For overseas buyers, engineers, and procurement managers, sheet metal hardware installation is one of those details that rarely appears in marketing brochures—but it quietly decides whether your project succeeds in the field.

Wrong fastener choice, poor material pairing, or inconsistent installation can lead to loose doors, rusted cabinets, difficult assembly, and warranty claims that are painful to trace back to the real root cause. Getting this right is not only an engineering issue; it is a supply‑chain and total cost of ownership (TCO) decision.

This guide is written from the perspective of an experienced OEM / ODM sheet metal manufacturer in China serving wholesalers and brand owners in 50+ countries. It explains, in practical language:

- How self‑clinching and other sheet metal hardware actually work in the metal.

- Why hardness, material compatibility, and finishing matter more than unit price.

- The real risks of galvanic corrosion and hydrogen embrittlement in fasteners.

- How Design for Manufacturing (DFM) and automation affect your lead time and cost.

- A clear checklist to evaluate the right sheet metal hardware installation partner.

The goal is simple: help you buy smarter, avoid hidden quality risks, and choose a partner who can support long‑term, repeat orders—not just ship one good prototype.

Why Sheet Metal Hardware Installation Matters for B2B Buyers

When you purchase custom sheet metal parts or finished assemblies, hardware is often a small line on the BOM. However, it directly affects:

- Product lifetime and reliability

- Assembly efficiency at your factory or at your customer’s site

- Corrosion resistance in real operating environments

- Serviceability and ease of maintenance

Typical projects that rely heavily on sheet metal hardware installation include:

- Server racks, data center cabinets, and network enclosures

- Vending machines and smart lockers

- EV charging cabinets and power storage systems

- Medical device housings and diagnostic equipment

- Industrial control panels, HVAC units, and switchgear

- Animal and pet equipment, agricultural machinery covers, and building fixtures

If the hardware fails, the whole product is considered low quality—no matter how good the sheet metal bending, welding, or painting is.

From Google search behavior, overseas buyers usually type in phrases like:

- “sheet metal hardware installation for enclosures”

- “self‑clinching fasteners in sheet metal”

- “custom sheet metal fabrication with PEM hardware in China”

- “OEM sheet metal enclosure manufacturer with hardware installation”

This article is written to match those practical search scenarios and answer the questions behind them.

How Sheet Metal Hardware Works Inside the Metal

Self‑Clinching Fasteners and Cold Flow

For many sheet metal fabrication projects, self‑clinching hardware (often called PEM hardware) is the preferred solution. These fasteners do not cut threads directly into thin sheet; instead, they create a mechanical lock by deforming the sheet around a specially designed groove or undercut.

This process is based on cold flow:

- Under controlled pressing force, the softer sheet metal is displaced.

- The material flows into the serrations or undercut of the fastener.

- Once the press force is removed, the fastener is locked in place.

Unlike welding or riveting:

- There is no extra heat‑affected zone in the sheet.

- The assembly can remain flat and dimensionally stable.

- Hardware can be installed quickly and consistently with the right tooling.

For products such as server racks or vending machine doors, this gives high resistance to push‑out and torque‑out, even under vibration or repeated use.

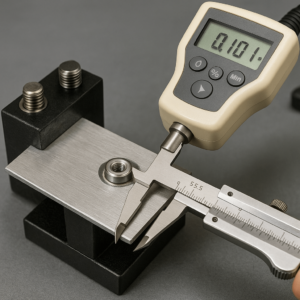

Hardness: Why the Sheet Must Be Softer Than the Fastener

Cold flow only works when the hardness relationship is correct. In simple terms:

The sheet must be soft and ductile enough to flow. The fastener must be significantly harder to form a reliable lock.

Some basics for buyers:

- Rockwell B (HRB) is commonly used for sheet steel hardness.

- Rockwell C (HRC) is often used for hardened fasteners.

A typical cold‑rolled steel sheet might measure 55–65 HRB. To work well, a self‑clinching fastener should normally be at least 20 hardness points higher than the sheet material. Many self‑clinching fasteners are heat treated and rated in the HRC range.

A practical example:

- Sheet: 1.5 mm cold‑rolled steel, 60 HRB

- Fastener: 28–32 HRC self‑clinching nut

Here, the hardware is hard enough to bite into the sheet and create a durable mechanical interlock.

Material Compatibility Beyond Hardness

Hardness is only one side of the story. Material selection must also consider:

- Ductility – If the sheet is too brittle, it may crack around the hardware.

- Thickness – Below a minimum thickness, hardware pull‑out resistance drops dramatically.

- Environment – Outdoor cabinets, medical devices, or food equipment may require specific materials and finishes.

