I. Why Steel “Type” Matters in Cross-Border Procurement

For many international wholesale buyers, low carbon steel is a familiar line on a purchase order. It appears in RFQs, drawings, and contracts every day. Yet in practice, “low carbon steel” is not a single material. Different types of low carbon steel behave very differently in forming, welding, coating, and outdoor service.

If the type is not matched to the end use, you are the first person who hears about the problem. Your customer may report cracking during bending, deep drawing failures, paint peeling, or early rust on outdoor installations. Claims, production delays, and rework can quickly wipe out the margin on a project.

This guide is written from a sourcing angle, reflecting how a manufacturer like YISHANG communicates with engineering teams and buyers. The goal is not to overload you with classroom theory, but to give you a clear, practical understanding of how different low carbon steel types affect price, risk, and performance in real orders.

By the end, you should be able to read a drawing or RFQ and quickly think:

“Which type of low carbon steel fits this job?”

and

“How should I describe it to my supplier so they deliver the right material?”

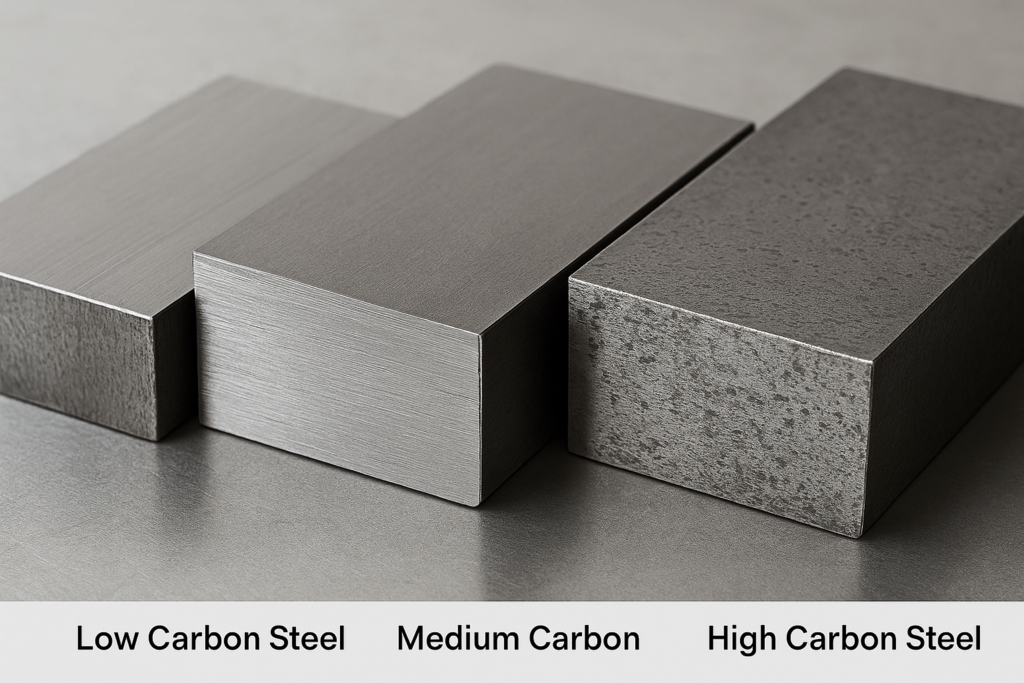

II. Low vs Medium vs High Carbon Steel – A Quick Buyer View

Before going deep into low carbon steel types, it helps to see where they sit among other carbon steels. Many buyers search for “types of carbon steel” or “high carbon vs low carbon steel” when they try to clarify what they actually need.

A. Snapshot Comparison

| Type of carbon steelTypical carbon rangeKey propertiesTypical uses | |||

|---|---|---|---|

| Low carbon steel | ~0.05–0.25% | High ductility, easy to weld and form | Sheet metal parts, cabinets, frames, enclosures |

| Medium carbon steel | ~0.25–0.60% | Higher strength, less ductile | Shafts, gears, mechanical parts |

| High carbon steel | ~0.60–1.50% | Very hard, wear resistant, brittle | Tools, springs, wear components |

For most sheet metal fabrication, frames, and enclosures, low carbon content steel is the natural choice. Medium carbon steel and high carbon steel grades are important, but mostly for forged and machined components rather than thin sheet metal parts.

