Introduction: The $50 Component That Protects Your Brand and Bottom Line

It’s a scenario that haunts supply chain managers. A new product line, representing millions in investment, is stalled. The cause? Not a complex microprocessor, but a simple mounting plate.

A batch of generic brackets arrived with inconsistent tolerances, halting assembly lines. A shipment of enclosures for an outdoor product began showing premature corrosion, threatening a costly recall and damaging brand reputation.

In the world of high-volume manufacturing, the integrity of an entire system—and the profitability of a product line—often hinges on its most underestimated component.

The mounting plate is far more than a piece of hardware; it is a critical interface that dictates structural stability, thermal performance, and long-term reliability. For a wholesale buyer, the choice of this component is not a simple procurement task; it is a strategic decision about supply chain risk.

Opting for a low-cost, unvetted supplier for a “simple” part introduces a hidden vulnerability that can lead to catastrophic component failure, production delays, and unforeseen costs. The only path to ensuring product integrity and supply chain stability is through a partnership with a true manufacturing expert to create an engineered solution: the custom aluminum mounting plate.

This article serves as a decision-making playbook for procurement professionals and their engineering teams. We’ll walk you through the essential considerations that distinguish a reliable supply partner from one that represents operational risk, using real-world logic and technical insight. From heat dissipation to weight-sensitive assemblies, and from design-for-manufacturability (DFM) to CNC precision machining, this guide delivers the insights you need to evaluate vendors and sourcing strategies for OEM mounting plate projects.

First Act: The Litmus Test — Has Your Project Crossed the “Must-Customize” Red Line?

Before issuing a Request for Quotation (RFQ), the first strategic decision is to determine whether an off-the-shelf component is a viable option or a hidden liability for your product line. Generic plates are designed for generic problems, but high-performance products present specific, non-negotiable challenges.

Answering the following questions will reveal if your project has crossed the red line where a custom aluminum mounting plate is no longer a luxury, but a fundamental requirement for product success and brand protection. This checklist outlines the primary reasons for a custom mounting plate from both a technical and business perspective.

The Thermal Question: Does Your System’s Reliability Depend on Dissipating Heat?

In modern electronics, power density is increasing, making thermal management a primary driver of product reliability and lifespan. If your device’s core components—be it a processor, a power converter, or high-intensity LEDs—generate significant heat, warranty claims and field failures are directly tied to how effectively that heat is removed.

In these scenarios, the mounting plate must function as an active part of the thermal solution. If the answer is yes, specifying a generic steel or plastic plate is a significant risk. You require a material with high thermal conductivity, and this is where aluminum excels.

With a thermal conductivity of aluminum around 205 W/m·K, it is vastly superior to stainless steel (~15 W/m·K). A custom-designed aluminum heat sink mounting plate can be engineered with the precise thickness and surface area needed to draw thermal energy away from sensitive components, preventing overheating and ensuring the long-term reliability your customers expect.

The Weight Question: Is Every Gram a Penalty to Performance or Your Supply Chain?

In industries like aerospace, automotive, and robotics, weight is a critical performance metric. Every gram saved translates into tangible benefits like better fuel efficiency, longer battery range, or faster robotic movements.

For a procurement manager, weight also impacts logistics. Lighter components mean lower shipping costs, easier handling during assembly, and potentially reduced structural requirements for the final product.

If weight is a key factor, the high density of steel makes it a costly liability. Aluminum, at approximately one-third the weight of steel, offers a transformative advantage. The crucial metric is the aluminum strength-to-weight ratio.

An aluminum structure can be engineered to support the same load as a steel one while weighing as little as half as much. For any product where mass impacts performance or shipping costs, specifying lightweight aluminum parts is a smart business decision.

The Environment Question: Will Your Product Face the Real World?

The operational environment is a silent killer of mechanical components. Moisture, salt spray, industrial chemicals, and even frequent cleaning can degrade materials and lead to premature product failure.

If your equipment is destined for anything other than a climate-controlled room, its long-term durability—and your brand’s reputation—depends on its inherent ability to resist corrosion.

If your product faces these environmental challenges, a standard coated steel plate is a future warranty claim waiting to happen. Any scratch in the coating becomes an entry point for rust.

Aluminum, however, possesses an intrinsic defense mechanism: a thin, tough, and self-healing layer of aluminum oxide that provides robust protection. For the most demanding conditions, specialized marine grade aluminum alloys offer superior aluminum corrosion resistance, making them the mandatory choice for any product marketed for its durability in harsh environments.