For example:

- Stainless steel 304/316 is common for food equipment, medical, and outdoor environments.

- Low‑carbon steel or galvanized steel is widely used in industrial cabinets where cost and paint coverage matter.

- Aluminum is preferred for lightweight enclosures and transportation equipment.

Common Types of Sheet Metal Hardware Used in OEM Projects

For buyers comparing hardware options, here are common fastener families used in enclosure manufacturing:

- Self‑clinching nuts – Threaded attachment in thin sheet.

- Self‑clinching studs – Provide mounting points for components.

- Standoffs – Create spacing for PCBs or covers.

- Rivet nuts – Hollow threaded inserts for blind locations.

- Weld studs – Used on thicker panels or structural points.

- Hinges, handles, and latches – Functional hardware for access panels and doors.

Understanding these categories helps align BOMs across multiple product lines and improves maintainability.

An experienced sheet metal manufacturer will check these factors before confirming your design. At YISHANG, engineers routinely review hardness and ductility when designing custom enclosures for automotive, electronic, vending, and energy storage applications.

The Hidden Enemies: Corrosion and Hydrogen Embrittlement

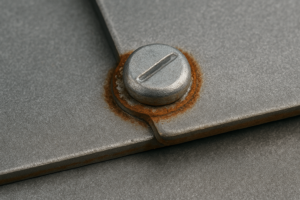

Galvanic Corrosion Between Dissimilar Metals

In real use, your product will face humidity, salt spray, fingerprints, cleaning chemicals, or industrial atmospheres. When dissimilar metals touch in the presence of an electrolyte (water with ions), galvanic corrosion can occur.

Typical risk scenarios in sheet metal hardware installation:

- Zinc‑plated steel screws used in stainless steel panels.

- Plain carbon‑steel fasteners in aluminum cabinets without correct coating.

- Mixed hardware materials inside outdoor electrical or EV charging enclosures.

What happens:

- The less noble metal becomes the anode and corrodes faster.

- The more noble metal becomes the cathode and is protected.

- If the anode has small surface area and cathode is large, corrosion is concentrated and severe.

Result: hardware rust, stained paint, swelling around joints, and eventually structural weakness.

To control galvanic corrosion, you can:

- Match hardware and sheet metal materials more closely.

- Use appropriate coatings (e.g., zinc‑nickel, stainless, or passivated finishes).

- Apply non‑conductive washers or gaskets where needed.

A good manufacturing partner will suggest compatible combinations early in the design stage.

Hydrogen Embrittlement: Failures That Appear Later

Hydrogen embrittlement is a more subtle risk. It mainly affects high‑strength fasteners (typically above ~32–34 HRC) that undergo processes such as pickling, electroplating, or acid cleaning.

What can happen:

- During surface treatment, hydrogen atoms enter the metal.

- Over time, hydrogen accumulates at areas of stress.

- The fastener becomes brittle and may suddenly crack under load—even after successful assembly and shipment.

To manage this, professional suppliers:

- Select the correct fastener strength level for the application.

- Use appropriate plating processes and rinsing steps.

- For critical parts, perform post‑plating baking to drive out hydrogen.

For overseas buyers, it is important to ask:

- What is the hardness or strength class of the fasteners?

- How is hydrogen embrittlement risk controlled?

- Is there documentation or process control for post‑plating baking when needed?

This is where experience and ISO 9001 quality management make a real difference.

Design for Manufacturing (DFM) for Sheet Metal Hardware

Why DFM Starts Before You Send the PO

DFM is the process of aligning your design with your supplier’s real capabilities. For hardware‑intensive sheet metal parts, DFM should cover at least:

- Hole size, tolerances, and position for each hardware type.

- Minimum edge distances to avoid deformation or cracks.

- Metal thickness ranges that are compatible with the selected hardware.

- Choice of material (stainless, low‑carbon steel, galvanized steel, aluminum, copper, brass).

- Finishing sequence: when to install hardware in relation to powder coating, plating, or anodizing.

If DFM is ignored, you may see issues such as:

- Hardware that spins or pulls out under load.

- Distorted panels after pressing.

- Powder coating cracking around hardware.

- Extra rework and manual fitting during assembly.

Practical DFM Checklist for Buyers

Before you freeze your design, go through a simple checklist with your sheet metal partner:

- Confirm hardware type and brand – Self‑clinching nuts, studs, standoffs, rivet nuts, weld studs, hinges, latches, etc.

- Verify metal thickness per location – Match it to the minimum and maximum values recommended by the fastener supplier.

- Check hole tolerances – Ensure laser cutting or CNC punching accuracy can consistently meet hardware requirements.

