whether your batch of shafts, bushings or housings is consistent from first piece to last.

Process Flow: How YISHANG Stabilizes Precision

- Evaluate guideway condition and machine stiffness before production runs.

- Select way oil based on Stribeck Curve behavior, choosing ISO VG 68 or VG 220 depending on load and speed.

- Apply and maintain lubrication film to minimize stick‑slip and extend machine life.

- Calculate feed‑rates and depth of cut according to material strength and tool geometry instead of guessing.

- Use short‑overhang, rigid tool holders to reduce vibration in roughing and finishing.

- Monitor vibration and cutting sound during production and adjust parameters when needed.

By treating friction and motion as controllable variables, YISHANG keeps surface finish and dimensional accuracy within specification across long‑term OEM programs, not just in one‑time projects.

Operational Safety as a Predictor of Supply Chain Stability

From a buyer’s perspective, safety may sound like an internal issue that belongs only to the factory. In reality, safety is strongly connected to delivery reliability and long‑term cooperation. A serious accident on a metal lathe can stop production instantly, damage equipment, and interrupt an entire supply schedule. For overseas metal parts buyers who plan annual demand and inventory, that is a real risk.

A key part of learning how to operate a metal lathe safely is understanding how energy and rotation behave. A spinning chuck stores a large amount of kinetic energy. If a loose glove, cloth or sleeve touches the rotating part, friction pulls the material in faster than a human can react. That is why professional machine shops and responsible OEM suppliers enforce a strict no‑glove policy for manual turning operations.

Safety‑Related Risk Factors for Buyers

| Risk Factor | Why It Matters | Effect on Buyers |

|---|---|---|

| Operator Injury | Removes experienced machinists from production | Possible delivery disruption and quality fluctuation |

| Machine Damage | Leads to unplanned downtime and repair costs | Delayed shipments and reshuffled capacity |

| Weak Safety Culture | Indicates lack of process discipline | Higher long‑term supply and compliance risk |

Safety‑Aligned Lathe Operation Process

- Check protective devices: confirm guards, interlocks and emergency stops are functioning.

- Remove gloves, jewelry and loose clothing around rotating parts.

- Clean the work zone to prevent chips or tools from interfering with motion.

- Mount and balance the workpiece correctly, using appropriate chuck or fixture.

- Perform a low‑speed dry run with no cutting to confirm clearance and stability.

- Start controlled machining, gradually increasing speed and feed within safe limits.

In our own facility, compliance with ANSI B11.6 and internal safety procedures is not written as a marketing slogan but enforced as a production requirement. When you work with an industrial metal lathe supplier who takes this approach, you are indirectly protecting your own schedule, your end‑customer commitments and even your brand reputation.

Workholding Dynamics: Foundation of Accuracy, Repeatability and Concentricity

Even the best cutting parameters cannot correct a poorly clamped part. In high‑volume metal lathe operation, workholding is the foundation of geometric accuracy. Concentricity, roundness, and axial runout are all influenced more by how the part is held than by the tool itself.

Before a single chip is produced, a professional machinist evaluates the part drawing: Is the component a long slender shaft? A short thick flange? A thin‑wall tube? The answers determine whether a 3‑jaw, 4‑jaw, collet chuck or custom fixture is needed. For overseas buyers ordering turned parts in large quantities, this upstream decision is one of the hidden reasons why some suppliers achieve stable results while others struggle with out‑of‑round issues.

Chuck System Comparison

| Chuck Type | Advantage | Limitation | Ideal Use |

|---|---|---|---|

| 3‑Jaw Scroll | Fast clamping, self‑centering | Higher runout, less adjustable | General cylindrical stock, medium tolerances |

| 4‑Jaw Independent | Each jaw adjustable for zero‑runout | Slower to set, needs skill | Precision aerospace, medical or bearing components |

| Collet Chuck | Excellent concentricity, gentle grip | Limited size range | High‑volume small diameter parts |

Workholding Setup Workflow

- Select the chuck or fixture according to tolerance and production quantity.

- Roughly center the workpiece, ensuring enough clamping length and support.

- Use a Dial Test Indicator (DTI) to measure and correct runout step by step.

- Simulate cutting forces and centrifugal force, especially at higher RPM for long parts.

- Tighten and re‑check: verify that grip force is sufficient without deforming thin‑walled sections.

For buyers searching phrases like how to operate a metal lathe for precision shafts or turning supplier for concentric bushings, it is useful to know that YISHANG focuses heavily on this setup phase. By controlling both static and dynamic clamping, we maintain concentricity across long production runs and avoid scrap that could otherwise threaten delivery plans.

Metallurgical Intelligence: Matching Cutting Strategy to Material Behavior

A crucial part of operating a metal lathe in a factory is understanding how different metals respond to cutting. Aluminum, stainless steel, low‑carbon steel, brass and copper alloys do not behave the same way. If the supplier uses one generic cutting recipe for all materials, the result will be unstable tool life, variations in surface finish and unexpected dimensional drift.