B. The Core Difference Between Low Carbon and High Carbon Steel

When buyers ask about the difference between low carbon and high carbon steel, they usually want to know:

- which is easier to form and weld;

- which is better for general fabrication;

- which is more appropriate for their customer’s product.

In simple terms:

- low carbon steel → easier to cut, bend, draw, and weld; better for cabinets, enclosures, brackets, and general sheet metal;

- high carbon steel → much harder and stronger, but difficult to form and weld; more suitable for cutting tools, springs, and wear parts.

So if your drawing shows laser-cut, bent, and welded sheet metal components, you almost always want low carbon steel or one of its sub-types, not the highest carbon steel available.

III. What Low Carbon Steel Means in Manufacturing – In Buyer Language

Low carbon steel usually contains around 0.05%–0.25% carbon. Together with manganese, silicon, and tightly controlled impurities, this low carbon content generates a ferrite-based microstructure that bends, stretches, and welds reliably.

For buyers, the practical meaning is:

- low carbon steel = good ductility and weldability;

- it is the natural choice for sheet metal parts, metal cabinets, frames, machine covers, and other fabricated parts;

- but different low carbon steel grades and processing routes lead to very different behavior in your customer’s factory.

A. Microstructure and Why Buyers Should Care

Low carbon steels are mostly ferrite, with some pearlite. Ferrite gives flexibility; pearlite adds strength. The balance between them, plus grain size and cleanliness, affects how the steel behaves in real processes.

This is why two coils with the same low carbon steel name or nominal grade can perform differently in deep drawing or tight-radius bending. If one coil is hot-rolled, not annealed, and has more residual strain, it will crack sooner than a properly processed deep drawing grade.

From a buyer’s view, the lesson is simple: grade labels are not enough; you must understand the type and processing route.

B. Typical Mechanical Performance – A Practical Reference

Most commercial low carbon steel for sheet products falls roughly in these mechanical ranges:

| PropertyTypical range | |

|---|---|

| Yield strength | 140–350 MPa |

| Tensile strength | 270–450 MPa |

| Elongation (A50) | 26%–40% |

| Brinell hardness (HB) | ~90–170 |

You can use these values as a quick reference when checking mill test reports. If a supplier offers “low carbon steel material” with very low elongation or unusually high hardness, it might not behave as expected in forming or welding.

IV. Process-Defined Types: How Production Route Changes the Steel You Buy

The first dimension buyers need to understand is how the steel is processed. This determines the surface condition, internal stress state, and often the price.

A. Hot-Rolled (HR) Low Carbon Steel

Hot-rolled steel is produced at high temperature and cooled in air. The surface usually has scale, edges are less sharp, and thickness tolerances are wider. In return, HR is cost-effective and available in heavier gauges, which makes it popular for:

- welded frames;

- structural components;

- industrial bases and supports.

If your customer does not need a fine surface or very tight dimensions, HR can be the most economical option. It is rarely used for cosmetic panels or precise deep drawn parts without further processing.

B. Cold-Rolled (CR) Low Carbon Steel

Cold-rolled steel is rolled at or near room temperature. The process improves:

- thickness accuracy;

- surface smoothness;

- dimensional stability.

For buyers supplying sheet metal parts, cabinets and enclosures, machine housings, shelving systems, or retail fixtures, CR low carbon steel is often the default choice. It provides the right base for powder coating or painting, and it helps your customer achieve consistent visual quality.

C. Annealed Low Carbon Steel

Annealed steel is cold-rolled material that has been heat treated to remove internal stresses and soften the microstructure. It is particularly important when:

- the part has tight-radius bends;

- the drawing depth is moderate;

- the customer reports occasional cracking with standard CR material.

For buyers, specifying “CR annealed low carbon steel” instead of just “CR” can be a simple way to resolve forming complaints in large-volume orders.

D. Pickled & Oiled (P&O)

Pickling removes mill scale, and oiling offers temporary corrosion protection. P&O low carbon steel is widely used where:

- laser cutting must be clean;

- welding quality matters;

- the surface needs to be free of heavy scale before coating.

