Why "Use" Matters More Than "Technology"

If you’re sourcing CNC suppliers for mid-volume metal parts fabrication, this guide shows where CNC delivers the most value. International buyers today don’t just evaluate the machines used—they assess how well those capabilities solve specific supply challenges.

From functional telecom housings to custom vending enclosures and certified energy brackets, CNC machining enables production agility, consistency across shipments, and procurement predictability. This article maps seven critical CNC applications to real B2B sourcing decisions and quality requirements.

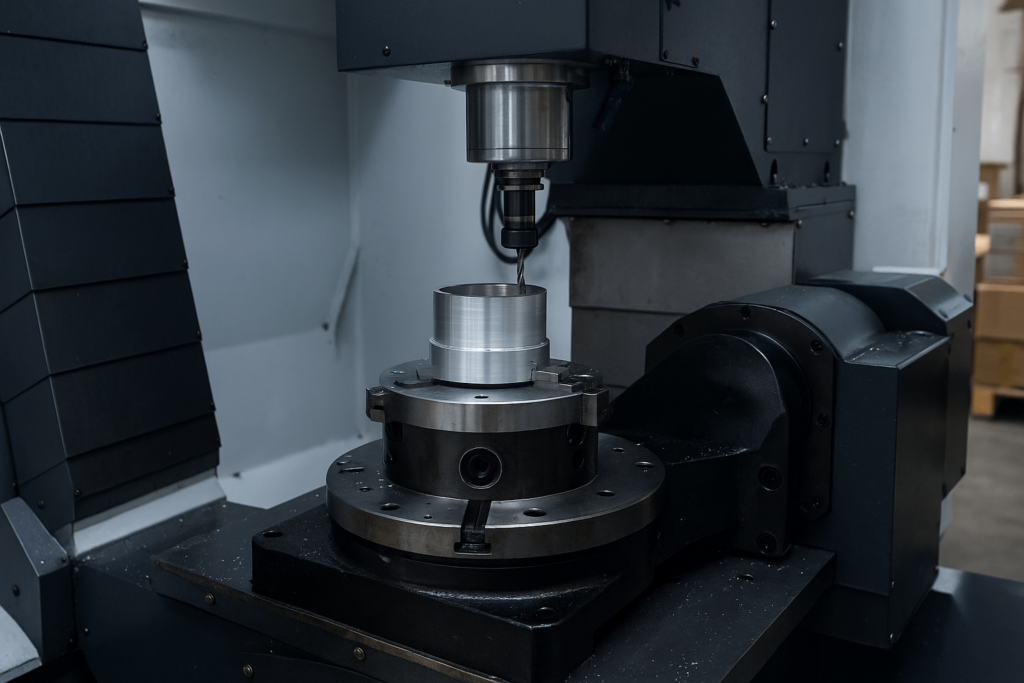

Digital to Physical: Why CNC Fits Fast Production

▶ Rapid Design Turnaround

CNC turns CAD files into precision parts without the need for physical molds or tooling. This reduces production prep time, ideal for shifting design specs mid-project.

▶ Real-Time Spec Flexibility

Buyers can switch between 6061 aluminum and 304 stainless, or alter hole spacing and surface treatments—without restarting tooling or production.

Cross-Border Consistency and Material Compatibility

▶ Consistent Output Across Locations

Whether you’re sourcing telecom enclosures or vending machine panels, CNC ensures ±0.01mm accuracy across multi-location shipments. For example, buyers exporting five aluminum rack SKUs to both Europe and Southeast Asia can count on tolerance consistency.

