Overseas wholesale buyers and industrial procurement teams don’t read a supplier blog the same way end users read product reviews. Most buyers skim, search within the page, and jump to the sections that answer immediate sourcing questions. When they type queries like metal fabrication techniques, metal manufacturing processes, or types of fabrication, they are usually trying to validate one thing: whether a supplier can deliver repeatable production without surprises.

A prototype that looks good in photos is expected. What buyers want to see is a supplier’s grasp of scale‑up realities: tolerance control across batches, the cost curve from sampling to volume, stable lead times, and predictable quality in international shipments. In other words, they are looking for decision quality, not just process names.

This article is written for that evaluation mindset. It does not try to teach fabrication from first principles. Instead, it explains how decisions across cutting, forming, joining, machining, and finishing shape outcomes that matter most in wholesale sourcing: consistency, risk control, and lifecycle performance.

What “Metal Fabrication Techniques” Means in a Sourcing Context

In procurement terms, metal fabrication techniques do not refer to a checklist of machines or operations. They describe how a supplier combines multiple metal manufacturing processes into a repeatable system that can scale, adapt to change, and deliver consistent output over time.

For wholesale buyers, the distinction matters. Two suppliers may both offer laser cutting, bending, welding, and CNC machining, yet produce very different results at volume. The difference lies in how techniques are selected, sequenced, and controlled under real constraints such as tolerance accumulation, inspection capability, and logistics requirements.

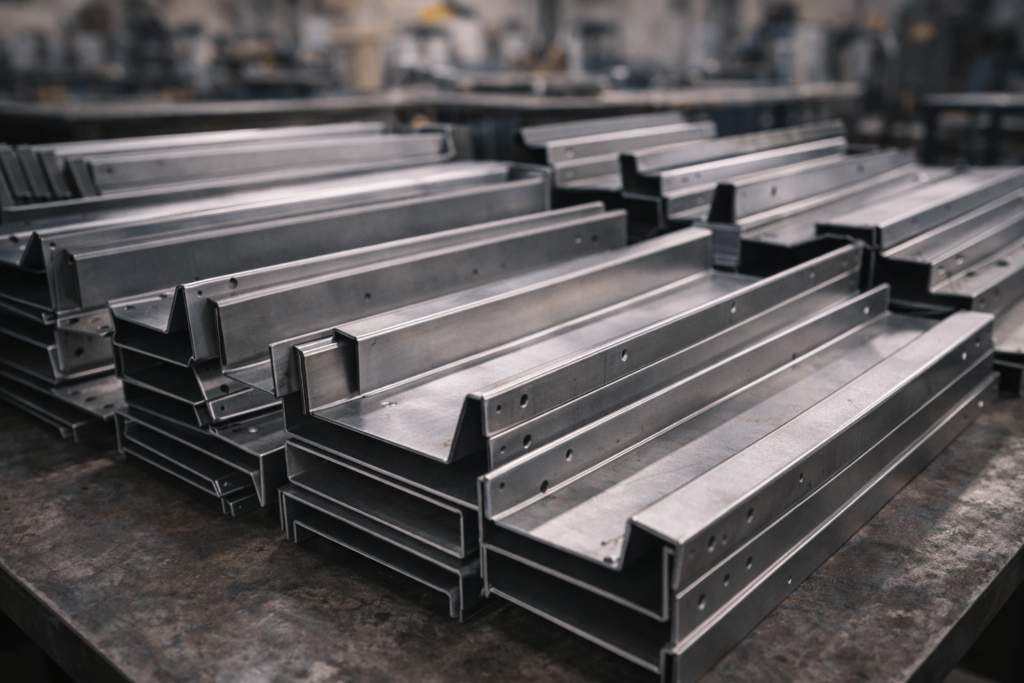

This article focuses primarily on sheet metal–based fabrication and its related secondary operations, because that is where many sourcing challenges appear: enclosures, frames, racks, cabinets, brackets, and structural assemblies. Where relevant, we will briefly reference other manufacturing routes to help buyers understand where sheet metal fabrication fits within the broader landscape of types of fabrication.

