The Hidden Language of Surfaces: Why It Matters to Your Bottom Line

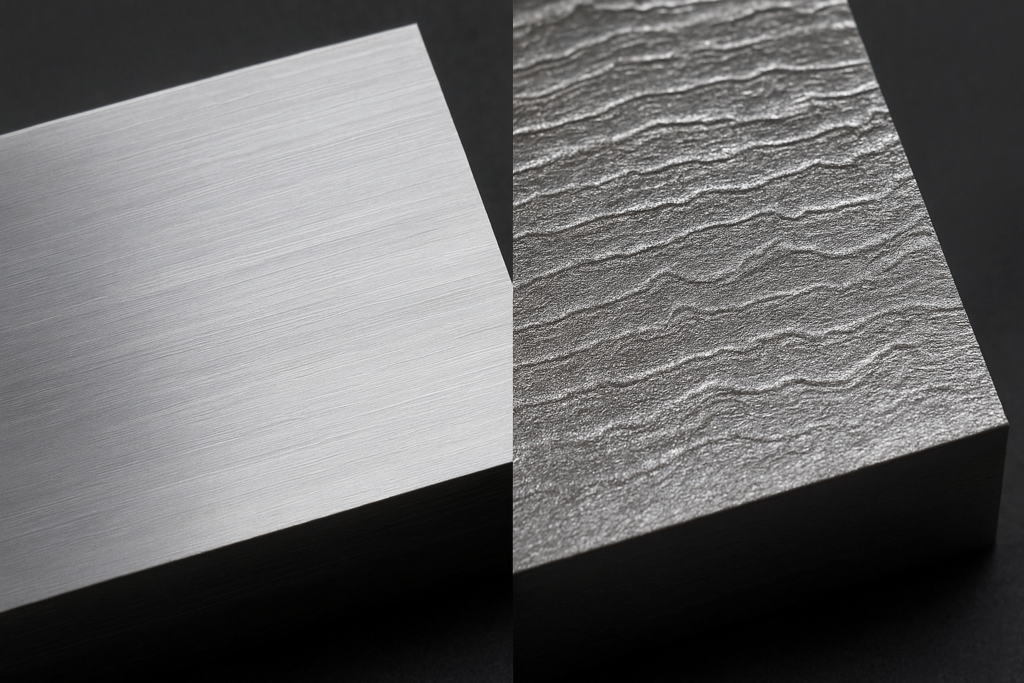

In global supply chains, part failure is not just a technical problem—it’s a business risk. A component failing prematurely due to unforeseen wear can lead to costly recalls, warranty claims, and damage to your brand’s reputation. Often, the root cause isn’t a design flaw but a microscopic detail: the surface roughness.

Understanding CNC surface roughness is therefore a crucial aspect of value engineering and risk mitigation for any wholesale buyer. It governs part performance, longevity, and total cost of ownership.

Incorrect surface texture can result in excessive friction, rapid wear, or fatigue failure. This guide delivers the practical knowledge required to specify the correct surface finish—so you can source parts that are not only dimensionally accurate but functionally reliable and application-ready.

Surface Roughness At-a-Glance: A Practical Guide for Design and Procurement

For busy procurement managers and engineers, quick access to practical data is essential. This machining surface finish chart connects common industry-standard values to their real-world applications and, more importantly, their cost implications.

Using this guide during Design for Manufacturability (DFM) discussions helps avoid over-engineering and keeps unit costs under control. For example, specifying a 32 surface finish (0.8 µm Ra) when a 125 surface finish (3.2 µm Ra) is sufficient could raise production costs by over 5% without enhancing functionality.

| Ra Value (µm / µin) | Common Name / Finish No. | Visual/Tactile Feel & Example | Typical Applications & Procurement Decisions | Relative Cost Factor |

|---|---|---|---|---|

| 3.2 µm / 125 µin | Standard Machined / 125 Finish | Visible tool marks, smooth to the touch. A typical 125 surface finish example is a structural bracket. | The default, most cost-effective option for non-critical, non-mating surfaces. Ideal for internal components and structural parts. | 1x (Baseline) |

| 1.6 µm / 63 µin | Fine Machined / 63 Finish | Faintly visible tool marks. | A good balance of cost and quality for mating surfaces with light loads and slow movement. A common choice for precision fasteners. | ~1.5x – 2.5% increase |

| 0.8 µm / 32 µin | High-Grade Finish / 32 Finish | Tool marks nearly invisible. A smooth, refined surface often called a 32 machine finish. | Required for stressed parts or components needing smooth, reliable motion. Often specified for bearings with occasional movement. | ~2.5x – 5% increase |

| 0.4 µm / 16 µin | Ultra-Fine Finish / 16 Finish | No visible tool marks, semi-reflective. | Reserved for high-performance applications like high-speed bearings and shafts where minimal friction is critical. | 4x+ |