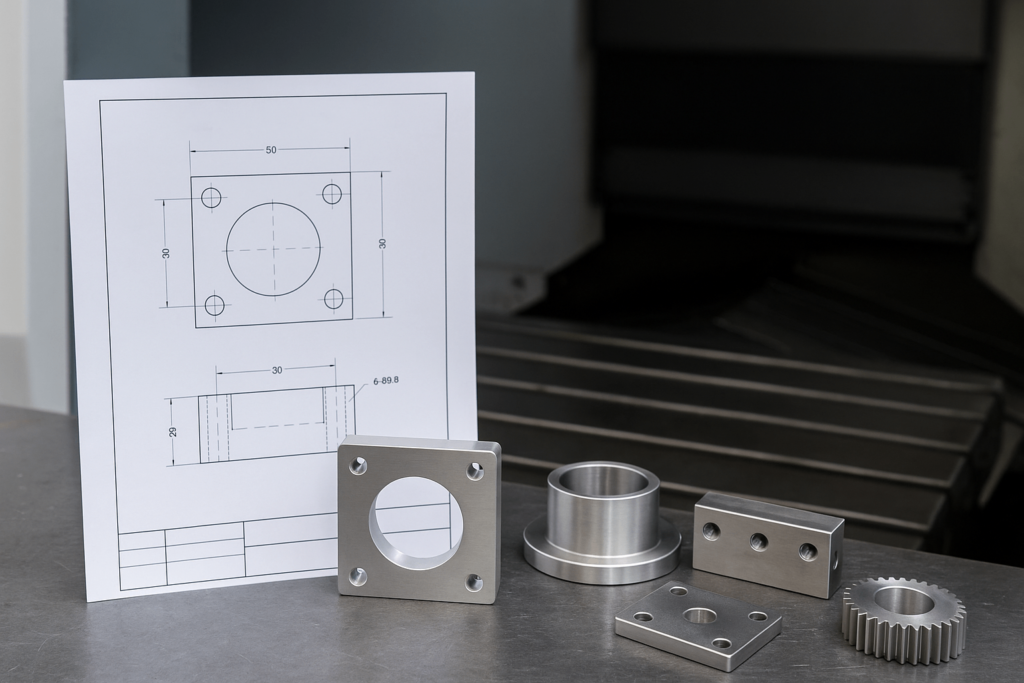

▶ CNC for Diverse Metal Parts Fabrication

CNC processes accommodate a broad range of materials—304 stainless steel, 6061 aluminum, red copper—ideal for telecom, energy storage, and advertising equipment frames.

Functional Structural Fabrication

▶ Cabinets, Racks, and Frames

CNC plays a vital role in producing telecom enclosures, vending machine housings, and energy storage frames—typically made from aluminum or low-carbon steel.

▶ Integrated Fabrication Workflow

Operations like bending, laser cutting, welding, and powder coating are combined into one streamlined workflow. This reduces vendor delays and improves shipping timelines.

▶ Regional Standard Adaptation

Suppliers can quickly adjust slot patterns, vent dimensions, and hardware types to meet regional compliance or installation standards.

Mid-Volume Customization for OEMs and ODMs

▶ Designed for 200–1,000 Unit Orders

This volume is too large for hand tools, too small for injection molds. CNC is optimal for medium-batch customization.

▶ Adaptation with No Downtime

Need five housing variations for five export markets? CNC handles that with CAD edits—no tooling changes required.

▶ Budget Predictability + Technical Flexibility

For contract metal fabrication, CNC offers a stable balance: flexible specs and stable pricing.

Use in Regulated & Certified Markets

According to a 2023 McKinsey report on industrial procurement digitization, over 70% of global buyers now prioritize traceable, certifiable production when selecting suppliers for regulated sectors like telecom, medical devices, and energy systems.

▶ Medical, Energy & Telecom Compliance

CNC helps suppliers meet RoHS, ISO 9001, and ISO 13485 with full traceability for components like orthopedic brackets or telecom shields.

▶ Documentation-Ready Deliverables

Export-ready files, barcode traceability, batch QA reports—especially critical when shipping to Europe or North America.

▶ Accuracy in High-Consequence Parts

Whether it’s a copper terminal for solar arrays or a titanium fastener for implants, CNC maintains tight tolerances. For instance, the standard tolerance range for 6061 aluminum in telecom brackets is typically ±0.005–0.01mm, depending on geometry and finish.

