The Modern Procurement Dilemma: When Supplier “Close Enough” Costs Everything

For a procurement manager sourcing precision metal components, the greatest risk lies in the gap between a supplier’s promise and their delivered product. Imagine a container of CNC-machined parts arriving after a six-week journey, only to discover a critical dimension is out of tolerance across the entire batch.

The consequences are immediate and severe: production lines halt, project deadlines are jeopardized, and the costs of rework, returns, and expedited replacements cascade through the supply chain. This scenario represents the true cost of “close enough”—a supplier’s inability to consistently verify that their physical output matches the digital design intent.

In today’s global market, where tolerances are measured in microns and component complexity is ever-increasing, relying on a supplier’s basic quality control with hand tools is a significant gamble. The core challenge for wholesale buyers is mitigating this risk. How can you be certain that a supplier has the robust processes and technological capability to guarantee part conformity, batch after batch?

This is where a supplier’s investment in a Coordinate Measuring Machine (CMM) becomes a critical differentiator. A CMM is far more than an inspection tool; it is a statement of capability and control. It represents a commitment to a data-driven quality philosophy that replaces ambiguity with certainty. For a procurement partner, understanding a supplier’s CMM capabilities is essential, as it offers one of the clearest indicators of their ability to deliver not just parts, but confidence and consistency—especially for buyers sourcing custom OEM sheet metal components or high-precision fabrications for demanding sectors.

How a CMM Thinks: A 3-Minute Guide for the Business Professional

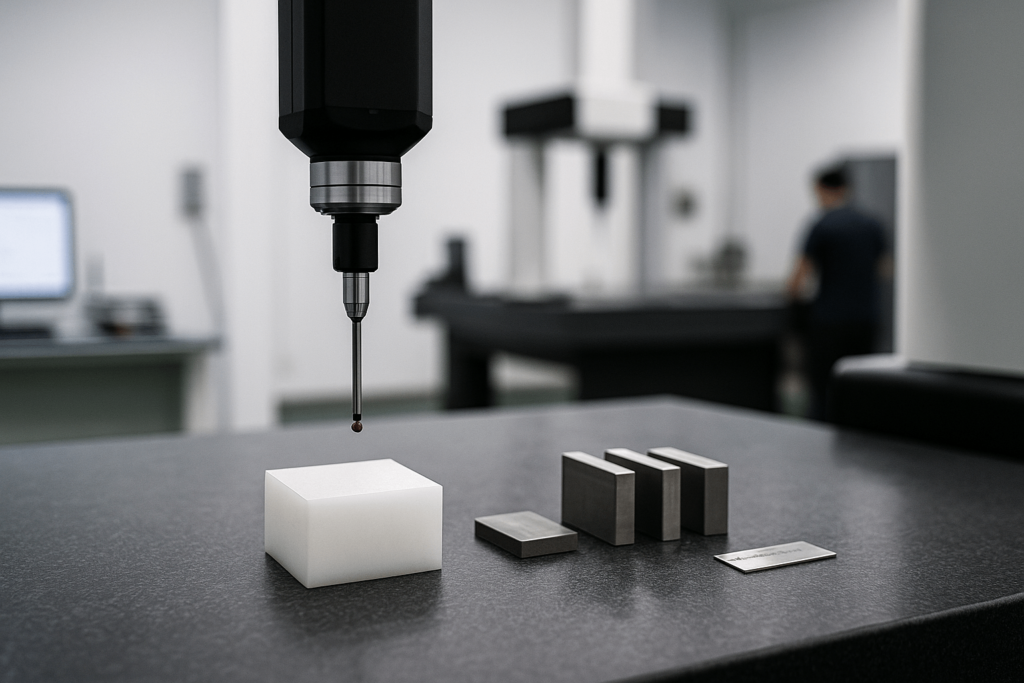

At its core, a Coordinate Measuring Machine (CMM) operates on a simple yet powerful principle. Think of it as a hyper-accurate GPS for manufactured parts. While a GPS pinpoints a location in 3D space, a CMM uses a highly sensitive probe to touch various points on a metal component and record their precise location within a three-dimensional (X, Y, Z) coordinate system.

