For overseas wholesale buyers, selecting CNC plastic milling services is rarely about whether a supplier can machine a plastic part that looks correct the moment it leaves the machine. Commercial risk usually appears later—after cross‑border shipment, storage, and final assembly—when parts that initially passed inspection begin to drift, tighten, or lose interchangeability.

In high‑volume or repeat procurement, these delayed issues are far more costly than early rejections. They disrupt assembly schedules, increase rework, and damage downstream customer relationships. Most of these failures are not random. They stem from predictable interactions between plastic material behavior, workholding, cutting heat, and stress relaxation.

This article is written for procurement and engineering teams sourcing CNC plastic machining services or CNC plastic milling services for wholesale and OEM supply. It avoids generic material catalogs and marketing claims. Instead, it focuses on how machining decisions affect stability, tolerance risk, and total cost of ownership—the factors that actually influence sourcing outcomes.

At YISHANG, we support buyers who evaluate suppliers based on how well they understand and manage these risks. The structure of this article follows the same logic procurement teams use internally: identify misconceptions, understand mechanisms, locate risk sources, and evaluate suppliers accordingly.

Why Plastic Should Not Be Treated as “Easier-to-Machine Metal”

A common sourcing shortcut is to assume that plastic machining is simpler than metal machining because cutting forces are lower. In practice, this assumption often leads to underestimated risk. Plastics may be easier to cut, but they are harder to keep stable.

The key difference is stiffness and recovery. Metals resist elastic deformation at the part scale, so deflection during machining is relatively predictable. In plastic CNC milling, the part itself can flex under clamping and cutting loads, temporarily conforming to the fixture. Once released, it may slowly recover toward its original stress state. For wholesale buyers managing batch interchangeability, this recovery introduces uncertainty that does not usually appear in metal projects.

Thermal behavior further separates plastic from metal. Most engineering plastics have low thermal conductivity, which allows heat to concentrate near the cutting zone. Even modest temperature increases can locally soften the material without visible melting. This affects surface integrity, dimensional stability, and how the part relaxes after machining. Suppliers who apply metal-centric assumptions—strong clamping and aggressive cuts—often optimize for speed rather than stability, shifting risk downstream to the buyer.

Another upstream factor buyers often inherit unknowingly is residual stress in plastic stock. Extruded plates and rods can carry internal stress from their own manufacturing process. When machining redistributes that stress, parts may move after leaving the fixture. This is why identical drawings and materials can yield very different results across suppliers offering CNC plastic machining services.

For procurement teams, the practical takeaway is clear. The supplier who treats plastic as “easy metal” typically delivers parts that pass initial inspection. The supplier who treats plastic as a distinct material system delivers parts that remain stable after machining, shipping, and assembly.

What Changes Inside Plastic During CNC Milling—and Why It Matters in Production

Buyers do not need deep materials science training to source successfully, but understanding what changes inside plastic during machining explains why problems often appear late.

One critical factor is residual stress redistribution. Many plastic stocks—especially extruded materials—contain internal stress before machining begins. As material is removed, that stress redistributes. At the same time, workholding introduces external stress by compressing or constraining the part. Once machining is complete, the part seeks a new equilibrium. That process can take hours or days, resulting in gradual dimensional movement that is invisible at the moment of inspection.

Heat interacts with stress in subtle but important ways. Plastics dissipate heat slowly, so localized temperature rise near the tool path can temporarily soften the material. Even without visible damage, this softening changes how the part responds to clamping and how it relaxes afterward. Repeated tool engagement in the same area can concentrate both heat and stress, which is why stability issues often appear in predictable locations.

Moisture sensitivity adds another layer of risk for certain polymers. Hygroscopic materials such as nylon absorb moisture from the environment, which can cause small but meaningful dimensional changes. For wholesale supply chains involving long transit times and multiple climate zones, this effect can influence fit and assembly consistency. Managing this risk does not require excessive complexity, but it does require alignment between material selection, inspection timing, and packaging expectations.

From a procurement perspective, suppliers who can explain these mechanisms—and how their process controls address them—demonstrate competence that goes beyond basic machining capability.

Where Errors in CNC Plastic Milling Are Introduced

When dimensional issues appear, buyers often question machine accuracy first. In plastic milling, the machine is rarely the root cause. Errors are typically introduced through the interaction between material behavior and the machining system: workholding, toolpath strategy, and tool condition.

