CNC steel fabrication is often described as a standardized manufacturing service. For overseas wholesale buyers, however, it functions more like a risk and consistency system that must perform reliably over time.

The real question is rarely whether a steel part can be machined. What matters is whether CNC steel parts can be produced repeatably, at a predictable total cost per good part, across months or years of reorder cycles.

This article is written for B2B procurement managers, sourcing teams, and wholesale buyers who evaluate CNC steel fabrication, CNC metal manufacturing, and CNC sheet metal fabrication for long-term supply. It follows a buyer’s real decision path: where risk enters, how cost forms, why batches drift, and how to identify suppliers capable of scaling without surprises.

Why CNC Steel Fabrication Projects Often Fail During Scaling

Most CNC machining steel projects do not fail at the prototype stage. They fail during scaling, when production shifts from a small sample run to repeated batches and scheduled replenishment. For wholesale buyers, this transition is where supply risk becomes visible.

A typical scenario starts positively. The RFQ is clear, the quotation is competitive, and the first article inspection passes. Problems often emerge later, when a subsequent batch arrives with minor issues such as burrs that require extra deburring, threads that feel inconsistent, or a slight shift in a critical fit.

Individually, these issues seem manageable. Across hundreds or thousands of parts, they become expensive. Steel magnifies these effects compared with many other CNC metal materials because cutting forces are higher, heat accumulation is more significant, and internal stress can influence dimensional stability after material removal.

If buyers assume that a steel component that passes inspection once will behave identically across batches, production windows, or suppliers, risk enters the supply chain. Scaling also changes process economics: tool wear becomes a production variable, fixture repeatability is tested over repeated cycles, and inspection load increases because the cost of a bad batch is far higher than the cost of a bad prototype.

For procurement teams, the key shift is conceptual. CNC steel fabrication must be evaluated as a controlled production system, not as a single machining event.

What Actually Happens Once Steel CNC Machining Begins

Once production starts, CNC steel fabrication becomes a continuous control challenge. Steel CNC machining is governed by the interaction of material behavior, cutting tools, machine rigidity, and clamping conditions, all of which evolve over time.

Heat is the most common hidden driver. Steel does not dissipate heat as efficiently as many other CNC metal materials, so localized heat can temporarily expand the workpiece during machining and contract after cooling. A part may measure in tolerance at the machine and shift slightly later, which is one reason identical drawings can yield different results across suppliers.

Buyers searching for cnc metal fabrication near me often value fast iteration and short feedback loops. That approach helps during early development, but overseas sourcing can be just as stable when suppliers apply consistent thermal control and inspection discipline.

Tool wear is the second major variable. As cutting tools gradually degrade, cutting forces rise, surface finish often changes before dimensional drift becomes obvious, and burr formation increases. Threads may lose consistency, which is why mature CNC steel fabrication suppliers plan tool life and apply offsets before defects appear rather than reacting after rejection occurs.

Fixturing and clamping form the third variable. A fixture that performs adequately for prototypes may shift subtly under repeated cycles, and for thin-walled parts or sheet metal CNC projects, clamping pressure alone can introduce distortion that worsens over time. For buyers, true capability is defined not by machine type but by how well a supplier controls these variables as conditions change.

Steel Machining Challenges Are About Predictability, Not Hardness

In sourcing discussions, steel machinability is often simplified to hardness values or grade labels. In real CNC machining steel environments, predictability matters far more.

Tool wear is inevitable, but what matters is whether it is managed. Steel accelerates wear through abrasion and adhesion at the cutting edge, and as wear progresses, surface finish degradation often appears before measurable dimensional variation. For wholesale buyers, this is rarely cosmetic; surface changes often signal increasing cutting forces and a narrowing process window.

Residual stress introduces another predictability challenge. Steel components may retain stress from forming, welding, or heat treatment, and when machining removes material, that stress can release unevenly. This can cause subtle distortion after machining is complete and is a common reason parts assemble correctly in early batches but interfere later.

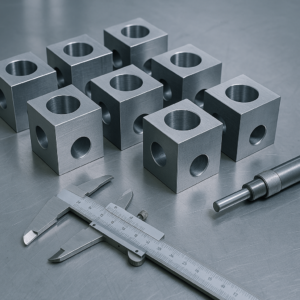

From a procurement perspective, predictability translates into consistency: consistent hole locations, consistent thread engagement, consistent flatness and perpendicularity, and consistent assembly performance at the customer’s site. Suppliers who can clearly explain these risks and controls tend to be easier to scale with.

