Introduction: Why CBN Inserts Matter in Modern Machining

In a manufacturing landscape increasingly defined by speed, durability, and operational precision, cutting tool technology plays a pivotal role in cost control and quality assurance. Among the numerous options available, CBN (Cubic Boron Nitride) inserts have emerged as the tool of choice for machining hardened steels and ferrous alloys—especially in bulk production environments. For industrial buyers, especially those sourcing at scale, the decision to invest in a specific cutting insert is less about surface-level specifications and more about lifecycle cost, compatibility with automation, and long-term process efficiency.

This article provides a deep, structured look into how CBN inserts enhance modern machining workflows and how industrial procurement teams can leverage this knowledge to optimize sourcing decisions. Unlike generalist overviews, this guide focuses specifically on the B2B buyer’s needs: cost-benefit clarity, precision performance benchmarks, and strategic procurement insights.

The Industrial Logic Behind CBN: A Material Engineered for Purpose

Cubic Boron Nitride, second only to diamond in hardness, is uniquely suited for cutting hard ferrous materials such as hardened tool steels, cast irons, and high-speed steel components. But what differentiates it isn’t just its hardness—it’s its thermal stability and chemical inertness. While diamond-based tools degrade quickly in iron-rich environments due to chemical affinity, CBN resists this deterioration, making it ideal for repeatable, high-tolerance manufacturing.

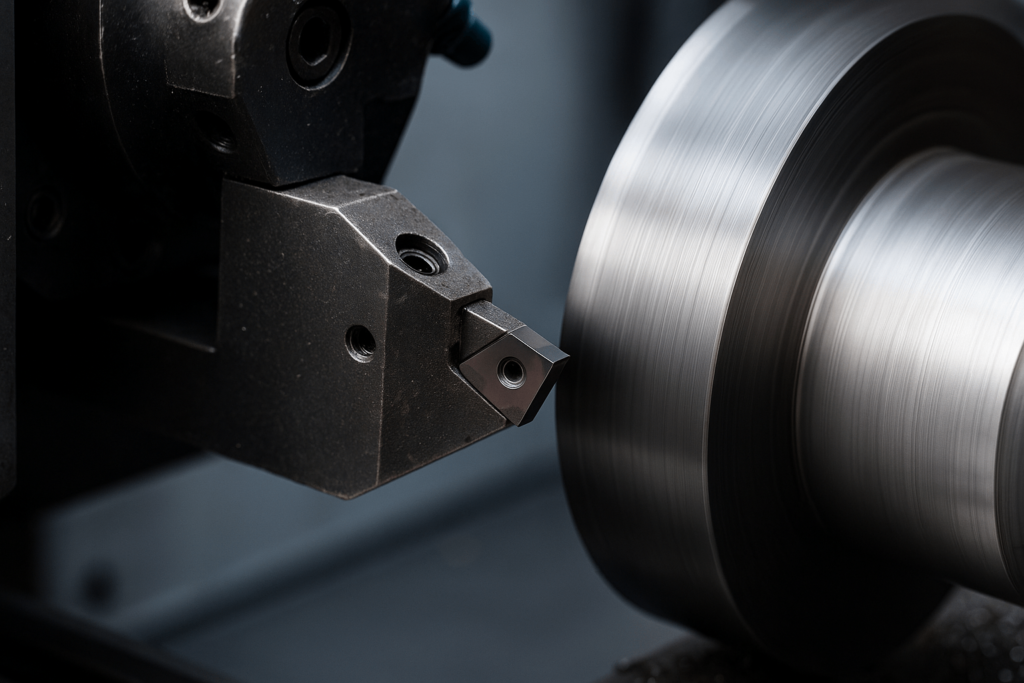

CBN inserts are engineered to withstand temperatures up to 1,370°C (2,500°F), reducing wear and minimizing the need for coolant-intensive setups. For high-speed turning and dry machining, particularly in automotive or heavy machinery sectors, this translates to substantial operational savings. CBN’s microstructure—typically synthesized under high pressure and temperature—offers balanced fracture resistance and cutting-edge integrity, both critical in high-volume machining lines where tool failure equates to downtime.

For buyers in wholesale procurement, understanding these material-specific advantages is vital. The long-term performance and wear resistance mean fewer insert replacements and lower per-part costs, a key metric in strategic sourcing. When machining hardened parts with high Rockwell ratings (often > 50 HRC), conventional carbide inserts simply don’t offer the same life cycle performance.

