The Surface Is the Start: Why Bead Blasting Matters to Professional Buyers

Bead blasting isn’t about aesthetics—it’s about consistency. For B2B buyers sourcing high-volume metal parts, surface prep isn’t decorative—it’s performance-critical.

A uniform blasted finish minimizes coating defects, ensures bonding readiness, and reduces rework rates. This makes it a core part of quality assurance, not just visual refinement.

Buyers focus on whether surface finishing is treated as a controlled process. Finish uniformity, seamless downstream integration with coatings, adhesives, or masking, and supplier SOPs for abrasive blasting are critical decision points.

Bead Blasting Defined: Clean Surfaces, Controlled Performance

What Is Bead Blasting?

Bead blasting is a controlled abrasive process using glass or ceramic spheres. It removes minor flaws while preserving part geometry—ideal for precision components, such as in automotive or telecom metal surface preparation.

How It Differs from Sandblasting

Compared to sandblasting, bead blasting is gentler and yields more uniform finishes. It enhances microtexture and surface energy—key for downstream processes like adhesion or coating application.

Bead Blasting vs. Sandblasting vs. Shot Peening: Key Differences

| Process | Media Type | Typical Ra Range (µin) | Surface Impact | Best-Fit Applications | Cost / Efficiency |

|---|

| Bead Blasting | Glass or ceramic beads | 15–65 | Uniform finish, mild cleaning, geometry preserved | Precision parts, coating prep, scratch-free finishes | Medium |

| Sandblasting | Quartz sand or grit | 40–120 | Aggressive removal, may erode details | Heavy rust removal, structural steel, low-precision work | Low |

| Shot Peening | Steel or ceramic shot | Not Ra-driven | Induces compressive stress, improves fatigue life | Aerospace, automotive components needing durability | Medium–High |

| Polishing | Buffing wheels, compounds | <10 | Glossy, mirror-like surface | Decorative parts, medical instruments, food-grade equipment | High |

Why It Matters for Downstream Processes

For buyers, bead blasting enables predictable Ra spec compliance and repeatable results. We apply blasting per spec sheet Ra targets to align with coating, welding, and masking processes.

Matching Media to Material: What Sourcing Teams Need to Know

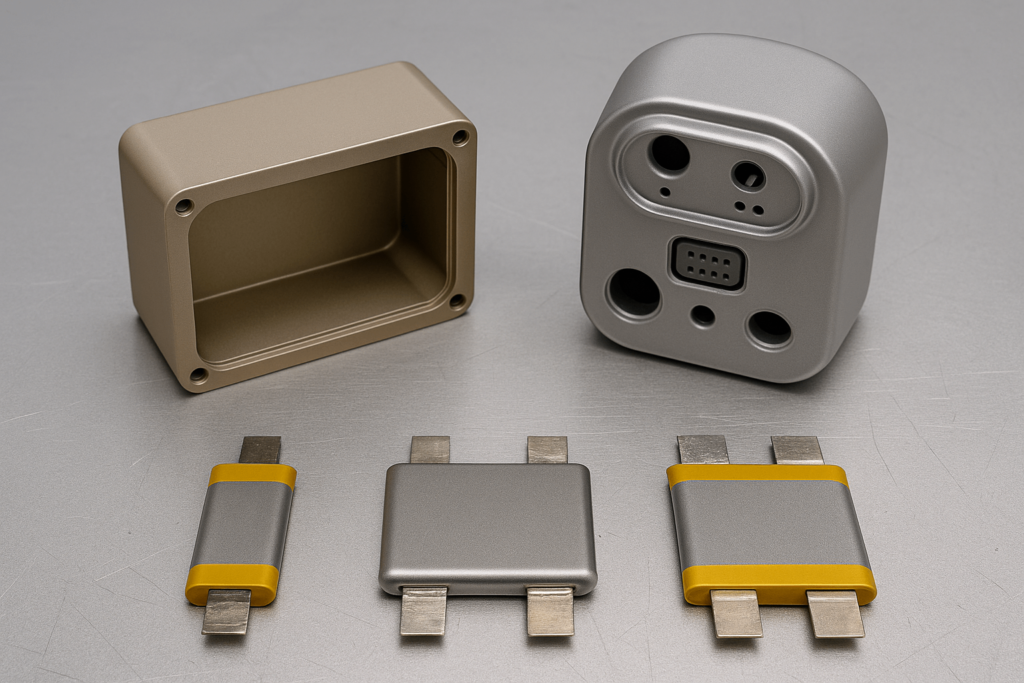

Not all metal parts require the same blasting media. Buyers sourcing stainless housings or aluminum enclosures must ensure their supplier selects media that aligns with substrate and end-use performance.

