What Are Electromechanical Assemblies—In Practical Terms?

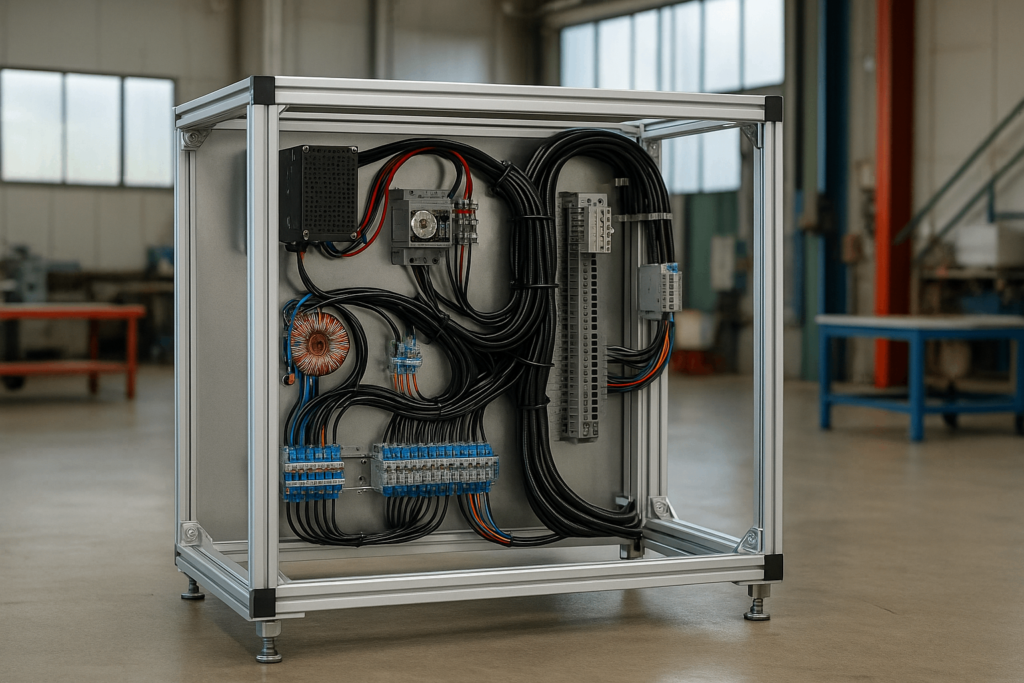

Electromechanical assemblies (EMAs) are where mechanics meet electronics—wiring, brackets, PCBs, enclosures, and control logic come together in one integrated unit.

But for global procurement managers, the question isn’t just “what is it”—it’s “can it be delivered repeatably, traceably, and at scale?”

Structured Systems, Not Just Parts

Modern EMAs involve structured integrations of mechanical sub-assemblies, control circuitry, and engineered housings—assembled with production consistency in mind.

For B2B buyers, this means aligning with a system-oriented electromechanical assembly manufacturer—not just a metal shop or wiring vendor.

What Technical Buyers Are Actually Evaluating

When procurement leads evaluate a mechanical assembly service, they’re asking questions that go far beyond the BOM:

✅ Are FAIR or PPAP protocols followed for sample approval?

✅ Can electrical continuity, torque settings, and insulation be verified?

✅ How is traceability maintained across production runs?

✅ Will late-stage design changes delay production?

These define supplier readiness, not just capability.

If your product is destined for critical infrastructure, EV integration, or smart-grid control, your supplier must act as an engineering ally—not just a builder.