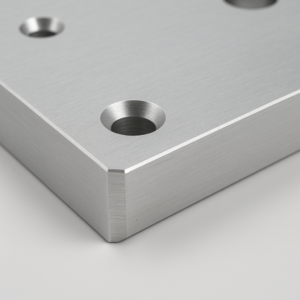

The Precision Question: Is Repeatable Assembly a Core Requirement?

In high-volume production, the precise and repeatable fit of components is non-negotiable. For automated or manual assembly lines, parts must align perfectly every time. When the relationship between components is measured in microns, the manufacturing method of your mounting plate is paramount to achieving efficient, trouble-free production.

If your product demands this level of precision, a stamped or roughly fabricated generic part introduces an unacceptable level of variability that can halt your assembly line. The solution lies in CNC machining.

A custom machined aluminum plate can be manufactured to incredibly tight tolerances, often within ±0.127mm or better, ensuring that every hole, datum, and mounting surface is perfectly located, part after part. This guarantees the precision alignment required for seamless assembly and reliable product function.

If you’re producing custom fabricated aluminum parts for industrial assemblies, and repeatable high-tolerance fit is a concern, then generic stock plates likely carry long-term costs that far outweigh initial savings.

Second Act: What Alloy? Why 6061 Isn’t Always the Answer

Once you’ve committed to customization, the next critical step is material selection. Too often, buyers default to 6061-T6 aluminum because of its reputation for general-purpose strength and wide availability. However, assuming 6061 is always the optimal choice can introduce hidden inefficiencies or overengineering.

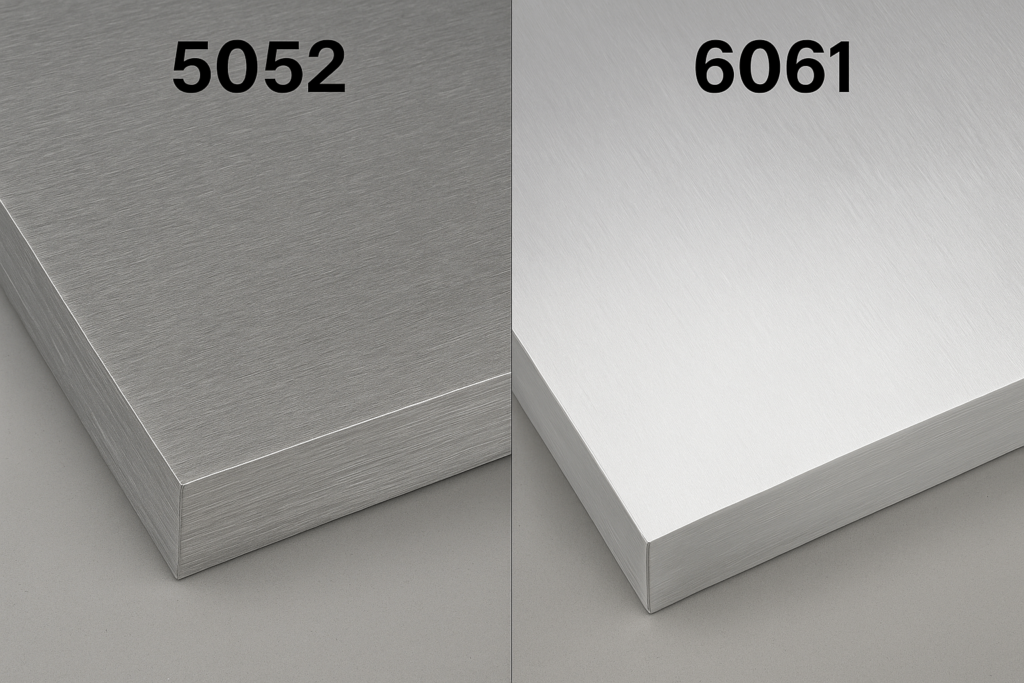

Know Your Alloys: Why 6061 and 5052 Are the Real Contenders

For mounting plates, two alloys dominate: 6061-T6 and 5052-H32. While both offer solid mechanical properties, their performance characteristics differ in key areas:

- 6061-T6 Aluminum: High strength, excellent machinability, poor formability, moderate corrosion resistance. Ideal for CNC-machined components that must hold tight tolerances and bear loads.

- 5052-H32 Aluminum: Medium strength, excellent corrosion resistance, high ductility. Ideal for formed or bent parts, especially in marine or outdoor environments.

Selecting the wrong alloy can lead to unexpected cracking during forming or premature corrosion in the field. That’s why expert material consulting is critical.