Why Fabrication Techniques Are Often Blamed for Problems They Didn’t Create

When issues show up in production, it’s natural to blame the most visible step. A buyer sees warped parts and thinks welding is the problem. They see burrs and assume laser cutting is inconsistent. They see misaligned holes and conclude bending is unstable. These conclusions feel practical because each symptom appears tied to a familiar process.

In real manufacturing, the root cause is often upstream or hidden at the handoff between processes. A laser‑cut blank can meet drawing dimensions yet assemble poorly if bend allowance and K‑factor assumptions were never aligned with the press brake setup. A welded enclosure can pass strength tests yet become difficult to service because welding permanently locked in a geometry that should have allowed adjustment.

For wholesale sourcing, this distinction changes how suppliers should be evaluated. Instead of focusing on machine lists, buyers benefit from understanding how a supplier manages decision flow across the entire fabrication chain.

A scenario many buyers recognize

A common complaint is “perfect parts that don’t fit.” Each component measures within tolerance, yet the assembly still fails. This happens when tolerances stack in the same direction. It is not a laser problem or a bending problem in isolation. It is a tolerance strategy problem that only appears when processes are treated as separate islands.

Suppliers who can explain this clearly are often the ones who can prevent it.

The Context Missing From Most Discussions of Metal Fabrication

Many articles about types of fabrication divide the topic into cutting, forming, welding, and finishing, then stop. While this structure is easy to publish, it does not reflect how fabrication is managed in production.

Wholesale buyers rarely buy a process. They buy a finished part that must assemble correctly, ship without damage, and perform reliably in service. That reality introduces questions that basic process lists often ignore: how parts are fixtured during assembly, how finished surfaces are protected during shipping, and how inspection scales when volumes increase.

Another missing element is commercial context. A technique that is ideal for sampling can become a cost or risk liability at volume. Buyers may accept flexibility early, then require stability as forecasts firm up. A supplier’s ability to navigate that transition is a strong signal of maturity.

Where Sheet Metal Fabrication Fits Among Metal Manufacturing Processes

When buyers search for metal manufacturing processes, they are often trying to determine which production route best fits their part and volume profile. Sheet metal fabrication is one of several options, each with different strengths and constraints.

| Manufacturing route | Typical strengths | Key trade‑offs |

|---|---|---|

| Sheet metal fabrication | Fast iteration, assembly‑friendly geometry, scalable tooling | Requires tolerance management across multiple steps |

| Casting / forging | High strength, complex forms at scale | High tooling cost, limited design flexibility |

| Extrusion | Efficient for long, uniform profiles | Limited cross‑section variation |

| CNC machining | High precision, flexible for low volume | Higher cost per part for large quantities |

For many wholesale products, sheet metal fabrication offers the best balance between flexibility and scalability, especially when combined with selective machining and controlled finishing. The key is not choosing one route blindly, but understanding where each approach creates or reduces risk.

The Constraints That Actually Shape Fabrication Decisions

Fabrication decisions are driven less by what is technically possible and more by what is constrained. Four constraints repeatedly influence outcomes in wholesale sourcing.

Production volume and the cost curve

Most metal fabrication techniques behave differently as volume increases. Laser cutting offers speed and flexibility at low to medium volumes, while punching or stamping can deliver lower unit cost and higher repeatability once tooling is justified.

A buyer‑friendly question is not “Which process is cheaper?” but “At what volume does the cost structure change?” Suppliers who can discuss this transition openly tend to be more reliable long‑term partners.

Tolerance accumulation and assembly yield

Every step introduces variation. Cutting affects edge and position accuracy. Forming introduces springback. Welding adds thermal distortion. Finishing adds thickness. If these effects are not treated as a system, small deviations compound into assembly problems.

For buyers, this often appears as rework, sorting, or delayed shipments. Early discussion of tolerance strategy is usually a sign that a supplier is managing risk, not reacting to it.

Lifecycle conditions and service environment

Static strength is rarely the only requirement. Vibration, thermal cycling, and corrosion exposure often determine long‑term performance. Joining and finishing decisions frequently dominate these outcomes.