📊 Comparison Table: CBN vs Carbide Inserts (Example for Hardened Steel Machining)

Parameter CBN Insert Carbide Insert Average Tool Life 250-300 parts 20-30 parts Suitable Hardness > 50 HRC ≤ 45 HRC Dry Machining Yes Not recommended Cost per Piece (incl. rework) ↓ Lower in bulk ↑ Higher in bulk

How CBN Inserts Solve Industrial Procurement Pain Points

While technical performance is essential, buyers in industrial settings face practical pressures: production deadlines, cost targets, supplier reliability, and compliance with international machining standards. CBN inserts directly support these goals in several key ways:

- Tool Life Extension: With durability levels up to 30 times that of conventional inserts, CBN significantly reduces changeover frequency. This extends uninterrupted production cycles, improving equipment utilization rates.

- Precision Repeatability: Dimensional accuracy is non-negotiable in sectors like aerospace, automotive transmissions, or medical devices. CBN inserts maintain edge integrity over long runs, which translates to lower scrap rates and better part consistency.

- Dry Machining Compatibility: Eliminating the need for coolants not only cuts costs but also aligns with sustainability mandates. Many OEMs are moving toward dry or MQL (minimum quantity lubrication) practices—CBN fits perfectly into this evolution.

- Automation Readiness: In automated turning centers, insert failure causes major downtime. The predictable wear pattern of CBN makes it ideal for integration into lights-out manufacturing or robotic machining cells.

Each of these pain points maps directly to quantifiable business metrics: cost per part, OEE (Overall Equipment Effectiveness), and process capability indices (Cp, Cpk). Thus, choosing CBN is not just a technical decision—it’s a procurement strategy.

📌 Need help calculating ROI for your production line? Request a CBN Tooling Cost Comparison Sheet →

Evaluating CBN Insert Types Through a Procurement Lens

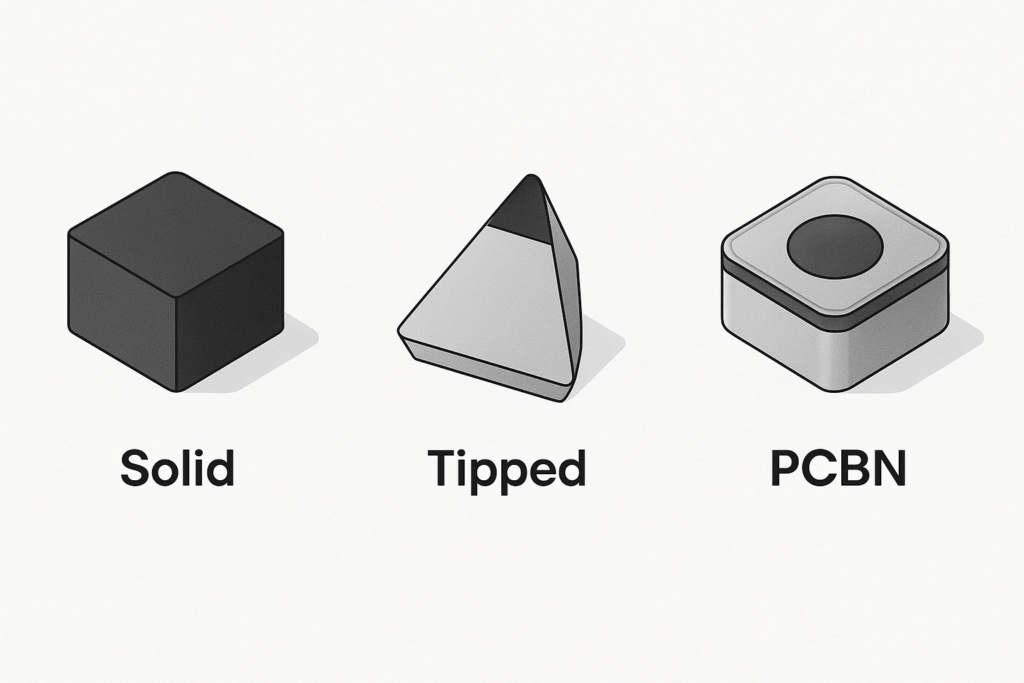

CBN inserts aren’t one-size-fits-all. Understanding the design differences among insert types is crucial for industrial buyers to specify the right tool for each machining scenario. The main types include:

