In a fast‑moving global supply chain environment, speed has become the new currency. Yet, while today’s digital tools allow engineers to design a complex assembly in hours, obtaining an accurate precision sheet metal fabrication or CNC machining quote often takes days. For sourcing managers handling wholesale and custom production, this delay isn’t just inconvenient—it stalls approvals, delays tooling, and increases landed cost exposure.

Why is pricing still slow when manufacturing automation is faster than ever? The root problem lies in the “information entropy” trapped inside many RFQs (Request for Quotes). Ambiguity forces estimators to pause, email questions, and add risk premiums.

Whether the estimator is a 26‑year veteran at YISHANG, a CNC programmer on the night shift, or a cloud‑based quoting engine assisted by AI, the logic is the same: quotes are calculated, not guessed. When data is missing or unclear, the quote enters a high‑risk queue.

This guide breaks down the physics, workflow logic, and decision economics of quoting, then shows how to engineer your RFQ so it moves through the estimator’s process faster. By mastering six strategic tips, you reduce RFQ back‑and‑forth, accelerate production approvals, and position your company for more competitive bulk pricing from overseas metal fabrication suppliers.

What Is a Metal Fabrication RFQ and Why It Affects Quote Speed

A metal fabrication RFQ (Request for Quote) is the bundle of drawings, files, specs, finishes, Incoterms, and volume information you send to a factory for pricing. You get a faster quote when your RFQ includes complete CAD data, realistic tolerances, clear finish standards, commercial terms, and order volumes—organized so the estimator can understand everything in one look.

Who This Guide Is For

If you are:

- An overseas wholesale buyer working with OEM / ODM metal factories in China

- A procurement or sourcing manager responsible for metal parts, metal cabinets, metal display racks, or welded frames

- A project engineer preparing drawings for sheet metal fabrication or precision machining

- A supply chain manager comparing quotes from different custom metal fabrication manufacturers

…this article is written for you.

The examples below are based on real‑world projects that YISHANG handles daily: sheet metal enclosures, brackets, welded frames, vending machine parts, storage energy cabinets, automotive hardware, medical device components, and other customized metal products produced in volume for export.

Almost every tip can be applied directly to your next RFQ for custom metal parts—whether you need laser‑cut, bent, welded, CNC‑machined, or fully assembled products.

Hack #1: Optimize Data Fidelity (The “Digital Twin” Strategy)

Before anyone reads your blueprint, software reads your file. Modern CAM engines calculate surface area, tool paths, material volume, and cutting time automatically—but only if your CAD data communicates correctly.

Poor data fidelity is one of the biggest hidden reasons why a sheet metal fabrication quote or CNC machining quotation gets delayed or comes back with a risk premium.

CNC Machining: STEP vs. STL

A recurring RFQ bottleneck is the use of STL files for machining quotes. STL is ideal for 3D printing but harmful for subtractive manufacturing quoting.

- STL mesh data represents geometry as thousands of triangles. CAM software cannot identify drillable holes, threads, or precise radii. It forces manual reconstruction or feature recognition.

- STEP / B‑Rep data recognizes “12x M6 holes,” pockets, bosses, and faces and supports Model‑Based Definition. Estimators at YISHANG can instantly evaluate cycle time, machining strategy, and tolerance‑critical areas.

If the supplier has to remodel or repair your file before they can even start estimating, your CNC machining quote automatically moves to the slow lane.

🔹 Procurement Tip: Always send STEP (.stp / .step) files for machining RFQs instead of STL. If possible, include a neutral PDF or 2D drawing for dimensions and notes. This accelerates analysis, eliminates rework, and reduces misunderstandings.

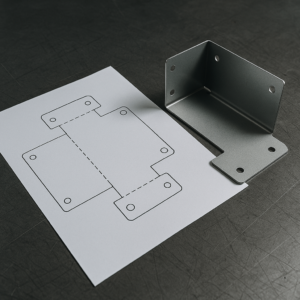

Sheet Metal Needs Both 3D and Flat Pattern

Sheet metal bending introduces deformation variables. If only a folded 3D file is sent, the estimator must unfold it manually to calculate blank size, material usage, and nesting.

To accelerate sheet metal manufacturing quotes:

✔ Submit a 3D STEP file

+

✔ A 1:1 DXF flat pattern with clean cut layers and no overlapping geometry.

This allows instant nesting, material utilization calculation, and laser‑cutting readiness. Your RFQ can move directly into a costed routing instead of sitting in a “to‑repair” folder.

Avoid Fully Modeled Threads

Modeled threads create heavy files, slow software, and mislead automated quoting logic. The visual detail is not needed for a fast, accurate price.

✔ Use cosmetic threads in the model

✔ Define actual thread specs in the 2D drawing or PDF (e.g., “M6 x 1, through, 2x both sides”).