Case Study in Misalignment: The 6061 Over-Spec

We were once approached by a client in the vending equipment industry who had specified 6061 plates for a series of enclosures that needed to be formed into complex angles. The problem? Cracking at the bends.

The design had assumed the “stronger alloy” was better, but ignored formability. We helped them transition to 5052-H32, which bent cleanly and still met strength requirements, saving thousands in scrap and rework.

Optimize for Application — Not the Datasheet

6061 is not a “bad” choice — but it’s not the default best. In many cases, switching to 5052 can reduce machining time and material waste while enhancing corrosion resistance — critical for outdoor, marine, or medical devices.

Knowing which aluminum alloy to specify requires a supplier who understands not just the datasheet but also real-world forming, finish compatibility, and end-use environment. Partnering with a supplier that specializes in CNC aluminum plate solutions will help bridge the gap between theoretical specs and manufacturing realities.

Third Act: The Hidden ROI of DFM and Design Consultation

Selecting the correct material is only one dimension of a successful custom aluminum mounting plate project. The real cost savings, long-term reliability, and supply chain resilience are unlocked when your supplier doesn’t just manufacture to spec—but actively contributes engineering insight through Design for Manufacturability (DFM).

A capable supplier goes beyond execution; they become a co-developer. Their input during the design stage can drastically impact material usage, machining time, tooling life, and ultimately unit cost—without compromising performance. This collaborative process is not a courtesy; it is a high-leverage investment in ROI.

Design Intent Meets Fabrication Reality

We often encounter CAD drawings optimized for function but blind to the realities of fabrication. Sharp internal corners that require expensive tooling, overly tight tolerances that add machining time, or hole patterns that don’t align with standard drill bit sizes—these details add cost without adding value.

Through proactive DFM collaboration, a seasoned supplier will recommend subtle design changes—such as increasing bend radii to match tooling, relaxing tolerances that don’t affect fit, or reorienting parts to reduce material waste. These changes can reduce cost by 10–30% and improve production speed. When sourcing OEM mounting plate suppliers, prioritize those with a proven track record of offering these insights up front.

The “Cost of Precision” Trap

One common error is overengineering. Designers, in the name of precision, may default to ±0.01 mm tolerances across all features. This level of precision may be required in aerospace applications—but not for mounting a PCB enclosure in a vending machine.

Every micron of tolerance adds setup time, machine wear, and inspection complexity. A competent supplier will flag these instances and suggest functional tolerancing, where tight specs are applied only where functionally necessary. This helps avoid the trap of precision for its own sake—cutting production costs without compromising product function.

Build Repeatability into the Design

High-volume products succeed or fail on repeatability. The design must not only perform but do so consistently over thousands of units. DFM plays a crucial role in achieving this.

For example, symmetrical designs may appear elegant but create ambiguity in orientation during assembly. A good supplier will suggest the addition of asymmetric features—like keyed tabs or offset holes—to eliminate potential misassembly and reduce downstream quality issues.

Additionally, when you loop in your supplier early, they can guide decisions on:

- Optimizing blank nesting for material yield

- Consolidating multiple parts into a single stamping or bend operation

- Pre-defining datum structures that simplify inspection and QA

These aren’t theoretical benefits—they translate into shorter lead times, lower scrap rates, and fewer supplier change orders.

Case Example: 22% Cost Savings through Design Revision

We once supported a client designing a mounting plate for an industrial touchscreen. The original design required six bends and three machine setups. After reviewing the design, we suggested reducing the number of bends by re-orienting the interface bracket and shifting some tolerances from ±0.05 mm to ±0.2 mm where fit wasn’t affected.

The result? Fewer operations, lower tooling wear, and a simplified QA checklist—culminating in a 22% cost reduction per unit and a 17% improvement in takt time.

DFM Is Not an Upsell—It’s a Partnership Multiplier

Too many buyers view DFM as a courtesy review or a sales tool. In reality, it is a multiplier on your supplier’s value. It transforms them from a vendor into a long-term stakeholder in your product’s success.

When choosing a supplier for your custom aluminum mounting plates, prioritize those who don’t just say “yes” to your drawings but ask, “Why?” and “What’s the intent behind this geometry?” That level of partnership isn’t a bonus—it’s the foundation of operational excellence.

Fourth Act: Real-World Validation — Case Studies from the Field

Data sheets and supplier promises only go so far. In high-stakes manufacturing, real-world validation is the ultimate proof of capability. When evaluating a custom aluminum mounting plate supplier, look not just for technical proficiency, but for a track record of successful deployment across industries.

Whether you’re building vending machines, solar energy systems, industrial automation, or medical diagnostic equipment, you need a partner who understands how to deliver not just a part—but a solution tested by fire.

