Overseas wholesale buyers usually don’t land on a brand website to “learn what steel is.” They arrive because a sourcing decision is already in motion—quotes are being compared, lead times are being negotiated, and the real question is whether a part can be produced consistently across repeat orders.

That is why cnc steel parts is a high-intent query. It often sits next to searches like custom CNC parts, custom machine shop, online CNC parts, or custom metal machining quotes—all signals that the buyer is evaluating suppliers and trying to reduce uncertainty.

This article follows that buying reality. It stays focused on what matters to wholesale procurement: repeatability, tolerance control, finish and heat-treatment trade-offs, and the cost drivers that show up only after you scale. The tone is practical on purpose—closer to how a good supplier explains decisions during an RFQ review, not how a textbook describes materials.

1. Why “CNC Steel Parts” Is Usually Searched When a Project Is Already at Risk

A procurement team rarely searches cnc steel parts during the earliest design brainstorm. The search tends to appear later—after a prototype has exposed instability, or after two suppliers quoted the “same” part and their prices were nowhere near each other. In wholesale buying, that gap is a warning sign. It suggests the part may be difficult to produce consistently, or the drawing leaves room for interpretation.

Steel often enters the conversation at this risk point because it feels predictable. But what buyers actually want is not “steel.” They want a production path that keeps dimensions stable, holds tolerances without excessive rework, and remains manufacturable even if volumes grow or shipments need to be split.

When buyers search CNC machining steel, they are usually validating three things:

What the buyer is really validating

First, they want to know whether steel will reduce variability in real operation—load, vibration, thermal cycling, or abrasive wear. Second, they want to predict how steel will affect lead time: tool wear, cycle time, and whether secondary operations will be required. Third, they want to understand what a credible supplier will ask for in the RFQ: not just a file upload, but details like functional datums, surface requirement intent, and whether any features are cosmetic versus performance-critical.

The strongest content for this audience acknowledges that reality. It avoids consumer-style education and instead addresses how decisions change when a project moves from a one-off sample to repeat CNC orders. If you are a wholesale buyer, the keyword is not “precision.” It is “repeatable precision.”

2. Steel Is Rarely the First Material Considered — But It Often Ends the Debate

Early-stage material comparisons often start with lighter options. Aluminum can be faster to machine; engineering plastics can be lower cost and corrosion-resistant. In low-stress applications, those choices can be perfectly correct. But the procurement criteria shift when the buyer’s responsibility shifts from “get a prototype” to “keep a supply chain stable.”

Steel CNC parts become more attractive when buyers need consistent behavior across batches. Steel’s stiffness can help reduce deflection under load, which protects mating features and alignment in assemblies. Its fatigue performance is well characterized, which is helpful for components that cycle daily, not just occasionally.

Predictability is a supply-chain feature

For wholesalers, predictability is not an abstract engineering concept. It is a supply-chain feature. Predictable materials make it easier to forecast scrap risk, stabilize inspection workload, and avoid sudden process changes when a new lot of material arrives. In many manufacturing environments, this predictability can matter more than shaving seconds off a machining cycle.

Steel also tends to narrow the debate because it broadens the safe operating window. Even when steel is not optimized for one metric, it can remain acceptable across many: load capacity, wear resistance, temperature tolerance, and long service life.

If you are comparing cnc metal parts suppliers, you will often find that steel is chosen not because it is “best,” but because it keeps the project controllable as it scales.

3. When Choosing Steel Becomes a Shortcut — And Why That Can Backfire

Steel can reduce uncertainty, but it can also become a shortcut. When schedules tighten, teams may default to steel without revisiting the drawing assumptions that were built around a different material. That is when steel begins to feel “expensive”—not because the material is inherently problematic, but because the design now conflicts with the process.