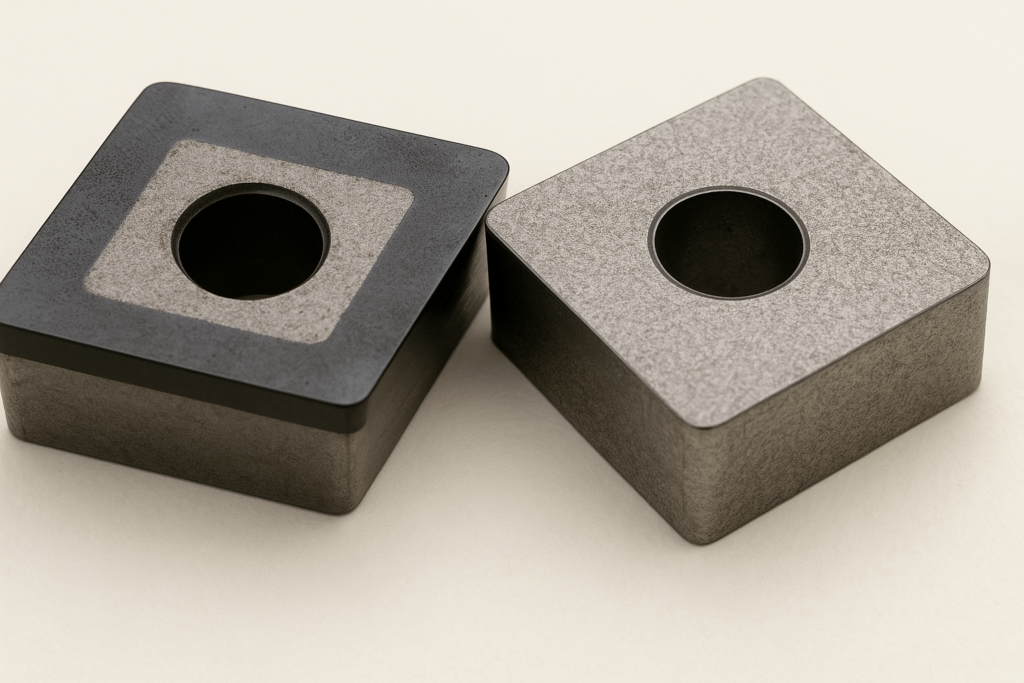

1. Solid CBN Inserts

These are made entirely of CBN material and are typically used in continuous cutting applications involving hardened steel or chilled cast iron. They offer superior wear resistance but are costlier, making them ideal for long batch runs where tool life optimization justifies the investment.

2. Tipped CBN Inserts (Brazed)

These consist of a CBN tip brazed onto a carbide or steel substrate. This hybrid design reduces costs while retaining much of the cutting performance. It’s a balance between economic efficiency and machining effectiveness—particularly useful in mixed-material production environments.

3. PCBN (Polycrystalline CBN)

PCBN inserts are made by sintering CBN grains with ceramic binders, improving toughness. These are particularly suitable for interrupted cuts or when vibration is a factor. They help reduce chipping and are often specified in industries such as heavy machinery or railway components.

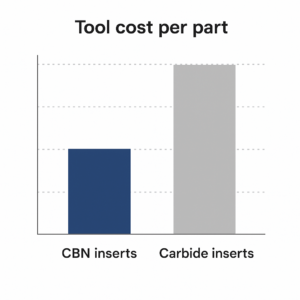

The Cost-Efficiency Equation: ROI of CBN in Bulk Procurement

Price is always top of mind, but cost without performance context is misleading. In bulk procurement, especially in metal product manufacturing, understanding the true ROI of CBN inserts is key.

Let’s consider an example. A standard carbide insert might last 20 parts in hard turning, while a CBN insert might machine 300 parts. On a per-piece basis, the CBN insert, though priced higher, reduces the total tool cost by over 70%. Add reduced downtime for tool changes and minimized part rework, and the cost advantages scale exponentially.

Moreover, CBN inserts reduce post-machining steps. Their capability for near-net surface finishing reduces reliance on secondary grinding or polishing processes. This simplification saves both time and labor—a crucial factor when machining bottlenecks can delay entire production timelines.

🧠 Buyer Insight Tip: Always compare cost per finished component, not per insert.

Strategic Applications: Where CBN Inserts Make the Most Impact

The value of CBN inserts is magnified in industries where precision, wear resistance, and production consistency define competitive advantage. Some high-relevance sectors include:

- Automotive: Especially in machining gears, shafts, and bearings. CBN inserts are used to finish hardened surfaces with tolerance requirements within microns.

- Medical Equipment: Where tool life must be predictable to avoid material inconsistencies in surgical or orthopedic components.

- Energy Storage & Power Transmission: Machining of hardened steel frames, enclosures, and structural supports used in power cabinets or EV battery trays benefits from CBN’s heat resistance and dry-machining capabilities.