Choosing P&O instead of standard HR can reduce grinding, cleaning, and rework cost for your customer, especially in projects with extensive laser-cutting and welding.

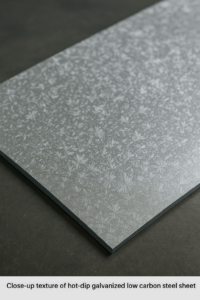

E. Galvanized Types (HDG, EG, GA)

Galvanized steel adds a zinc layer to protect the underlying material:

- HDG (Hot-Dip Galvanized) – a thick, robust zinc coating. Best for outdoor cabinets, traffic equipment, and harsh environments.

- EG (Electro-Galvanized) – a thin, very smooth coating with excellent paintability. Suitable for cosmetic panels that still need some corrosion resistance.

- GA (Galvannealed) – a zinc-iron alloy coating that combines good paint adhesion with protection, common in automotive and appliance sectors.

If your customer sells products into coastal markets or high-humidity regions, galvanized low carbon steel is usually the safest choice.

V. Performance-Defined Types: Function-Oriented Low Carbon Steels

Beyond processing route, low carbon steel can be tailored for specific performance targets. These are often mentioned directly on engineering drawings or material specifications.

A. Mild Steel – The Baseline Option

“Mild steel” usually refers to a basic, non-alloyed low carbon steel with standard strength and ductility. It works well for:

- brackets and mounting plates;

- simple frames and racks;

- indoor structures and support components.

When you see “mild low carbon steel” in an RFQ for simple parts, it often means the customer wants a cost-effective material, not extreme performance.

B. Drawing Quality (DQ) and Deep Drawing Quality (DDQ)

DQ and DDQ are developed for forming. They have better elongation and more controlled surface conditions. They shine in:

- deep drawn pans and covers;

- appliance housings;

- stamped shells and casings.

If a customer complains about cracks or wrinkles during forming, a move from mild steel to DQ or DDQ is often an effective solution.

C. Interstitial-Free (IF) Steel

IF steel is engineered with very low interstitial elements like carbon and nitrogen. This yields extraordinary formability, making it the preferred choice for:

- complex automotive body panels;

- large curved appliance fronts;

- multi-stage deep drawn components.

Wholesale buyers dealing with OEMs in automotive or white goods should clarify whether standard DDQ is sufficient or IF grades are specified.

D. Bake-Hardenable (BH) Steel

BH steels allow parts to be formed easily and then gain additional strength during the paint-bake process. They combine:

- good press formability during manufacturing;

- increased in-service rigidity after painting.

These steels are common in vehicle skins and structural panels where stiffness matters.

E. High-Strength Low-Alloy (HSLA) Low Carbon Steel

HSLA is a key part of the low carbon family. It uses microalloying and controlled rolling to raise strength while maintaining weldability and formability. It is especially useful when customers want:

- higher load capacity without increasing thickness;

- lighter equipment and transport structures;

- better performance than mild steel, but not the brittleness associated with low carbon steel vs high carbon steel comparisons that jump to high carbon.

For pallet racks, frames, lifting equipment, and heavy-duty shelves, HSLA is worth discussing.

VI. Low Carbon Steel Grades Chart – A Buyer-Friendly View

When you work with multiple suppliers and end customers across regions, grade systems matter. A simple carbon steel grades chart helps you quickly match standards and applications.

Below is a simplified view focused on low carbon steel grades:

| SystemLow carbon steel gradesApprox. C rangeTypical uses in sheet metal | |||

|---|---|---|---|

| SAE / AISI | 1006, 1008, 1010 | ~0.06–0.10% | Stamping parts, tubing, general fabrication |

| EN | DC01, DC03, DC04 | ~0.03–0.10% | DC01 for basic forming, DC03 / DC04 for deeper drawing |

| JIS | SPCC, SPCD, SPCE | ~0.03–0.10% | General CR sheet, drawing, deep drawing |

| GB | Q195, Q215, Q235 | ~0.06–0.20% | Structural parts, stamped frames, brackets |

This chart is not exhaustive, but it aligns with how many buyers and engineers classify carbon steel material in practice. When you receive offers from different suppliers, comparing their grades against this structure helps you avoid mismatches.