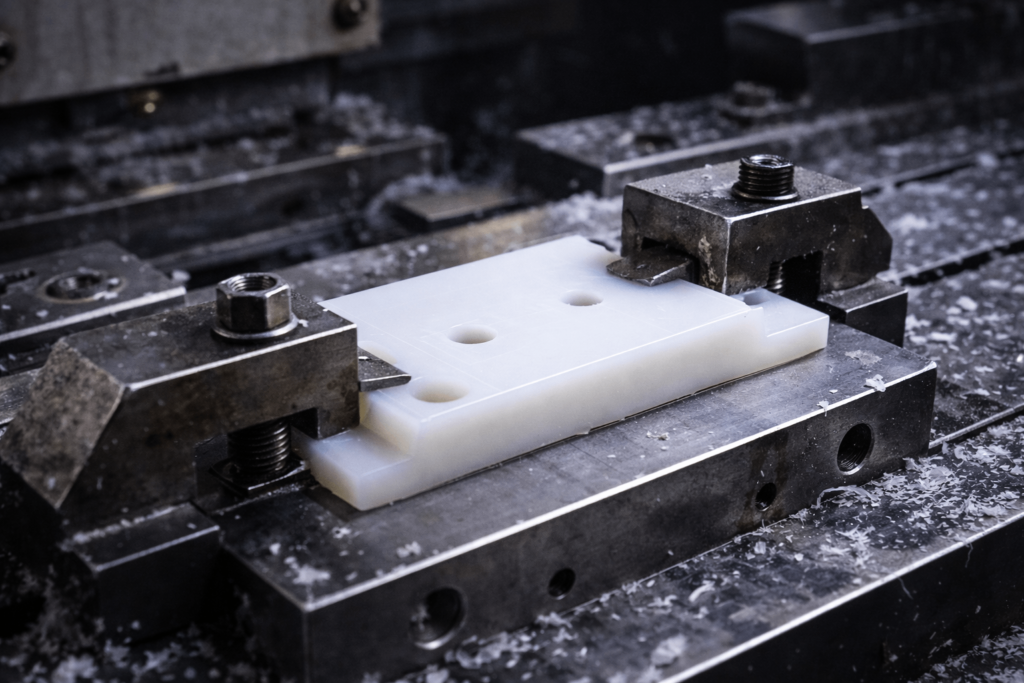

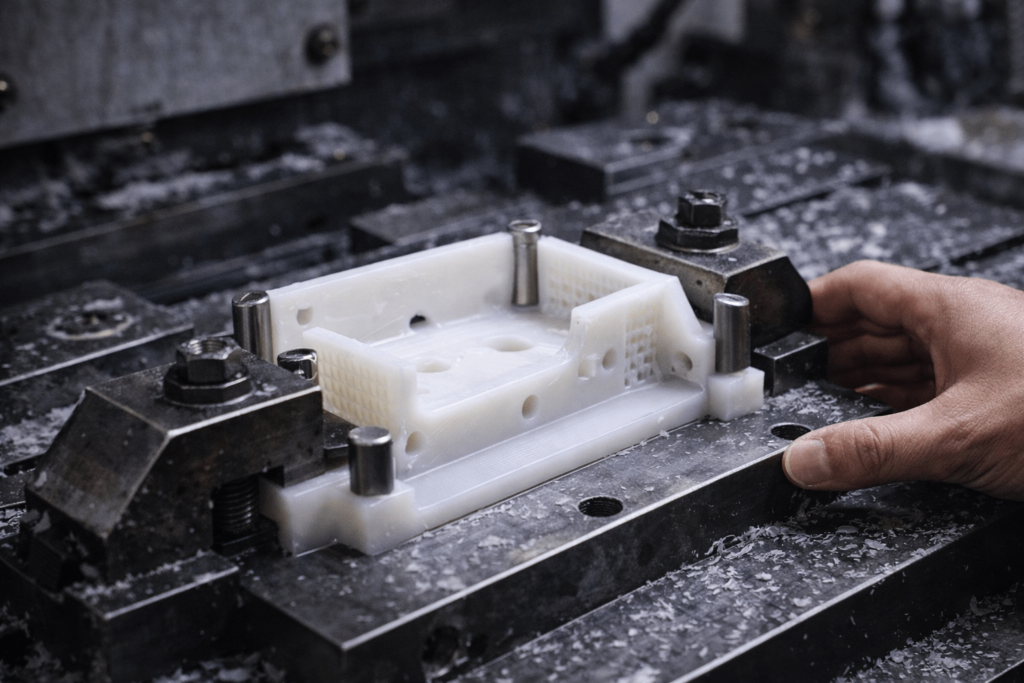

Workholding Distortion: Accuracy Can Be “Fixtured In”

Plastics compress more readily than metals under clamping pressure. Localized clamping can temporarily force a part into tolerance, only for it to relax after unclamping. This effect is especially pronounced in thin-walled components, covers, and large flat panels—geometries commonly ordered in wholesale quantities.