This cloud of data points is then used by sophisticated software to construct a perfect digital replica of the part. This allows for micron-level analysis of its geometry, providing a level of dimensional inspection that is impossible to achieve with manual tools or visual checks alone.

The Most Critical Step: Alignment

The foundational concept that ensures CMM data is meaningful is alignment. When a part is placed on the CMM, the machine must be taught how to “see” it from the same perspective as the engineering drawing. This is achieved by measuring key datum features on the part, which mathematically establishes the part’s coordinate system and locks it to the machine’s.

This step is essential. A proper alignment ensures that every measurement of a hole, surface, or feature is directly comparable to the blueprint’s specifications. For a buyer, this means the inspection report you receive is a true and accurate reflection of the part’s conformity to your design.

Measured vs. Constructed Features

A CMM’s intelligence lies in its ability to define two types of features. Measured features are the surfaces the probe can physically touch, like the wall of a bore or a flat machined face. But its real power is in creating constructed features—critical elements that cannot be physically touched but are mathematically calculated from measured points.

For instance, a CMM can measure four individual holes and then construct the virtual center of the bolt pattern, verifying its true position with incredible accuracy. This capability is essential for ensuring the complex assemblies common in modern metal products fit together flawlessly, avoiding any costly line-down situations or unnecessary rework at your facility.

Choosing the Right Tool for the Job: A Supplier’s CMM Arsenal

A supplier’s choice of CMM is a direct reflection of the type of work they are equipped to handle. For a procurement manager, understanding these distinctions provides insight into a potential partner’s capabilities and specializations. This section explores what a supplier’s investment in specific CMM technology reveals about their ability to meet your needs.

For High-Precision Machined Components: The Bridge CMM

The Bridge CMM is the versatile workhorse of the metrology world, renowned for its stability and high accuracy. A supplier with a bridge CMM is signaling a core competency in verifying tight tolerances on complex CNC-milled blocks, turned shafts, and multi-axis components. This is the gold standard for precision-critical applications in industries like automotive, aerospace, and medical devices. It assures you of consistent part performance when every micron matters.

For Large Weldments, Castings, and Frames: The Gantry CMM

When sourcing large fabrications like an automotive chassis or a heavy machine base, the logistics of inspection are a major challenge. A supplier equipped with a Gantry CMM has made a significant investment to solve this problem. These massive machines are built to measure very large and heavy parts in situ, demonstrating a capability to handle large-scale projects where dimensional integrity over long spans is critical.

For In-Process Checks and Agility: The Portable Arm CMM

The Portable Arm CMM signifies a modern, agile approach to quality control. A supplier using portable arms can perform in-process checks directly at the CNC machine, verifying critical features on a first-off part before an entire batch is run. This capability dramatically reduces the risk of systemic errors and reflects a proactive quality culture focused on prevention rather than just final inspection.

Probing Strategy for Metal Surfaces: Touch vs. Scan

The type of probe a supplier uses reveals the depth of their inspection capabilities. A touch probe acts like a sniper rifle, capturing individual points with extreme accuracy, ideal for verifying the location of critical holes or datums.

However, a scanning probe is like a high-resolution camera, collecting thousands of points per second to map the entire form of a surface. A supplier who invests in scanning technology can provide far richer data, verifying not just if a bore is the right size, but if it is perfectly round; not just if a surface is in the right place, but if it is perfectly flat. This advanced level of detail is essential for high-performance applications and is a clear indicator of a top-tier supplier.

Decoding the CMM Report: A Buyer’s Guide to Reading What Matters

A CMM report is more than a technical document. It is the proof that a manufactured part meets the intended design. For procurement professionals evaluating OEM sheet metal components, understanding this report is essential. It helps verify supplier performance and reduce uncertainty in decision-making.