Case Study: Outdoor Vending Enclosures — Surviving the Elements

A client in the retail vending sector approached us with persistent issues of corrosion and latch misalignment in their outdoor kiosks. The mounting plates they had been sourcing were fabricated from mild steel and then powder-coated. While this initially provided a clean finish, seasonal weather cycles and humidity compromised the coating, leading to rust migration and eventual failure.

We recommended switching to a 5052-H32 aluminum base, engineered with integrated drainage slots and a redesigned mounting geometry to reduce stress points. After twelve months in various climates, field reports showed a 91% drop in corrosion-related service calls, and misalignment was completely eliminated thanks to tighter tolerances and warpage control.

This validated that the right alloy, paired with smart design, could dramatically enhance outdoor durability and lower service costs.

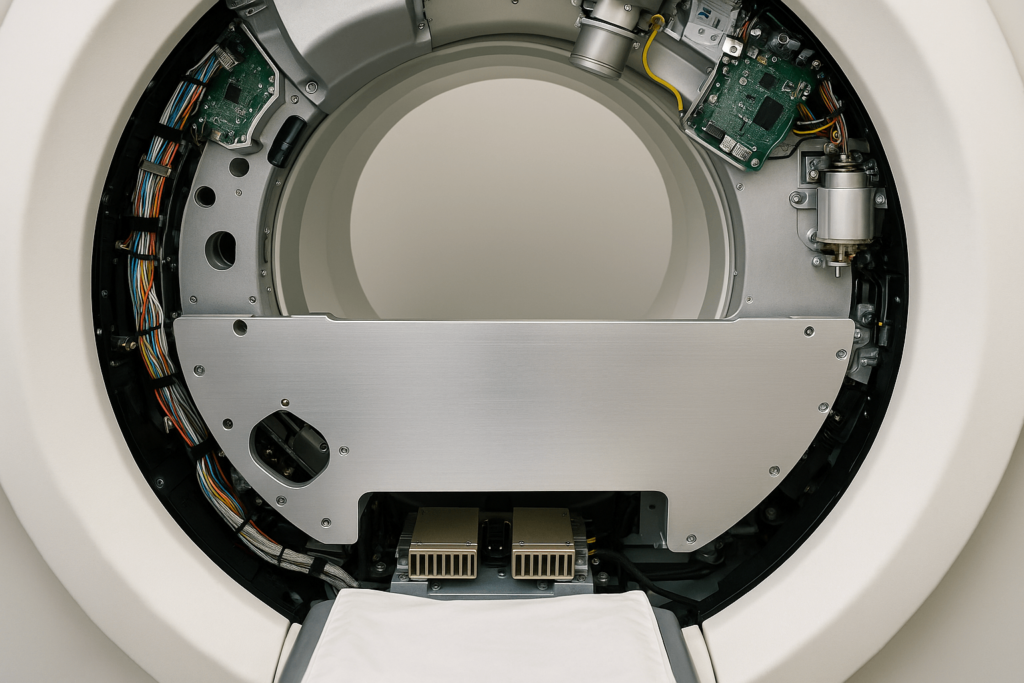

Case Study: Medical Equipment — When Precision is Patient-Critical

In another scenario, a manufacturer of diagnostic imaging equipment needed ultra-flat, vibration-resistant mounting plates to secure sensitive optical components. These parts required flatness within ±0.1mm and the ability to resist slight deflection during operation.

Rather than relying on traditional press-formed sheet metal, we produced CNC-machined aluminum plates from 6061-T6 billet, which were stress-relieved post-machining and verified using CMM (Coordinate Measuring Machine) analysis.

Not only did the components meet geometric specifications, but the customer also experienced a 12% reduction in calibration drift over six months of use. This translated to fewer recalibrations, greater uptime, and higher end-user satisfaction.

This case reinforces that precision machining and material selection go hand-in-hand in regulated industries like healthcare and aerospace.

Case Study: Energy Storage — Supporting Thermal Stability

A fast-growing startup in the energy storage space came to us with a need for lightweight plates that could double as thermal spreaders within lithium-ion battery packs. The original design used copper for its excellent conductivity, but cost and weight were concerns.

We recommended a hybrid solution: anodized 6061 aluminum plates, optimized in thickness and contact surface area to meet thermal requirements while cutting total part weight by 58% and raw material costs by 43%.

In field testing, the new plates kept battery temperatures within optimal operating range even under rapid discharge conditions. This not only ensured system stability but also extended battery lifespan by 18%, adding real end-user value.