This preserves accuracy while keeping your file light and readable. It also reduces the chance that a non‑critical aesthetic detail is misinterpreted as a functional requirement.

Hack #2: Master Tolerance Economics (The Cost‑Precision Curve)

Once geometry is known, tolerances drive cost. Procurement managers can dramatically influence lead time and price by understanding how tolerances behave in real workshops.

Many RFQs specify “tight everywhere” tolerances, not because the part needs it, but because the drawing template was never updated. This is one of the most common killers of a fast precision machining quote.

The ±0.01 mm “Cost Cliff”

Machining precision cost growth is exponential—not linear.

- ±0.1 mm: Standard machine capability on modern CNC equipment.

- ±0.05 mm: Requires slower feed rates, extra passes, more tool wear, and sometimes special tools.

- < ±0.01 mm: May require climate‑controlled rooms, custom fixturing, and full CMM inspection with documented reports.

Tight tolerances on non‑functional features trigger senior review delays and higher risk premiums. An estimator will ask:

“If everything is ±0.01 mm, what happens if it’s ±0.03 mm? Is this really necessary?”

✔ Ask engineering to loosen tolerances where possible, especially on cosmetic or non‑mating surfaces.

✔ Add a global note such as: “Unless otherwise specified, tolerances per ISO 2768‑m.”

This gives manufacturers freedom to optimize the production process while still protecting function.

Use GD&T as a Cost Optimization Tool

GD&T (Geometric Dimensioning and Tolerancing) isn’t just for strict control—it can make tolerance zones larger and more efficient.

Example:

- A ±0.1 mm coordinate tolerance on X and Y creates a square zone.

- A true position Ø0.28 mm creates a circular zone that is 57% larger, giving more room for process variation while still protecting fit.

Even better, MMC (Maximum Material Condition) allows “bonus tolerance” when parts come in slightly smaller or lighter than the worst‑case. This makes parts easier to produce, measure, and accept.

Shops like YISHANG work with international standards (ISO, DIN, ASME) every day. When your RFQ for metal parts uses clear GD&T with sensible defaults, it signals that you understand manufacturing reality—quotes become faster and more competitive.

Hack #3: Align with Global Supply Chain Physics

Quotes stall when designs do not align with available raw material standards. The part might be perfectly engineered but poorly adapted to the material ecosystem in China or your chosen manufacturing region.

Designing with globally common stock sizes is one of the simplest ways to speed up a metal fabrication quote from China.

Machining: Raw Stock Size Logic

Example problem: designing a Ø25.5 mm shaft.

China / EU standard precision rod sizes might be Ø25 mm, Ø30 mm.

This forces the supplier to:

- Purchase a larger bar

- Remove more material

- Increase cycle time and tool wear

All of that leads to higher cost and slower quotation, because the estimator must recalculate material utilization and possibly change suppliers.

✔ If functionally acceptable, design around Ø25 mm instead of 25.5 mm. Small changes like this can reduce material cost, machining time, and scrap rate—all of which show up as a better unit price in your quote.

Sheet Metal Gauge Confusion

“Gauge” varies by material and region. 16 GA steel ≠ 16 GA aluminum, and different suppliers may interpret gauge tables differently.

For an international RFQ, gauge language can create confusion and email ping‑pong.

✔ Specify decimal thickness instead (e.g., 1.5 mm cold‑rolled steel) and add a note such as:

“Nearest local stock substitution permitted after confirmation.”

This lets the supplier use their best available coils or sheets and respond faster with a sheet metal fabrication quotation.

“Or Equivalent” Unlocks Instant Quoting

Specifying brand‑locked materials (for example, a very specific paint system or proprietary alloy) forces shops to source niche inventory with long lead times.

Unless regulatory or certification requirements apply, write:

✔ 6061‑T6 or equivalent aluminum

✔ Acetal / POM‑C or equivalent engineering plastic

✔ SGCC or equivalent galvanized steel for cabinets

This lets YISHANG and other suppliers quote based on local stock availability and standard coatings—accelerating both price response and sampling.

Hack #4: Quantify Aesthetics (Surface Finish Standards)

Aesthetic ambiguity = risk pricing. Everyone has seen RFQs that say “nice finish” or “no scratches,” but these phrases are hard to convert into process parameters.

The result is either over‑processing (to be safe) or clarification emails (to avoid risk). Both slow down your precision fabrication quote.

Use Measurable Surface Roughness and Coating Standards

Where possible, use measurable standards rather than subjective language.

- Ra 3.2 μm: Standard machined finish for non‑cosmetic areas.

- Ra 1.6 μm: Fine machining for visible or sliding surfaces.

- Ra 0.8 μm or better: Polished / cosmetic / sealing surfaces.

