Introduction: Breaking the “Per-Kilogram Price” Myth

The price you are quoted for an aluminum sheet is almost never the final price you pay. That “sticker price,” the seemingly simple cost per kilogram, is merely the beginning of a complex story.

For procurement managers and engineers, focusing solely on this single figure is a critical oversight. It’s a path that often leads to unforeseen expenses, budget overruns, and compromised project outcomes.

This guide is designed to demystify the entire cost structure. We will move beyond the surface-level price and provide the insights needed to become a strategic sourcing expert.

Together, we will uncover the invisible factors that inflate your budget, compare the industry’s most common materials, and look ahead to the powerful trends reshaping the aluminum market.

Part 1: The “Sticker Price” is a Trap — Uncovering the Three Layers of Aluminum Cost

To truly understand the aluminum price breakdown, you must first accept that the final “all-in” price is not a single number but a composite of three distinct layers often hidden behind wholesale aluminum sheet prices.

Layer 1: The Global Benchmark (LME Price) — The Starting Point

Nearly every commercial aluminum transaction in the world begins with a single reference point: the LME aluminum price. This is the raw commodity value that fluctuates daily based on global supply and demand dynamics. When suppliers quote a base price, it’s usually anchored to the current LME rate.

However, the LME price alone doesn’t tell the whole story. It’s simply the beginning.

Layer 2: The Regional Premium — Why Your Location Inflates the Cost

Depending on where you’re located, you will encounter regional premiums that sit on top of the LME price. These include:

- Import duties and taxes (especially in the EU or US)

- Local transportation and warehousing costs

- Energy surcharges if the local electricity grid is expensive

These regional premiums can vary by $200–$500/MT, which significantly impacts your landed cost.

Layer 3: From Ingot to Your Specification — Understanding Mill Processing Fees

Once raw aluminum ingots are produced, they must go through a conversion process to become the sheets you require. This step includes:

- Rolling or extrusion

- Annealing or tempering

- Surface treatments (mill finish, brushed, etc.)

- Cutting to size, deburring

Each of these steps incurs additional processing fees, which can often exceed the cost of the aluminum itself—especially for small runs or custom specifications.

Part 2: The Core Cost Driver — Choosing the Right Alloy and Temper

While macroeconomic factors set the stage, the single biggest decision that drives your final aluminum sheet cost is the selection of a specific alloy and its temper.

The Price Tiers of Aluminum Alloys: From Economical 3003 to High-Performance 7075

Different alloys contain varying amounts of elements such as magnesium, silicon, copper, or zinc. These additives influence both price and performance:

- 3003: Economical, corrosion-resistant, non-heat-treatable (often used for signage or roofing)

- 5052: Mid-range price, excellent for bending and marine applications

- 6061: Strong and versatile, heat-treatable, ideal for structural parts

- 7075: Aerospace-grade, very strong but expensive and harder to work with

Choosing the wrong alloy can cause overengineering or premature failure, both of which are costly.

The Three Workhorses: A Head-to-Head Showdown of 3003 vs. 5052 vs. 6061

| Alloy Strength Corrosion Resistance Weldability Cost Level | ||||

|---|---|---|---|---|

| 3003 | Low | Excellent | Good | $ |

| 5052 | Medium | Excellent | Good | $$ |

| 6061 | High | Moderate | Excellent | $$$ |

5052 is often considered the best aluminum alloy for bending due to its combination of strength and ductility.

The Hidden Cost Multiplier: How Temper (-T6 vs. -O) Impacts Your Budget

Temper defines the hardness or softness of an aluminum sheet. Hard tempers (-T6) are stronger but less formable. Soft tempers (-O) are easier to bend but weaker. Choosing a higher temper often increases costs due to additional heat treatment and handling.

Always match your temper to the final forming process. Otherwise, you risk cracking during fabrication or wasting money on unnecessary hardness.