Change control and future revisions

Wholesale products evolve. A fabrication strategy that locks in geometry too rigidly can make later revisions expensive. Decisions that preserve flexibility often reduce total lifecycle cost.

Cutting Techniques: Precision Versus Production Stability

Cutting is often described as the start of quality, but for wholesale sourcing it is more accurately the start of repeatability. Precision matters, but stability across batches matters more.

Laser cutting is widely used because it supports complex geometries and fast design changes. As volumes increase, however, buyers often prioritize cycle time consistency, edge condition, and predictable cost. In these cases, punching or blanking can offer better long‑term stability for standardized features.

What buyers should evaluate in cutting

Rather than asking which cutting method is most precise, buyers benefit from asking whether the method supports downstream forming, welding, and finishing without creating hidden rework. Burr control, feature consistency, and process monitoring are practical indicators.

Forming Techniques: Structural Behavior Beyond Shape

Forming is where many long‑term outcomes are quietly decided. Press brake bending, stamping, and deep drawing change material behavior through work hardening, grain deformation, and residual stress.

For wholesale buyers, the key issue is stability. A bend that looks acceptable initially can drift under load or after finishing if stress is not well managed. Inconsistent springback can create variation across batches.

Suppliers who discuss bend allowance, springback control, and in‑process verification are usually managing these risks intentionally.

Welding Techniques: Strength, Flexibility, and Long‑Term Risk

Welding is often framed as a strength decision, but for buyers it is equally a flexibility decision,and introduces heat and permanence. Heat affects dimensional control, and permanence affects serviceability and future changes.

Early discussion of fixturing, sequencing, and post‑weld verification helps buyers assess whether distortion is being controlled or simply corrected later.

In some cases, mechanical fastening or mixed joining strategies offer lower lifecycle risk, even if initial assembly is more complex.

When CNC Machining Becomes Necessary

CNC machining is sometimes viewed as an upgrade, but in many wholesale projects it is essential. Tight hole location, critical interfaces, and datum features often require machining to stabilize assembly.

A hybrid approach—sheet metal for efficient shapes, machining for critical features—often delivers the best balance between cost and consistency.

Surface Finishing and Lifecycle Performance

Surface finishing affects corrosion resistance, wear, and perceived quality. It also interacts directly with earlier processes. Coating thickness influences fit, surface preparation affects adhesion, and welding after coating can create corrosion risks.

Buyers benefit from finish discussions that connect environment, inspection method, and packaging strategy rather than treating finishing as cosmetic.

Process Integration as a Signal of Supply Reliability

Reliable outcomes come from integrated decisions, not optimized steps. Cutting, forming, joining, machining, finishing, inspection, and packaging must reinforce each other.

For wholesale buyers, integration is a leading indicator of supply reliability. It often shows up in how suppliers explain trade‑offs and anticipate scale‑up challenges.

Frequently Asked Questions Buyers Actually Search

What is the best metal fabrication technique for repeat orders?

There is no single best technique. The most reliable approach is one where process choices match volume, tolerance, and change expectations.

Laser cutting vs punching: which is cheaper at scale?

Laser cutting is flexible at low volume. Punching often becomes more economical once features repeat and tooling cost is absorbed.

What tolerances are realistic for sheet metal fabrication?

General tolerances are often defined using standards such as ISO 2768, with tighter tolerances applied only to critical features.

How can weld distortion be controlled in production?

Through fixturing, weld sequencing, controlled heat input, and post‑weld verification rather than corrective rework.

What should I request for first‑article inspection?

Dimensional checks on critical features, process notes, and confirmation that production intent matches approved samples.

Conclusion: Decision Discipline Matters More Than Technique Selection

Metal fabrication techniques are rarely the limiting factor in manufacturing success. For overseas wholesale buyers, outcomes such as cost stability, consistent quality, and reliable delivery depend on how decisions are integrated across the entire process.

Suppliers who can explain trade‑offs clearly, anticipate scale‑up risks, and connect processes into a coherent system tend to support repeat business more effectively.

At YISHANG, we favor technical discussions centered on constraints and practical decision paths. If you are sourcing for repeat production or complex assemblies, sharing drawings and requirements is often the most productive next step.