Introduction: Precision as the Foundation of Modern Guitar Manufacturing

Every detail in guitar production influences sound and consistency. Today, OEMs and wholesale buyers rely on CNC machining for accuracy, repeatability, and scalability across thousands of guitar components. From bridges to tuning pegs, each CNC guitar part impacts tone, durability, and assembly efficiency.

At YISHANG, precision drives every product we make. As a professional custom metal parts manufacturer, we supply global buyers with ISO- and RoHS-certified components designed for consistent fit and performance. This article explores the top 23 CNC guitar parts that combine technical precision with practical value in large-scale manufacturing.

Body Components: Structure and Acoustic Performance

Guitar Body Plates and Control Cavities

The body anchors tone. CNC-machined metal cavity plates and control covers ensure perfect alignment, burr-free edges, and threaded inserts suitable for OEM assembly lines. This results in faster installation and minimal rework during mass production.

Bridge Mounting Systems

The bridge is where vibration becomes tone. Our CNC bridge baseplates and saddle rails deliver ±0.01 mm positional accuracy and mirror-smooth surfaces (Ra ≤ 0.8 µm). These details reduce tuning instability and long-term wear—critical for repeat production runs.

Pickup Cavities and Mounting Rings

Pickup placement defines sound balance. Using 5-axis CNC setups, YISHANG ensures precise cavity depths and mounting ring dimensions that align magnetic centers with string paths—maintaining tonal uniformity across batches.

Neck and Headstock: The Guitar’s Mechanical Core

Truss Rod Channels and Covers

Neck stability relies on precise channel depth and shape. CNC machining achieves ±0.02 mm tolerance, while anodized aluminum truss rod covers provide long-term protection and clean aesthetics for branded hardware lines.

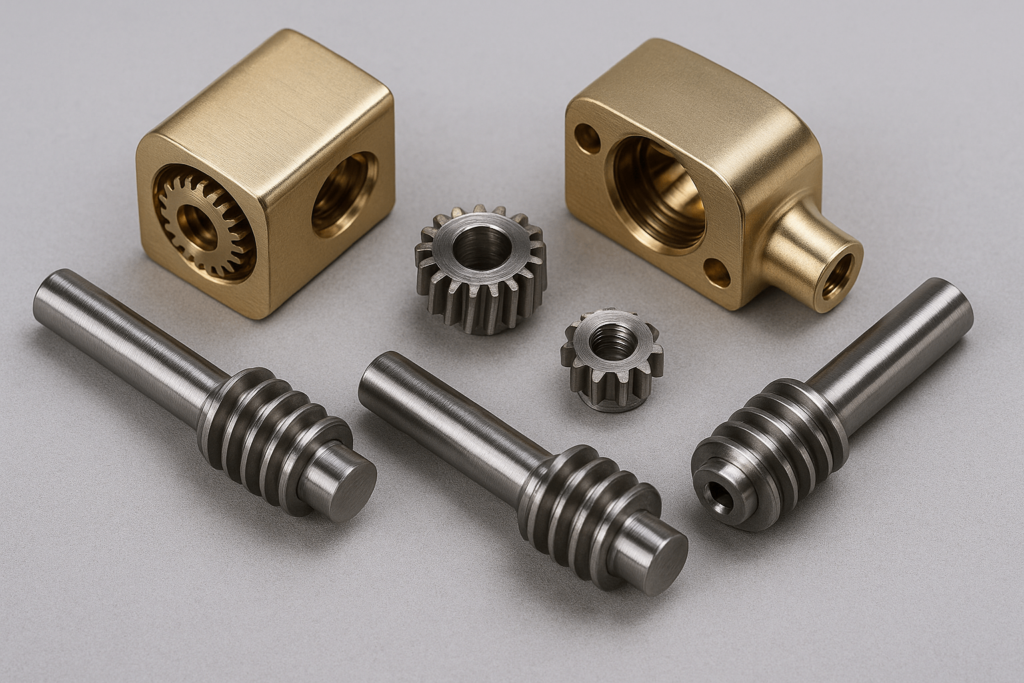

Tuning Peg Components

Each CNC tuning peg part—gear, washer, or housing—is inspected with CMM technology to ensure concentricity. OEM buyers benefit from smooth gear motion and torque uniformity, reducing end-user tuning complaints.