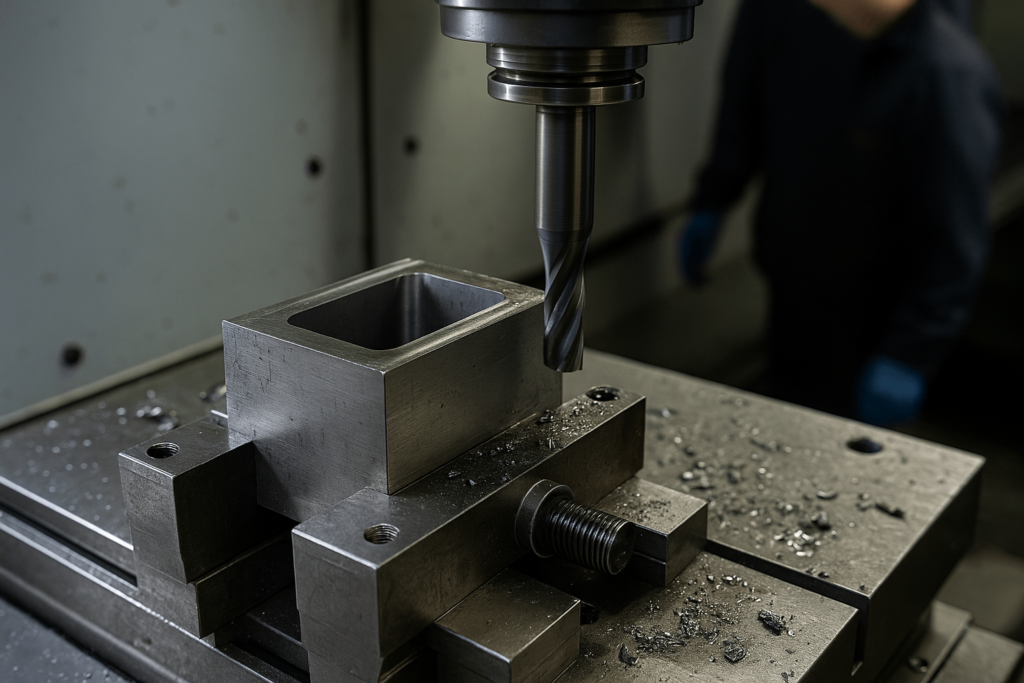

In CNC machining steel, small choices in geometry and tolerance strategy can multiply cost. Tight positional tolerances, deep pockets, and thin unsupported features raise tool load and increase the probability of chatter. The result is longer cycle times, more finishing passes, and greater tool consumption. If you are buying high-volume custom machined metal parts, these small changes can become large budget swings.

The sourcing symptom: unstable quotes

Wholesale buyers typically notice this as instability in quotes. Two suppliers may interpret the same print differently, or one supplier may plan more conservative tooling and setups to protect yield. That difference is real manufacturing risk being priced in.

The practical takeaway is not “avoid steel.” It is: avoid using steel as a band-aid. If the project is moving toward steel, treat it as a deliberate change that triggers a DFM review. A credible custom machine shop will explain where steel increases risk and what design adjustments can bring cost back under control.

4. CNC Machining Steel Is Predictable — Poor Design Is Not

A lot of web content frames steel as “hard to machine,” which is only half true. In reality, CNC machining steel is highly predictable when part geometry respects known constraints. The unpredictability buyers experience is more often driven by design decisions that amplify vibration, tool deflection, or heat concentration.

Deep cavities, long-reach tooling, sharp internal corners, and abrupt section changes are classic risk multipliers. On a quote, these show up as extra setups, reduced feeds and speeds, or requests to relax tolerance callouts. On the shop floor, they show up as chatter marks, edge burrs, and inconsistent dimensional results.

A design lens wholesale buyers can use

You don’t need to be a machinist to spot red flags. If a feature requires a very long tool relative to its diameter, the process will be sensitive. Tall, thin walls tend to deflect during machining, especially across multiple setups. Overly tight tolerances applied across the entire part also increase measurement effort and correction time without always adding functional value.

Standards can help frame this conversation without turning your RFQ into an argument. For example, using a general tolerance note (commonly aligned with standards like ISO 2768) can reduce ambiguity for non-critical dimensions, while leaving tight tolerances only where function requires it. For GD&T-driven features, referencing ASME Y14.5 practices helps ensure suppliers interpret datum strategy consistently.

If you want stable steel CNC production, design intent must be explicit. Predictability is not an “equipment feature.” It is the result of alignment between design and process.