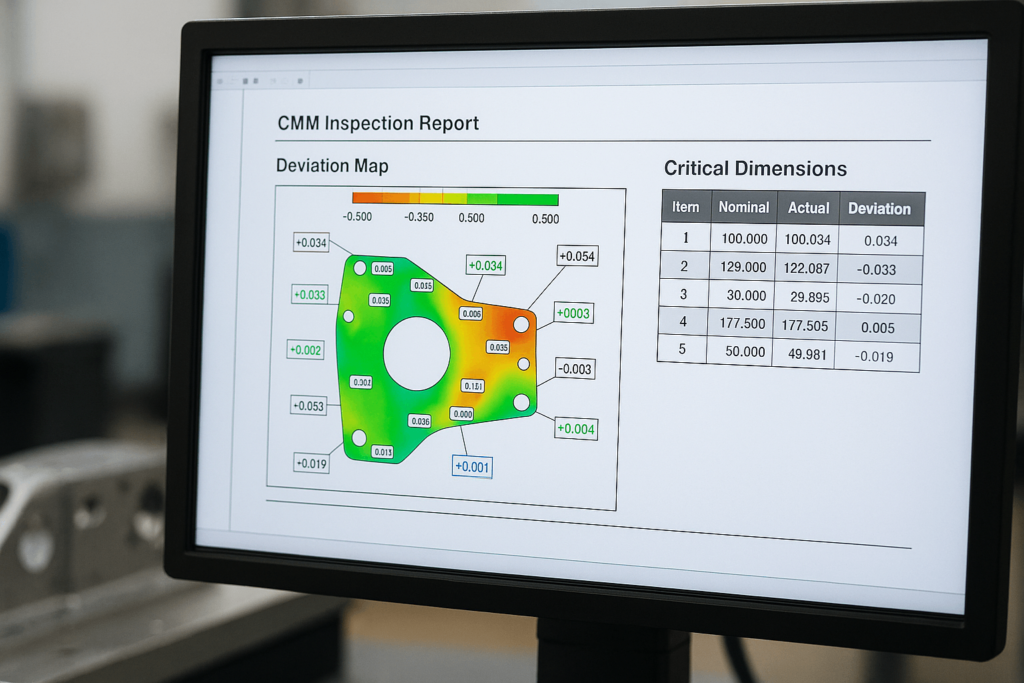

At first glance, the report may seem complex. However, it answers a simple question: Did the part meet the design intent? Each line item refers to a specific geometric feature from the part drawing. It compares the nominal value (design specification) to the measured value (actual result).

Focus first on critical dimensions. These are typically tied to tolerances that affect how parts fit, align, or function. If they fall out of tolerance, they can cause serious issues in final assembly or product performance.

Modern reports often include color-coded deviation maps. These maps visually highlight where surfaces deviate from specification. This makes it easier to evaluate part quality, even for team members without technical training.

Also examine how the report handles datum verification, alignment strategies, and constructed features. A reliable supplier documents these elements clearly. This confirms they understood your engineering drawings—not just copied measurements.

Finally, review traceability elements. Reports should include part numbers, batch codes, CMM machine ID, operator initials, and calibration records. These data points help support audits and build confidence in quality control processes. For buyers focused on long-term supply chain quality, traceable CMM inspection services are a must.

Understanding how to read a CMM report allows procurement teams to detect risks early. It transforms a static document into a powerful insight tool.

Measurement Uncertainty and Calibration: The Silent Variables of Risk

Even the most advanced coordinate measuring machine can produce poor results if calibration and uncertainty are ignored. Precision depends not only on machine quality, but also on how well it is maintained and managed.

Measurement uncertainty refers to the range in which the true value of a measurement falls. Influencing factors include temperature, vibrations, probe wear, and human handling. A CMM in a climate-controlled lab will naturally offer better accuracy than one in a variable environment.

Buyers should ask suppliers about their uncertainty budgets. This shows the supplier understands their machine’s limits. If a supplier can’t explain their uncertainty values, that may suggest shallow metrology processes.

Calibration ensures CMMs produce consistent, accurate results. Reputable suppliers follow ISO 10360 standards and maintain traceability to national standards. Regular calibration helps prevent accuracy drift.

Some suppliers enhance performance through volumetric error mapping. This method adjusts for known machine deviations across all axes. For GD&T measurement using CMM, this is especially valuable.

Buyers who understand these concepts can better evaluate suppliers. A supplier who manages uncertainty and calibration effectively is less likely to introduce risk into your supply chain. For those sourcing OEM sheet metal parts, this is not a detail—it’s a necessity.

