Introduction — Enhancing Production Line Efficiency with PLCs

In today’s fast-paced manufacturing world, reliable automation systems are essential for optimizing production and maintaining a competitive edge. For wholesale buyers and industrial purchasers, choosing the right Programmable Logic Controller (PLC) is crucial for ensuring smooth operations, reducing costs, and increasing production efficiency.

At YISHANG, we understand that your goals go beyond simply automating processes. You need a system that is cost-effective, customizable, and scalable to meet your unique production needs. Whether you are managing automated assembly lines, quality control systems, or complex machinery in the automotive or electronics industries, PLCs provide the necessary reliability and precision.

In this guide, we’ll explain how PLCs work, the benefits they offer, and how they can be tailored to suit your production requirements. Let’s dive into how YISHANG PLCs can help streamline your operations, enhance efficiency, and optimize long-term costs.

What Is a PLC? The Heart of Industrial Automation

A Programmable Logic Controller (PLC) is an industrial-grade computer designed to automate and control machinery. Unlike traditional computers, PLCs are built for real-time control in harsh environments, providing deterministic control and reliable performance.

Key Benefits of PLCs for Wholesale Buyers

For wholesale purchasers, the primary benefit of PLCs lies in their ability to consistently automate processes with high precision. By integrating PLC systems into your manufacturing processes, you can:

-

Increase production efficiency by automating repetitive tasks.

-

Minimize human error, leading to fewer production defects.

-

Improve system reliability, reducing downtime and costly maintenance.

Whether you need to control temperature, pressure, or motion, a PLC ensures that your systems operate in a predictable, reliable, and consistent manner.

How PLCs Work: Real-Time Control and Automation

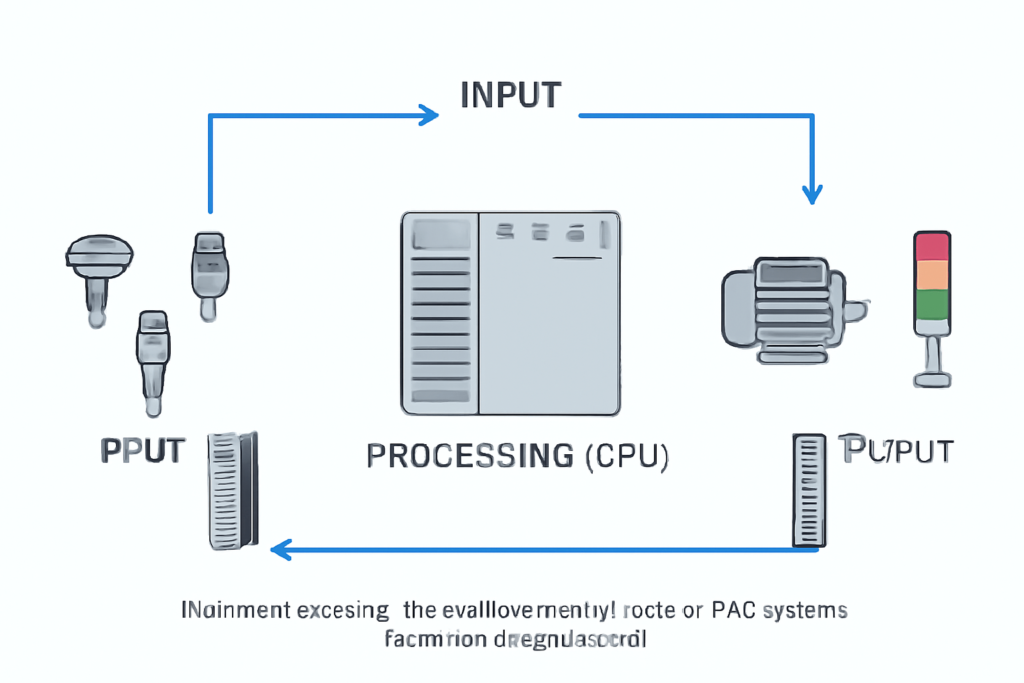

PLCs operate through a continuous cycle of three stages: Input, Processing, and Output. This cyclical process ensures real-time decision-making and precise control over your industrial processes.

1. Input Stage — Collecting Real-Time Data

PLCs collect real-time data from sensors, switches, and other input devices. These inputs can be digital (on/off signals) or analog (e.g., temperature or pressure readings). The accuracy and versatility of PLCs in handling both types of inputs are key to ensuring that your production system works efficiently and effectively.