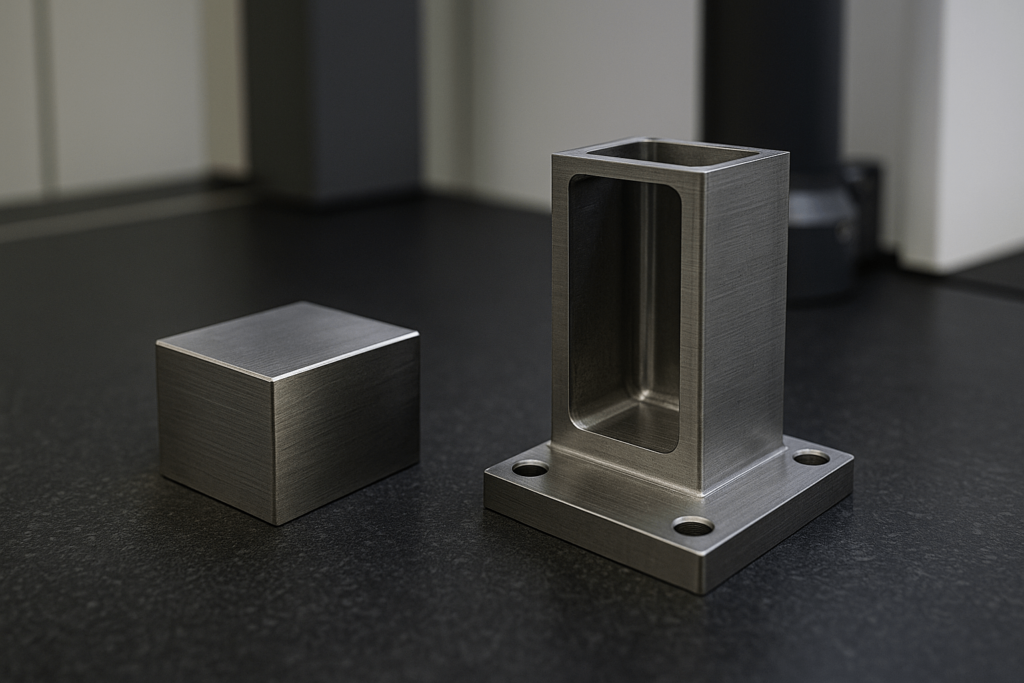

5. Why Two CNC Steel Parts Can Behave Like Completely Different Materials

Buyers often say “it’s just steel,” but steel is a family of behaviors, not a single material. Composition, condition (annealed, normalized, quenched and tempered), and internal stress state all influence machinability, surface finish response, and tool life. That is why two parts can look identical on a drawing but behave very differently during production.

Some steels cut cleanly and produce manageable chips, which supports higher throughput. Others prioritize strength and wear resistance, which increases cutting forces and makes finishing more sensitive. Stainless steels add another layer: many grades work-harden, meaning the material can become tougher as the tool rubs rather than cuts—raising the importance of stable tool engagement.

How this impacts procurement decisions

For wholesale buying, this is less about memorizing grades and more about forecasting risk. A supplier quoting custom CNC parts should clarify material condition (not just grade) and confirm whether heat treatment is required for performance or just assumed. The supplier should also explain whether the process sequence will include stress relief, rough machining before heat treatment, or final finishing after treatment.

If you are using online CNC cutting service platforms for early sourcing, be aware that automated quoting often underestimates this behavior difference. A human review—especially for steel—can prevent surprises later.

The procurement-friendly lesson is simple: steel selection is not only “which grade,” but “which behavior and which state.” That nuance is where stable production is won.

6. The Exact Moment Steel Becomes the Right Choice

Steel becomes the right choice when the commercial cost of failure outweighs the convenience of lighter materials. That moment often arrives when the part becomes load-bearing, safety-relevant, or fatigue-sensitive—and when the buyer expects repeat orders where variation will accumulate into real downstream cost.

Steel’s stiffness and fatigue behavior can protect assembly integrity. When a component must maintain alignment under load, small deflections can turn into big problems: premature wear, noise, vibration, or assembly mismatch. In these cases, the material decision is inseparable from the production decision.

A decision frame used by experienced buyers

Wholesale buyers often adopt a simple frame: what happens if this part drifts by a small amount? If the answer is “nothing,” then you can optimize for cost and speed. If the answer is “the assembly fails,” then steel and a tighter process window become justified.

This is also where custom CNC becomes meaningful. The goal is not customization for its own sake; it is customization that stabilizes function. That might include revising fillets to improve tool access, adding datum features to improve measurement repeatability, or defining surface requirements only where they affect performance.

Steel is strategic when it reduces system-level risk—quality, assembly, warranty exposure—not just when it increases strength.

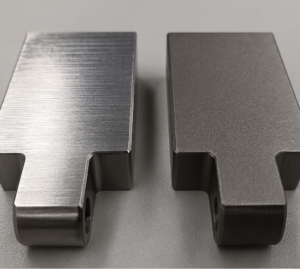

7. Surface Finish and Heat Treatment: Where Many Steel Projects Quietly Go Wrong

Surface finish and heat treatment are frequent sources of surprise in steel projects because they are often finalized late. Buyers compare custom metal machining quotes based on a drawing that lists Ra requirements and hardness targets, but the process sequence is left implicit. Two suppliers may assume two different sequences—and the quote gap can be large.