CMM as a Business Asset: What It Means for the Buyer

Many still view CMM equipment as a technical detail. But for strategic buyers, it’s a business safeguard. A supplier using CMM machines is reducing your risk, not just checking tolerances.

Here’s how:

- CMM inspections help prevent defective parts from reaching production lines. This means fewer delays, emergency fixes, and late deliveries.

- Reports support Statistical Process Control (SPC). This helps detect trends and keep manufacturing stable.

- CMMs enable faster first article approvals. This shortens time to production.

- Measured data enables better feedback to your engineers. They can adjust designs based on actual manufacturing results.

All of these benefits translate into fewer problems, better quality, and more reliable delivery. CMM inspection services aren’t optional—they are a smart investment in stability and performance.

Choosing a supplier with a mature metrology system helps ensure better part quality and fewer surprises. In competitive markets, that’s a real advantage.

Beyond Measurement: CMM in the Age of Digital Twins and Smart Manufacturing

CMMs are no longer just inspection tools. In Industry 4.0 environments, they serve as data engines for connected manufacturing.

Modern CMMs integrate with Product Lifecycle Management (PLM) systems. This creates a closed loop between design and production. Measured data flows back to the digital model, enabling faster corrections and smarter decisions.

CMMs also feed data into Manufacturing Execution Systems (MES). This allows factories to respond in real time. If a part begins trending toward an out-of-tolerance condition, machines can automatically adjust or notify the operator.

Suppliers also use CMM output to train machine learning algorithms. These tools detect early patterns that indicate process drift. Adjustments are made before real problems occur.

For buyers, this means more than just consistent output. It shows a supplier is ready for the future—where digital twins and smart factory systems are the norm.

Suppliers using CMMs in these ways are not just measuring parts. They are building intelligent, responsive production systems. That kind of foresight is invaluable.

Conclusion: Why the Right Supplier Measures More Than Metal

Choosing a supplier with a CMM is not just about inspection. It’s about ensuring your project runs smoothly.

A supplier who can show verifiable, traceable CMM results is providing you with peace of mind. They are proving that every part shipped meets your requirements. That reduces surprises and builds trust.

CMMs also reflect process maturity. Suppliers with advanced measurement systems are less likely to make costly errors. They are more likely to fix problems before they reach your facility.

Especially in OEM sheet metal fabrication, where parts must fit precisely, you need a partner who gets measurement right. That partner will help you avoid waste, reduce returns, and meet your deadlines.

A CMM isn’t just a machine—it’s a signal. It says: “We take quality seriously.” When evaluating suppliers, don’t just ask if they have a CMM. Ask how they use it. The answer will tell you everything you need to know.

Frequently Asked Questions (FAQ)

Q: What is the purpose of a coordinate measuring machine (CMM) in metal fabrication?

A: A CMM ensures that manufactured metal parts conform precisely to design specifications. It helps detect dimensional deviations before parts reach assembly, improving quality control and reducing production risks.

Q: How often should a CMM be calibrated for accurate results?

A: Most manufacturers follow ISO 10360 standards, recommending annual calibration. However, high-use environments or critical tolerance projects may require more frequent checks.

Q: What types of parts can benefit from CMM inspection services?

A: Any component requiring tight dimensional tolerances—such as automotive brackets, medical device housings, or precision electronic enclosures—can benefit from CMM inspection.

Q: How does a supplier’s use of a CMM affect procurement decisions?

A: A supplier using CMMs demonstrates process maturity and risk control. This gives buyers confidence in batch consistency, traceability, and quality assurance—crucial for OEM and ODM procurement.

Q: Can CMM machines support GD&T measurements?

A: Yes, advanced CMMs support Geometric Dimensioning & Tolerancing (GD&T) to verify complex geometric relationships like cylindricity, flatness, and true position with high accuracy.

Q: Are there different types of coordinate measuring machines for different use cases?

A: Absolutely. Bridge CMMs suit precision machining, gantry CMMs handle large structures, and portable arm CMMs enable flexible in-process inspection at the machine side.