Metal casting is one of the oldest metalworking methods, but for modern wholesale buyers it is also one of the most strategic. When you purchase cast components at scale, you are not only buying metal parts. You are effectively buying a complete casting manufacturing process: tooling design, melting control, cast forming, inspection, machining and logistics.

For overseas wholesalers, importers and sourcing managers, the question is not simply “what are castings” in theory. The real questions are: how does the casting process affect quality stability, landed cost, lead time, and the risk of returns in your own market? In many industrial projects, a single casting defect can trigger claims, lost contracts or damaged reputation.

Studies from foundry associations and OEM case reports suggest that a large portion of casting‑related quality problems originate at the RFQ and specification stage, not on the shop floor. Drawings are incomplete, tolerances are unclear, material grades are vague, or testing requirements are not defined. Understanding casting in industry from a buyer’s perspective helps you avoid these pitfalls.

This guide has one purpose: to explain metal castings in a way that matches how professional buyers think and work. We move step by step, from definition, to geometry and process logic, to cost and risk, and finally to RFQ structure. The tone is practical rather than academic, so you can apply the ideas directly in sourcing discussions with suppliers such as YISHANG or any other industrial casting supplier.

What Are Metal Castings? A Practical Definition With Procurement Relevance

A simple definition says that a casting is a part made by pouring molten metal into a mold cavity and letting it solidify. That description works for textbooks, but it is not enough for people responsible for sourcing casting parts and managing risk.

From a procurement and quality point of view, a more useful way to think about castings is this:

A casting is a metal component whose shape, internal soundness and base mechanical properties are created during controlled solidification of molten metal inside a designed mold.

This definition matters because it connects geometry, material behavior and process capability. Once solidification is finished, the basic structure of the part is fixed. Later steps such as CNC machining or surface finishing can improve accuracy and appearance, but they cannot repair serious internal issues. Two castings that look identical from the outside may have very different internal porosity, shrinkage or microstructure.

In the casting manufacturing process, several related terms appear in supplier communication and search results:

- casting process / casting processes for metals – overall terms covering how molten metal is handled, poured and solidified

- cast forming / casting and moulding process / cast molding process – phrases used to describe how the mold cavity is created and filled, especially in sand and investment casting

- different types of metal casting / metal casting methods / types of metal casting – families of processes such as sand casting, investment casting, die casting and permanent‑mold casting

As a buyer, you do not need to become a process engineer. However, it is useful to know that each casting method has its own cost structure, tooling requirement, typical defect modes and volume sweet spot. When you search for terms like “custom metal castings”, “OEM metal casting supplier” or “casting parts manufacturer”, what you are really looking for is a partner who can match the right casting method to your part and then control that process consistently.

A Quick Overview of Common Casting Methods

Across casting metalworking, four process families appear most often in RFQs and quotations:

- Sand casting – flexible and economical for medium‑to‑large parts and varied geometries; common for machinery and construction components.

- Die casting – excellent for high‑volume, high‑precision non‑ferrous parts such as aluminium or zinc components.

- Investment casting – suitable for complex shapes and finer detail, often used where surface finish and precision matter.

- Permanent‑mold and gravity casting – useful for repeatable production with better surface finish than basic sand casting.

For buyers, knowing these categories helps interpret supplier proposals like “switching this part from sand casting to gravity die casting” or “moving from fabrication to investment casting”. It also makes your own searches more precise when you look up “metal casting methods” or “casting manufacturing process” for specific projects.

The Universal Steps in Any Casting Manufacturing Process

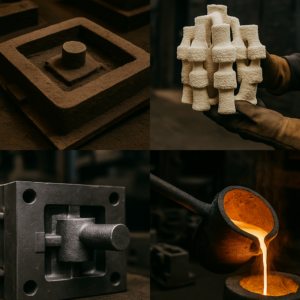

Regardless of the specific method, most casting manufacturing follows a similar sequence:

- Pattern and mold design – defining the cavity, shrinkage allowance and feeding system.