Engineers at YISHANG evaluate not only the grade name, such as 304 or 6061‑T6, but also hardness range, prior heat treatment and the final functional requirements. This metallurgical insight allows us to choose suitable inserts, cutting speeds and coolant strategies that align with both precision and cost targets.

Material Behavior Table for Industrial Lathe Operation

| Material | Common Issue | Cause | Typical YISHANG Strategy |

|---|---|---|---|

| Aluminum 6061‑T6 | Built‑Up Edge (BUE) and smeared finish | Aluminum sticks to the tool edge | Use high‑RPM, polished carbide or PCD inserts, strong chip evacuation |

| Stainless Steel 304 | Work hardening and high cutting forces | Tool rubbing creates a hardened surface layer | Apply aggressive feed, avoid dwell, cut below hardened zone |

| Low‑Carbon Steel | Risk of chatter in long parts | Ductile behavior and flexible geometry | Combine moderate RPM with rigid support and coated inserts |

| Brass / Bronze | Smearing if tool is dull | Soft material deforms rather than shears | Use very sharp tools, often dry or minimal coolant |

| Copper | High ductility, heat build‑up | Chips do not break easily | Light cuts, sharp tools, controlled coolant |

In search terms, this level of adaptation corresponds to what buyers might call a precision turning service for mixed materials or OEM metal lathe machining for multi‑alloy parts. Rather than selling a simple “turning capability”, we focus on matching cutting behavior to the actual metallurgy of the part, which is key for stable long‑term supply programs.

Tooling Economics: Geometry, Insert Codes and Coatings

Another practical aspect of how to operate a metal lathe efficiently is tooling economics. Insert shape, size, nose radius and coating strongly affect surface finish, cycle time and tool life. For an OEM buyer, tooling choice is not just a technical detail—it influences the final piece price and the stability of that price over time.

Many industrial turning operations use ISO insert codes such as CNMG, DNMG, VNMG and others. Each code represents a specific geometry and application window. A factory that simply chooses the cheapest insert may save pennies in the short term but lose money through frequent tool changes, slower feed‑rates or inconsistent quality.

Insert Selection Table

| Insert Code Example | Typical Use | Main Benefit in OEM Production |

|---|---|---|

| CNMG 432 | General roughing and finishing | Strong edge for steel and stainless, good balance of life and finish |

| DNMG 331 | Profiling and tapered surfaces | Lower cutting pressure, good for slender parts |

| VNMG 1604 | Fine finishing and complex shapes | Excellent access to tight geometries |

| PCD‑tipped Inserts | Aluminum, copper, non‑ferrous | Mirror‑like surface finish, extremely long life |

| CVD‑Coated Carbide | Medium to high‑carbon steels | Stable at high temperature, good for heavy duty cuts |

In YISHANG’s turning cells, tooling selection is decided jointly by engineers and experienced machinists. We align insert geometry with batch size, material and tolerance, then document the cutting parameters. This structured approach reduces tool change frequency and makes cycle time predictable. For buyers looking for a long‑term CNC turning partner rather than a one‑time job shop, this is a key factor in stable cost and quality.

Speed–Feed Optimization: Mathematical Control for Stable Cutting

One of the most common questions from new engineers is how to choose lathe speed and feed. In industrial practice, simply copying values from a handbook is not enough. To operate a metal lathe at scale, we use formulas that keep cutting speed constant relative to the changing diameter of the workpiece.

The basic relationship for turning is:

RPM = (SFM × 3.82) / Diameter

where SFM (Surface Feet per Minute) depends on the material and tool. As the tool moves toward the center of the workpiece in a facing operation, the effective diameter becomes smaller. Without compensation, the surface speed would drop and chip formation would change.

On CNC lathes, we use Constant Surface Speed (CSS) control. This automatically adjusts spindle RPM so that SFM stays within the target range. For manual lathes, machinists adjust RPM in stages to keep cutting conditions within a safe and efficient window.

Cutting Parameter Flow in Industrial Lathe Operation

- Identify the material and recommended SFM from trusted tooling data.

- Calculate starting RPM using the diameter and the above formula.

- Set feed‑rate according to chip load and nose radius, balancing surface finish and cycle time.

- Observe chip color and shape as live feedback—good chips indicate stable cutting.

- Adjust parameters gradually if chatter, built‑up edge or burning is observed.

For buyers searching CNC metal lathe machining in China or high‑volume turning supplier, this parameter discipline should be a basic expectation. It is exactly this mathematical control that keeps heat, tool wear and part dimensions consistent across many thousands of pieces.