✔ Apply Ra 3.2 to non‑visible surfaces. Reserve premium finishes for critical areas only. Clearly mark these on the drawing.

For coatings, reference industry standards:

- Powder coat: reference RAL color codes and gloss level.

- Wet paint: reference Pantone or known brand systems where necessary.

- Plating: specify zinc‑nickel, chromate, or electropolishing with thickness ranges.

The clearer your finishing requirements, the easier it is for the estimator to choose the correct process steps, batch size, and quality control plan.

Texture Coatings Can Save Time and Cost

High‑gloss metal finishing is expensive and visually unforgiving. Every tiny scratch becomes visible, which can trigger rework and rejection.

For many metal cabinets, display racks, vending machines, and enclosures, a texture powder coat is more realistic and robust.

✔ Use texture powder coat specifications for high‑touch surfaces.

✔ State a standard RAL color (for example, RAL 9005, RAL 7035, or your brand color) instead of “black” or “grey.”

Shops spend less time polishing, and output consistency improves. You maintain a professional appearance without paying for unnecessary cosmetic perfection.

Hack #5: Run a DFM Pre‑Check (Avoid Design Red Flags)

Today, many factories combine human estimators with automatic DFM (Design for Manufacturability) checks. If the software flags your part as “risky,” your RFQ will wait in the engineering queue for review.

Running your own mini‑DFM review before sending the RFQ is one of the fastest ways to get a quick sheet metal fabrication quote or CNC quote.

CNC: Internal Square Corners and Tool Access

Round tools cannot cut perfect internal square corners. When the CAD model shows a sharp corner with zero radius, the estimator must assume:

- Additional EDM or wire‑cut operations, or

- Corner reliefs that must be negotiated with you.

Both add cost and discussion.

✔ Always model internal radii slightly larger than the tool diameter you expect the shop to use (for example, R3 for an endmill of Ø6).

✔ Check for deep, narrow pockets where tool access is difficult. These often need special tooling or 5‑axis machining.

Fixing these before the RFQ can move your parts into a standard 3‑axis machining process and a lower price bracket.

Sheet Metal: Hole Distance to Bend and Bend Sequencing

For sheet metal, one classic red flag is the distance from a hole to a bend line. As a rule of thumb, keep holes 3–4× the sheet thickness away from bends.

If this is violated, shops may:

- Need special tools

- Re‑work holes after bending

- Add manual operations and jigs

All of these slow down quoting and increase price.

✔ Design around the 4T principle (hole center distance at least 4 × material thickness) where possible.

✔ Avoid very small flange heights and extremely tight bend radii unless functionally required.

When a supplier sees that you understand DFM, your drawings move more quickly through engineering review and into the quoting stage.

Hack #6: Package Commercial Information Strategically (De‑Risk the Quote)

Quotes aren’t just technical—they’re commercial commitments. Estimators need to understand not only “Can we make it?” but also “Under what terms and at what risk?”

Well‑structured commercial information makes it much easier for a factory to respond quickly with a complete metal fabrication quote, especially for overseas buyers.

Choose Incoterms That Enable Speed

Different Incoterms carry different workloads for the supplier.

- DDP (Delivered Duty Paid): Slowest to quote due to complex logistics, duties, and local delivery calculations.

- EXW (Ex Works): Fastest for the factory but shifts all logistics burden and risk to you.

- FOB / FCA: A practical balance—suppliers know these patterns well for export.

✔ When requesting quotes from China or other manufacturing hubs, ask for FOB (port name) or FCA (airport / hub). Shops quote faster while you retain flexibility to choose your own forwarder or shipping solution.

Declare Estimated Annual Usage (EAU)

Even if the first RFQ is for small volume or trial orders, always state projected annual demand and potential ramp‑up.

✔ Suppliers may subsidize prototype or tooling costs to secure long‑term production.

✔ Factories can plan fixtures, jigs, and dedicated processes that reduce your unit cost over time.

This transforms your RFQ from a one‑off price request into a potential strategic partnership.

Improve BOM Hygiene and RFQ Structure

Clear BOMs accelerate quoting and reduce errors, especially when you are dealing with assemblies, metal cabinets, or vending machine structures.

Best practice for an RFQ package:

- Excel or CSV format

- Item / part number

- Part name and brief description

- Material and thickness

- Finish / coating

- Quantity per order and EAU

- Target price range (if you have one)

- Required certifications (RoHS, REACH, ISO 9001, etc.)

Target pricing gives suppliers clarity to respond realistically. They can suggest alternative processes (for example, switching from machining to laser‑cut + bending + welding) to hit your cost window.

Working with an Overseas Metal Fabrication Supplier (China‑Focused Tips)

Because many procurement teams now source directly from China, it’s worth calling out a few extra points that influence the speed and quality of your China metal fabrication quote.