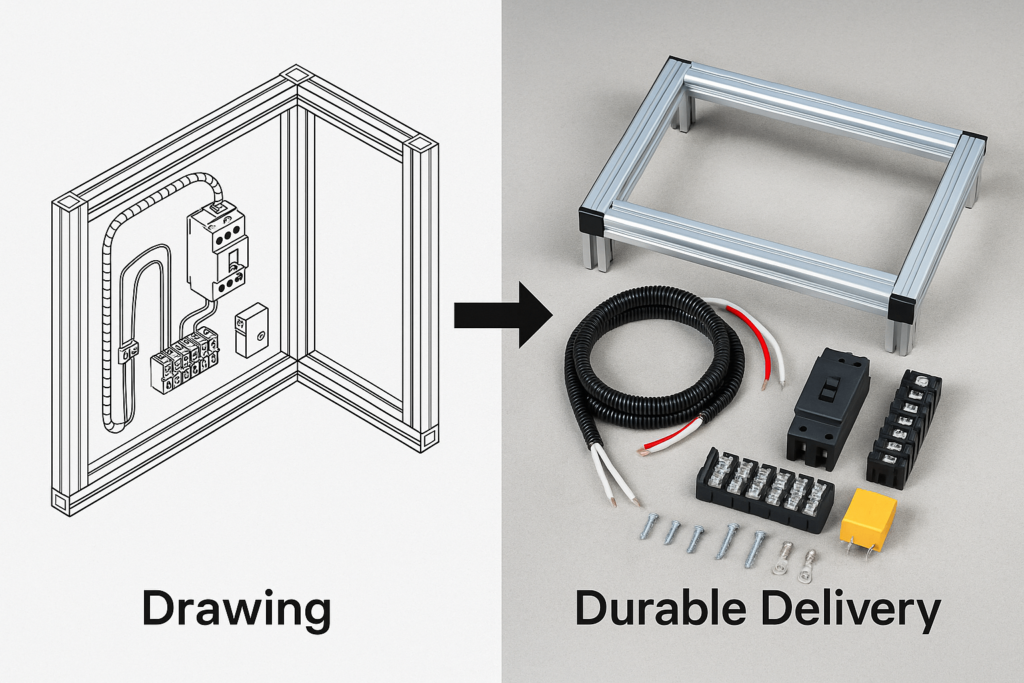

Procurement Realities: From Drawing to Durable Delivery

Electromechanical assemblies often begin with incomplete specs. YISHANG collaborates with engineers to:

Translate sketches into production-ready DFM files

Optimize connector layout, harness routing, and heat shielding

Suggest substitutions based on lead time or certification match

We handle volume planning with consistency:

| Quantity | Lead Time (Est.) | QC Coverage |

|---|---|---|

| 50–200 | 15–20 days | 100% electrical + visual test |

| 500–1000 | 25–30 days | Lot-sample testing + doc pack |

By coordinating directly with vetted component suppliers, we ensure stable timelines—even across international builds.

Use Case Snapshot: Industrial Performance Under Real Load

A client in Spain needed solar inverter control panels built to withstand:

High ambient temperatures (+55°C)

Dust ingress (IP65 enclosure)

Surge conditions at 1500V

Our solution:

Powder-coated steel chassis with gasket seal

3-layer cable harness, insulation tested at 2kV

Labeled terminals, routed per CE guidelines

Why it worked: We aligned mechanical parts assembly with electrical spec from day one—avoiding downstream rework.

Other examples include:

Modular electrical box builds for U.S. EV fleets

Custom bracket + sensor assemblies in German HVAC retrofits

Welded frames for energy storage units in the Middle East

Traceability & Documentation: What Your Quality Team Needs to See

Why does traceability matter in contract assembly services? Because your downstream compliance depends on upstream accountability.

Our clients routinely request traceable outputs, especially for:

ISO 9001 audit trails (YISHANG is ISO 9001-certified since 2012)

HIPOT, continuity, and torque test records

Visual inspection reports per production lot

Full-Chain Documentation with ERP Integration

Each electro mechanical assembly is tracked via our ERP platform, linking:

Operator identity and timestamp

Component source + batch ID

Process checklist sign-offs and non-conformance logs

This traceability structure is aligned with IPC/WHMA-A-620 Class 2 cable assembly guidelines and is fully auditable.

Result: Your QA and compliance teams receive a ready-to-submit documentation bundle—without chasing loose PDFs or emails.

Design Gaps in Off-the-Shelf Parts—and How to Close Them

Common Misalignments Procurement Teams Face

Even well-documented BOMs can fail in real-world integration when assumptions like these are made:

One-size-fits-all connectors across different panel sizes

Generic enclosure cutouts for tightly packed builds

Cable exit points ignoring thermal/vibration conditions

YISHANG’s Engineering Support for Customization

As part of our OEM electromechanical integration service, we:

Offer mechanical sub-assembly revisions tailored to housing type

Customize layouts per IEC 60204 or NEMA panel design standards

Recommend insulation/EMI strategies during early-stage review

These changes are logged in both your drawing set and production checklist, so compliance doesn’t fall through the cracks.

Why it matters: Redesigns at the fabrication assembly stage cost less and validate faster than late-stage fixes.

How We Align With Modern Manufacturing Demands

Electromechanical assemblies aren’t just hardware—they’re building blocks of automation, IoT, and electrification.

Our solutions cover:

OEM control box builds with field-serviceable modules

Wire harnesses with built-in test points

Preassembled, labeled components ready for drop-in

Industry trend: The global electro-mechanical assembly market is expected to exceed $2 trillion by 2027. Buyers need scalable partners who can fabricate, integrate, and test.

We’ve delivered:

Smart grid cabinets for Nordic automation firms

EV charge station controllers for U.S. infrastructure

Remote-sensing panels for Asian agricultural tech

Choosing the Right Partner (Not Just the Cheapest Vendor)

Electromechanical assembly isn’t low-value outsourcing. Choosing wrong delays projects, triggers returns, and invites certification failure.

Look for:

⚙️ Multi-discipline DFM support

📦 Electrical + mechanical BOM integration

📊 Documentation readiness for audits or field compliance

YISHANG’s contract assembly services are built to match tight regulatory timelines and application-specific tolerances. We deliver DFM alignment, traceable documentation, and scalable integration—from prototypes to full-volume shipments.

Final Takeaway: Supply Chain Stability Starts Here

CNC machining enables sourcing teams to bridge fast design iteration with certified production. Its key value lies in precision with flexibility—keeping costs stable while supporting customization, traceability, and export readiness.

Submit your RFQ to receive a tailored CNC solution within 48 hours.