Introduction: Beyond the Price Tag—Why Your Filler Metal Choice is a Critical Business Decision

For a procurement manager sourcing materials for global distribution, the choice of an aluminum welding rod extends far beyond a simple line item. A suboptimal or inconsistent filler metal can lead to significant business liabilities, from costly product recalls to damaged client relationships.

Welding aluminum is a complex metallurgical process. It involves managing a tenacious oxide layer, extreme thermal conductivity, and the constant risk of hydrogen porosity—a defect that can severely compromise joint integrity. The filler metal is the single most critical variable in controlling these factors.

At YISHANG, with over 26 years of experience supplying metal products to more than 50 countries, we understand that clients are investing in the quality and reputation of their final product. This guide provides strategic insights necessary for procurement decisions that ensure performance, reliability, and long-term value.

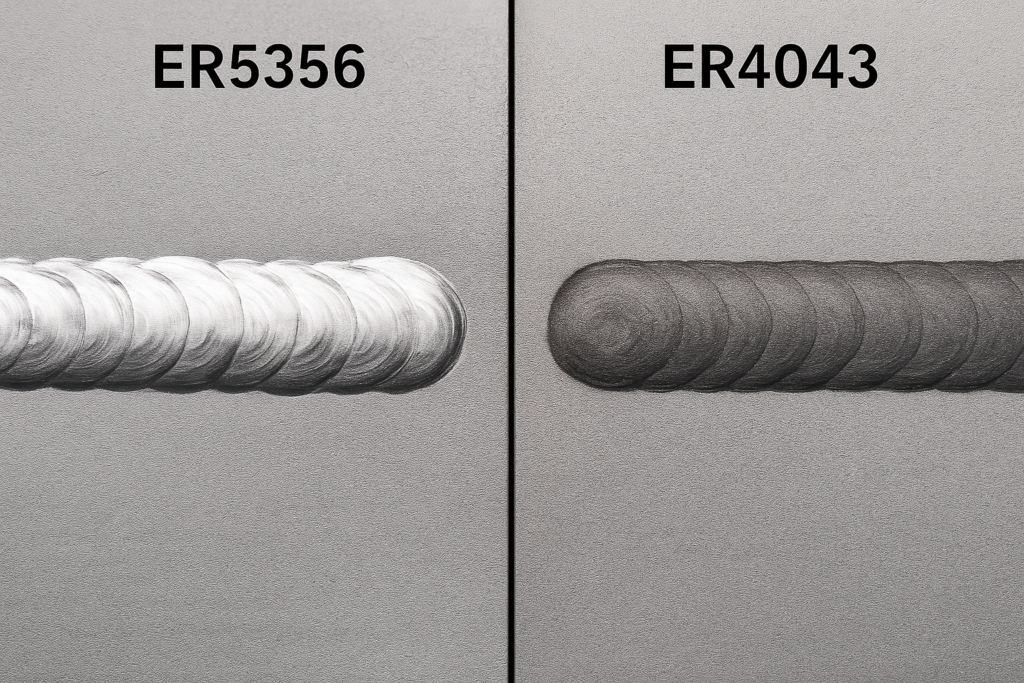

The Industry Standard: A Comparative Analysis of ER4043 vs. ER5356

In the global fabrication market, two filler metals, ER4043 and ER5356, represent over 80% of all consumption. A deep understanding of their properties is essential for any procurement professional. The decision impacts mechanical performance, finishing requirements, and service life.

Quick Comparison Table: ER4043 vs. ER5356

| Attribute | ER4043 | ER5356 |

|---|---|---|

| Composition | Al-Si (Silicon ~5%) | Al-Mg (Magnesium ~5%) |

| Shear Strength | ~11 KSI | ~18 KSI |

| Cracking Resistance | Excellent | Good |

| Anodizing Appearance | Gray/Black Discoloration | Bright Color Match |

| Fluidity (Weldability) | High | Moderate |

| Suitable for Marine Use | ❌ | ✅ |

| High Temp Performance | ✅ (better) | ❌ (max 66°C / 150°F) |

Strength and Structural Integrity

ER5356, an aluminum-magnesium (Al-Mg) alloy, exhibits a significantly higher shear strength—typically around 18 KSI (124 MPa)—compared to the 11 KSI (76 MPa) of ER4043, an aluminum-silicon (Al-Si) alloy.