Machining before heat treatment generally reduces cutting resistance and lowers tool wear, but it introduces distortion risk. Machining after heat treatment improves wear resistance and protects functional surfaces, but it increases tool cost and can reduce achievable surface finish without additional passes.

Use standards to remove ambiguity

For surface texture, it helps to reference intent rather than blanket requirements. Standards like ISO 1302 (surface texture indication) provide a common language for specifying surface finish where it matters. When only a few interfaces require a tighter finish, you can reduce cost by not applying that requirement everywhere.

The buyer-friendly approach is to ask: which surfaces are functional, and which are cosmetic? A supplier offering custom metal machining should be able to explain how finish and treatment decisions affect lead time, not just price. This is a key differentiator between “quote-only” providers and partners that help you stabilize production.

8. Most Quality Problems in CNC Steel Parts Start Long Before Machining

In wholesale sourcing, “quality problem” is often understood as an inspection issue. In reality, most quality problems begin earlier—at the point where the drawing, material spec, and process assumptions fail to align. Inspection can detect a deviation, but it cannot fix the underlying mismatch.

Dimensional accuracy in steel depends on fixturing strategy, sequence planning, and tolerance interaction. Parts that are thin and require multiple clamping steps tend to introduce more variation over time. Unclear datum definitions make measurement inconsistent from one setup to the next. When tight tolerances are applied without clear functional justification, suppliers are forced to either price defensively or accept a higher scrap risk.

What B2B buyers should ask in an RFQ review

Instead of asking only for certificates and photos, ask how the supplier will control repeatability: What datums will they use? How many setups are planned? Where do they expect distortion? What is the inspection method for critical features?

A supplier running a true cnc fabrication service should be able to describe these decisions in plain language. ISO 9001 systems help with traceability and corrective action, but the real signal of competence is whether the process plan shows forethought.

For buyers, quality is not a checkbox. It is a design-and-process agreement.

9. The Real Cost of CNC Steel Parts Is Not in Machining

When buyers ask why steel costs more, the honest answer is that machining time is only part of the story. Total cost is shaped upstream by decisions that influence yield, tool life, and rework risk.

Tight tolerances increase measurement time and can require extra finishing passes. Complex internal geometries often force slower toolpaths and more setups. Surface finish requirements can turn a straightforward operation into multiple staged cuts. These are not “shop inefficiencies.” They are costs that reflect the physics of steel machining.

A practical cost driver table for sourcing discussions

| Cost driver in steel parts | What it does to production | What a buyer can do early |

|---|---|---|

| Blanket tight tolerances | More measurement, more correction, higher scrap risk | Tighten only functional dimensions; use general tolerance notes elsewhere |

| Deep pockets / long reach tools | Slower feeds, chatter risk, extra passes | Adjust geometry; add radii; reduce depth-to-width ratios |

| Heat treatment after machining | Distortion risk; possible rework | Plan allowances; consider rough/finish sequence |

| High surface finish everywhere | More finishing passes; higher cycle time | Specify finish only on functional surfaces |

| Multiple setups | Stack-up variation; longer lead time | Redesign for better fixturing; add datum features |

This table is not meant to replace engineering review. It is a way for procurement teams to discuss cost drivers with a supplier in a structured, non-confrontational way. It helps buyers compare quotes on manufacturing logic, not just on a number.

10. What Actually Matters When Sourcing CNC Steel Parts

Wholesale sourcing is a risk game. Price matters, but the most expensive outcome is instability: late shipments, inconsistent dimensions, rework loops, and unexpected process changes mid-program. That is why buyers searching online CNC parts or custom CNC parts are often trying to identify suppliers who can keep production stable after the first shipment.

A credible supplier of metal CNC services should do more than accept files. They should clarify ambiguous tolerances, ask about functional surfaces, and propose changes that protect repeatability. This is not “teaching the customer.” It is collaborating to make the supply chain predictable.

Where supplier capability shows up in buyer terms

Capability shows up in how a supplier communicates during the RFQ stage, how they treat process planning, and how they handle trade-offs in plain language. It also shows up in how they support scale: stable material sourcing, controlled inspection, and consistent packaging that protects the same surfaces every time.