- Mold preparation – producing sand molds, ceramic shells or metal dies.

- Melting and pouring – heating metal to the correct temperature and filling the cavity under controlled conditions.

- Cooling and solidification – allowing the casting to form its internal structure.

- Shakeout and cleaning – removing molds, gates and risers.

- Inspection and finishing – applying NDT, machining, surface treatment and final checks.

You rarely need this level of detail in everyday sourcing conversations, but it helps to know that when you negotiate price and lead time you are really discussing how these steps are planned and controlled. Most importantly, understanding that castings are created during the liquid‑to‑solid transition helps you see why early engineering decisions and RFQ clarity matter more than any sorting or rework later.

Why Castings Exist — Geometry, Structure and Commercial Logic

Not every metal part should be cast. Many components are better made by sheet‑metal fabrication, forging, machining or extrusion. So a natural question for a buyer is: when does casting make sense, and why does it exist at all in modern industry?

Casting Solves Geometry Problems That Fabrication Cannot

Casting is chosen when geometry makes other options inefficient or impossible. Typical cases include:

- Internal flow channels or enclosed cavities that must be pressure‑tight

- Complex, organic external shapes that follow fluid or structural paths

- Thick‑wall sections with multi‑directional stress paths that cannot be formed from plate

- Integration of multiple features—ribs, bosses, flanges, mounting pads—into one body

Trying to machine such shapes from billet stock would lead to excessive cycle time and material waste. Trying to fabricate them from plate and profiles would require extensive welding, distortion control and inspection. In contrast, the casting process can create a near‑net‑shape, monolithic structure in one pouring and solidification cycle.

This is why so many pump housings, gearboxes, compressor covers, valve bodies, turbine housings, motor frames and heavy brackets across industries are cast rather than fabricated. If you look through a catalog of industrial equipment, you are effectively looking at all the places where casting in industry has been selected as the most rational option.

Casting Enables Structural Integrity and Long Service Life

A cast component is a single piece of metal. That monolithic structure provides continuous load paths and fewer potential crack initiation sites compared with welded assemblies. Under cyclic loading, shock or vibration, this makes a difference.

For overseas wholesale buyers, the structural advantages of cast parts show up later as fewer field failures, lower warranty costs and a stronger reputation with downstream distributors and end users. When you evaluate offers for casting parts versus fabricated alternatives, it is worth considering not just unit price, but also lifecycle cost in demanding environments.

When Casting Provides the Most Economical Path

Casting is also a commercial decision. It tends to be the most cost‑effective method when several conditions align:

- Tooling amortization – annual usage and project lifetime justify investment in patterns or dies

- Machining reduction – a near‑net‑shape casting significantly reduces machining time and scrap

- Material efficiency – casting minimizes offcut waste compared with machining from solid stock

- Performance margin – cast geometry allows you to put material only where strength is required

When these factors line up, casting not only offers technical benefits but also creates a competitive landed cost structure for wholesale programs. This is why many buyers search specifically for “wholesale casting parts” or “industrial casting supplier” when planning long‑term product lines.

Inside the Casting Development Process — How Engineering Decisions Shape Cost, Quality and RFQs

To understand why casting quotes differ, and why some suppliers deliver more stable quality than others, it helps to see casting as a sequence of interconnected engineering decisions. This is true whether the part is produced by sand casting, investment casting or another casting method.

Geometry Determines Mold Strategy

The starting point is geometry. The designer’s 3D model and 2D drawings determine:

- where parting lines can be placed

- whether cores are required to form internal cavities

- how metal should enter and flow through the cavity

- where feeders (risers) must be positioned to avoid shrinkage

Complex geometry is not automatically a problem. It simply requires more careful mold design, more detailed simulation and more tooling work. For buyers, the key message is that geometry complexity translates into tooling complexity and process risk. Providing accurate, well‑dimensioned models early is one of the best ways to avoid surprises in both price and quality.

