Mastering the Systemic Approach to High-Performance EV Transmission Gears

The automotive industry is undergoing a profound transformation, driven by the global shift to electric vehicles (EVs). This evolution is redefining performance, and at its heart is the challenge of silence.

The absence of a loud internal combustion engine has unmasked a new engineering imperative: managing the subtle, high-frequency sounds of the drivetrain. The faint gear whine, once imperceptible, is now a critical factor in brand perception and passenger comfort.

For procurement managers and engineers sourcing critical drivetrain components, this shift presents a new set of non-negotiable requirements. EV drivetrains subject gears to instantaneous torque, extremely high rotational speeds, and reversed loading during regenerative braking.

These punishing conditions mean that manufacturing a gear for an EV is not an isolated task; it demands a holistic, system engineering approach from a manufacturing partner. This guide provides a look “under the hood” at the capabilities required to be a trusted supplier in the demanding world of modern gear manufacturing and CNC machined gear production.

Foundational Decisions: Material and Thermal Processing Control

The reliability of a gear is largely determined long before the first chip is cut. The foundational choices of material and heat treatment are strategic decisions that dictate the entire manufacturing process, cost, and the final component’s ability to perform.

For a procurement partner, understanding a supplier’s expertise in this “genetic engineering” phase is the first step in assessing their true capability and mitigating supply chain risk.

The Art of Material Selection: Balancing Performance and Cost

The selection of a gear material is a calculated balance of mechanical properties, weight, and cost-effectiveness. A supplier’s material expertise directly impacts the final product’s viability.

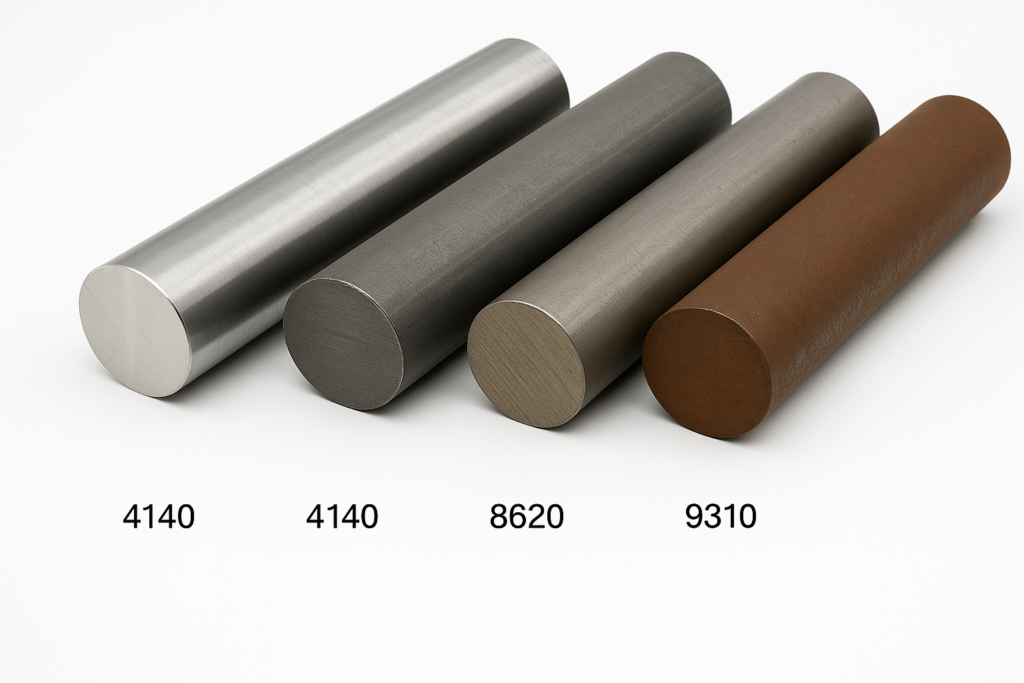

High-performance gear steels are the cornerstone of high-load applications. At YISHANG, we work with a range of specialized alloys suitable for custom metal gear manufacturing and low-noise transmission gears:

- 4140 Alloy Steel: A versatile through-hardening alloy offering an excellent balance of strength (up to 900 MPa) and toughness, representing a robust and cost-effective solution.