For wholesale buyers, PLCs allow for easy integration with existing machinery and sensors, giving you the ability to monitor and control various aspects of your production process simultaneously.

2. Processing Stage — Real-Time Decision Making

Once the input data is collected, the PLC’s central processing unit (CPU) processes the data based on the pre-programmed logic. This logic ensures that decisions are made in real-time, and the necessary actions are triggered based on input changes. The deterministic nature of PLCs guarantees that actions are performed without delay.

For bulk buyers, this real-time processing is crucial. Whether you are controlling a conveyor system, robotic arm, or quality inspection system, PLCs ensure that your production line operates smoothly and predictably.

3. Output Stage — Executing Precise Actions

The PLC sends output signals to control actuators, motors, relays, and other devices based on the processed input data. These actions could range from activating machinery to adjusting parameters in the production system.

For wholesale buyers, having real-time control over outputs ensures that all processes, from conveyor belts to automated arms, are working in sync and according to the plan, improving overall production line efficiency.

4. Continuous Scanning — Why It’s Critical for Reliability

The PLC operates continuously, scanning inputs, processing them, and updating outputs, ensuring that your production system is always in sync. This continuous operation is essential for keeping systems running without disruption and for responding to changes in real time.

For bulk buyers, the continuous scanning capability of PLCs guarantees that your systems are always up-to-date, minimizing downtime and ensuring consistent production.

PLC Architecture: The Core Elements for Scalability and Flexibility

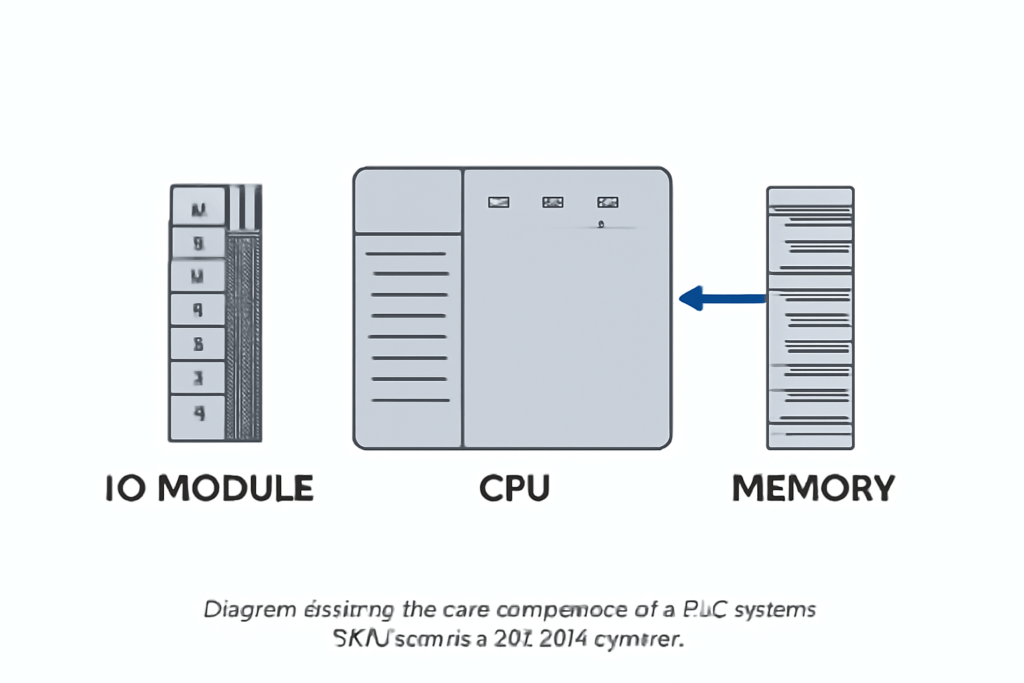

When choosing a PLC, it’s important to understand its architecture to ensure it meets the specific needs of your production system. The core components of a PLC system include:

| Subsystem | Role / Analogy | Why It Matters for Wholesale Buyers |

|---|---|---|

| CPU + Memory | The “Brain & Memory” | Ensures reliable decision-making and stores control programs. |

| I/O Modules | “Sensory Interface” | Allows PLC to interact with real-world devices (sensors, actuators). |

| Power Supply | “Energy Backbone” | Ensures stable power to the PLC, reducing the risk of system failure. |

| Communication Interface | “Nervous System” | Facilitates communication between PLC and other networked systems. |