From a sourcing standpoint, the issue is not whether clamping is used, but how it is applied. Distributed support, soft jaws that spread load, and fixtures designed to support thin features reduce local compression. Buyers evaluating CNC plastic milling services should expect suppliers to discuss how they avoid introducing distortion through workholding, even if proprietary fixture details are not disclosed.

Toolpath Strategy and Heat Accumulation

Plastic machining is highly sensitive to tool engagement patterns. Repeated passes near the same feature can build heat and soften the material locally. Finishing thin features too early can leave them vulnerable to later operations. In contrast, a balanced sequence that controls engagement and allows cooling intervals can improve stability without relying on cosmetic finishing.

This is why two suppliers with similar equipment can produce different results. One optimizes for throughput; the other optimizes for stability. For procurement teams comparing CNC plastic machining services, asking about toolpath sequencing and thermal management often reveals more competence than asking about spindle speed or axis count.

Tool Condition and Chip Evacuation

Tool sharpness and chip evacuation matter more in plastics than many buyers expect. A tool that still performs acceptably on aluminum may smear plastic, increasing heat and leaving a surface that behaves unpredictably in assembly. Stable plastic milling relies on clean chip formation, sharp cutting edges, and consistent chip removal.

For buyers, the relevance is practical. Suppliers who control these variables are controlling the real sources of variation.

Why Prototypes Rarely Reveal Production-Level Risk

Prototype approval is often treated as proof of production readiness. In CNC plastic milling, that assumption frequently leads to downstream issues.

Immediate Inspection vs. Time-Dependent Behavior

Prototypes are commonly measured shortly after machining, before stress relaxation and thermal equilibration have occurred. That timing favors initial accuracy but hides delayed movement. In wholesale supply chains, where parts may sit in inventory or transit for days or weeks, stability over time matters more than momentary conformance.

Scale Changes the Process

Production introduces tool wear, longer run times, and higher throughput. These factors increase heat accumulation and amplify stress variation. The result is often not obvious defects, but gradual tolerance drift and assembly variation that only becomes apparent after multiple batches.

Lot-to-Lot Material Variation

Even within the same polymer grade, stock can vary in internal stress and moisture condition. Hygroscopic materials may change dimension with humidity exposure. For buyers supplying multiple regions, these small variations can accumulate into noticeable field issues.

The procurement takeaway is constructive. Prototypes validate geometry and feasibility. Production readiness is demonstrated by stability controls—how the supplier manages tool wear, inspection timing, and batch repeatability when sourcing CNC plastic milling services.

Rethinking Tolerance in CNC Plastic Milling

Tolerance discussions in plastic machining require a time-aware perspective. Buyers often request tight tolerances to ensure assembly reliability. The challenge is that tolerance can mean two different things: what is achievable immediately after machining, and what remains true after the part relaxes and experiences normal temperature exposure.

Achievable vs. Stable Tolerance

Many suppliers can meet tight numbers on a CMM immediately after machining. As residual stress redistributes and temperature equalizes, dimensions may shift. For wholesale buyers, stable tolerance—not spot accuracy—is what determines real usability.

The table below provides realistic reference ranges for CNC-milled plastic parts under controlled conditions. These are practical planning ranges, not contractual guarantees.

| Feature Type | Initial Achievable Range | Typical Stable Range | Procurement Implication |

|---|---|---|---|

| Overall dimensions | ±0.05 mm | ±0.08–0.15 mm | Thin sections increase drift risk |

| Holes / bores | ±0.03–0.05 mm | ±0.05–0.10 mm | Heat sensitivity shifts geometry |

| Flatness | 0.05–0.10 mm | 0.10–0.30 mm | Workholding dominates large surfaces |

Measurement Conditions and Standards

Standards such as ISO 2768 provide general tolerance guidance, but plastics are more sensitive to measurement conditions. International practice typically references ISO 1, which defines 20 °C as the standard measurement temperature. Deviations from this baseline can influence readings on plastic parts more than on metals.