- 8620 Carburizing Steel: This low-carbon alloy is designed for case hardening, creating an extremely hard, wear-resistant surface while the core remains tough to absorb shock loads.

- 9310 Alloy Steel: A premium carburizing steel with higher nickel content, 9310 offers superior core strength and fatigue resistance, essential for safety-critical EV transmissions.

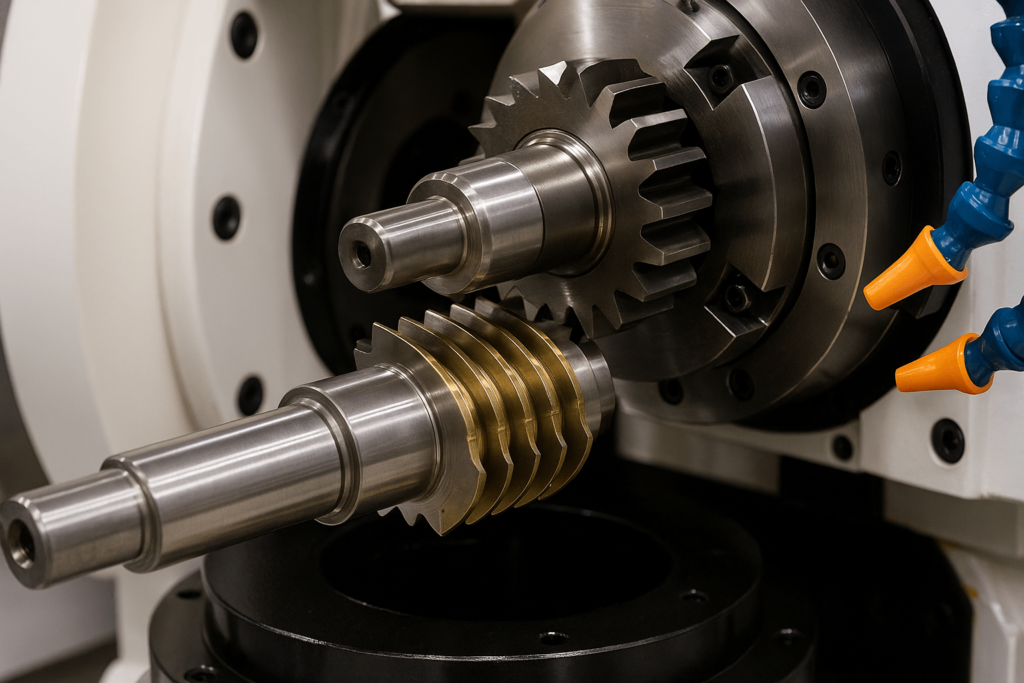

Beyond steel, we have experience with different kinds of gears made from alternative materials. For specific applications like worm gears, a bronze gear may be specified for its low-friction properties. In other cases, PEEK (Polyether Ether Ketone), a high-performance thermoplastic, offers a superior strength-to-weight ratio and noise-damping characteristics, making it ideal for metal replacement in non-critical drivetrain components.

The Strategic Choice of Heat Treatment: A Key Cost and Quality Driver

The gear heat treatment process is what transforms a machined part into a durable component. The choice of method has significant downstream consequences on the entire production line.

- Carburizing vs. Nitriding: This is a critical strategic decision. Carburizing is a high-temperature process that creates a deep, robust case (up to 7.6 mm), essential for withstanding immense torque. However, it inevitably causes gear distortion, which must be corrected by precision grinding. A capable supplier must have integrated grinding capacity to manage this reality.

- Nitriding, conversely, is a lower-temperature process (around 500°C) that induces minimal distortion. For high-precision gears where maintaining dimensional stability is the top priority, nitriding can reduce or eliminate post-treatment grinding, directly impacting the total cost of production.

- Induction Hardening: This technique offers a fast, clean, and repeatable process for locally hardening specific areas, such as the teeth on an integrated shaft-gear, providing flexibility in design and production.

The decision between these methods is a clear indicator of a manufacturer’s process maturity. It’s not about which is “best,” but which integrated process chain delivers the required performance, quality, and cost-effectiveness.