If a project requires higher strength or different hardness, you may also see medium carbon steel grades or types of high carbon steel listed in separate charts. Those are important for mechanical parts, but less relevant for typical sheet metal enclosures and frames.

VII. How Low Carbon Steel Types Behave in Real Manufacturing

To make informed sourcing decisions, it helps to visualize what happens at your customer’s factory.

A. Forming and Deep Drawing

For sheet metal parts with simple bends, mild steel or standard CR material is often enough. When drawings show deep cups, multi-stage forming, or sharp corners, DQ, DDQ or IF are safer choices. These grades:

- reduce crack risk;

- keep springback more predictable;

- lower scrap and rework rates.

If you regularly sell components like metal cabinets, vending fronts, or deep-drawn electrical enclosures, asking about forming depth and tooling upfront will help you pick the right type and present it clearly in your quotation.

B. Welding Performance

Low carbon steels in general weld well. Challenges appear when:

- thick galvanized coatings lead to porosity;

- HSLA steels are welded without controlled heat input;

- dissimilar materials are joined.

When discussing a project, it is useful to ask your customer which welding process they use—MIG, TIG, spot, laser—and confirm that your proposed steel type and surface condition support that process.

C. Cutting, Machining, and Laser Processing

P&O and CR steels usually provide the cleanest laser cuts and lowest secondary finishing costs. HR and heavy-scale products may require extra work to achieve the same quality.

For buyers purchasing laser-cut blanks or machined sheet metal parts, specifying the base material and surface condition clearly can reduce consumable costs, improve edge quality, and shorten lead times.

D. Coating and Surface Treatment

For indoor metal cabinets and displays, customers often combine CR steel with powder coating. For outdoor products, they may prefer galvanized plus coating. If your end markets include coastal regions, high humidity warehouses, or industrial areas, asking whether a combination of HDG or EG with powder coating is expected will help you recommend the right type.

This is where low carbon steel vs high carbon steel also shows up in practice: low carbon steels accept coatings and welding more easily, making them the first choice for most painted sheet metal assemblies.

VIII. Five Practical Decision Models for Wholesale Buyers

To make the content actionable, here are five recurring scenarios linked to suitable low carbon steel types. You can treat them as quick internal guidelines when preparing RFQs or quoting to your own customers.

Model 1: Complex Forming

- Situation: deep drawn components, tight-radius bends, multi-step forming.

- Recommended types: DQ, DDQ, IF.

- Buyer impact: lower rejection rates, fewer forming complaints, more stable supply.

Model 2: Higher Strength at Same Thickness

- Situation: pallet racks, structural frames, material handling equipment.

- Recommended type: HSLA low carbon steel.

- Buyer impact: meet load requirements without changing design thickness, improve competitiveness.

Model 3: Outdoor and Corrosive Environments

- Situation: street-side boxes, outdoor cabinets, parking equipment, coastal markets.

- Recommended types: HDG, EG, GA with appropriate coating.

- Buyer impact: fewer rust complaints, extended product life, better brand reputation.

Model 4: Visible Cosmetic Surfaces

- Situation: retail fixtures, visible machine covers, kiosks.

- Recommended types: CR or skin-pass steel.

- Buyer impact: consistent appearance, smoother coating, fewer visual defects.

Model 5: Budget-Driven Projects with Simple Function

- Situation: simple brackets, indoor supports, non-critical frames.

- Recommended type: mild low carbon steel with suitable coating.

- Buyer impact: lowest material cost with acceptable performance.

IX. Common Misunderstandings in International Steel Procurement

Even experienced buyers sometimes encounter problems caused by subtle misunderstandings.

A. “Same Grade, Same Performance”

Two batches of SPCC or 1008 from different mills can behave differently because of annealing, rolling schedules, or impurity levels. Always insist on full mechanical data and, if the project is critical, run a forming test on samples.

B. “CR Is Always Better Than HR”

CR is superior for cosmetic quality and precise forming. But for heavy welded frames or thick sections, HR may be more economical and entirely adequate. Matching the steel to the application is more important than always choosing CR.