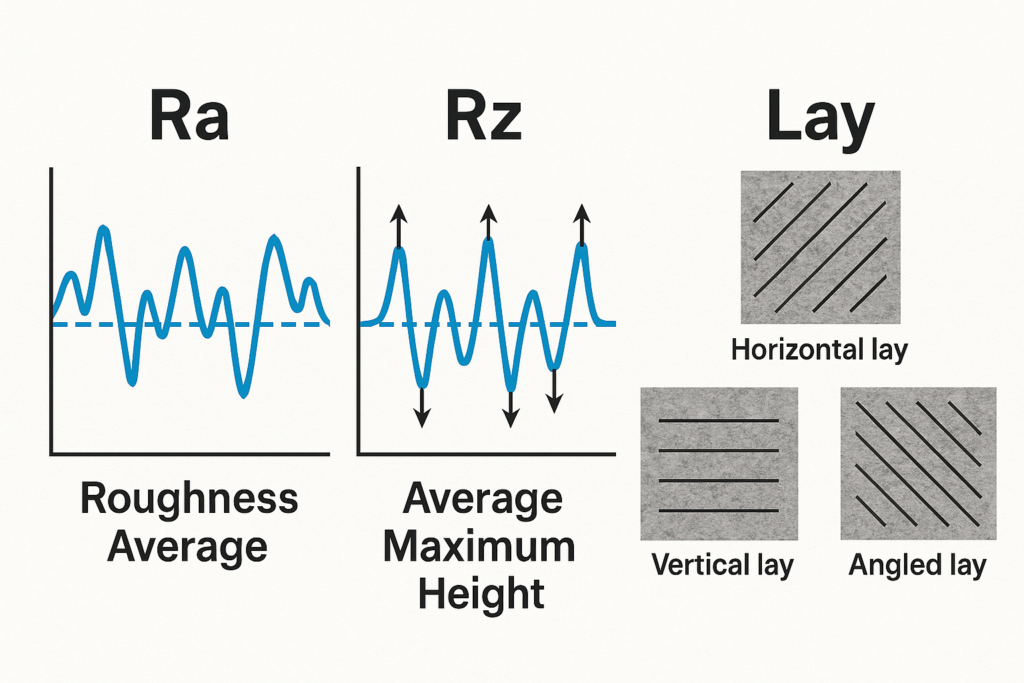

Decoding the Jargon: Ra, Rz, and Lay Explained for Your Part

To specify and procure parts with confidence, it’s essential to understand the language of surface texture. These parameters on a technical drawing are direct instructions to the manufacturer and define the functional quality of the surface.

Ra (The Average Joe)

What is Ra surface finish? Ra, or Roughness Average, is the most common parameter in manufacturing. It represents the arithmetic average of a surface’s microscopic peaks and valleys. It’s a useful, single-number metric for general process control.

But Ra can be misleading. A surface with uniform, gentle waves can have the same Ra as one with a deep scratch. For parts where a single flaw could cause leakage or failure, relying solely on Ra is insufficient.

Rz (The Detective)

Where Ra gives an overview, Rz surface roughness highlights extremes. It measures the average distance between the highest peaks and lowest valleys—making it better at detecting scratches, burrs, or defects.

For seals or fatigue-sensitive parts, specifying Rz alongside Ra provides more robust surface quality control and helps avoid functional issues.

Lay (The Grain)

Beyond height, the direction of the surface pattern—called the surface lay—matters. It’s determined by the machining process (e.g., turning, milling) and behaves like wood grain.

The direction of lay impacts part performance. For sliding parts, it should be parallel to motion to reduce friction. For seals, circular lay may be required. The finished surface symbol on drawings communicates this detail.

The Machinist’s Playbook: 5 Levers That Impact Quality and Cost

Achieving the right surface finish involves controlling five key factors. For wholesale buyers, understanding these levers helps evaluate a supplier’s process control capability.

1. Parameters: The Game of Speed, Feed, and Depth

Feed rate heavily influences surface roughness. In turning, roughness is proportional to the square of the feed rate. Halving the feed rate improves finish but doubles cycle time and cost.

Cutting speed also matters. At low speeds, ductile metals like aluminum form “Built-Up Edge” (BUE), where material adheres to the tool, worsening surface quality. Higher speeds reduce BUE but increase tool wear. A skilled supplier like YISHANG balances these dynamics for quality and efficiency.

2. Tooling: The Choice of Geometry, Material, and Coating

Tool nose radius affects finish—a larger radius smooths the surface but raises cutting forces. This trade-off must be expertly managed.