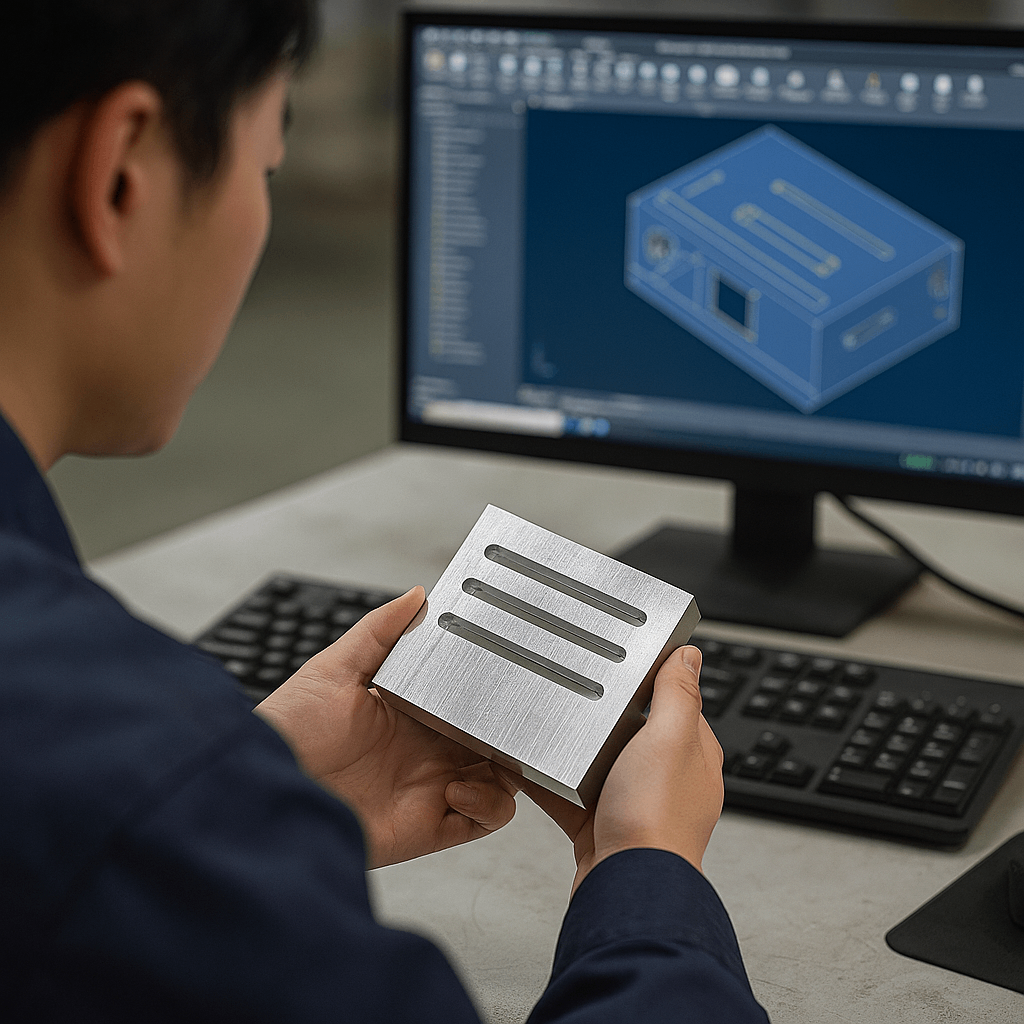

Production-Grade Prototyping

▶ Metal Prototypes for Real Testing

Instead of brittle 3D prints, CNC lets teams test 6061 aluminum or 4140 steel for thermal, vibration, and structural behavior.

▶ Feedback Loop Compression

Designers get real-world validation fast—without waiting for mold fabrication. CNC enables functional iteration within days.

▶ Fewer Surprises During Scaling

Validating form-fit-function early prevents connector skew or chassis misalignment in multi-component telecom systems.

When CNC Fits—and When It Doesn’t

To help buyers make informed sourcing decisions, here’s a quick comparison chart illustrating where CNC offers true procurement value—and where it may fall short.

▶ Best For: Medium Volumes, Varying Specs

Projects with multiple SKUs, fluctuating geometries, or evolving BOMs benefit most from CNC.

▶ Not Ideal For: High-Volume Plastic Parts

For parts over 50,000 units or soft polymers, injection molding offers better cost per unit.

▶ Fit Matrix for Buyers

| Use Case | CNC Suitable? | Reason |

|---|---|---|

| Telecom housings (500/month) | ✅ Yes | Easy regional variation |

| Molded battery holders (50k) | ❌ No | Better with molding |

| Custom steel racks (OEM batch) | ✅ Yes | Works with varied design/volume |

| Decorative trim (plastic) | ❌ No | CNC not efficient for cosmetic plastic |

Digital Traceability in CNC Supply Chains

▶ Transparent Sourcing Process

Buyers gain visibility into order status, tolerances, and QA through integrated ERP dashboards. Many suppliers now link RFQ systems directly to real-time production updates.

▶ Full Supply Chain Visibility

Barcode tracking, batch-linked QA reports, and digital shipment logs ensure every metal part—whether a vending bracket or a telecom shield—is traceable end-to-end.

▶ CNC as a Procurement Partner

Suppliers go beyond machining by offering labeling, multi-SKU packaging, export documentation, and kitting for improved last-mile fulfillment.

What Procurement Really Gains

CNC machining enables sourcing teams to bridge fast design iteration with certified production. Its key value lies in precision with flexibility—keeping costs stable while supporting customization, traceability, and export readiness.

Submit your RFQ to receive a tailored CNC solution within 48 hours.

Frequently Asked Questions

Q1: What’s your MOQ for CNC aluminum housings?

We support small-batch orders starting from 100 units for aluminum telecom enclosures, depending on design complexity.

Q2: Can you supply RoHS-compliant CNC parts for the EU market?

Yes. All aluminum and steel parts can be processed with RoHS-compliant finishes and batch-linked compliance documentation.

Q3: How do I track production status?

Once your PO is confirmed, you’ll receive ERP-based status updates and access to quality control reports per lot.