- Define installation side and direction – Important for assembly sequence and for parts that are difficult to access.

- Clarify finishing flow – Decide if hardware is installed before or after powder coating, plating, or anodizing.

- Plan for assembly and service – Think about the tools your technicians or end users will use.

An experienced OEM / ODM partner will often suggest design tweaks that lower risk and cost, such as standardizing hardware types across multiple models.

Manual vs Automated Hardware Insertion

When Manual Insertion Makes Sense

Manual hardware insertion using simple presses or hand tools can be suitable for:

- Low‑volume orders or prototypes.

- Pilot runs for a new enclosure design.

- Complex assemblies where some locations are hard to reach with automated presses.

Advantages:

- Very flexible for engineering changes.

- Low initial investment in tooling and fixtures.

Disadvantages:

- Higher labor cost per part.

- Greater risk of inconsistent press force and positioning.

- More dependence on operator skill and attention.

When Automated Insertion Is the Better Choice

For medium to high‑volume sheet metal projects, automated insertion systems (such as Haeger or PEMSERTER type presses) become much more efficient.

Benefits include:

- Controlled, repeatable press force and dwell time.

- Faster cycle times with automatic feeding of hardware.

- Lower risk of missing or incorrectly oriented fasteners.

- Better traceability when combined with in‑line quality checks.

If your annual demand is stable or increasing, it is usually worth asking your supplier:

- What is your hardware insertion capacity per shift?

- Do you use dedicated hardware insertion machines?

- Can you support automation for my key fastener types?

In‑Die Fastening for Very High Volumes

At the highest production levels, in‑die fastening can be used. Hardware is installed directly in the stamping die, combining forming and fastening into one operation.

- This approach minimizes handling and speeds up production.

- It requires higher upfront tooling cost and engineering work.

- It is most suitable for automotive and similar industries with long product lifecycles.

For many overseas wholesalers and brand owners, a combination of automated insertion for the majority of hardware and manual insertion for special locations offers the best balance between cost and flexibility.

The Economics of Quality: Understanding the 1‑10‑100 Rule

Quality Costs Multiply Downstream

When evaluating quotes from different sheet metal suppliers, it is tempting to focus on hardware unit price. However, the true cost is reflected in the total lifecycle:

- $1 – Prevention

Early engineering review, material and finishing validation, correct hardness pairing, and structured process control. - $10 – Internal correction

Rework, scrap, or delay when problems are found before shipping. - $100 – External failure

Field repairs, shipping replacement parts, brand damage, and lost customers when hardware fails in the market.

Good suppliers invest in prevention so you do not pay 10× or 100× later.

Practical Ways to Reduce TCO

You can reduce TCO of sheet metal hardware installation by:

- Standardizing hardware families across multiple products.

- Avoiding non‑standard or rarely used fasteners unless necessary.

- Aligning finishing and hardware choices to minimize corrosion risks.

- Requesting first‑article inspection (FAI) reports for critical assemblies.

- Monitoring defect and return data to identify patterns linked to hardware.

How to Evaluate the Right Sheet Metal Hardware Installation Partner

Key Questions to Ask Your Supplier

When you work with an overseas sheet metal manufacturer, especially in China, hardware installation capability should be part of your supplier audit. Consider asking:

- Experience – How many years of sheet metal fabrication and hardware installation experience do you have? What types of products do you mainly make?

- Market focus – Do you mainly serve B2B / wholesale customers or retail end users?

- Material range – Can you work with stainless steel 304/316, low‑carbon steel, galvanized steel, aluminum, red copper, and brass?

- Industries served – Have you supplied parts for automotive, electronics, medical, vending, construction, or energy storage?

- Process capabilities – Can you provide laser cutting, CNC punching, bending, deep drawing, stamping, welding, CNC machining, surface treatment, assembly, and packaging in‑house or within a stable network?

- Quality system – Are you certified to ISO 9001? How is RoHS compliance managed?

- Hardware sourcing – Do you use branded hardware, local equivalents, or customer‑specified suppliers?

- Inspection methods – How do you check push‑out, torque‑out, alignment, and cosmetic quality around hardware locations?

- Engineering support – Can you support DFM, provide design suggestions, and help choose hardware that suits your application?

- Communication and documentation – Are drawings, BOMs, inspection reports, and change records maintained clearly and consistently?

A reliable partner will welcome these questions and provide clear, structured answers.

What an Experienced Manufacturer Like YISHANG Brings

YISHANG is a metal products factory based in China with 26+ years of experience in sheet metal fabrication, metal cabinets, metal display stands, and metal frames. We focus on OEM & ODM projects for B2B and wholesale customers only.

