Global procurement teams, wholesalers, and OEM buyers who search for what is 304 stainless steel are rarely interested in academic theory. Their real concern is simple and practical: will this material support stable production, predictable quality, and acceptable lifecycle cost? Every decision on stainless steel has consequences for warranty exposure, maintenance plans, lead time, and customer satisfaction.

This guide is written with that reality in mind. Instead of repeating data‑sheet content, it explains what 304 stainless steel means in day‑to‑day industrial use. Drawing on long‑term export fabrication experience at YISHANG, it connects material properties with forming, welding, surface finishing, assembly, and long‑term field performance. The aim is to give professional buyers a clear, experience‑based reference they can use when comparing suppliers, planning projects, or deciding whether 304 is truly the right choice.

Quick Definition — What Does 304 Stainless Steel Mean?

304 stainless steel is an austenitic, chromium-nickel stainless steel containing approximately 18% chromium and 8% nickel. It is the world’s most widely used stainless grade because it offers a strong balance of corrosion resistance, formability, weldability, and cost. In industrial fabrication, 304 behaves predictably during bending, deep drawing, welding, and finishing, making it the preferred choice for large-volume sheet-metal manufacturing.

The Essence of 304 Stainless Steel

What 304 Stainless Steel Really Means for Industrial Buyers

For many industrial buyers, the practical answer to what is 304 grade stainless steel is: a dependable, general‑purpose stainless steel that fabricators worldwide know how to work with. It is used extensively in metal cabinets, machinery housings, commercial fixtures, vending machines, EV battery frames, medical equipment structures, and countless other products where corrosion resistance and structural integrity must be balanced with cost.

In procurement terms, 304 is attractive because it reduces uncertainty. It bends cleanly in press brakes, behaves predictably in deep‑draw processes, and welds with stable results when the right procedures are followed. That predictability lowers scrap rates and reduces the number of quality issues that turn into claims. When buyers type queries like what is 304 ss, what is 304 stainless, or what is ss 304 material, they are often trying to confirm that this material can support repeatable mass production rather than just reading another chemistry table.

Key Specifications and International Designations for 304 Stainless Steel

A brief reference table below helps industrial buyers quickly verify whether different suppliers are quoting the same material:

| Property / Standard | Typical Value / Designation |

|---|---|

| AISI / ASTM Grade | 304 |

| UNS Number | S30400 |

| EN Standard | 1.4301 |

| ISO Equivalent | X5CrNi18-10 |

| Chromium (Cr) | 17.5–19.5% |

| Nickel (Ni) | 8.0–10.5% |

| Carbon (C, max) | 0.08% |

| Yield Strength | ~205 MPa |

| Tensile Strength | ~515–720 MPa |

| Density | 8.0 g/cm³ |

This structured information is essential for cross-border procurement, especially when RFQs involve mixed standards or region-specific names.

Why 304 Is an Austenitic Stainless Steel — and Why Buyers Should Care

304 is part of the austenitic stainless steel family. Its face‑centred cubic (FCC) crystal structure, supported by roughly 18% chromium and 8% nickel, gives it the classic 18/8 profile known in many markets. This structure is at the core of its behaviour. It keeps the material tough at low temperatures, supports high ductility for forming, and allows the surface passive film to renew itself when damaged.

For buyers evaluating what is 304 steel or what is ss 304 material for demanding projects, the key is that this microstructure makes 304 more forgiving during fabrication. Tight bends, complex geometries, or reinforced designs can be produced without excessive cracking, and properly passivated surfaces hold up well in most indoor and light outdoor environments. This is why 304 is still one of the most frequently specified stainless steels worldwide for industrial fabrication.

Key Characteristics That Matter in Industrial Applications

Corrosion Resistance — Real Environmental Performance, Not Theory

Technical literature describes 304 as corrosion‑resistant, but industrial buyers need to interpret that statement against real conditions. In indoor environments—such as medical devices, display fixtures, food‑service equipment, and commercial furniture—304’s chromium‑rich passive layer performs very well. The surface resists staining, recovers from minor damage, and maintains a professional appearance with normal cleaning routines.

Real‑world field data, however, shows clear limits when 304 is exposed to chlorides or aggressive chemicals over many years. Coastal air, de‑icing salts, cleaning agents with high chloride content, and certain industrial emissions all attack the passive layer. Localised pitting and discoloration can develop on equipment that would perform perfectly in a controlled interior setting. When buyers ask what is 304 stainless steel used for, the honest answer is that it excels in mild to moderate environments but requires cautious evaluation for long‑term outdoor or chemical exposure.