Material Controls Solidification Behaviour

Once geometry is defined, material selection comes next. Cast irons, steel castings and non‑ferrous alloys each have different shrinkage rates, pouring temperatures and feeding needs. A change from one grade to another can affect:

- how thick sections must be to avoid misruns

- how fast different regions cool and solidify

- the type of defects most likely to appear

Using recognized standards (ASTM, EN, ISO) is a simple but powerful way to align expectations. Instead of writing “cast steel” on an RFQ, specifying an exact grade and required mechanical properties gives the supplier a clear target and simplifies comparison between quotes from different casting suppliers.

Solidification Predicts Defects and Scrap Rate

Solidification is where many risks live. Defects such as porosity, shrinkage cavities, hot tears and cold shuts are not random accidents; they follow thermal gradients and feeding paths. Modern foundries use casting development tools like simulation software to test gating and feeding designs before cutting tooling.

For buyers, it is reasonable to ask high‑value suppliers whether they use simulation as part of their casting development workflow. A supplier who can discuss hot spots, directional solidification and riser efficiency is more likely to control scrap rate and deliver stable quality for OEM and wholesale programs.

Defects Define Inspection and Documentation

The risk level of a part—and the consequence of failure—determine the appropriate inspection strategy. In practice this means agreeing upfront on:

- whether X‑ray, CT or UT will be used and on which regions

- what sampling rate will be applied to NDT

- what pressure tests are needed for fluid‑handling components

- which dimensions are critical to function and require tighter control

Defining these points in the RFQ avoids price disputes and ensures that inspection cost is visible, not hidden inside a unit price that may later prove unsustainable.

Engineering Choices Shape Final Pricing

When you receive several quotes for the same drawing, the spread often reflects different assumptions about tooling life, scrap rate, inspection effort and machining allowances. A supplier pricing aggressively may be assuming minimal QC or optimistic scrap. Another supplier with a higher price may be building in realistic scrap and robust inspection.

Understanding that casting prices are tightly linked to earlier engineering decisions helps buyers compare offers intelligently. Instead of focusing only on cost per kilogram, you can ask targeted questions about process flow, tooling design, simulation, NDT and machining strategy.

When Casting Is the Right Production Choice — A Decision Framework for Industrial Buyers

Industrial buyers often face a recurring question: should this component be cast, machined from bar, or fabricated from plate and profiles? A simple, procurement‑oriented framework can make that decision more transparent.

When Geometry and Function Favour Casting

Casting is usually the right choice when a component:

- contains internal cavities or enclosed passages that cannot be machined economically

- must integrate multiple load‑bearing features into one body

- requires complex external contours or organic shapes

- will operate under vibration, shock or cyclic loading where welds are potential weak points

These conditions are common in pump bodies, valve housings, axle carriers, compressor covers, gearbox housings and many other critical parts. In such cases, casting is not just one option among many; it is often the only method that supports both function and cost.

When Volume and Project Life Justify Tooling

Tooling is an investment. The payback depends on annual usage and program length. For many industrial series, patterns and dies pay for themselves within a year when volume is stable.

Sharing realistic volume forecasts and MOQ expectations with your casting supplier allows them to offer a pricing structure that supports both parties over the long term. This is particularly important for buyers sourcing from overseas casting manufacturers where logistics lead time and batch planning have a larger impact on unit cost.

When Reliability and Lifecycle Cost Matter Most

In markets where equipment downtime is expensive, reliability outweighs small price differences. Cast components have inherent advantages in structural continuity, stress distribution and vibration resistance. For buyers supplying machinery, construction equipment, energy systems or transport components, that reliability feeds directly into brand reputation and repeat business.

When you evaluate quotations, it helps to ask not only “what is the unit price” but also “what is the expected lifecycle behaviour of this casting in real service”. A slightly higher price from a supplier with strong casting process control can be cheaper over the full product life.