Why This Matters for Wholesale Buyers

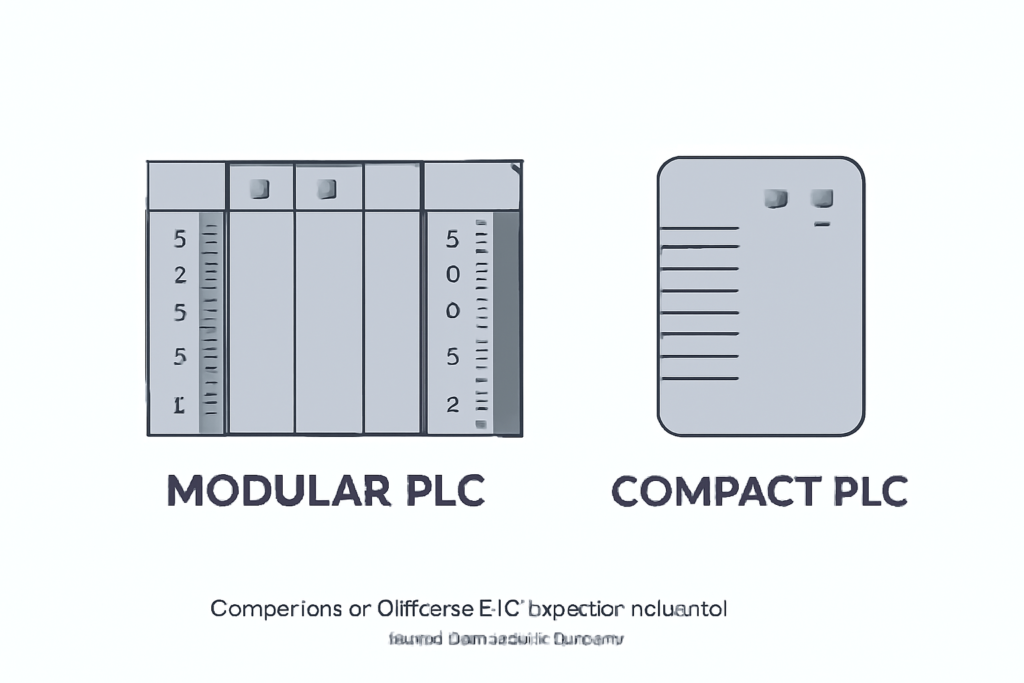

For wholesale purchasers, understanding the architecture helps ensure you choose a PLC that can scale and adapt as your needs evolve. A modular PLC system, for example, allows you to add or remove components (like I/O modules) as your production demands change, without needing to replace the entire system.

Choosing the Right PLC for Your Business

When selecting a PLC, there are several factors to consider beyond just the price. As a wholesale buyer, you need to look at the long-term value of the PLC, which includes customization options, scalability, and maintenance costs.

Total Cost of Ownership (TCO)

While a low-cost PLC might seem appealing, it’s important to consider the Total Cost of Ownership (TCO). This includes the upfront cost as well as ongoing expenses such as maintenance, upgrades, and energy consumption. A modular PLC system might have a higher upfront cost, but it allows you to expand and upgrade your system without a complete overhaul, reducing long-term costs.

Customization and Flexibility

As manufacturing needs change, having a customizable PLC ensures that your system can grow with you. YISHANG PLCs offer tailored solutions that can be configured to meet the specific requirements of your production line, making them ideal for dynamic industries that need to adjust to new processes or product designs.

Why YISHANG PLCs? Reliability, Flexibility, and Efficiency

At YISHANG, we offer high-quality PLC solutions designed to meet the demands of modern industrial applications. Our PLC systems are:

-

Reliable: Built to withstand harsh environments, ensuring consistent performance and reducing downtime.

-

Flexible: Modular design allows for easy expansion and integration with existing systems.

-

Cost-effective: With low long-term maintenance costs, YISHANG PLCs provide high ROI by minimizing operational costs and improving production line efficiency.

Our PLCs are ideal for automotive, electronics, food processing, and other manufacturing sectors, offering tailored solutions that deliver maximum operational efficiency.

Conclusion — Enhance Efficiency and Reduce Costs with YISHANG PLCs

Choosing the right PLC for your manufacturing needs is a crucial decision for wholesale buyers. At YISHANG, we provide customized PLC solutions that offer the reliability, scalability, and cost-effectiveness needed to ensure your production lines operate smoothly and efficiently.

By investing in YISHANG PLCs, you are choosing a partner that can help you achieve your automation goals, enhance efficiency, and reduce long-term costs. Send your inquiry today and discover how our PLCs can optimize your production lines.