Introduction: Beyond the “Rust-Proof” Myth – The Engineering Reality of Aluminum Durability

Aluminum is a cornerstone material in industrial manufacturing, valued for its high strength-to-weight ratio and adaptability. A common question from overseas sourcing managers and engineers is: does aluminum rust? Technically, it does not—only iron-based metals rust. However, this fact often leads to the risky misconception that aluminum is immune to corrosion. The truth is more nuanced and crucial for long-term product performance.

Here’s the paradox: Aluminum is among the most reactive metals on the periodic table, yet it excels in extreme environments—from marine vessels to aerospace components. This performance is not accidental; it results from a complex, self-protective behavior of the material at a molecular level.

Understanding this resilience is essential for procurement specialists, design engineers, and B2B buyers responsible for specifying durable, cost-effective solutions. Aluminum components are often expected to perform reliably in corrosive, humid, or chloride-rich settings—making correct alloy choice and treatment paramount.

This guide cuts through generic explanations to deliver a technically grounded, commercially relevant blueprint. You’ll learn about the mechanisms of aluminum corrosion, how to identify common failure modes, and which proven prevention strategies can help you minimize risk, reduce lifecycle costs, and increase product longevity.

The Foundation: Understanding Aluminum’s Self-Healing Shield and Its Critical Weaknesses

The key to aluminum’s robust performance lies in a natural phenomenon known as aluminum passivation. When a fresh aluminum surface is exposed to oxygen, it reacts almost instantaneously to form a thin, dense, and highly adherent layer of aluminum oxide (Al₂O₃). This aluminum oxide layer is not a flaw; it is a feature—a chemically inert, self-healing shield that seals the reactive metal beneath from further environmental attack.

(Passivation: A natural process that allows aluminum to form a protective oxide layer when exposed to air, preventing further corrosion.)

This protective film possesses a unique combination of properties that distinguish it from the degradation products of other metals:

- Tenacious Adhesion: Unlike the porous, flaky rust that forms on steel, the aluminum oxide layer bonds firmly to the substrate, preventing it from chipping away to expose fresh metal.

- Impermeable Barrier: The layer is dense and non-porous, effectively blocking the diffusion of oxygen, moisture, and other corrosive agents.

- Instant Regeneration: Perhaps its most critical property for long-term performance is its ability to self-heal. If the surface is mechanically damaged, the newly exposed aluminum immediately reacts with oxygen to reform the protective oxide layer, instantly repairing the breach.

However, the shield is not invincible. For procurement managers and quality engineers, understanding the layer’s environmental limitations is essential to preventing failures. There are two primary vulnerabilities to consider:

- pH Window Sensitivity: The oxide film is amphoteric and only stable within a narrow pH range—typically between 4 and 9. Highly acidic or alkaline environments, such as wet concrete or aggressive detergents, dissolve this protective layer and expose bare aluminum.

- Chloride Ion Penetration: Chloride ions (Cl−), prevalent in marine environments and de-icing salts, are especially aggressive. They can infiltrate microscopic defects or grain boundaries, initiating localized corrosion that bypasses the self-repairing mechanism of the oxide film.

Understanding these weaknesses allows engineers to select appropriate alloys, coatings, and processing techniques, especially when designing aluminum components for harsh environments like offshore structures, cooling enclosures, solar panel frames, or utility cabinets.

The Corrosion ID Kit: A Visual Guide for Fabricators and Inspectors

When aluminum components begin to show signs of deterioration, early identification of the corrosion type is critical to preserving structural integrity and avoiding costly replacement. Each corrosion mode has distinct visual and functional symptoms—making accurate diagnosis essential for engineers, quality inspectors, and procurement teams.

This section provides a categorized overview of the most common forms of aluminum corrosion, with practical descriptions tailored to real-world applications in industrial, marine, and architectural environments.

The Proactive Prevention Blueprint: A 4-Tiered Defense Strategy

Mitigating aluminum corrosion isn’t just about reactive repairs—it starts with smart design, alloy selection, and manufacturing discipline. The following 4-tier strategy empowers engineers and B2B buyers to implement proactive defenses.

Tier 1: Select the Right Alloy

Choose marine-grade aluminum for coastal or high-humidity environments. Alloys from the 5xxx series (e.g., 5052, 5083) offer excellent resistance to saltwater and stress corrosion.

Tier 2: Apply Protective Coatings

Use chromate conversion (Alodine) where electrical conductivity is needed, or Type III anodizing for abrasion and corrosion resistance. Powder coating adds a decorative yet highly protective finish.

Tier 3: Optimize Design Details

Design for drainage and airflow. Avoid crevices and galvanic coupling by using dielectric barriers between dissimilar metals. Incorporate sealants where needed.