Managing Casting Risks — A Practical Guide for Procurement Teams

Risk management is a core part of industrial buying, and castings are no exception. The goal is not to eliminate all risk—that is impossible—but to understand where it lives and how to reduce it to an acceptable, predictable level.

Porosity Risks and How Buyers Reduce Them

Porosity comes from trapped gas or inadequate feeding. Its impact depends on location and severity. In pressure‑containing parts it can cause leakage. In rotating or load‑bearing parts it can reduce fatigue life.

Buyers can manage porosity risk by:

- specifying pressure tests for castings that carry fluids or gases

- agreeing on acceptance levels using relevant ASTM or EN standards

- requiring X‑ray or UT on critical cross‑sections when needed

Clear expectations here reduce disputes and help casting suppliers decide which process route and inspection plan to use for each part.

Shrinkage and Hot Spot Risks

Shrinkage defects arise when thick regions or junctions solidify last and are not properly fed by risers. They often concentrate in hot spots at section changes.

Procurement teams can support better outcomes by:

- accepting reasonable design modifications proposed by the foundry to improve feed paths

- asking whether simulation will be used for gating and riser design on complex castings

- reviewing sample inspection reports before approving mass production

This collaborative approach recognises that good casting quality often depends on both design and process.

Cracks, Distortion and Cooling‑Stress Failures

Cracks, hot tears and distortion are usually linked to internal stresses during cooling. These stresses can be amplified by sharp corners, uneven wall thickness or restraint in the mold.

To reduce these risks, buyers can:

- mark stress‑sensitive regions on drawings and discuss them with the supplier

- allow minor geometry changes that improve stress distribution

- include NDT checks on high‑risk regions for safety‑critical applications

With this approach, casting risk management becomes a shared engineering and procurement task, rather than a problem pushed entirely onto the supplier.

Casting Value Today — A Manufacturing and Procurement View

Despite the growth of laser cutting, CNC machining and additive manufacturing, casting remains a backbone process in many industries. From a buyer’s viewpoint, its value shows up in three main areas: structural integrity, cost stability and process integration.

Casting Strengthens Structural Integrity

A cast structure has no weld seams, fewer joints and continuous load paths. This is especially important in:

- gearbox housings and differential carriers

- pump and valve bodies in fluid systems

- machine frames and bases

- suspension and axle components

In these roles, casting supports long service life and predictable performance. When your business model depends on selling reliable equipment through distributors, structural integrity at the casting level supports the entire value chain.

Casting Supports Stable and Competitive Costs

Once tooling and process parameters are stabilised, casting becomes a very repeatable way to produce complex metal parts. Patterns and dies ensure consistent geometry. Standardised work instructions and fixture setups allow efficient machining.

For wholesale buyers, this repeatability translates into:

- predictable unit cost over time

- fewer surprises from rework or scrap

- easier cost forecasting in tenders and long‑term contracts

This is why many sourcing teams include “metal casting services” or “OEM casting manufacturer” as a distinct category in their supplier base, separate from general fabrication.

Casting Integrates With CNC and Finishing for Turnkey Supply

In modern supply chains, casting is usually one step in a larger value flow. Many casting suppliers now provide integrated services including CNC machining, heat treatment, surface coating and sub‑assembly.

For overseas buyers, working with a partner capable of delivering ready‑to‑assemble or fully finished castings reduces supplier count, handling cost and lead time. Instead of coordinating multiple factories, you receive casting parts that fit directly into your own assembly or distribution process.