From the perspective of hardware installation, our capabilities include:

- Comprehensive material options – Stainless steel 304/316, low‑carbon steel, galvanized steel, aluminum, red copper, and brass.

- Industry coverage – Automotive components, hardware accessories, electronic equipment, appliances, agriculture, building and construction, medical devices, vending equipment, energy storage, and advertising equipment.

- End‑to‑end process support – Laser cutting, CNC punching, bending, deep drawing, stamping, welding, CNC machining, surface finishing, design support, prototyping, assembly, packaging, quality inspection, and shipping.

- Quality and compliance – ISO 9001 quality management system and RoHS compliance for relevant materials and finishes.

Instead of pushing one fixed solution, we work with buyers to balance performance, cost, and lead time—so the same design can run reliably for many years of repeat orders.

Quality Control and Testing for Hardware‑Intensive Assemblies

To support stable long‑term cooperation, a hardware‑focused quality approach is essential. Key practices include:

- Incoming inspection of hardware – Checking dimensions, hardness, and finish of fasteners before use.

- Process control during insertion – Verifying press force settings, insertion sequence, and operator training.

- Dimensional inspection of sheet metal parts – Ensuring hole size, location, and flatness meet design requirements.

- Functional tests – Push‑out and torque‑out tests for self‑clinching hardware on sample basis.

- Corrosion resistance checks – Where applicable, salt‑spray or environmental testing for finished assemblies.

- Final quality inspection – Checking appearance, completeness of installed hardware, and packaging protection.

For overseas buyers, asking for sample inspection reports or photos from mass production can provide confidence that sheet metal hardware installation is under control—not just assumed.

How to Work With Your Supplier for Better Results

To get the most from your sheet metal hardware installation partner, consider these practical tips:

- Share complete drawings and 3D models

Include hardware specifications, orientation, and critical tolerances in your 2D drawings and 3D files. - Provide application background

Is the product used indoors or outdoors? In coastal or industrial environments? For medical, food, or general industrial use? This helps your supplier recommend suitable materials and finishes. - Clarify annual volume and ramp‑up plan

If your volume will grow, your supplier can plan automation and fixtures early, reducing long‑term cost. - Align on inspection standards

Define what is considered a defect around hardware: minor paint cracks, small indentations from pressing, acceptable torque range, etc. - Start with a pilot run

Before locking in a large order, run a pilot batch to validate assembly, logistics, and end‑user feedback. - Build a long‑term relationship

The more your supplier understands your product line and quality expectations, the more proactive they can be in preventing problems and suggesting improvements.

Conclusion: Turn Hardware from a Risk into an Advantage: Turn Hardware from a Risk into an Advantage

Hardware is a small component with a big impact. For overseas B2B buyers and procurement teams, sheet metal hardware installation should not be an afterthought. It touches:

- Mechanical reliability and safety

- Corrosion resistance in real‑world environments

- Assembly efficiency and labor cost

- Warranty claims and brand reputation

By understanding cold flow, hardness relationships, material and finishing compatibility, corrosion risks, and the economics of quality, you can set smarter requirements for your supplier.

Working with an experienced OEM / ODM sheet metal manufacturer in China, such as YISHANG, helps you:

- Translate engineering requirements into stable mass production.

- Balance performance, cost, and lead time across your product range.

- Build repeatable, long‑term hardware solutions instead of one‑off fixes.

If you are planning your next custom sheet metal project with hardware installation, consider using this guide as a checklist when you talk to potential partners. The right questions at the start can save months of troubleshooting later—and turn your hardware from a hidden risk into a competitive advantage for your brand.

Ready to Discuss Your Sheet Metal Hardware Installation Project?

To receive an accurate quotation and engineering feedback, prepare:

- 2D drawings and 3D models

- Material and surface treatment requirements

- Annual forecast and target batch sizes

- Hardware specifications or preferred brands

- Application industry and operating environment

Frequently Asked Questions (FAQs)

Q1: What is sheet metal hardware installation?

It is the process of mechanically integrating fasteners (nuts, studs, hinges, latches etc.) into thin sheet metal, ensuring structural strength and efficient assembly.

Q2: When should self‑clinching fasteners be used?

When sheet thickness is too thin to tap threads and long‑term vibration resistance is required.

Q3: What matters most when choosing a supplier?

Experience, automated insertion capability, engineering support, and ISO‑based quality control.

Q4: Can hardware be installed after powder coating?

Sometimes—but typically, hardware is installed before finishing to avoid cracking coatings.

Q5: Do I need samples or pilot runs?

Yes—pilot runs help validate installation strength, assembly flow, and coating compatibility.