| Material | Recommended Media | Mesh Size | Ra Range (µin) | Production Benefit |

|---|---|---|---|---|

| Aluminum | Glass beads | 100–170 | 20–35 | Ideal for adhesion-ready surfaces |

| Stainless Steel | Ceramic or SS Beads | 80–150 | 25–45 | Low-particulate finish for cleanroom use |

| Brass/Copper | Glass beads | 70–120 | 15–30 | Preserves tone; avoids micro-pitting |

| Mild/Carbon Steel | Ceramic | 100–200 | 30–60 | Removes oxides; supports weldable finish |

The choice of media—glass bead vs ceramic—should match the part’s material and final finish. International buyers expect this consistency. Our SOPs for metal fabrication ensure correct media selection based on drawings and prior lot approvals.

Bead Blasting Process: Step-by-Step Workflow

Media Selection

Match glass or ceramic beads to the substrate (aluminum, stainless, brass, etc.).

Choose mesh size based on target Ra range.

Part Preparation

Degrease and remove oxide scale.

Apply masking to protect no-blast areas.

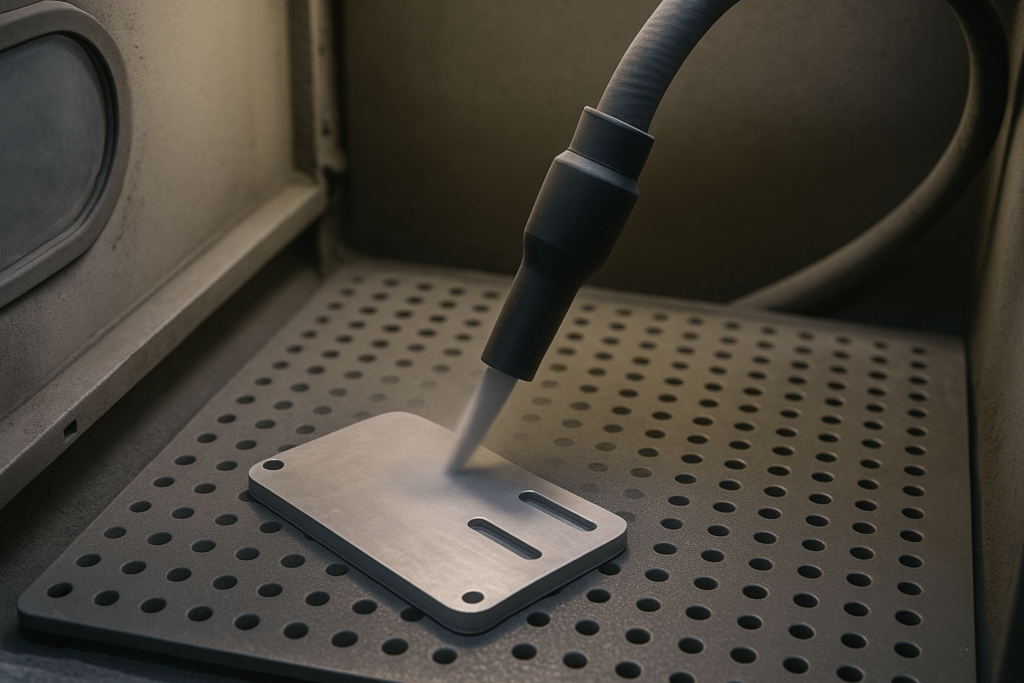

Parameter Setup

Set air pressure (40–80 psi).

Control nozzle angle (70–90°) and standoff distance.