Key Sourcing Factors — Helping Buyers Build a Strong RFQ

A clear RFQ is one of the most effective tools buyers have to control cost and risk in casting projects. The table below links core technical topics to practical buyer actions:

| Technical Factor | Why It Matters | Buyer Action |

|---|---|---|

| Geometry complexity | Drives tooling design and process risk | Provide detailed 2D/3D drawings, highlight critical regions |

| Material grade | Controls solidification and mechanical properties | Specify ASTM / EN / ISO standards and required test values |

| Casting tolerance | Influences machining cost and feasibility | Refer to ISO 8062‑3, mark key dimensions and datums |

| Annual volume | Determines tooling payback and cost structure | Share forecast, MOQ and expected program life |

| NDT requirements | Defines the depth and cost of quality control | State UT / X‑ray level, sampling rate and acceptance criteria |

| Machined features | Affects downstream process routing | Provide tolerance, thread and surface finish specifications |

Using this structure, buyers can move from vague requests like “cast this part” to precise, professional RFQs that experienced casting suppliers can respond to efficiently. This improves quote quality and makes it easier to compare offers from different foundries or OEM casting partners.

Why Many Casting Guides Do Not Help Buyers — And What This One Does Differently

If you search online for “what are castings” or “metal casting methods”, you will find many articles that explain basic definitions or list casting types. These are useful as an introduction, but they rarely go further. Most of them do not show how casting choices affect cost, risk and RFQ structure for real purchasing projects.

This guide is written from a different angle. It treats casting as a chain of decisions that directly influence sourcing outcomes. Instead of focusing on every technical detail of the casting and moulding process, it focuses on the points where engineering and procurement intersect: geometry, material choice, process route, inspection level and commercial impact.

The aim is not to lecture buyers, but to give you a clear, structured way to talk with suppliers, ask the right questions and interpret the answers. When both sides share a common understanding of casting logic, it becomes much easier to develop long‑term, stable supply programmes for wholesale and OEM markets.

FAQ — Common Questions From Casting Buyers

Q1. Is casting cheaper than machining or fabrication?

It depends on geometry and volume. For simple shapes and low quantities, machining or fabrication may be cheaper because there is no tooling. Once geometry becomes complex and annual volume increases, casting usually reduces both material waste and machining time, leading to a lower cost per part over the life of the project.

Q2. What information should I include in an RFQ for casting parts?

At a minimum, provide detailed 2D/3D drawings, material grade to ASTM / EN / ISO, tolerance class, annual volume and batch size, machining requirements, surface finish, and any NDT or pressure‑test expectations. The clearer the RFQ, the more reliable the quotation and delivery performance will be.

Q3. How do I choose between different types of metal casting?

Start with the function of the part: size, load, temperature, pressure and surface requirements. Sand casting is versatile for larger parts and varied geometries; die casting suits high‑volume non‑ferrous components; investment casting is ideal for smaller, complex shapes; permanent‑mold processes sit between sand and die casting for repeatable production. A capable supplier can recommend the most suitable route once they see your drawings and volume.

Q4. How can I reduce the risk of casting defects in my projects?

Define realistic quality levels, accept simulation‑driven design feedback, and agree inspection plans early. Working with suppliers who understand casting development, simulation, and NDT, and who are transparent about scrap control, will lower risk more than any after‑the‑fact sorting.

Q5. What industries rely most on casting in industry today?

Casting remains critical in construction machinery, agricultural equipment, mining, fluid handling, power generation, railway and heavy transport, among others. If your products serve these sectors, your customers are already depending on casting performance—even if they never see the foundry behind it.

Conclusion — Better Casting Knowledge Leads to Better Sourcing Decisions — Better Casting Knowledge Leads to Better Sourcing Decisions

Metal castings remain essential because they offer a combination of shape flexibility, structural integrity and cost efficiency that other manufacturing routes cannot always match. For overseas wholesale buyers and sourcing managers, understanding the basics of casting logic is not a technical luxury; it is a commercial advantage.

With a clearer view of how geometry, material, process and inspection decisions influence the performance and cost of casting parts, you can prepare stronger RFQs, choose more capable suppliers and reduce your overall risk in the supply chain.

If you want to explore options for custom metal castings, wholesale casting parts or integrated casting and machining supply, you are welcome to reach out to YISHANG for a discussion about your next project.