- Aerospace & Defense: High-performance alloys used in turbine components or armored parts demand inserts with stable wear rates and minimal dimensional deviation.

📎 Case Study: An aerospace client switched to CBN inserts and reduced overall tooling costs by 28% while improving delivery timelines by 11%.

How to Specify the Right CBN Insert in RFQs and Bulk Orders

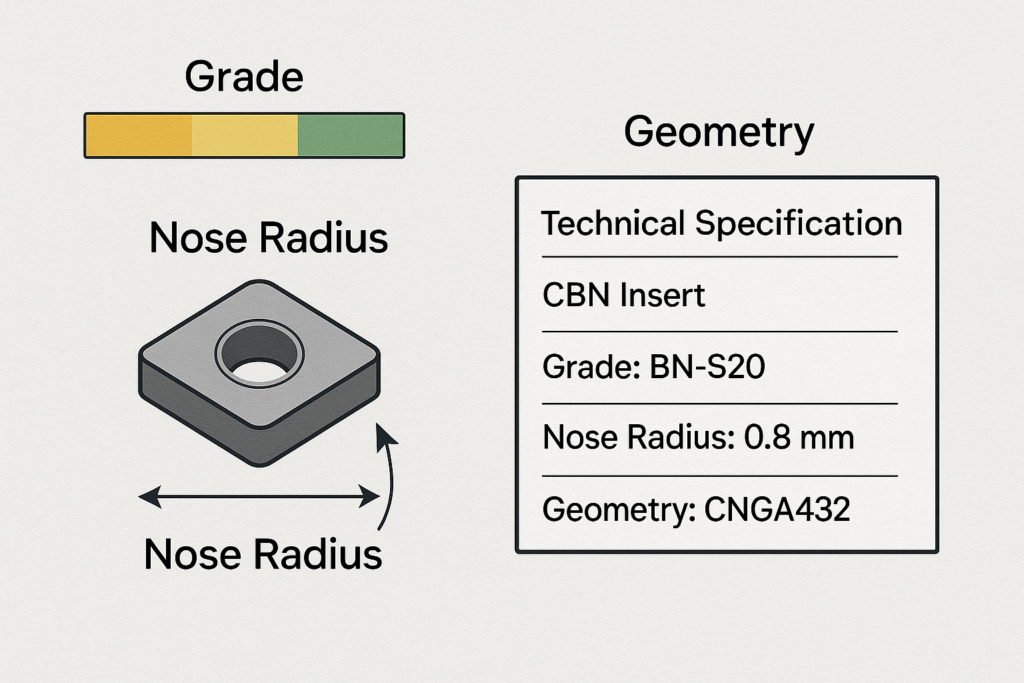

When issuing RFQs (Requests for Quote) or planning procurement cycles, specifying insert parameters precisely reduces errors, returns, and delays. Key criteria include:

- Grade Selection: Choose the right CBN grade based on material hardness, surface finish requirements, and cutting speed. Reputable suppliers provide grade tables and machining parameter charts.

- Geometry and Nose Radius: Influences surface finish and tool strength. For example, larger radii handle heavier cuts, but may reduce finish quality.

- Coatings: While CBN itself is hard, some tipped versions come with thermal barriers to reduce insert wear during dry machining.

- Cutting Conditions: Include whether the operation is continuous or interrupted, wet or dry, roughing or finishing.

🧾 Pro Tip: Add tolerances, machine type, and material grade in your RFQ for more accurate supplier responses.

Common Buyer Questions: A Quick Technical FAQ

Q: Can CBN inserts be used for interrupted cuts?

A: Yes, PCBN inserts are specifically engineered for this purpose due to their improved toughness.

Q: What’s the difference between CBN and PCD inserts?

A: PCD (Polycrystalline Diamond) is suited for non-ferrous materials. CBN performs best with hardened steels and cast irons.

Q: How do I know if a solid or tipped insert is better for my line?

A: Consider production volume, part hardness, and budget. Solid is better for long runs; tipped is more cost-efficient for medium runs.

Conclusion: Making CBN Inserts Part of Your Procurement Strategy

CBN inserts are not simply another tooling option—they are a strategic investment in process stability, product consistency, and long-term cost control. For industrial buyers, especially in OEM or contract manufacturing environments, the decision to shift from traditional carbide to CBN should be data-driven and performance-led.

From higher throughput to better part integrity and enhanced tool change intervals, CBN inserts deliver real-world, bottom-line improvements. With the right supplier support, technical documentation, and post-sale engineering collaboration, CBN becomes more than a cost—it becomes a performance multiplier.

📩 Request a Custom CBN Insert Proposal or Free Technical Datasheet →