This is a critical factor for fillet and lap welds. For any product where these welds are a primary structural component, such as in marine or transportation applications, specifying ER5356 is a crucial engineering requirement to ensure safety and durability.

However, for butt joints on heat-treatable alloys like 6061-T6, the failure point is typically the weaker Heat-Affected Zone (HAZ), not the weld itself. In this case, ER4043 is often a more strategic choice, providing excellent crack resistance without the added cost of an over-specified filler.

Post-Weld Finishing and Aesthetic Value

For high-value consumer or architectural products, the final finish is a key selling point. A weld made with ER4043 will turn a dark, smutty gray or black upon anodizing due to its high silicon content. This can ruin a product’s aesthetic and lead to costly rejections.

Conversely, ER5356 provides a clean, uniform, and often seamless color match after anodizing. For any product line that will be anodized, specifying ER5356 in your procurement documents is an absolute requirement to ensure visual quality and brand consistency. (Related: AWS A5.10 Specification)

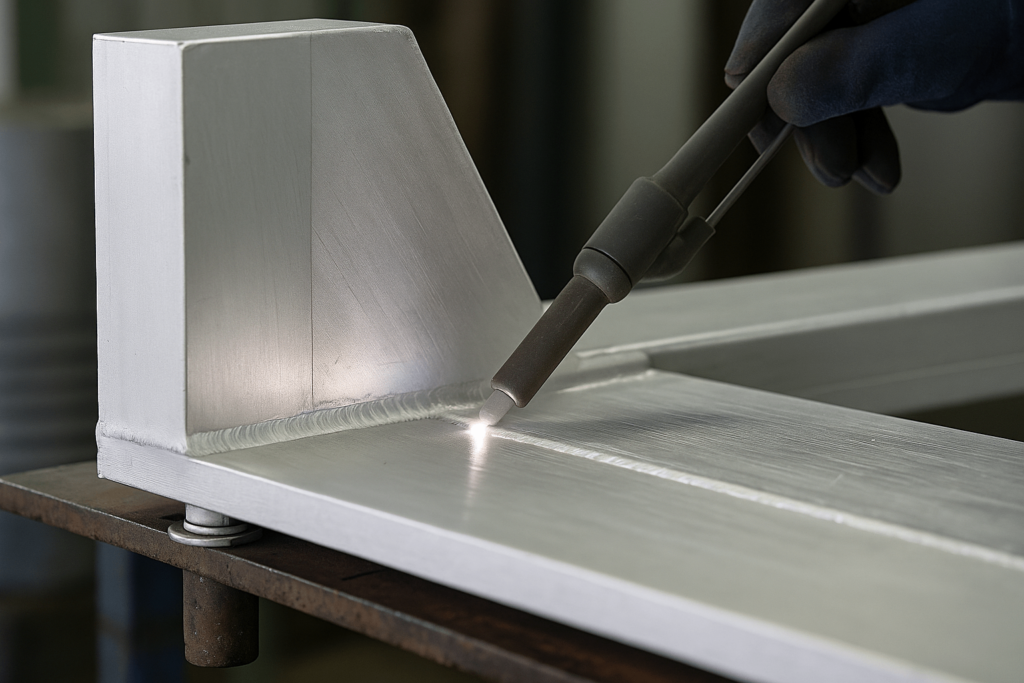

Production Efficiency and Weldability

From a production standpoint, these fillers impact efficiency. ER4043’s high fluidity results in flatter, cleaner beads with less spatter, potentially reducing post-weld cleanup time.

ER5356 wire is significantly stiffer, making it a robust partner for automated or semi-automated MIG (GMAW) welding. It is far less susceptible to the wire feeding issues that can cause production stoppages, translating to higher uptime and greater overall efficiency in high-volume manufacturing.

Service Limitations and Metallurgical Compatibility

A critical service limitation governs ER5356: it is not recommended for sustained exposure to temperatures above 66°C (150°F) due to the risk of stress corrosion cracking. For high-temperature applications, ER4043 is the mandatory choice.