Experienced procurement teams often treat 316 as the preferred choice for marine or chemical installations, not because 304 is “bad,” but because 316’s added molybdenum offers better resistance to these specific risks. From a lifecycle perspective, the slightly higher material cost is often offset by lower maintenance and fewer replacements over a multi‑year project.

Mechanical Behavior During Forming, Bending, Welding, and Assembly

Mechanical behaviour is where 304 often proves its value most clearly. In forming, it offers high elongation and stable behaviour across common thickness ranges. Tight‑radius bends and deep‑drawn geometries can be achieved with proper tooling and process control. For buyers, that means complex designs are feasible without resorting to exotic alloys, keeping costs manageable.

During welding, 304 provides strong, clean joints when heat input, shielding gas, and joint design are controlled. The alloy does expand under heat more than carbon steel, but seasoned fabricators manage this through fixturing and weld sequencing. Buyers who want to avoid distortion in large cabinets, kiosks, or frames should always confirm that their supplier has a clear procedure for managing heat and has invested in training and fixture design.

Assembly performance is another concern for overseas buyers. Long shipping distances and handling stages can magnify small alignment issues. A supplier who understands 304’s behaviour under cutting, welding, and cooling will plan tolerances and processes to minimise misalignment, reducing field adjustments and installation time on the customer side.

Surface Finish, Tolerances, and Appearance Stability

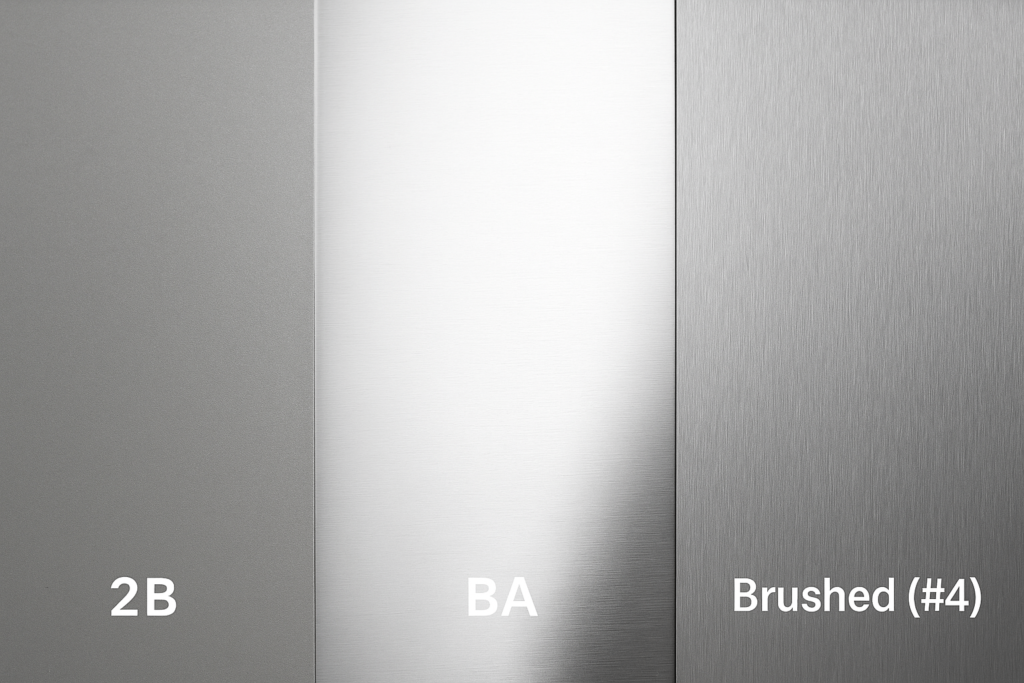

Surface finish and tolerance control strongly influence how end customers perceive quality. Common choices such as 2B, BA, and #4 brushed each have their own strengths. 2B provides a clean, versatile base for further processing. BA offers a brighter, more reflective surface often used in hygienic applications. Brushed finishes create a more premium appearance and hide minor scratches, which is popular for exposed panels and retail fixtures.

However, each finish behaves differently over time. Brushed finishes can trap contaminants in the grain, while bright finishes show fingerprints easily. Buyers specifying what is the best stainless steel finish for an application should always weigh visual expectations against cleaning and maintenance capability in the field. This is particularly important for export projects where local cleaning practices vary.