Part 3: Beyond the Sheet — Design, Finishing, and Handling Costs

Many procurement managers focus exclusively on base material costs and ignore the “invisible” expenses that drive up project budgets later in the process. These hidden costs can be grouped into three key categories:

1. Design for Manufacturability (DFM) Mistakes

Poor design decisions—such as specifying overly tight tolerances or non-standard hole placements—can drastically increase fabrication complexity. For instance, a 0.2mm tolerance that forces CNC machining instead of laser cutting can increase production costs by 2–4 times.

If your part is meant to be bent or formed, failing to include proper reliefs or radius tolerances could result in cracked corners or unusable scrap.

2. Surface Finishing — Don’t Underestimate Anodizing or Powder Coating Costs

Surface treatments are often treated as afterthoughts, but they represent 10–20% of the total aluminum sheet cost. For example:

- Mill finish: Cheapest, but scratches easily

- Anodized aluminum sheet: Offers corrosion resistance, but adds setup and masking costs

- Powder coating: More durable, ideal for outdoor applications, but expensive in low volumes

If your supplier doesn’t have in-house coating capabilities, subcontracting introduces delays and markup layers.

💡 Tip: Always specify finish type in RFQs, especially if cosmetic appearance or corrosion resistance is critical.

3. Handling, Packaging & Freight — The Final Markup Layers

Aluminum is lightweight but bulky. Improper stacking, insufficient padding, or non-standard pallet sizes can lead to:

- Shipping damage

- Storage inefficiency

- Higher freight class charges

Ensure your supplier includes detailed packaging specs in the quote (palletized or bundled, protective film, export crates, etc.) to avoid surprise charges or returns.

Part 4: Strategic Sourcing Tactics — How to Cut Cost Without Cutting Corners

Buyers often ask how to save money without sacrificing quality. Here are four proven tactics used by OEMs and industrial buyers:

Tactic 1: Simplify the Alloy Without Sacrificing Strength

Don’t overengineer. If your application doesn’t need aerospace-grade strength, 5052 or 6061 is more cost-effective than 7075.

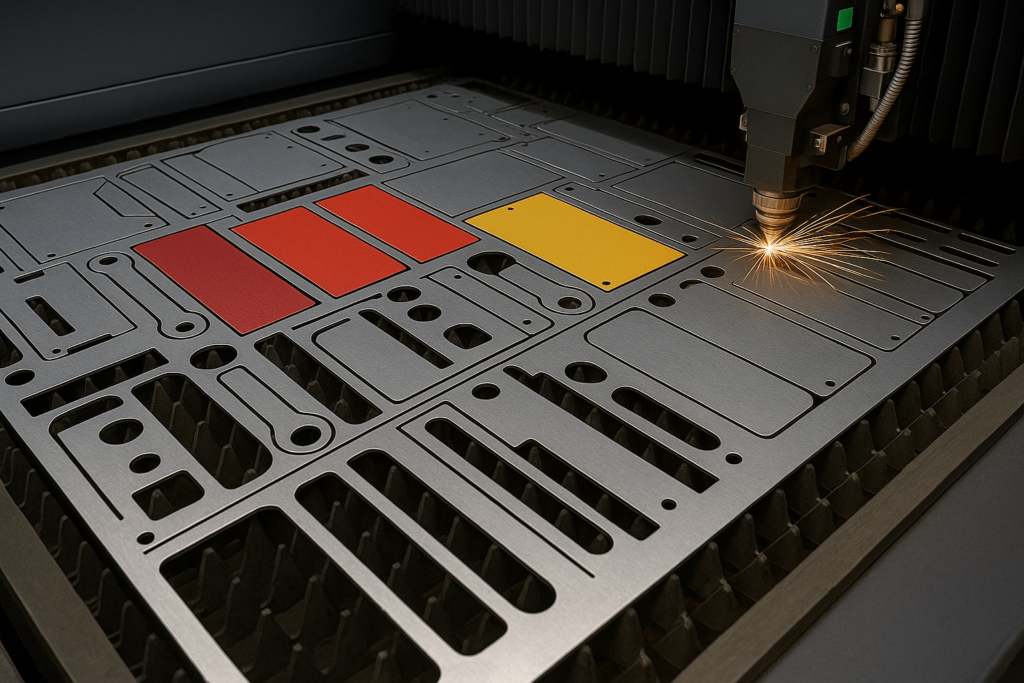

Tactic 2: Design for Flat-Pack and Low-Waste Nesting

Design your parts to nest efficiently within standard sheet sizes (e.g., 4×8 ft or 5×10 ft). Reduce empty space to minimize scrap rate. A few millimeters of optimization can save hundreds per batch.