Why These Stories Matter

Case studies like these demonstrate that success in mounting plate design isn’t just about cutting material or machining a shape. It’s about understanding the end-use environment, collaborating with engineering teams, and optimizing every decision—geometry, material, surface finish—for performance, cost, and longevity.

They also validate that your supplier isn’t experimenting with your product—they’ve done it before, across applications that demand durability, precision, and thermal control.

When your product is on the line, there’s no substitute for proven, field-tested expertise. A supplier who can deliver measurable results across sectors is the one who can scale with your ambitions. Whether you’re designing corrosion-resistant aluminum plates for outdoor devices or lightweight thermal interfaces for battery applications, the right supplier ensures performance meets environment.

Final Act: Selecting the Right Supplier Isn’t a Line Item—It’s a Strategic Decision

By now, it’s clear: your mounting plate supplier is not just a vendor—they’re an extension of your design, engineering, and manufacturing capabilities. The decision to select a partner for custom aluminum mounting plates should follow the same rigorous standards as choosing a subcontractor for critical components.

Five Non-Negotiables in a Strategic Supplier

- Proven Expertise in Aluminum Fabrication: Look for deep, demonstrated experience in CNC machining, bending, forming, and finishing aluminum—especially alloys like 6061-T6 and 5052-H32. Check if the supplier offers guidance beyond production.

- In-House Design & DFM Capabilities: The best suppliers act as co-engineers, offering DFM services that optimize your design for cost, strength, and manufacturability.

- Material Traceability & Certification: Especially if you operate in automotive, aerospace, or medical sectors, ensure the supplier can provide ISO 9001 compliance, RoHS documentation, and full traceability of raw materials.

- Repeatable Quality Systems: Ask about their quality control procedures—do they conduct 100% inspections? Use CMMs? Apply Six Sigma or lean principles? Consistency is king.

- Flexibility for Volume & Customization: Can they support both prototyping and full-scale production? Are they willing to accommodate custom packaging, surface treatments, or integrated assemblies?

A supplier who meets these five pillars isn’t just meeting your needs—they’re minimizing your risk.

A Checklist to Benchmark Your Next RFQ

Before issuing your next Request for Quotation, benchmark potential suppliers using these strategic criteria:

- Can they match tolerances within ±0.1mm or better for CNC work?

- Are they comfortable switching between 6061 and 5052 depending on form vs. strength requirements?

- Do they proactively suggest DFM improvements before quoting?

- Can they scale from 100 units to 10,000 with no tooling bottlenecks?

- Do they have real examples of aluminum projects in your industry?

If the answer is “no” to any of the above, you’re not just comparing quotes—you’re comparing risk profiles.

Why It Matters for You

As a procurement or project manager, your role isn’t just to find the lowest cost—it’s to ensure sustained product quality, protect margins, and eliminate supply chain volatility. Choosing a supplier with end-to-end aluminum fabrication expertise isn’t a premium expense—it’s strategic risk mitigation.

The best decisions leave nothing to chance. A well-vetted, technically proficient partner doesn’t just supply a plate—they help you launch faster, scale smarter, and sleep better at night.

Looking for a reliable CNC aluminum plate supplier that understands your market, your volumes, and your tolerances? Start a conversation with a manufacturer that treats your custom plate like a mission-critical component.

Final Word: The Quiet Backbone of Product Excellence

The custom aluminum mounting plate may not get headlines in your product brochure, but it’s the hidden backbone of your assembly—impacting thermal performance, structural rigidity, and reliability.

Don’t let this critical detail become an afterthought. Choose a partner who understands that the quietest part in your product deserves the loudest commitment to quality.

If your current supplier treats mounting plates like an afterthought, it may be time to upgrade to one who treats them like a cornerstone.

Frequently Asked Questions (FAQ)

Q1: What’s the best aluminum alloy for mounting plates in outdoor environments?

A1: 5052-H32 aluminum is often preferred for outdoor use due to its excellent corrosion resistance and formability.

Q2: How tight can tolerances get with CNC-machined aluminum plates?

A2: Tolerances as tight as ±0.05mm or even ±0.01mm are achievable depending on design and application.

Q3: Is DFM really necessary for simple aluminum parts?

A3: Yes, even “simple” parts can benefit significantly from DFM, with potential cost reductions of 10–30% through design adjustments.

Q4: Can I order low-volume prototypes before committing to full production?

A4: Many suppliers, including us, offer low MOQ and prototype runs before scaling.

Q5: Does anodizing aluminum reduce conductivity?

A5: Yes, anodizing creates an insulating oxide layer. If conductivity is critical, selective masking or post-processing is recommended.