Use CNC-controlled cabinets for repeatability.

Blasting Execution

Maintain uniform nozzle movement.

Monitor surface temperature and finish consistency.

Surface Inspection

Verify Ra values using profilometers or ISO 8503 comparators.

Record batch data for full traceability.

Post-Blast Handling

Clean and dry parts to remove residual media.

Move immediately to next stage: anodizing, powder coating, welding, or packaging.

Controlling the Process: Repeatability Buyers Can Rely On

Consistency in blasting is essential. One poorly finished batch can compromise final assembly or lead to downstream quality failures.

Our team applies CNC blasting, Ra testing, and parameter control to ensure repeatable finishes across lots. This abrasive blasting process for OEMs maintains uniform roughness in batch production.

Need low-particulate blasting? Wet blasting reduces friction and debris—ideal for EV, medical, or telecom parts.

We integrate CNC-controlled cabinets, Ra profile testing, and air pressure/angle documentation. All blasting records are traceable to specific PO numbers.

We validate surface profiles using ISO 8503 comparators and media properties via ISO 11127, ensuring compliance with the required blasting spec.

Why Surface Performance Impacts Your Return Rate

Surface quality affects post-processing outcomes—coating, bonding, corrosion resistance. In our audits across electronics and housing sectors, optimized blasting reduced defect rates by 25–30%.

Fewer defects translate to lower returns and warranty claims. Buyers managing strict tolerance specs and line throughput see clear ROI.

That’s why blasting specs appear in nearly every RFQ across the electronics and energy sectors. We often support clients with Ra finish charts for CNC parts or EV housing finishes to align with automated production workflows.

Use Case Context: When Bead Blasting Is a Fit

Bead blasting is commonly required for:

Battery housings needing surface prep for coating

Anodized aluminum parts in architectural assemblies

Stainless panels requiring non-glare finishes

Aerospace parts with strict Ra requirements

Medical housings with biocompatible surface specs

It’s less applicable when:

Polished or mirrored finishes are needed

Base material is too soft or thin

Oxide scale exceeds 100µm (pre-treatment required)

Buyers should submit drawings with Ra and masking expectations early. This aligns blasting parameters from the start.

Blasting in the Manufacturing Chain: One Step in a Larger System

Blasting is part of a timed production chain—not an isolated task. Surface energy degrades within hours, so sequencing matters.

In our workflow for OEMs, blasting is followed by:

Rinse and air-drying

Conversion coating or masking

Powder coating or protective packaging

This closed-loop process reduces oxidation, contamination, and finish variability. It limits post-arrival quality issues and rework for bulk buyers.

We align with ASTM D3359 (adhesion testing) and ASTM B117 (salt spray) where required. Ra profiles are verified via ISO 8503 comparators.

Buyer-Focused Checklist: Bead Blasting Questions to Ask

When evaluating a supplier’s blasting capability, buyers should ask:

Are Ra measurements reported?

Can results be linked to batch IDs?

What blasting equipment and media are used?

Is there a SOP for post-blast handling?

We provide process traceability and inspection reports upon request. In medical, EV, and telecom sourcing, this documentation is critical.

FAQ

Can blasting improve powder coating adhesion?

Yes. It increases microtexture, enhancing bond strength and finish reliability.

What Ra range can be provided?

Typically 15–65 µin depending on substrate, verified via profilometer and ISO comparators.

Is blasting used before anodizing?

Yes. Especially for electronics and architectural components, it improves adhesion and color consistency.

What ensures cleanroom compatibility?

Low-particulate ceramic media and ionized rinsing post-blast.

How soon should parts be coated after blasting?

Within 1–2 hours to maintain surface energy.

Can you meet tight delivery timelines?

Yes, if blasting is integrated in-line with final finishing.

Do you blast assembled parts or multi-process items?

Yes, with sample validation to assess masking needs.

We’re here to help B2B buyers reduce rework, improve downstream quality, and achieve consistent surface specs. In precision metal fabrication, surface control isn’t cosmetic—it’s contractual. Let us know your requirements, and we’ll tailor our blasting process to your needs.