Tactic 3: Use Fabricator Feedback to Eliminate Over-Specification

A good supplier can help you simplify hole sizes, edge conditions, or bend radii without compromising function. Don’t finalize drawings without their input.

Tactic 4: Consolidate Orders and Standardize SKUs

Instead of ordering small lots across 10 specs, consolidate to fewer SKUs with higher quantities. Many aluminum sheet suppliers offer price breaks at 500 kg, 1 ton, and 2 ton thresholds.

📈 Pro Tip: Ask about partial coil utilization or shared batch production if your order is small. This reduces MOQ surcharges.

Part 5: Quick Answers to the Most Common Aluminum Sheet Pricing Questions

Here we answer the questions our industrial clients ask most frequently. Use this as a reference when preparing your next RFQ.

Q1: What’s the current cost per square foot of aluminum sheet?

It varies significantly based on alloy, thickness, temper, and finish. As of Q3 2025, standard 5052-H32 1.5mm aluminum sheet with mill finish ranges from $3.5 to $5.0 per square foot for bulk orders over 1 ton.

Q2: Why is 5052 more expensive than 3003 even though they look the same?

5052 contains magnesium, which improves strength, weldability, and corrosion resistance, particularly in marine environments. It also undergoes more rigorous rolling and tempering, justifying the higher cost.

Q3: Can I substitute 6061 for 5052 or vice versa?

Not always. 6061 is heat-treatable and much stronger, but less corrosion-resistant and harder to bend. For structural load-bearing parts, 6061 is ideal. For flexible fabrication or marine use, 5052 is preferred.

Q4: Are anodized aluminum sheets worth the extra cost?

If your application requires corrosion protection, UV resistance, or decorative finish, anodizing is worth the investment. For purely internal structural use, mill finish may suffice.

Q5: What is the MOQ for custom aluminum sheet orders?

Most Chinese metal fabricators set MOQs between 300–500 kg per spec. However, flexible factories like YISHANG support mixed-alloy orders in shared production runs.

Q6: Can I get aluminum sheets cut to my custom shape?

Yes. Laser cutting, CNC punching, and die cutting are widely available. Expect to pay for setup cost, nesting layout optimization, and extra lead time. Always share detailed CAD drawings early.

Q7: Why does my quote vary from supplier to supplier even with the same specs?

Hidden variables include regional aluminum billet pricing, in-house vs. outsourced processing, packaging specs, and freight efficiency. That’s why total landed cost analysis is more important than comparing unit rates alone.

Q8: How do I ensure I’m not overpaying for aluminum sheet?

Break down quotes into material, processing, surface treatment, packaging, and shipping. Benchmark each component and cross-reference with at least 3 factories. Also ask about alloy substitutions or layout efficiencies.

Conclusion: It’s Not Just a Sheet — It’s a Strategic Asset

Aluminum sheet pricing is more than a matter of commodity rate monitoring. It’s a strategic sourcing decision that intersects with engineering, supply chain logistics, and vendor management.

Smart procurement managers look beyond the kilogram price. They understand alloy performance, leverage design-for-cost principles, and build relationships with technically capable fabricators.

At YISHANG, we work with industrial buyers across 50+ countries, helping them source the right aluminum sheet with optimal cost-performance trade-offs. Whether you’re designing outdoor enclosures, vehicle panels, vending machine components, or signage systems — our team helps you reduce waste, improve formability, and hit your target price.

📩 Ready for your aluminum sheet quote? Contact us for expert guidance, drawings review, and fast RFQ turnaround.