Communicate in Simple, Structured English

Most export‑oriented factories have English‑speaking sales engineers, but they handle dozens of RFQs per day.

✔ Use short, clear sentences and bullet points.

✔ Avoid local slang and very long paragraphs.

✔ Highlight deadlines: “Need quote by [date] for internal review.”

This aligns well with the reading habits of busy overseas account managers and helps your email stand out as “easy to process.”

Clarify What You Expect in the Quote

To reduce back‑and‑forth:

- List which items you need separately priced (parts, tooling, packaging, freight options).

- State whether you need CNC machining only, sheet metal only, or full assembly with standard fasteners and hardware.

- Indicate if you are open to design suggestions (DFM) to save cost.

This makes your RFQ more attractive to high‑quality OEM factories, because they can see you are organized and serious about long‑term cooperation.

Step‑by‑Step: How to Prepare a Fast RFQ for Sheet Metal and CNC Machining

- Gather all 3D STEP files and 2D PDFs.

- Export DXF flat patterns for sheet metal parts.

- Review tolerances and apply ISO 2768‑m as default.

- Confirm materials and allow “or equivalent” where possible.

- Define Ra finishes, colors, and plating requirements.

- Create a clean RFQ Excel sheet with item data, coatings, and quantities.

- Add EAU and your preferred Incoterms.

- Compress everything into a single RFQ package.

- Send to shortlisted suppliers.

- Request DFM feedback before finalizing.

Conclusion: Speed Is Engineered, Not Requested

The difference between a 24‑hour quote and a 5‑day delay is almost always information quality—not the estimator’s mood, and not just “supplier responsiveness.”

A “Perfect RFQ” for precision sheet metal fabrication or CNC machining typically includes:

- 3D STEP AP242 files for each custom metal part

- 2D drawings or PDFs for tolerances, notes, and critical features

- DXF flat patterns for sheet metal components

- Standardized material definitions that match global or Chinese stock sizes

- Clearly defined finish standards and realistic cosmetic expectations

- Commercial terms + Incoterms + EAU in a structured BOM and RFQ sheet

These RFQs rise to the top of quoting queues because they signal professionalism, repeat business potential, and low communication risk.

At YISHANG, our 26+ years in OEM metal fabrication—including sheet metal parts, metal cabinets, metal display racks, welded frames, and custom metal structures—allow us to interpret high‑fidelity RFQs quickly and quote efficiently for wholesale buyers in 50+ countries. Design smarter, package your data better—and let us manufacture faster.

Quick Reference: The “Instant Quote” Checklist

Use this table as a fast self‑check before you send your next RFQ to a metal fabrication supplier in China:

| Topic | Slow Method | Fast Method |

|---|---|---|

| File Format | Native CAD / STL only | STEP + PDF drawing |

| Sheet Metal | 3D model only | 3D + DXF flat pattern |

| Tolerances | Tight everywhere | ISO 2768‑m + GD&T on criticals |

| Material | Brand‑specific, no substitution | Standard grade + “or equivalent” |

| Finish | Vague terms like “nice finish” | Ra values + RAL / Pantone / process |

| Logistics | DDP only | FOB / FCA with your forwarder |

| Business Info | No EAU, no target | EAU + target price range |

Follow these moves to transform the RFQ cycle from bottleneck to competitive advantage—and to consistently obtain faster, clearer precision fabrication and CNC machining quotes from your global suppliers.

FAQ: Getting a Fast Precision Fabrication or Machining Quote

Q1: How can I get a faster sheet metal fabrication quote from a Chinese factory?

Focus on clean CAD data (STEP + DXF), realistic tolerances, clear finish requirements, and structured BOMs. Add Incoterms and EAU so the factory can see the full picture in one look.

Q2: What files do I need for a CNC machining quote?

At minimum, send a STEP file and a 2D drawing / PDF. Avoid STL unless you are 3D printing. Include material, finish, tolerance class, and any inspection or testing requirements.

Q3: Does sending more detail always slow down the quote?

Not if it is organized. Long emails with mixed information are hard to process, but a concise RFQ package with complete data allows the estimator to work faster and avoid guesswork.

Q4: How important is EAU and long‑term forecast for pricing?

Very important. For custom metal fabrication, factories invest in fixtures, jigs, and quality control plans. When they see stable volume, they can offer more aggressive pricing and prioritize your projects in production.

Q5: Can YISHANG support OEM / ODM projects and assemblies, not just single parts?

Yes. YISHANG focuses on OEM & ODM metal products for overseas wholesale buyers—including sheet metal fabrication, CNC machining, welding, surface treatment, assembly, packaging, and shipping coordination. A single integrated RFQ covering parts and assembly can often be quoted faster than splitting the work across many suppliers.