Furthermore, a fundamental rule of metallurgy must be respected: never use ER4043 to weld high-magnesium 5xxx series alloys like 5083. This combination creates a brittle weld prone to failure. Ensuring your suppliers adhere to these compatibility rules is a crucial aspect of quality control.

Choosing the Best Aluminum Welding Rod for Your Application

Long-term performance and joint integrity start with the right filler metal. Consider the following when making your selection:

- Base Alloy Compatibility (e.g., 5083 vs 6061)

- Required Strength & Ductility

- Anodizing Appearance Needs

- Service Temperature Limits

- Application Environment (Marine, Structural, etc.)

Whether you’re buying aluminum welding rod for 5083, ER5356 MIG wire for marine fabrication, or ER4043 filler for architectural aluminum, always verify with your welding engineer before procurement.

Beyond the Basics: Specifying Fillers for High-Value and Demanding Applications

Sourcing for high-performance industries requires knowledge of specialized filler metals. These are not interchangeable commodities; they are engineered solutions designed to meet specific, often certified, performance criteria.

Solution 1: For Maximum Strength and Marine Applications (ER5183 & ER5556)

For demanding structural and marine applications, high-magnesium fillers offer performance beyond ER5356. ER5183 contains more manganese, providing a measurable increase in strength and toughness. It is the preferred filler for welding 5083 marine-grade aluminum, ensuring joint integrity in harsh saltwater environments.

When the design specifies the absolute highest as-welded strength, ER5556 is the definitive choice. It delivers unparalleled tensile and shear strength, making it the specified filler for critical applications like truck trailers, rail cars, and military hardware.

Solution 2: For Casting Repair and Hermetic Sealing (ER4047)

ER4047 contains approximately 12% silicon, giving it the lowest melting temperature and highest fluidity of any common aluminum filler. This exceptional flowability allows it to penetrate and seal the fine cracks and porosity inherent in cast aluminum.

This makes ER4047 the premier choice for high-value repair work on castings and for fabricating components that require a guaranteed hermetic seal, such as heat exchangers and pressure vessels.

A Manager’s Guide to Defect Prevention and Quality Control

From a procurement perspective, weld defects are direct threats to product reliability and your company’s reputation. Understanding their root causes is key to establishing effective quality control protocols with your suppliers.

Porosity: The Hidden Threat to Structural Integrity

Porosity from trapped hydrogen gas drastically reduces the load-bearing cross-section of a weld, which can lead to premature failure. The business impact can be catastrophic, leading to liability claims and brand damage.

Your quality assurance program should mandate that suppliers adhere to a strict two-stage cleaning process and ensure filler metals are stored in a sealed, dry environment to prevent the moisture and hydrocarbon contamination that causes this defect.

Black Soot (Smut): An Indicator of Process Control

This black deposit is magnesium oxide, common with 5xxx fillers. While not a structural defect, excessive smut requires additional cleaning, increasing labor costs and production time.

It can also signal underlying issues with shielding gas coverage. Verifying that your fabricator’s Welding Procedure Specifications (WPS) call for proper parameters, such as the correct torch angle and arc length, is a key quality control checkpoint.

