Introduction

When sourcing carbon steel vs alloy steel components for international B2B supply chains, procurement professionals don’t just evaluate technical performance—they calculate lifecycle value, fatigue resistance, processing complexity, and supply chain predictability. Choosing between carbon steel and alloy steel isn’t a theoretical debate. It’s a decision that impacts warranty claims, production lead times, and long-term supplier relationships.

At YISHANG, we support OEM and industrial buyers across over 50 countries. This guide draws from hands-on metal fabrication experience to help you align material decisions with real-world performance and cost expectations.

Carbon Steel and Alloy Steel: What You’re Really Choosing Between

Base Properties of Carbon Steel

Carbon steel (low, medium, or high carbon) is the go-to choice for many industries due to its affordability, availability, and workability. It’s ideal for basic structural enclosures, low-impact frames, and high-volume metal brackets. Grades like A36 and 1045 are commonly used for general fabrication.

However, carbon steel’s limitations in corrosion resistance, fatigue life, and impact strength restrict its use in harsh or load-intensive environments. Without coating or regular maintenance, carbon steel tends to rust, deform, or fail early, especially in outdoor or vibration-prone settings.

Where Alloy Steel Adds Strategic Value

Alloy steels such as 4130, 4140, or 42CrMo introduce controlled levels of elements like chromium, molybdenum, or nickel, improving tensile strength, heat treatability, and corrosion performance. These are ideal for shafts, couplings, and OEM-grade assemblies where mechanical reliability over time is essential.

Buyers targeting low maintenance cost, longer life cycles, or high-duty applications will benefit from alloy steel despite the higher upfront material cost. This holds especially true in export markets with limited aftersales service capability.

Global Sourcing Caution: Overlapping Grades

Some steel specifications like Q345 or ASTM A572 straddle the border between carbon steel and low-alloy steel. These ambiguous classifications can create major sourcing inconsistencies. Always verify material test certificates (MTCs), and don’t rely solely on grade names—especially if importing from multiple origins.

Performance Matters—But So Does Predictability in OEM Parts

Strength, Ductility & Dimensional Stability

High-load applications require more than raw strength—they demand predictable performance. AISI 1045 carbon steel reaches up to 700 MPa tensile strength, but suffers under sudden impact. In contrast, 4140 alloy steel exceeds 1000 MPa post heat treatment, maintaining ductility and dimensional stability, even under cyclical load.

This dimensional reliability reduces part rejections and post-machining refinishing—ideal for OEM exports requiring repeatable tolerances.

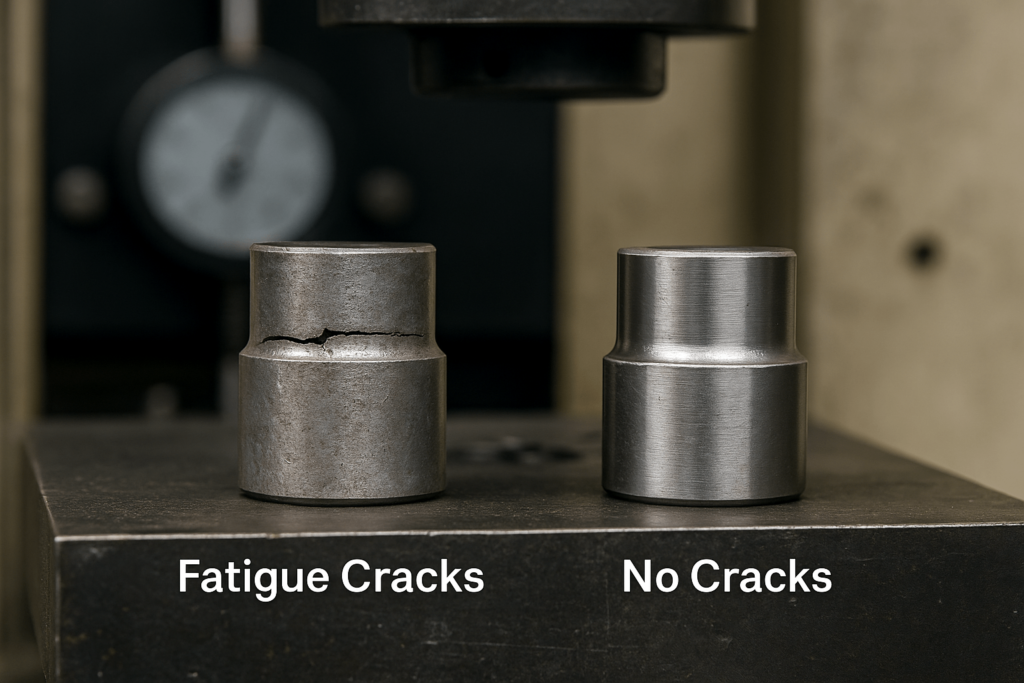

Fatigue Resistance: Think Beyond the First Shipment

Carbon steel may perform well in the lab but falter in real use. For components like axles, pins, and rotating joints, fatigue resistance is key. Alloy steels, especially quenched-and-tempered grades, last longer under cyclic stress. This translates to fewer warranty claims and better field feedback.

If your end users operate in low-maintenance environments, choosing the right alloy steel means fewer product failures and lower service overhead.

Corrosion Behavior: Surface Cost vs Long-Term Performance

Uncoated carbon steel rusts easily in tropical or coastal climates. While paint or galvanization helps, these layers often degrade in high-friction or high-impact zones.