C. “Coating Solves Everything”

Coating systems protect against corrosion but cannot fix poor formability. If the steel cracks during forming, coatings will only hide the symptom temporarily, not prevent failure.

D. “Higher Strength Is Automatically Better”

A very high-strength grade may look attractive on paper, but if it has low elongation, it can cause brittle failures in bending and welding. Balance strength with ductility, especially for formed and welded components.

X. Case Studies with Real Procurement Impact

Case 1: Bending Cracks in a European Project

A European buyer sourced brackets made from HR mild steel. The parts had tight bends, and scrap rates were high. After switching to CR DQ steel and slightly adjusting the bend radius, cracking disappeared and yield improved significantly.

Case 2: Premature Rust in Coastal Markets

A Middle Eastern distributor sold powder-coated CR cabinets into coastal areas. Within months, rust spots appeared at edges and damaged coating zones. Using HDG low carbon steel as the base material, combined with powder coating, solved the problem in later batches and reduced complaints.

Case 3: Frame Deformation in Logistics Equipment

A North American customer reported deformation in pallet rack frames. The frames used mild steel of moderate thickness. The solution was to change to HSLA low carbon steel, keeping thickness similar but raising yield strength. The result was better performance without major design changes.

These cases show that specifying the right steel type at the purchasing stage can prevent costly quality issues later.

XI. FAQ: Buyer Questions About Low Carbon Steel Types

Q1. What is the difference between low carbon and high carbon steel in fabrication?

Low carbon steel is easier to cut, bend, weld, and coat. It is used for sheet metal parts, cabinets, frames, and general fabrication. High carbon steel is much harder and stronger but difficult to form and weld, so it is used mainly for tools, wear parts, and springs.

Q2. What are common low carbon steel grades for sheet metal work?

Common low carbon steel grades include SAE 1008 / 1010, EN DC01–DC04, JIS SPCC–SPCE, and GB Q195–Q235. Each offers slightly different formability levels. For deep drawing, buyers often choose DC03 / DC04 or SPCE.

Q3. When should I not use low carbon steel?

Low carbon steel is not ideal for parts that must resist extreme wear without surface treatment, or where very high hardness is needed, such as cutting edges and heavy-duty springs. In those cases, medium or high carbon steels, or alloy steels, may be better options.

Q4. Is low carbon steel suitable for cabinets and enclosures?

Yes. For indoor cabinets, CR low carbon steel with powder coating is a standard solution. For outdoor enclosures, galvanized low carbon steel (HDG, EG, or GA) plus coating usually offers much better long-term corrosion resistance.

Q5. How should I describe low carbon steel in an RFQ to a supplier?

Instead of only writing “low carbon steel”, consider including:

- desired type (HR, CR, P&O, galvanized);

- forming requirements (e.g., deep drawing, tight-radius bending);

- surface expectations (cosmetic or non-cosmetic);

- environment (indoor, outdoor, coastal);

- relevant standard (SAE, EN, JIS, GB).

This level of detail helps your supplier, such as YISHANG, propose the correct material from the start.

XII. Buyer’s Practical Checklist Before Issuing an RFQ

Before you send an RFQ or confirm a drawing, consider:

- What is the forming complexity?

- How will the part be cut, bent, welded, and coated?

- Is the part visible or hidden in the assembly?

- Will it be used indoors, outdoors, or near the sea?

- What are the load and stiffness requirements?

- How sensitive is the project to material cost versus performance?

Mapping these questions to the decision models above gives you a clear starting point for specifying the correct type of low carbon steel.

XIII. Conclusion

For international wholesale buyers, low carbon steel is not just a generic commodity. It is a flexible family of materials whose types differ in processing, formability, strength, and corrosion resistance. Understanding these types helps you:

- align material selection with your customer’s real production process;

- reduce claims and delays caused by material mismatch;

- support your brand as a reliable, technically competent supplier.

If you would like to discuss which low carbon steel type fits your specific sheet metal parts, metal cabinets, or custom frames, YISHANG is always ready to share practical advice and technical support.