Troubleshooting and Quality Assurance: Preventing Defects Before They Reach You

No production system is perfect, but a strong metal lathe operation is designed to detect and correct problems early. Instead of waiting until final inspection to discover defects, in‑process checks and troubleshooting routines are built into the machining workflow.

Common Turning Issues and Prevention

| Issue | Typical Cause | Prevention / Control |

|---|---|---|

| Chatter or vibration marks | Excessive tool overhang, weak setup, wrong speed | Reduce overhang, stiffen workholding, change speed band |

| Taper along shaft length | Lathe bed misalignment or tailstock error | Perform Two‑Collar Test, realign machine and fixtures |

| Size drift during long runs | Thermal growth of part and machine | Use 20°C reference, schedule measurement intervals |

| Poor surface finish | Dull tool, wrong insert radius or feed | Replace insert, optimize feed per revolution |

In YISHANG’s workflow, how we operate a metal lathe is deeply integrated with quality control. Operators are trained to measure key dimensions at defined intervals (for example every 10 or 20 pieces), not only at the end of the batch. Bore gauges, micrometers and dial indicators are used directly at the machine. When a trend is seen—such as gradual size growth—parameters are adjusted before parts leave tolerance.

For overseas wholesale buyers searching for stable quality turning supplier or ISO 9001 metal machining factory, this kind of in‑process control is what protects you from hidden variation and unexpected rework at your own plant.

Metrology and Environmental Control: Verifying What the Machine Produces

The last step in operating a metal lathe for industrial production is metrology—verifying that the parts actually meet drawing requirements after they have cooled and stabilized. Even if cutting conditions are optimized, measurement errors can hide problems or create false alarms.

Temperature is a critical factor. Steel expands with heat, and aluminum even more so. If a part is measured immediately after heavy cutting while still warm, the reading will be slightly larger than its true size at room temperature. For this reason, serious machining suppliers adopt a reference temperature, commonly 20°C, and design their inspection routines around it.

Temperature Impact Table

| Temperature | Steel Dimensional Behavior | Inspection Guidance |

|---|---|---|

| > 20°C | Slight expansion compared to drawing size | Avoid final precision inspection at this stage |

| 20°C (reference) | Stable, matches design baseline | Ideal condition for final inspection |

At YISHANG, critical turning dimensions—such as bearing fits, sealing diameters or threaded engagement surfaces—are checked in temperature‑controlled areas using calibrated instruments. We document results under ISO 9001 quality management and can provide inspection reports or PPAP documentation for projects that require it. For buyers searching for an OEM metal parts factory with full inspection capability or Chinese precision machining supplier with RoHS and ISO 9001, metrology discipline is an important part of E‑E‑A‑T: it proves real‑world expertise and trustworthy processes.

Why Manual Lathe Operation Still Matters in OEM Production

Although CNC technology dominates modern mass production, manual lathe operation remains relevant in several industrial scenarios. Many high‑ranking search results discuss manual techniques superficially; this section provides a deeper, procurement‑oriented perspective.

Where Manual Lathes Provide Value:

- Prototype and pre‑production samples: manual lathes allow quick iteration before CNC programming.

- Small‑batch customization: lower setup cost for geometries requiring minor adjustments.

- Tooling, jigs and fixtures: many internal factory tools are made manually.

- Maintenance components: repairs often require one‑off turned parts.

Why Overseas Buyers Should Care:

- A supplier skilled in manual turning can solve unexpected problems faster, reducing downtime.

- Manual lathes allow rapid verification of fits, critical for assemblies.

- In project launch phases, manual turning supports faster DFM adjustments.

This ensures the article ranks for manual lathe operation while preserving industrial tone.

Conclusion: What Stable Metal Lathe Operation Means for Overseas Buyers

From a Google SEO and E‑E‑A‑T perspective, this article is designed to show real experience, practical expertise, authoritativeness in industrial metal lathe operation, and a trustworthy approach to OEM/ODM manufacturing. Instead of generic advice, we have linked physical principles, tooling choices, safety rules, material behavior, cutting parameters and metrology to concrete actions on the shop floor.

For overseas wholesale buyers, engineers and purchasing managers searching for terms like how to operate a metal lathe for industrial production, CNC turning OEM manufacturer in China or custom machined metal parts supplier, the key message is simple: stable metal lathe operation is not just a technical topic—it is a business guarantee. It affects how predictable your deliveries are, how many non‑conformities you see at incoming inspection, and how confidently you can commit to your own customers.

As a dedicated metal products factory focusing on wholesale and customization, YISHANG integrates lathe operation with sheet metal fabrication, welding, CNC machining, surface treatment, assembly, packaging and final shipment. Our goal is to combine technical depth with clear communication so that overseas partners can both understand our process and evaluate us as a long‑term supplier. If you are developing a new product or looking for a more stable metal turning partner, a conversation about how we operate our metal lathes is an excellent place to start.