Dimensional tolerances complete the picture. A cabinet that is only slightly out of square may still leave a strong negative impression if doors do not close smoothly or mounting holes do not align. Suppliers experienced in working with 304 anticipate distortion from thermal processes and compensate with fixture design, process planning, and inspection routines. This is one of the key distinctions between suppliers who merely “use 304” and those who truly understand how to control it.

Why Not All “304 Stainless Steel” Performs the Same

Material Variation Between Global Mills and Regions

In global procurement, it is common to assume that 304 from different mills is interchangeable. In reality, there are measurable differences. Melting practices, control of alloying elements, rolling reductions, annealing schedules, and surface conditioning all leave an imprint on how the sheet behaves in production.

Two coils certified to the same standard may show different responses when bent or welded. One may exhibit slightly higher springback, requiring re‑tuning of bending programs. Another may show more pronounced grain pattern in brushing, affecting visual uniformity on visible faces. For buyers consolidating production across multiple countries, these differences can become a hidden source of variability in finished products.

Understanding this does not mean buyers need to become metallurgists. It does mean that stable sourcing from known mills and manufacturers with strong incoming inspection and traceability is worth serious consideration. A slightly higher but consistent material cost often reduces total project risk compared to constantly chasing the lowest price from unverified sources.

Manufacturing Practices That Impact Final Performance

When surface rust or distortion occurs in service, it is tempting to blame “bad steel.” In many investigations, however, the root cause lies instead with process control. Examples include bending with inadequate radii that cause micro‑cracks, incomplete weld cleaning that leaves heat tint or embedded oxides, and fabrication on contaminated tooling that transfers carbon particles onto stainless surfaces.

From the buyer’s standpoint, these are preventable issues that should be addressed by the supplier’s process design and quality systems. Evaluating a supplier’s welding qualifications, cleaning and passivation procedures, and handling practices is therefore an essential part of qualifying a stainless steel partner. Buyers who include these checks in their supplier audits typically see more stable performance over multiple years and production batches.

Typical Industrial Uses of 304 Stainless Steel

Industrial buyers searching what is 304 stainless steel used for often operate across diverse industries. The following categories reflect real procurement scenarios rather than generic textbook lists:

Heavy-Duty Industrial Equipment and Control Cabinets

304 is widely used for electrical enclosures, machine housings, automation equipment frames, and fabrication components due to its dimensional stability and welding performance. Buyers value reduced distortion, cleaner welds, and consistent tolerances in large structures.

Food-Contact, Medical, and Hygiene-Critical Equipment

304’s smooth passive layer supports sanitation requirements in commercial kitchens, food-processing lines, medical carts, and laboratory fixtures. It allows repeated cleaning without rapid surface degradation, provided chlorides are controlled.

Commercial Fixtures, Retail Structures, and Display Systems

Brushed or BA-finished 304 is used for signage frames, retail shelving, POS structures, and decorative metalwork. Its surface appearance longevity is a key advantage for brands demanding consistent aesthetics across multiple store locations.

Energy, Electronics, and Technical Assemblies

Battery frames, inverter housings, ventilation structures, and structural brackets often specify 304 due to its strength-to-weight balance, machining consistency, and global availability, which helps buyers secure multi-country supply chains.

Comparing 304 With Other Grades — Insights for Smarter Procurement

When 304 Is the Best Choice

In many industrial scenarios, 304 is the most balanced option available. It offers good corrosion resistance for indoor and sheltered outdoor use, excellent formability for complex sheet‑metal parts, and broad global availability that supports multi‑country supply chains. For wholesalers and OEM buyers serving sectors such as general machinery, commercial equipment, point‑of‑sale structures, and light industrial infrastructure, 304 often hits the sweet spot between performance and cost.

Because it is so widely used, 304 also benefits from a robust ecosystem of standards, design practices, and field experience. This means that potential issues are well understood and can be addressed early when buyers and manufacturers communicate clearly about environment, loading, and service expectations. For many long‑running product lines, redesigning around 304, instead of constantly changing materials, can simplify procurement and reduce technical uncertainty.

When Another Grade Is More Suitable

There are also clear situations where other grades provide better business value. Projects located near the sea, exposed to de‑icing salts, or subject to frequent wash‑down with aggressive cleaners benefit from 316 stainless steel. Its molybdenum content provides greater resistance to chloride‑induced corrosion. While the material price is higher, long‑term maintenance and replacement costs are often lower.