Modern tools use coatings like PVD finish (e.g., TiAlN), forming a hard, low-friction surface to reduce BUE and extend tool life.

| Workpiece Material | Recommended Tool Material | Recommended Coating | Key Benefit for Production |

|---|---|---|---|

| Aluminum Surface Finish | Carbide, PCD | DLC, TiN | Prevents material adhesion/BUE at high speed |

| Low-Carbon Steel | Carbide | TiN / TiCN | Wear resistance for high-volume runs |

| Stainless Steel | Carbide | TiAlN / AlCrN | Handles heat and avoids BUE |

| Titanium Alloys | Carbide | TiAlN | Excellent thermal hardness for aerospace/medical use |

| Hardened Steel | CBN | Al2O3 | Superior hardness for post-heat-treat machining |

3. System Stability: The Impact of Rigidity, Wear, and Vibration

Even the best tool fails in an unstable system. CNC machine rigidity prevents deflection under cutting forces. Lack of rigidity causes chatter, leading to poor finishes.

Tool wear worsens finish over time. A capable supplier maintains tool life management to ensure the last part matches the first in quality.

4. Material’s “Temperament”: Hardness, Ductility, and Thermal Properties

Each metal machines differently. Ductile materials like some aluminum surface finishes form BUE; hard metals generate excessive heat.

Stainless steel and titanium trap heat and are prone to work hardening, increasing tool stress. These traits demand tailored machining strategies.

5. The Art of Cooling: The Role of Cutting Fluids

Cutting fluids serve to cool, lubricate, and clean the cutting zone.

Aluminum benefits from synthetic fluids for cooling. For stainless steel threading, high-lubricity straight oils prevent edge degradation. Coolant choice is a hidden variable that greatly affects finish and tool life.

Level Up: Advanced Tactics for a Flawless Finish

While standard finishes meet most specs, advanced strategies can dramatically improve consistency and reduce cost—especially in high-volume runs.

1. Intelligent Toolpath Programming

Modern CAM software allows for smooth toolpaths that maintain constant tool engagement, reducing vibration and extending tool life—resulting in consistent, high-quality surface finishes.

2. The Secret of Wiper Inserts

Wiper inserts flatten the cutting surface as they move, enabling a better finish at higher feed rates. They’re essential for balancing cycle time and finish quality.

3. Harnessing Speed: High-Speed Machining (HSM)

HSM uses high spindle speeds with small step-overs. This ejects heat with chips, minimizes thermal distortion, and delivers clean finishes—often eliminating secondary grinding.

From Theory to Reality: Achieving a 0.4 µm Ra Finish on 316 Stainless Steel

Real-world application: CNC machining 316 stainless steel to 0.4 µm Ra for a medical-grade part.

The Challenge: Why 316 Stainless is Difficult

316 work-hardens easily, conducts heat poorly, and produces long chips—making it difficult to machine and finish precisely.

The YISHANG Action Plan: An Integrated Strategy

At YISHANG, we implement an end-to-end system to meet stringent finish requirements:

- Stable Platform: Rigid machines and robust fixturing minimize vibration.

- Tooling: Sub-micron carbide inserts with TiAlN coatings are paired with wiper geometry.

- Parameters: High speed (120–150 m/min), low feed (<0.08 mm/rev), and shallow cuts (0.2–0.5 mm).

- Coolant: High-pressure (1000+ PSI) coolant delivery ensures chip evacuation and temperature control.

This process ensures repeatability, compliance, and performance for precision parts.

How to Measure Surface Roughness: A Commitment to Quality Control

Understanding how to measure the roughness of a surface confirms supplier accountability.

Contact Profilometers (Stylus Instruments)

The most common approach uses a diamond stylus to trace the surface, producing Ra and Rz values. It’s accurate and widely accepted for in-process checks.

Non-Contact Profilometers (Optical Instruments)

Optical profilometers use light-based 3D mapping for high-resolution, non-destructive analysis—ideal for delicate or high-spec parts.

A supplier equipped with both—like YISHANG—offers full-spectrum quality verification.

The Ultimate Surface Roughness FAQ

- What is the difference between surface roughness and surface finish? Roughness refers to measurable micro-variations (Ra, Rz). Finish includes lay and waviness as well.

- Does surface roughness mean larger surface area? Yes. Microscale peaks and valleys expand total contact area—important in coatings and chemical treatments.

- Can a surface be too smooth? Yes. Overly smooth surfaces may fail in lubrication-dependent assemblies. The right finish depends on function.

- What other metal finishing services are available? Options include bead blasting, powder coating, and anodizing—each enhancing appearance and corrosion resistance.

Ready to Optimize Your Machined Components?

YISHANG specializes in CNC machining for wholesale buyers in 50+ countries, delivering tight-tolerance, application-specific surface finishes at scale.

📩 Contact us for a free quote or drawing review.