Neck Plates and Bushings

Machined neck plates and brass bushings evenly distribute tension, minimizing fatigue in bolt-on assemblies. YISHANG maintains ISO 6H thread standards, enabling easy integration in automated production systems.

Bridge Assembly: Precision Meets Tone Control

Saddles and Intonation Blocks

Saddles define string action. Our CNC-machined saddles and intonation blocks, made from 7075 aluminum or C360 brass, ensure micron-level flatness and balanced vibration transfer—key to consistent sustain.

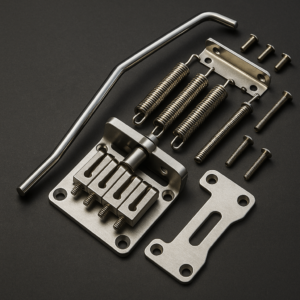

Tremolo Systems

Complex tremolo systems rely on multi-axis precision. Using zero-point fixturing and post-plating validation, YISHANG delivers pivot arms with verified torque resistance and dimensional stability—ideal for long-term OEM sourcing.

Electronic and Interface Components

Control Knobs and Selector Bushings

Anodized aluminum control knobs maintain uniform knurling and precise spline fits. For OEM buyers, this consistency reduces assembly variation and improves user ergonomics.

Output Jack Plates

Electrical interfaces require mechanical precision. Our CNC-machined jack plates hold concentric tolerances within ±0.01 mm, preventing cable fatigue and ensuring reliable signal grounding.

Switch Plates and Covers

CNC-machined switch covers are laser-verified for flatness before anodizing. These ensure perfect sealing and compatibility with electronic module layouts.

Decorative and Branding Elements

Logo Plaques and Truss Rod Covers

OEMs demand aesthetic consistency. YISHANG’s CNC-milled logo plaques and engraved covers combine mechanical precision with fiber-laser detailing, maintaining brand identity across production lines.

Pickguards and Mount Rings

Laser-assisted CNC milling provides clean edge geometry and accurate hole placement for pickguards and mount rings—ensuring functional protection and repeatable fit.

Materials and Surface Finishing

Material Options

| Material | Applications | Advantages |

|---|---|---|

| 6061/7075 Aluminum | Saddles, knobs | Lightweight, corrosion-resistant |

| C360 Brass | Bushings, bridges | Warm tone, machinability |

| 304/316 Stainless Steel | Plates, screws | Strength, durability |

All materials are certified and traceable, meeting OEM documentation requirements for international trade.

Surface Treatments

YISHANG offers multiple finishes tailored for precision assemblies:

- Anodizing for aluminum durability

- Chrome plating for visual appeal

- Black oxide for dimensional accuracy

- Powder coating for environmental resistance

Each coating is thickness-tested (+10 µm typical) to maintain fit tolerances.

Procurement Insights for B2B Buyers

Engineering Drawings and Data

For accurate RFQs, provide 2D/3D CAD files with GD&T notes and coating specs. Our engineers validate designs to prevent tolerance conflicts before production.

MOQ and Repeat Orders

We offer:

- MOQ 50 pcs for trials

- 300–500 pcs for stable OEM runs

Repeat batch machining guarantees consistency, minimizing post-delivery inspections.

Packaging and Logistics

Each shipment includes anti-scratch packaging, labeled assemblies, and QR-coded lot tracking. This supports easy inventory management for distributors and OEMs.

Case Study: Scalable Precision in Production

A European OEM ordered 5,000 CNC brass bridge saddles with ±0.05 mm tolerance. Through fixture optimization and process control, YISHANG achieved:

- ±0.02 mm accuracy

- 0.5% rejection rate

- 20% assembly time reduction

This project highlights how CNC process optimization directly enhances ROI and throughput for industrial buyers.

Conclusion: Engineering Confidence Through CNC Precision

Each of the 23 CNC guitar parts influences tone, playability, and product reliability. For B2B buyers, precision manufacturing means fewer defects and a stronger market position.

YISHANG turns mechanical precision into business value—offering scalable CNC guitar parts, metal fabrication services, and long-term OEM partnerships. Send your CAD drawings today for a technical consultation and quotation within 48 hours.