Practical stability signals wholesale buyers can request

| Stability signal | Why it matters for procurement | What to ask |

|---|---|---|

| Tool-life planning | Prevents drift across long runs | Planned tool-change intervals |

| In-process checks | Detects issues early | Which dimensions are monitored |

| Fixture repeatability | Reduces positional shift | How fixtures are verified |

| Cooling discipline | Avoids hot vs cold variation | Defined inspection timing |

Where Cost in CNC Steel Fabrication Really Comes From

CNC steel fabrication cost is often compared using hourly rates and raw material pricing. These figures are easy to benchmark, but they rarely represent the true procurement cost.

For wholesale buyers, the cost that matters is the total cost per accepted part, delivered on time. In steel CNC machining, the dominant cost drivers are process time and variability.

Process time increases when requirements are difficult to hold consistently. Suppliers respond by slowing feeds, adding finishing passes, and increasing inspection frequency, each of which adds cost without improving functional value.

Variability is the hidden multiplier. When a process drifts, rework, sorting, and scrap increase. These costs may not appear clearly on a quotation, but they surface later as delays, claims, and internal handling labor. This is why a lower unit price can become more expensive in practice, while a slightly higher quote may cost less overall if batch consistency is strong.

Cost drivers buyers can influence early

| Specification choice | Machining impact | Procurement consequence |

|---|---|---|

| Overly tight tolerances everywhere | Extra finishing and compensation | Higher drift risk and lead time |

| Unclear surface requirements | Over-processing for safety | Higher cost and inconsistency |

| Complex non-critical features | More setups and tool changes | Cycle time inflation |

| Missing functional datums | Ambiguous inspection | Disputes and re-approval |

Tolerance in Steel CNC Machining: Balancing Precision and Stability

Precision matters in CNC machining steel parts, but in batch production, repeatability is often the more valuable outcome.

Overly tight tolerances shrink the process window. Suppliers compensate by machining conservatively, which increases sensitivity to tool wear and heat. A single part may meet specification, while a full batch shows more variation, leading to higher inspection burden and rejection risk for wholesale buyers.

Functional tolerancing offers a more stable approach. When tolerances reflect assembly and performance needs, suppliers can choose robust machining strategies that improve consistency while reducing total cost.

Many international drawings reference standards such as ASME Y14.5, ISO 2768, and ISO 286. The specific standard matters less than clarity and alignment, as a clear tolerance strategy reduces approval cycles and sourcing friction.

CNC Machining Steel vs CNC Sheet Metal Fabrication: A Sourcing View

Wholesale buyers often evaluate both CNC machining steel parts and CNC sheet metal fabrication. The best choice depends on geometry, volume, and stability requirements.

