Why Metal Classification Still Matters for Procurement Professionals

Wholesale buyers don’t have time for theory. They’re here to evaluate whether a material fits project needs, meets compliance, and supports supply chain efficiency.

The difference between ferrous and non-ferrous metals impacts cost, machining, logistics, and certifications. For sourcing managers, especially in OEM and custom fabrication, understanding this choice can reduce risk and increase margin.

This guide breaks down the core distinctions of ferrous vs non ferrous metals, optimized for fast, procurement-driven decision-making.

What Sets Ferrous and Non-Ferrous Metals Apart?

Ferrous metals contain iron and are typically magnetic. Think carbon steel, alloy steel, and stainless steel.

They’re strong—ideal for heavy-duty applications—but prone to rust unless treated. These are often the best ferrous metals for heavy structural applications.

Non-ferrous metals like aluminum, brass, and copper don’t contain iron. They resist corrosion, weigh less, and are easier to machine.

Is aluminum a non ferrous metal? Yes. With a density of 2.7 g/cm³, it offers significant weight savings over steel (7.8 g/cm³), helping reduce freight cost and handling effort.

Aluminum’s natural REACH and RoHS compliance also simplifies export documentation.

Strength or Flexibility: What's the Priority?

Need raw mechanical strength? Ferrous metals win. Mild steel (ASTM A36) offers up to 550 MPa in yield strength.

For better machinability, corrosion resistance, or regulatory readiness, a non-ferrous metal like aluminum or brass may be the smarter choice.

Also consider which metals are easiest to machine—aluminum and brass lead in CNC environments, ideal for high-throughput production.

Which metal complies with REACH fastest? Non-ferrous selections often reduce delays and documentation complexity.

These attributes are essential when evaluating metal for REACH-compliant enclosures, where both fabrication speed and documentation readiness matter.

Real Applications: How Each Metal Type Performs in the Field

Retail Fixtures

Aluminum enables quicker installation due to lower weight. Stainless steel offers durability and a polished finish.

Best non ferrous metals for exporting retail enclosures include aluminum for logistics efficiency and brass for visual appeal.

Construction Supply

Ferrous metals are the go-to for load-bearing applications. But in humid or coastal zones, anodized aluminum or duplex stainless lasts longer.

Non ferrous metals for outdoor structures like kiosks, signage, and furniture offer strong weather resistance and shipping efficiency.

Medical & Electronics

Copper and brass offer electrical conductivity. Titanium suits biocompatible parts.

Non ferrous metals used in OEM enclosures improve thermal regulation and simplify safety certification.