For hygroscopic materials, ASTM D618 is often used as a reference for conditioning plastics before testing, typically at controlled temperature and humidity. While not every project requires formal conditioning, awareness of these standards helps buyers and suppliers align expectations around inspection timing and stability.

Aligning Tolerance With Function

Procurement disputes often arise when tolerance expectations are implicit. Buyers want assembly reliability; suppliers quote based on immediate inspection. Aligning on functional requirements—where stability matters, when parts are measured, and how acceptance is defined—reduces friction when sourcing CNC plastic machining services.

Surface Finish as a Functional Decision

Surface finish is frequently treated as a cosmetic requirement, but it has direct functional implications. In plastic parts, surface condition influences friction, sealing performance, wear, and fit consistency.

A surface can appear smooth while still being compromised. If the cutting zone runs warm, plastic can smear, creating a glossy appearance that hides a softened surface layer. That layer may behave differently under load, leading to stick‑slip, noise, or accelerated wear. For wholesale buyers, these effects show up as assembly variability or field complaints.

Surface finish also interacts with dimensional stability. Aggressive finishing passes can add heat where thin features are most sensitive. Suppliers who treat surface finish as part of the stability system—rather than a cosmetic afterthought—are more likely to deliver consistent functional performance when providing CNC plastic milling services.

When CNC Plastic Milling Is Not the Right Manufacturing Method

A credible supplier does not present CNC milling as the answer to every plastic part. Defining boundaries is a trust signal for buyers and a practical tool for cost control.

For stable, high‑volume programs, injection molding often provides better repeatability and lower unit cost once tooling is justified. For early‑stage development, additive manufacturing can shorten lead time but may introduce anisotropic properties and surface variability that limit functional use.

The buyer value is not to discourage CNC milling, but to select the method that reduces risk. Suppliers who openly discuss CNC plastic machining services alongside alternatives are more likely to guide buyers toward stable, commercially sound decisions.

How Experienced Buyers Evaluate CNC Plastic Machining Services

Wholesale procurement teams do not judge suppliers by machine lists alone. They assess how suppliers manage risk across batches, time, and real assembly conditions.

Process Control Signals That Matter

Competent suppliers can explain how they control workholding pressure, manage heat generation through cutting strategy, and time inspection to account for stress relaxation. Inspection confirms results; it does not create stability. Understanding this distinction is critical when evaluating CNC plastic milling services.

Measurement environment is another high‑signal area. Plastics are temperature sensitive, so uncontrolled measurement conditions can introduce noise. Suppliers who control inspection environment and acceptance timing demonstrate practical competence.

Total Cost of Ownership vs. Unit Price

The lowest unit price is not always the lowest cost. Reduced fixture development, aggressive cycle‑time optimization, or minimal stability validation may lower quotes but increase downstream cost through rework, delays, or returns.

For buyers, the most productive sourcing conversations focus on the “why” behind process choices. Suppliers who can discuss expected movement, risk areas, and validation methods are typically the most reliable partners for CNC plastic machining services.

RFQ Checklist for CNC Plastic Milling (Buyer-Oriented)

To evaluate feasibility and reduce back‑and‑forth during quoting, experienced buyers typically prepare a concise RFQ package. Beyond drawings, this often includes material grade or approved alternatives, target batch size, critical functional features, and when acceptance inspection will occur.

Clarifying whether dimensions must remain stable after a defined time—rather than only at immediate inspection—helps suppliers propose appropriate process controls. Packaging, storage conditions, and any expected climate exposure during transit can also influence stability for certain polymers.

Including this information upfront allows suppliers of CNC plastic milling services to quote more accurately and flag risk early, before it becomes a production issue.

Final Perspective for Wholesale Procurement Teams

CNC plastic milling is best viewed as a system‑level manufacturing decision, not a commodity service selection. Material behavior, workholding strategy, toolpath sequencing, thermal management, tool condition, and inspection timing interact to determine whether parts remain stable beyond the factory floor.

For wholesale buyers, the safest suppliers are those who can explain why risks arise and how they are controlled across batches. That depth of understanding supports consistent supply, predictable assembly performance, and fewer downstream surprises.

If you are evaluating CNC plastic milling services or broader CNC plastic machining services for wholesale or OEM production, a short technical discussion at the RFQ stage is often the fastest way to confirm feasibility and align on stability expectations. If helpful, you can share your drawing and functional requirements to review key risk points before committing to volume.