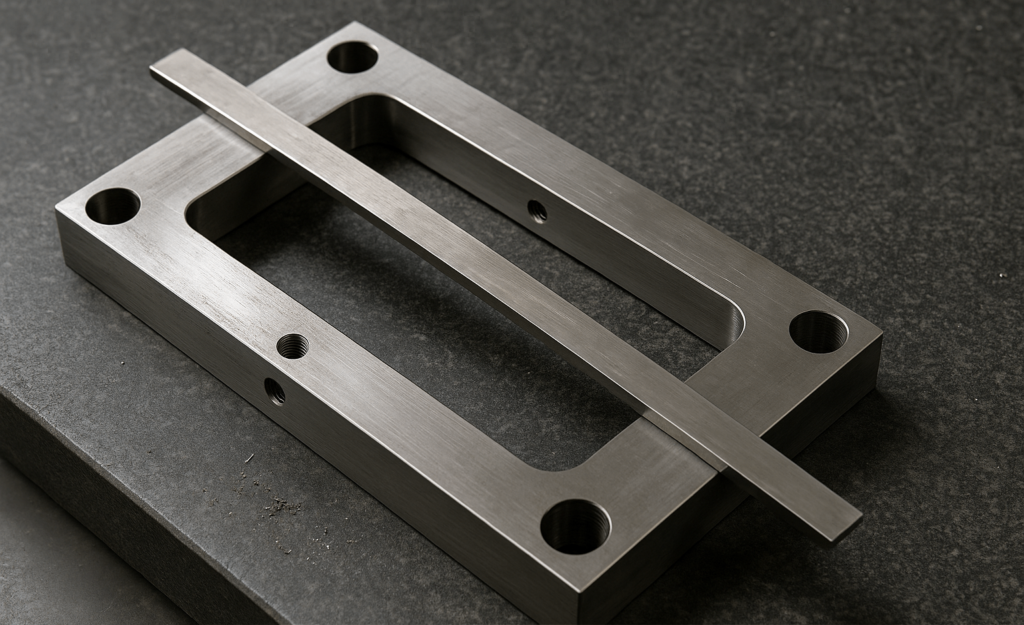

Machining from solid stock offers high precision for localized features, but it can become expensive for large, thin geometries. Sheet metal CNC processes, including laser cutting and bending, are often more efficient for flat or formed components, though they introduce their own distortion and tolerance considerations.

Many production projects combine both approaches. Understanding where each method adds value helps buyers avoid unnecessary cost and risk.

Understanding the Prototype-to-Production Gap in Steel CNC Machining

Prototype success does not prove scalability, and this gap is a frequent source of instability in CNC steel fabrication projects.

During prototyping, tools are new, heat accumulation is limited, and fixtures are lightly used. Batch production changes those assumptions: tool wear accumulates, thermal conditions fluctuate, fixtures experience repeated loading, and gradual dimensional drift appears.

For wholesale buyers, the right question is practical. How will the supplier keep the 500th part the same as the 5th. Mature suppliers describe tool-life management, in-process monitoring, and adjustment rules, while documentation such as first article inspection reports or control plans helps demonstrate stability.

When CNC Steel Fabrication Is Not the Right Manufacturing Method

CNC steel fabrication is versatile, but it is not always the most efficient option.

In high-volume programs with relatively simple geometries, stamping or forming often delivers a lower unit cost once tooling is amortized. When a part is dominated by flat profiles or formed features, laser cutting combined with bending tends to be more efficient than machining from solid stock. Where complex internal features or multi-axis details are required, hybrid manufacturing approaches can significantly reduce machining effort while maintaining functional accuracy.

Recognizing these boundaries helps buyers align manufacturing methods with cost and risk objectives.

How Wholesale Buyers Evaluate CNC Steel Fabrication Partners

Experienced buyers rarely select suppliers based on marketing claims alone. They look for process transparency and risk awareness.

Machine capability and certifications establish baseline confidence, but they do not guarantee batch consistency. Reliable suppliers can explain how they manage heat, tool wear, inspection timing, and drift correction, and they set realistic expectations rather than optimistic promises. This level of clarity supports trust and long-term collaboration.

Frequently Asked Questions from Wholesale Buyers

What causes batch-to-batch variation in CNC machining steel parts

Batch variation is most commonly driven by thermal fluctuation, tool wear, fixture movement, and inconsistent inspection timing, especially during long production runs.

How should inspection timing be defined

Parts should be measured after a consistent cooling period to avoid thermal distortion and to ensure repeatable acceptance decisions.

What should be included in an RFQ for CNC steel fabrication

A clear RFQ typically includes drawings with datums, material condition, quantity schedule, inspection expectations, and packaging or rust-prevention requirements.

When is CNC sheet metal fabrication preferable to machining

Sheet metal fabrication is often preferable for large flat parts or formed components where machining from solid stock adds unnecessary cost without functional benefit.

CNC Steel Fabrication as a Strategic Control System

At its core, CNC steel fabrication is about controlling variability across time, volume, and suppliers. Precision steel manufacturing succeeds when design intent, machining strategy, and production discipline stay aligned.

For overseas wholesale buyers, viewing CNC steel fabrication as a control system leads to more predictable sourcing outcomes. If you are evaluating long-term CNC steel fabrication or CNC metal manufacturing partners, YISHANG can support print review, tolerance strategy, and production stability discussions.

A short technical review upfront often prevents weeks of rework later. If helpful, you are welcome to share drawings and target quantities for an initial stability-focused discussion.