In global B2B metal sourcing, understanding how materials behave under stress isn’t just technical trivia—it’s central to quality control, manufacturing precision, and long-term reliability. For overseas wholesalers, supply chain engineers, and metal buyers, choosing between ductile and malleable materials can affect cost, structural integrity, and performance.

Ductility and malleability are often misunderstood as interchangeable. Yet, each plays a unique role in metal forming. This article provides a complete guide for technical professionals, buyers, and fabricators. You’ll discover the key difference between ductility vs malleability, practical testing methods, material structures, and engineering trade-offs, with examples from automotive, infrastructure, electronics, and jewelry industries.

Section 1: The 60-Second Answer (Engineers Need Speed, Not Fluff)

- Ductility is a metal’s ability to withstand tensile stress (pulling), allowing it to stretch or be drawn into wire.

- Malleability is a metal’s ability to withstand compressive stress (pushing), allowing it to be rolled or hammered into thin sheets.

- Quick Visual: Think of stretching mozzarella—ductile. Flattening dough—malleable.

- Procurement Tip: Lead is a perfect example—very malleable but not ductile. It rolls easily but breaks when pulled.

Section 2: From Confusion to Clarity – Why Not All Metals Behave the Same

Why are some metals bendable yet difficult to stretch? The explanation lies in two essential factors: crystal structure and bond strength.

- Slip Systems (Structure): FCC structures, like copper or gold, possess 12 easily activated slip systems that make them excellent candidates for both ductile and malleable applications.

- Bond Strength (Integrity): Metals like lead have weak atomic bonds. Even if the structure allows deformation, the bonds may fail under tension before any elongation occurs.

Section 3: Atomic Structure—The Blueprint Behind Every Forming Decision

Why Metals Flex and Ceramics Fracture

Metals are held together by electron sea bonds. This fluid-like electron arrangement enables layers of atoms to shift when force is applied, maintaining cohesion. In contrast, ceramics have rigid ionic or covalent bonds, making them brittle.

How Crystal Geometry Shapes Formability

- FCC Metals (e.g., aluminum, copper): Densely packed, providing 12 slip systems—ideal for stamping and wire drawing.

- BCC Metals (e.g., steel): Less dense, with more complex slip activation. Often require heating to deform.

- HCP Metals (e.g., magnesium): Limited slip systems—more difficult to form without specialized methods.

Section 4: From Spec Sheets to Shop Floor—Measuring Metal Performance

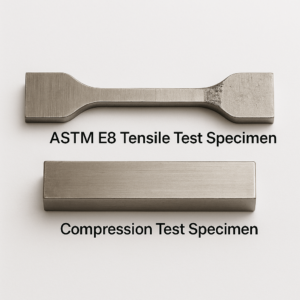

Ductility Tests (Tensile)

Standard tensile testing, such as ASTM E8, helps assess ductility through:

- Percent Elongation: Measures stretch before break.

- Reduction of Area: Measures local necking at the point of fracture.

Malleability Tests (Compression)

Compression tests evaluate how a metal behaves under pressure, revealing suitability for forming processes like rolling or stamping.

Four Ways to Control Ductility or Malleability

- Hot vs. Cold Working: Above recrystallization temperature = more ductility. Cold working = stronger but less formable.

- Work Hardening: Cold working increases dislocations, improving strength but reducing formability.

- Alloying: Adding elements (e.g., carbon in steel) can enhance strength while reducing ductility.

- Grain Refinement: Smaller grain size improves yield strength through boundary obstruction.

Section 5: The Strength-Ductility Trade-Off: No Free Lunch in Engineering

Engineering decisions often require compromise. Generally, increasing strength leads to reduced ductility.

- Cutting Tools: Demand hardness. Ductility is less important.

- Crash Frames: Require high ductility to absorb energy on impact.

- Structural Beams: Need a balance—strong enough to bear load, but ductile enough to bend before failure.

These trade-offs require strategic material selection based on application, safety, and cost.

Section 6: Real Use Cases—When Ductility or Malleability Makes or Breaks the Part

Rebar in Earthquake Zones

- Need: Controlled deformation under seismic stress

- Solution: High-ductility rebar with elongation >14.5%

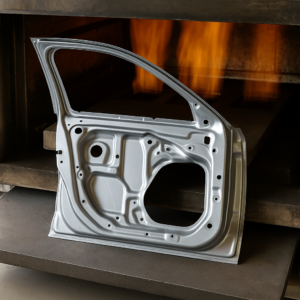

Aluminum Panels in Cars

- Challenge: Risk of cracking during cold forming

- Solution: Warm forming processes increase malleability and reduce spring-back

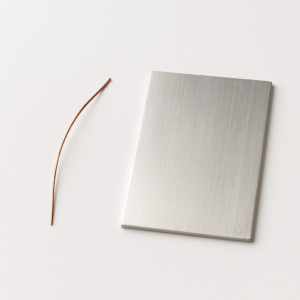

Ultra-Thin Copper Wire

- Need: Continuous reduction in wire diameter without breaking

- Solution: High-purity copper (≥99.9%) with excellent ductility for drawing

Durable Jewelry Alloys

- Need: Intricate forming + resistance to wear

- Solution: Gold alloys (e.g., gold-copper) combine formability with improved hardness

Section 7: What It Means for B2B Metal Buyers

Understanding ductility vs. malleability directly influences sourcing success:

- Buying sheet metal enclosures? Focus on malleability.

- Sourcing fine-gauge wires? Look for high ductility.

- Needing precision-formed structural parts? Seek a tailored balance.

At YISHANG, we support global B2B customers with practical, formability-driven solutions. With 26+ years of manufacturing experience, we offer OEM & ODM custom fabrication—ranging from CNC machining and laser cutting to forming and finishing.

✅ Need expert advice on material selection or part optimization?

YISHANG offers 1-on-1 engineer consultations and fast custom prototyping.

📩 Get a quote now or 📞 call our team directly.

FAQ

Q1: Can a metal be both ductile and malleable?

Yes. Metals like gold, aluminum, and copper are excellent examples of materials that are both highly ductile and malleable.

Q2: What is the best test to compare ductility between metals?

ASTM E8 tensile testing is widely used to measure and compare the ductility of metallic materials.

Q3: Which metal is the most ductile?

Gold is considered the most ductile metal—it can be drawn into extremely thin wire without breaking.

Q4: What’s the difference between tensile and compressive strength?

Tensile strength measures resistance to being pulled apart. Compressive strength measures resistance to being pushed or squashed.

Q5: Why does understanding these properties matter to procurement teams?

Because choosing the wrong type of metal for your forming process (e.g., deep drawing vs stamping) can cause cracking, breakage, or high scrap rates.