If you are comparing custom metal machining quotes, consider asking for a brief process summary alongside the price. Even a short explanation—setups planned, inspection method for key features, and post-processing sequence—can reveal whether the quote is based on a realistic plan.

11. RFQ and CNC Order Preparation: What Buyers Should Clarify Before Requesting Quotes

For overseas wholesale buyers, many cost and lead‑time issues originate not in machining, but in how a CNC order is defined at the RFQ stage. Steel amplifies ambiguity. When drawings leave intent unclear, suppliers must price risk into their custom metal machining quotes, which is why nominally identical RFQs can return widely different prices.

A well‑prepared RFQ does not need to be longer or more complex, but it should communicate priorities. Buyers benefit from explicitly distinguishing functional surfaces from cosmetic ones, identifying true datums used in assembly, and clarifying whether tight tolerances are performance‑critical or simply inherited from legacy drawings. These details allow a custom machine shop to plan process routes with confidence rather than conservative assumptions.

Another common source of confusion is inspection expectation. Steel parts with tight tolerances often require additional measurement steps. When buyers clarify whether first‑article inspection, batch sampling, or 100% inspection is expected, suppliers can align cost and lead time accordingly. This transparency reduces friction later and improves consistency across repeat CNC orders.

12. Manual Quotes vs Online CNC Cutting Services: Where Steel Needs Human Review

Online platforms offering online CNC parts and instant pricing have simplified early sourcing, especially for aluminum or simple geometries. For steel, however, automated quoting has limitations. Algorithms typically assume ideal machinability and standard process sequences, which may not reflect real cutting behavior or post‑processing needs.

Steel parts with deep pockets, thin walls, or post‑machining heat treatment often require judgment calls that software cannot reliably make. In these cases, a manual review by experienced engineers can identify risks early—such as distortion after heat treatment or tool access limitations—that automated systems may overlook. This is why quotes from online CNC cutting service platforms sometimes change after human evaluation.

For wholesale buyers, the practical takeaway is not to avoid online tools, but to recognize when escalation is necessary. If a steel part carries functional risk or is intended for high‑volume production, a manual quote from a supplier offering full metal CNC services often delivers more stable long‑term results.

13. Cost Drivers in CNC Steel Parts: A Buyer‑Focused Reference

Understanding cost drivers helps procurement teams compare quotes on manufacturing logic rather than headline numbers. In steel CNC production, several factors consistently influence cost and delivery stability.

| Cost Driver | Impact on Production | Buyer Action |

|---|---|---|

| Blanket tight tolerances | Increased inspection and rework risk | Tighten only functional dimensions |

| Deep cavities / long tools | Slower feeds, chatter risk | Adjust geometry or add radii |

| Post‑machining heat treatment | Distortion and extra finishing | Plan rough/finish sequence |

| High surface finish everywhere | Longer cycle time | Specify finish selectively |

| Multiple setups | Tolerance stack‑up | Add datums for better fixturing |

These factors explain why custom machined metal parts in steel may carry higher costs than expected. None are inherently negative, but all benefit from early discussion. Buyers who address them proactively often receive more consistent pricing across suppliers.

14. Frequently Asked Questions from Wholesale Buyers

What tolerance is realistic for steel CNC parts in production?

Realistic tolerances depend on geometry and function. For non‑critical features, general tolerances aligned with ISO 2768 help maintain cost control, while critical features can be tightened selectively.

Why are two quotes for the same steel part so different?

Differences usually reflect assumptions about process sequence, inspection level, or risk. Clarifying intent at the RFQ stage reduces this spread.

When is heat treatment necessary for steel CNC parts?

Heat treatment is justified when performance—wear resistance, strength, or fatigue life—requires it. It should not be assumed by default.

Are online CNC quotes reliable for steel parts?

They are useful for early comparison, but complex steel parts often benefit from manual review.

What makes a supplier strong in steel CNC machining?

Clear communication, process planning experience, and consistent inspection practices matter more than machine lists.

Final Takeaway: CNC Steel Parts Are a Manufacturing Decision, Not a Material Default

For overseas wholesale buyers, cnc steel parts represent a manufacturing decision that shapes cost stability, quality consistency, and supply reliability over time. Steel delivers its value when design intent, process planning, and sourcing expectations are aligned with how steel behaves in real CNC production.

If you are preparing a new CNC order or reassessing an existing design for higher volumes, a focused technical discussion can often reveal the true cost drivers early. For buyers seeking clarity rather than sales pressure, YISHANG supports engineering‑led conversations aimed at stable, repeatable custom CNC parts production.