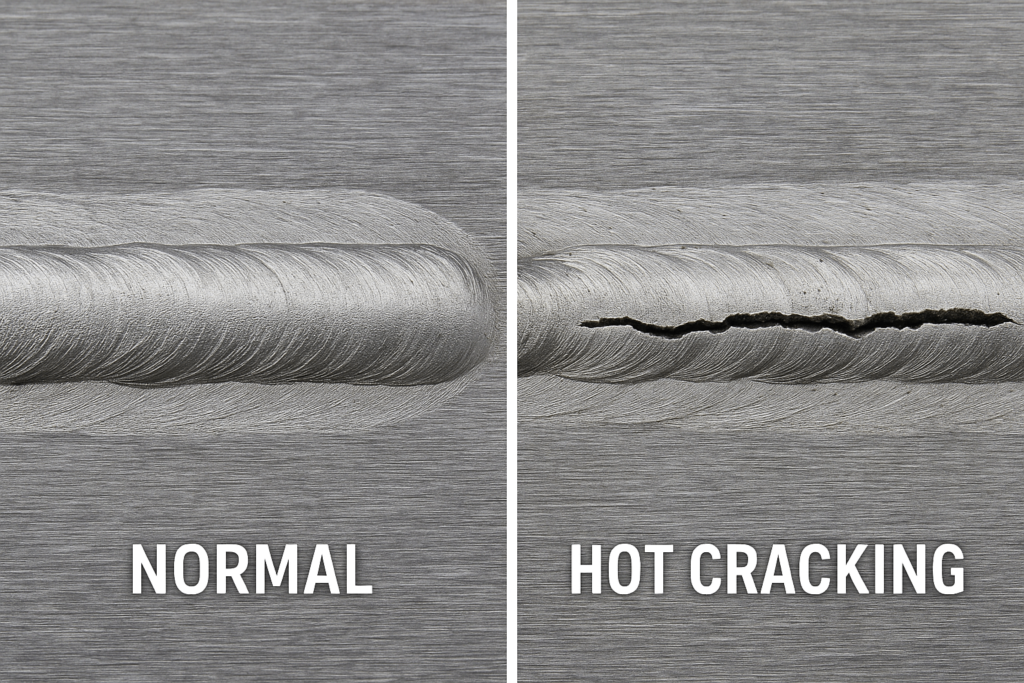

Cracking: A Critical and Unacceptable Defect

Hot cracking occurs as the weld solidifies due to aluminum’s high thermal expansion. Cracks render a part unusable and require costly rework or scrapping.

This is primarily a metallurgical problem solved by selecting the correct filler metal. For example, using a 4xxx series filler like ER4043 to weld a crack-sensitive 6xxx series alloy is standard industry practice. Your procurement specifications must call for the correct filler-base metal combination.

Beyond the Rod: What Wholesale Buyers Must Know About Quality, Compliance, and Supply

For a procurement professional, the product is only as good as the supplier behind it. Evaluating a potential partner for aluminum welding rods requires looking beyond the technical data sheet to their quality systems, compliance standards, and supply chain capabilities.

Quality Assurance and Compliance: The Importance of Certifiable Consistency

Consistency is paramount in bulk purchasing. A trustworthy supplier must demonstrate a robust quality management system. Insist on suppliers who can provide Certificates of Conformance (COC) with each shipment, verifying the chemical composition adheres to standards like AWS A5.10.

Certifications such as ISO 9001 are not just logos; they are evidence of a documented, repeatable process designed to ensure quality. This documentation is crucial for your own records and for traceability.

While TIG and MIG are the industry standards for quality aluminum fabrication, some buyers may inquire about alternative welding methods. Although stick welding (SMAW) exists, it is generally not recommended for aluminum due to a higher risk of contamination and defects. It remains outside the scope of high-reliability industrial use.

Packaging and Logistics: Protecting Your Investment

Aluminum filler metal is highly susceptible to moisture contamination. The supplier’s packaging is your first line of defense. High-quality suppliers like YISHANG provide rods and spools in hermetically sealed packaging to protect them during transit and storage.

A supplier who understands the importance of packaging demonstrates a comprehensive understanding of the product’s vulnerabilities and is more likely to be a reliable long-term partner.

Partnering for Success: Leveraging Supplier Expertise

The most valuable suppliers are technical partners. A supplier with deep, demonstrable experience—like our 26+ years at YISHANG—can provide invaluable support.

This collaborative approach helps you select the optimal filler for a new design, troubleshoot production issues, or recommend a more cost-effective solution, ultimately reducing your risk and enhancing your bottom line.

Internal Links for Deeper Guidance

For more information on related processes:

- Aluminum Sheet Metal Fabrication Services → Learn about how these filler rods integrate with CNC-cut parts

- TIG Welding Capabilities at YISHANG → Explore industrial-grade TIG welding for aluminum

- Custom Aluminum Parts OEM Solutions → Match filler wire to your OEM parts

Related Resource: ISO 9001 Certification Explained – ISO.org

Conclusion: A Strategic Partnership for Quality and Reliability

For the global procurement professional, selecting an aluminum filler metal is a decision that impacts production efficiency, product quality, and brand reputation. It requires a partner who delivers not just a product, but certifiable, consistent quality at scale.

Looking for a reliable aluminum welding rod supplier? YISHANG supports your procurement with certified quality, OEM customization, and on-time global delivery. Contact our team today for technical consultation or to request a quotation.