The Birth of the Tooth Form: A Strategic Comparison of Core Cutting Processes

Once the material is prepared, the heart of the gear cutting process begins. For a procurement professional, understanding a supplier’s capabilities across the dominant CNC techniques is key to assessing their flexibility for your product portfolio.

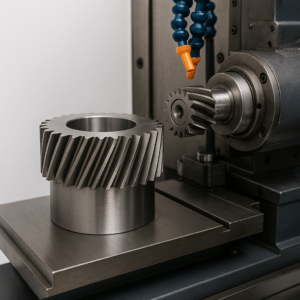

Gear Hobbing: The Engine of Efficiency

The gear hobbing process is the workhorse of high-volume gear production, prized for its speed and cost-effectiveness. Using a continuous cutting action, a CNC hobbing machine can produce vast quantities of high-quality spur and helical gears, making it the backbone of the automotive supply chain where cost-per-part and cycle time are critical metrics.

However, a capable partner must also understand its limitations. Hobbing cannot produce internal gears or cut teeth adjacent to a shoulder, which are common features in the different gear types found in modern EV transmissions.

Gear Shaping: The Master of Versatility and Complexity

Where hobbing’s capabilities end, the gear shaping process begins. It employs a reciprocating cutter that, while slower than hobbing, offers unmatched versatility for advanced applications.

Its strategic value lies in its ability to machine internal gears, the essential ring gears in the planetary systems that give EV transmissions their high torque density. A supplier without robust gear shaping capabilities cannot produce the full range of components required for today’s advanced drivetrains.

Gear Milling (Gashing): The Flexible Problem-Solver

Gear milling, or gashing, uses a form cutter on a standard CNC milling machine. While less common for mass production, it is a vital strategic option for prototyping, low-volume runs, or producing extremely large-diameter gears. Its flexibility extends to complex geometries, including bevel gear production.

Beyond economics, milling offers a distinct engineering advantage. For pinions with a low number of teeth, milling can produce a stronger tooth root profile than hobbing, mitigating a potential point of failure. This demonstrates how an alternative method can yield a more reliable part for precision gear manufacturing.

| Process Selection Matrix for Procurement | Gear Hobbing | Gear Shaping | Gear Milling (Gashing) |

|---|---|---|---|

| Key Capability | High-Speed External Gears | Internal & Shouldered Gears | Prototypes, Large & Bevel Gears |

| Production Speed | Very High | Moderate | Low to Moderate |

| Ideal Application | Mass Production (Automotive) | EV Planetary Gear Sets | Prototyping, Low Volume, Specialty |

| Strategic Value | Cost & Efficiency Leader | Complex Geometry Enabler | Versatility & Niche Strength |

The Pursuit of Silence: From “Perfect” Geometry to “Optimal” Performance

For a modern EV, a gear that is simply “cut” is not finished. The true measure of performance lies in precision gear finishing, a non-negotiable step to achieve the accuracy and surface quality required for gear noise reduction. This is a key differentiator for a top-tier supplier.

The Paradox of Gear Tooth Profile Modification

A paradox lies at the heart of high-performance gear design: a theoretically perfect gear is often not the best-performing gear. Under load, gear teeth bend and housings distort, causing stress to concentrate at the edges of the teeth, leading to noise and premature wear. This is known as Transmission Error (TE).

Expert manufacturers employ gear tooth profile modification to solve this. This involves intentionally introducing minute, precisely calculated deviations from the perfect involute shape to compensate for distortions that occur under load.

- Crowning: Applies a barely perceptible convex curve along the tooth face, ensuring contact remains in the central, strongest region even when the tooth bends.

- Tip Relief: Removes a microscopic amount of material from the tooth tip, allowing for smoother engagement and reducing the impact and vibration that generate noise.

Precision Grinding: Ensuring Final Dimensional Accuracy

The gear grinding process is the primary method for achieving the final, ultra-precise tooth geometry. It uses an abrasive wheel to correct the distortions caused by heat treatment and produce an exceptionally smooth surface finish.

This process can elevate a gear’s quality to AGMA Class 11 or higher, a critical requirement for quiet EV operation. The choice between form grinding (fast, for simple profiles) and generating grinding (slower, but more accurate and versatile) depends on the specific tolerance and complexity requirements of the component.