Tier 4: Ensure Fabrication & Maintenance Discipline

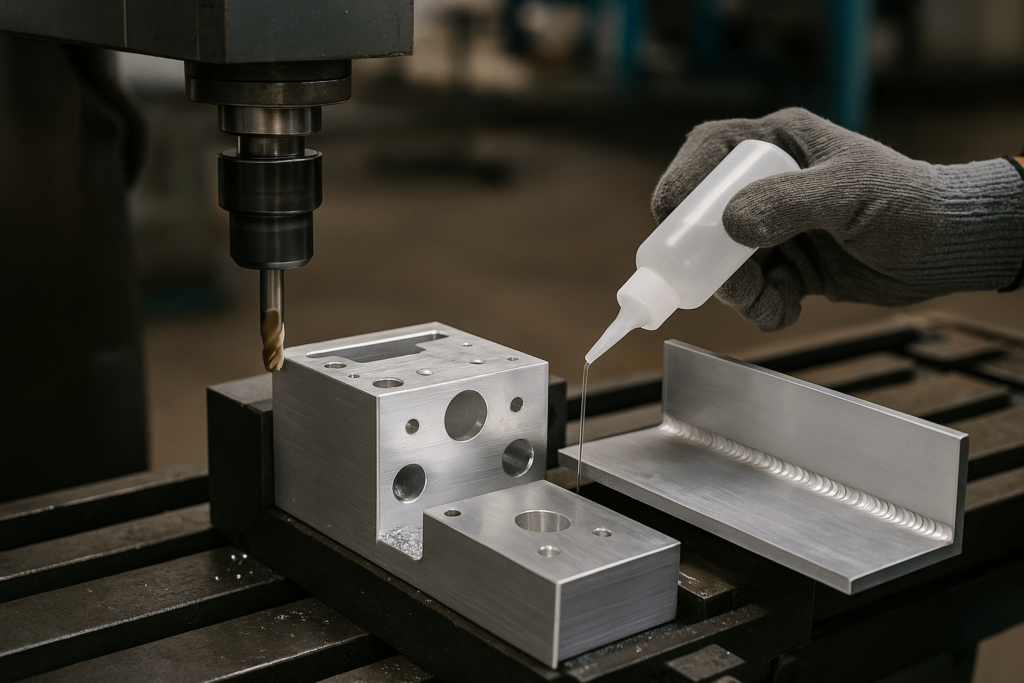

CNC aluminum components should be cleaned and sealed immediately post-machining. Welding processes must control heat input to preserve alloy properties. Plan regular inspection intervals and re-coating schedules for critical parts.

When this strategy is implemented end-to-end, it significantly reduces long-term maintenance and enhances the lifespan of aluminum structures.

Fabrication Details That Impact Corrosion Resistance

Corrosion protection isn’t just about alloy and coating—it’s about how your parts are fabricated. From raw material to final assembly, attention to detail makes the difference.

- Post-Machining Passivation: Even precision-machined parts need chemical cleaning or conversion coatings to restore surface protection.

- Welding Quality: Improper welding can induce residual stress or degrade corrosion-resistant properties. Use controlled TIG/MIG welding and post-weld treatment.

- Storage & Handling: Bare aluminum stored in humid or salty conditions can begin to oxidize before coating. Always protect parts between steps.

- Assembly Integrity: Bolt torque values, sealant coverage, and washer material all play a role in long-term corrosion behavior.

At YISHANG, we embed corrosion control into every stage of custom metal product manufacturing—especially for clients in marine, electronics, energy, and infrastructure sectors.

Final Checklist: Corrosion-Proofing Your Aluminum Designs

Before sending your next design for fabrication or procurement, run through this checklist:

✅ Alloy matches environment (e.g., 5xxx for marine)

✅ Surface finish specified (Alodine / Anodizing / Powder Coating)

✅ Crevice-prone zones eliminated or sealed

✅ Galvanic risks mitigated (isolators, same-metal fasteners)

✅ Handling and assembly protocols defined

✅ Maintenance schedule in place

With over 26 years of OEM & ODM expertise, YISHANG helps B2B buyers and industrial engineers build smarter, more durable aluminum products.

Ready to upgrade your corrosion resistance? Contact YISHANG for a custom quote or design review today.

Glossary: Key Terms for Procurement & Engineering Teams

- Passivation: Natural oxidation that creates a protective aluminum oxide layer.

- Alodine: Chromate conversion coating for corrosion resistance and conductivity.

- Anodizing (Type II / III): Electrochemical surface treatment for aluminum. Type III offers high wear and corrosion protection.

- SCC (Stress Corrosion Cracking): A failure mechanism due to combined tensile stress and corrosive exposure.

- Galvanic Corrosion: Accelerated corrosion due to contact between dissimilar metals in a conductive environment.

FAQ: Common Questions About Aluminum Corrosion

Q1: Does 7075 aluminum corrode easily?

A: Yes, especially in T6 temper. Use T73 and apply hard anodizing to improve resistance.

Q2: What is the best aluminum alloy for coastal applications?

A: 5052 and 5083 from the 5xxx series offer excellent marine corrosion resistance.

Q3: Can CNC-machined aluminum be made corrosion-resistant?

A: Yes. Post-machining treatments like Alodine, anodizing, or powder coating are essential.

Q4: What causes white spots on aluminum enclosures?

A: Often caused by pitting corrosion due to chloride exposure. It indicates protective failure.

Q5: Can I use stainless steel fasteners with aluminum?

A: Only with isolation techniques (e.g., nylon washers) to prevent galvanic corrosion.