Alloy steels with Cr > 0.5% provide intrinsic resistance to rust and chemical attack, making them better for outdoor electrical enclosures, telecom cabinets, and battery housing exports.

Processing Efficiency: Production Impacts Matter Too

Low-carbon steel processes easily and tolerates fabrication inconsistencies—ideal for budget products or manual assembly lines. On the other hand, alloy steels reduce tool wear, resist thermal distortion, and are better for precision cutting or CNC fabrication.

At YISHANG, we apply batch-level heat treatment QA and stress relief post-welding to ensure alloy steel components maintain dimensional stability in bulk OEM production.

Total Cost of Ownership: Price vs Long-Term Savings

Material Price vs Lifecycle ROI

Carbon steel may cost 30–50% less per ton upfront. But what about repainting, field service, and part replacement? For example:

Case Study: A Southeast Asia distributor chose Q235 carbon steel over 42CrMo for motor shaft housing to save $8/unit. Within 9 months, 12% failed under stress, leading to replacement and field technician costs—wiping out the savings 3x over.

Alloy steels with longer fatigue life and better corrosion resistance often prove cheaper over a 2–3 year lifecycle.

Fabrication Cost and Consistency

Carbon steel’s flexibility makes it ideal for basic welding and shearing, but it lacks predictability in complex assemblies. For international OEM orders, dimensional precision and microstructure stability are non-negotiable.

At YISHANG, alloy steel parts are machined to ±0.1 mm tolerance, minimizing adjustment needs during field installations or final assembly.

Logistics, Lead Time & Sourcing Risk

Carbon steel is globally available with short lead times. In contrast, alloy steel sourcing may require material traceability, batch certification, and extra logistics planning—but it pays off in performance assurance.

Buyers often use a dual-material strategy: carbon steel for non-load-bearing covers and alloy steel for critical stress components, balancing both cost and durability.

Application-Based Decisions: Choose by Function, Not Habit

Electrical Cabinets & Industrial Enclosures

SPCC or Q195 carbon steel suits indoor applications. But when these cabinets are shipped to humid or coastal areas, rust becomes a long-term issue.

Upgrading to 42CrMo or Cr-plated alloy steel for key panels can improve IP65/IP66 enclosure integrity, reduce corrosion returns, and increase buyer satisfaction.

Moving Parts: Shafts, Pins, Couplers

In rotating or impact-loaded parts, carbon steel fatigue becomes a bottleneck. 4140 or 20CrMo alloy steels extend life and improve product safety—especially for mobile machinery, mining components, and agriculture equipment.

Structural Frames or Mounting Systems

Where loads are minimal, powder-coated carbon steel may suffice. But in high-vibration installations or frequent on-site adjustments, alloy steels tolerate stress cycles better, reducing failure rates during reassembly or shipping.

Industrial Buyer’s Selection Framework for Carbon vs Alloy Steel

When evaluating carbon vs alloy steel for wholesale applications, ask:

- What’s the load type (static, cyclic, impact)?

- Will the product face outdoor exposure, chemical vapors, or heat?

- Is precision processing (e.g. CNC or robotic welding) required?

- Are international certifications or IP/NEMA ratings needed?

- Can your supplier deliver consistent microstructure at scale?

At YISHANG, we supply material certs, tensile test reports, and heat treatment validation, supporting procurement audits and international logistics.

Lessons from the Field: Sourcing Errors Buyers Should Avoid

- ❌ Used high carbon steel for a vibration-exposed smart meter case → mounting failures. ✅ Fixed with 4140 low-alloy.

- ❌ Overspecified alloy steel for non-load indoor covers → 22% cost overrun. ✅ Fixed with SPCC + powder coating.

- ❌ Supplier skipped tempering on quenched alloy for marine box → field cracking. ✅ Fixed with mandatory QA protocol.

These errors reveal why alignment of material grade with real-world application is essential in procurement.

Conclusion: Carbon or Alloy—Choose What Aligns with Long-Term ROI

Overseas B2B buyers should not default to carbon or alloy steel by habit. Consider:

- Lifecycle maintenance vs unit price

- Environmental durability

- Part precision & processing constraints

- Logistics, warranty, and audit traceability

YISHANG supports strategic sourcing with:

- Batch-level MTCs

- Custom steel grade matching

- Post-weld treatments

- OEM-focused packaging & inspection

Need a material recommendation based on your design? Contact our technical team today.

FAQs: Industrial Buyers Ask—We Answer

Q1: What’s the difference between 4140 alloy steel and 1045 carbon steel?

A1: 4140 alloy steel has higher tensile strength, fatigue resistance, and corrosion tolerance due to chromium and molybdenum content. 1045 carbon steel is cheaper but less durable under stress or in harsh environments.

Q2: Is carbon steel good for outdoor electrical enclosures?

A2: It can be used with coatings, but long-term exposure to moisture causes rust. Alloy steels like 42CrMo offer longer life with less maintenance in outdoor IP-rated cabinets.

Q3: Why is fatigue resistance important in OEM components?

A3: Many industrial parts undergo millions of load cycles. Alloy steel resists microfracture and dimensional shift, reducing returns and service calls.

Q4: Can I mix carbon and alloy steel in one product?

A4: Yes, many buyers use carbon steel for frames and alloy for wear zones. This dual-material approach balances cost and reliability.