The Final Verdict: Defining and Verifying Precision with Data

For any procurement professional, the most critical question is: “How do you prove the quality of your parts?” A trustworthy supplier like YISHANG must have a robust and transparent inspection process.

- AGMA and ISO Standards: We adhere to internationally recognized AGMA and ISO classification systems that quantify tolerances for profile, helix, and pitch. This establishes a shared language for defining gear quality.

- Metrology in Action: To verify these tolerances, we utilize advanced equipment. A CMM (Coordinate Measuring Machine) uses a high-precision probe to trace the tooth surface and compare it to the digital model, quantifying every geometric error. Functional gear roll testing meshes the finished gear with a master gear to measure composite deviation, providing a holistic assessment of its running smoothness and identifying potential noise sources before the part ever leaves our factory.

The Future of Gear Manufacturing: A Partner for Tomorrow’s Challenges

A strategic manufacturing partner must not only master today’s technologies but also be prepared for the challenges of tomorrow.

Industry 4.0: The Smart Gear Factory

The principles of Industry 4.0 are transforming production. Predictive maintenance is becoming a reality through advanced sensors that monitor vibration and temperature in real-time. Furthermore, digital twin technology allows us to create virtual replicas of gear systems, enabling performance simulation that drastically reduces development time and cost for new programs.

Additive Manufacturing: Potential and Present Reality

Additive manufacturing for gears, or 3D printing, holds immense promise for rapid prototyping and creating complex geometries. However, we are also realistic about its current limitations. For high-load production gears, the material properties and surface finish of 3D-printed metal often fall short of the standards achieved through forging and machining.

Advanced Surface Coatings: The “Super Armor” for Gears

For applications that push materials to their limits, advanced surface coatings provide a critical performance advantage. DLC (Diamond-Like Carbon) coating is a prime example. Applied via PVD (Physical Vapor Deposition), these coatings form an extremely hard, low-friction layer on the tooth surface, dramatically improving wear resistance and performance in extreme environments.

Conclusion: A Systemic Victory in Precision Gear Manufacturing

The journey from a raw metal alloy to a silent, high-performance EV gear is a testament to the power of a holistic, systems-based approach. For procurement professionals, selecting a supplier is no longer about the lowest price for a single operation. It is about choosing a partner with demonstrated expertise and process control over the entire manufacturing ecosystem.

At YISHANG, we’ve built our CNC machining and sheet metal capabilities around this systemic approach—from material science and heat treatment to precision cutting, advanced finishing, and rigorous, data-driven quality verification.

To discuss your specific component needs and learn how YISHANG’s gear machining expertise can support your supply chain, contact our engineering team today.

High-Value FAQ for Procurement and Engineering Professionals

Why is gear noise a more significant issue in electric vehicles?

In a traditional vehicle, engine noise masks the higher-frequency whine from the transmission. EVs are nearly silent, making the drivetrain the most prominent source of sound. This means even minor gear noise becomes highly noticeable and can negatively impact the perception of quality.

What is the difference between gear hobbing and shaping for my project?

The choice depends on geometry and volume. Gear hobbing is extremely fast and ideal for high-volume external gears where cost-per-part is a key driver.

Gear shaping is slower but more versatile, and is necessary for producing the internal gears essential for planetary gear sets or gears located close to a shoulder.

What is gear tooth modification, and why is it critical for reliability?

It is the intentional, precisely calculated deviation from a perfect tooth profile. It is critical because under load, teeth bend. Modifications like crowning and tip relief compensate for this, ensuring smooth contact across the center of the tooth, which reduces noise and improves long-term durability.

What is the practical difference between an AGMA 8 and an AGMA 13 quality gear?

The AGMA quality number is a standardized measure of geometric precision. An AGMA 13 gear has significantly tighter tolerances for tooth profile, spacing, and runout than an AGMA 8 gear. For a high-performance EV transmission, this higher precision results in smoother meshing, lower noise, and a more reliable operational life.

Can 3D printing replace CNC machining for high-strength gears?

At present, no. While 3D printing is revolutionary for prototyping, it cannot yet replace traditional CNC machining for high-strength applications. Forged and machined steel offers superior fatigue strength and material integrity. For any application requiring high reliability, CNC machining remains the definitive manufacturing process.