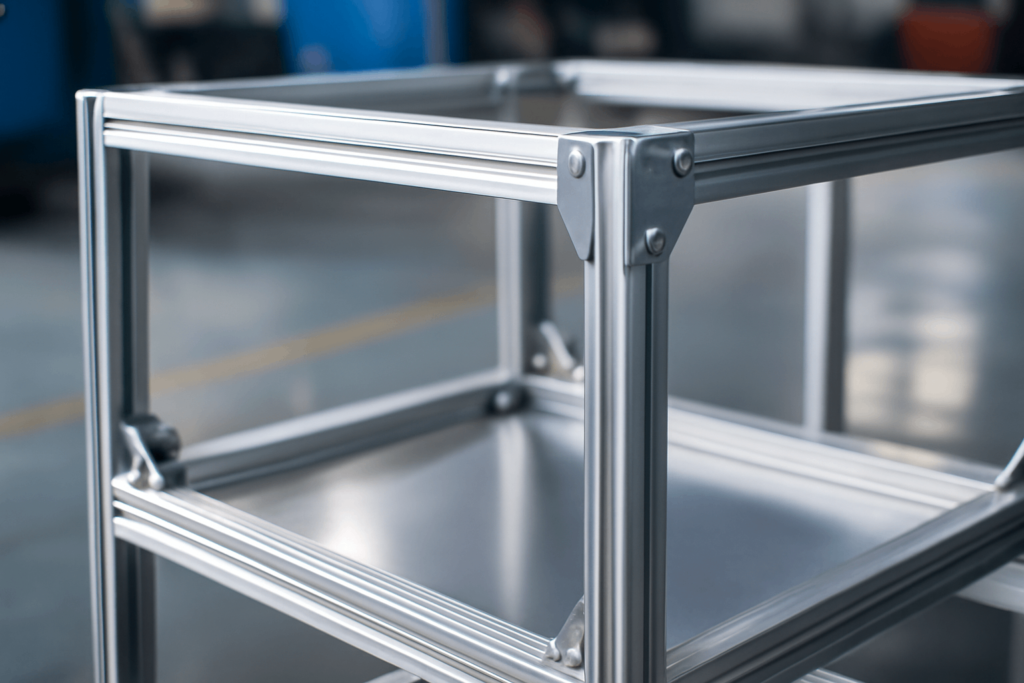

When designing modular racks or housing for kiosks and vending applications, buyers increasingly look for sheet metal for vending machines with anti-rust finish and reduced weight.

Quick Comparison Matrix for Sourcing Teams

| Metric | Ferrous Metals | Non-Ferrous Metals |

|---|---|---|

| Strength | Very High | Medium to High |

| Corrosion Resistance | Moderate to Low | High |

| Weight | Heavy | Light |

| Conductivity | Low | High (copper, brass) |

| Machinability | Moderate | Excellent |

| Export Compliance | Needs verification | RoHS/REACH compatible |

| Price Volatility | Lower | Higher (esp. copper) |

| Recyclability | High | Very High (esp. aluminum) |

This table gives buyers a fast track to the right shortlist. Always compare metals in the full sourcing context.

Logistics, Regulations, and What Affects the Final Quote

From a compliance and logistics standpoint, aluminum delivers across key export metrics. Its low weight supports easier handling, while corrosion resistance reduces protective packaging needs.

Galvanized steel may reduce initial cost but could increase total landed cost due to corrosion risk or extra treatments.

When sourcing for Europe, non-ferrous metals like aluminum or brass reduce delays through easier REACH/RoHS pathways.

Which metals comply with RoHS in Europe? Aluminum, copper, and brass are widely accepted. They also reduce documentation and certification overhead.

Recycled aluminum retains full mechanical properties at a fraction of the energy cost—cost-effective and sustainable.

If you’re prioritizing lightweight metals for international shipping, non-ferrous selections minimize freight handling and border compliance time.

For projects involving modular signage or enclosures, sourcing non ferrous materials for custom frames can streamline both transport and on-site installation.

What Works Best for You?

The optimal material depends on your priorities—strength, compliance, logistics, or processing.

Need structural load capacity? Choose ferrous. Exporting modular displays or electronic enclosures? Non-ferrous.

At YISHANG, we support OEM and wholesale clients with tailored material selection. Whether you need custom sheet metal material selection, non ferrous metals for corrosion resistance, or REACH-compliant materials for export, we’re here to assist.

Send us your spec or RFQ—we’ll help you match material to function. Simple as that.

FAQ: What Buyers Also Ask

Q1: What is the main difference between ferrous and non ferrous metals?

Ferrous metals contain iron and are typically stronger and magnetic. Non-ferrous metals don’t contain iron, offering better corrosion resistance, lighter weight, and easier machining.

Q2: Which non ferrous metals are best for outdoor or coastal use?

Aluminum (especially anodized), brass, and copper are commonly used in humid and salt-heavy environments due to their corrosion resistance.

Q3: Which metals help reduce export compliance risks?

RoHS/REACH compliance is typically easier with non-ferrous metals like brass, copper, and aluminum—all widely accepted for EU-bound manufacturing.

Q4: How do I choose between ferrous and non-ferrous for OEM fabrication?

Consider your use case: strength-heavy frameworks lean ferrous; lightweight, conductive, and regulation-sensitive projects favor non-ferrous.