Lower‑cost grades such as 201 or 430, by contrast, may be considered for decorative, low‑risk applications where appearance matters more than structural or corrosion performance. These grades offer savings, but they cannot be expected to perform like 304 in demanding conditions. For buyers, the key is to select grade and thickness according to clear performance targets instead of initial price alone.

A Practical Framework for Choosing 304 in Industrial Procurement

Five Strategic Factors Buyers Should Evaluate

To decide whether 304 is the right choice for a given project, buyers can apply a straightforward evaluation framework. First, assess the environment: is the application indoors, partially sheltered, or fully exposed in a coastal or chemical setting? Second, review mechanical demands: does the design require deep drawing, tight bends, or heavy welded structures? Third, define expected service life and acceptable maintenance intervals. Fourth, align finish requirements with the realistic cleaning practices of end users. Finally, consider volume, logistics, and total cost of ownership rather than only per‑unit material price.

This kind of structured assessment helps procurement teams answer not just what is 304 stainless steel in theory, but whether it is the most appropriate choice for their business case. In some scenarios, 304 will be optimal. In others, a different grade will deliver better lifecycle economics. The important point is that the decision is made consciously and with full understanding of trade‑offs.

How Design and Fabrication Decisions Influence Real Performance

Material selection is only one part of the outcome. Design choices—such as bend radii, joint placement, weld lengths, and stiffener layout—directly shape how 304 behaves in production and in service. A part that looks simple on a drawing can become difficult to fabricate if sharp corners, long unsupported spans, or unnecessary weld seams are specified.

By involving experienced manufacturers early, buyers can refine designs so they remain true to functional requirements while matching the real capabilities of 304 stainless steel. The result is shorter lead time, more consistent quality, and fewer surprises once products reach their final environment. This collaborative approach is especially valuable when scaling up from prototypes to full‑scale production.

Practical Manufacturing Insights for Buyers

Lessons Learned from Large‑Scale Production

Producing thousands of 304 stainless steel components for export has given YISHANG a clear sense of which practices have the greatest impact on long‑term performance. Thorough weld cleaning and passivation is one of the most effective steps for improving corrosion resistance in demanding applications. Selecting appropriate grain direction on brushed finishes yields more uniform appearance and reduces the visual impact of minor deformation.

Controlled welding sequences, combined with well‑designed fixtures, significantly limit distortion on large frames and cabinets. Attention to cutting parameters reduces heat‑affected zones and preserves edge quality. For buyers, these details may seem distant from the purchase order, but they are exactly what determine whether a product performs as promised in the field. Working with a supplier that understands and applies these lessons provides a concrete advantage in quality and reliability.

FAQ — Common Buyer Questions About 304 Stainless Steel

What does 304 stainless steel mean?

It refers to an 18% chromium, 8% nickel austenitic stainless steel widely used for industrial fabrication because of its predictable forming, welding, and corrosion-resistance characteristics.

What is 304 SS in sheet-metal manufacturing?

It is a widely used stainless grade for cabinets, machinery housings, display structures, vending equipment, and energy-storage components due to its stable bending and welding behaviour.

What is 304 stainless steel used for in wholesale manufacturing?

Large-scale buyers use it for control cabinets, food-equipment bodies, structural frames, retail fixtures, medical carts, and precision housings.

Is 304 the best stainless steel for every environment?

No. It performs very well indoors and in mild environments, but 316 is a better choice in chloride-rich, coastal, or chemical conditions.

When should buyers choose 201 or 430 instead?

Only for decorative or low-risk components where corrosion performance is not critical. These materials reduce cost but cannot replace 304 in demanding conditions.

Conclusion — A Smarter, Practical Understanding of 304 Stainless Steel

304 stainless steel remains one of the most versatile and fabrication‑friendly materials available to industrial buyers. It offers a strong combination of corrosion resistance, mechanical performance, and manufacturability. However, achieving the best results depends on more than just specifying the right grade. Environment, design, supplier capability, process control, and inspection practices all play a role in how 304 performs over the life of a product.

With a clear understanding of these factors, procurement teams can use 304 stainless steel with confidence where it fits, and make informed decisions to upgrade or downgrade when project conditions demand it. The outcome is more predictable quality, lower lifecycle cost, and stronger relationships with end customers.

Need Expert Support?

If you are evaluating stainless steel options for industrial procurement or planning a new sheet‑metal project, YISHANG can share practical, experience‑based input to support your sourcing decisions.