Introduction: The Hidden Costs of “Good Enough” Stamping

In global manufacturing, we often accept a familiar, multi-stage workflow: stamp a component, then pass it down the line for secondary operations like grinding, deburring, milling, or reaming to meet final specifications. This fragmented process seems like a standard cost of doing business, but it quietly erodes profitability.

Each handoff introduces complexity, extends lead times, increases the potential for quality escapes, and inflates the Total Cost of Ownership (TCO) for every single part. What if the “finishing” steps—and their associated costs and risks—could be engineered out of the process entirely? What if you could receive a component that is ready for assembly, produced in a single, highly repeatable press stroke?

This guide presents a new manufacturing philosophy, designed for procurement managers and engineers tasked with building resilient and cost-effective supply chains. It is not just a technical explanation of the fine blanking process; it is a strategic framework for rethinking precision.

We will explore how this advanced metal forming process moves beyond the limitations of conventional stamping to produce parts with edge quality and dimensional precision that rival machining—positioning it as a viable alternative in precision metal fabrication services, all while leveraging the speed and scalability of a press. This is a guide to eliminating hidden costs and building a decisive competitive advantage from the very first stroke.

Section 1: The “Is Fine Blanking Right for Me?” Diagnostic for Procurement Professionals

Before diving into tolerances, tooling, and tonnage, it’s critical to ask: Does my application actually warrant the use of fine blanking? This section walks you through a series of strategic procurement questions that help determine whether the value proposition of fine blanking justifies its investment.

Does Your Part Demand a Fully Sheared, Burr-Free Edge?

Fine blanking excels at producing edges that are 100% sheared, flat, and burr-free—ideal for custom sheet metal components requiring clean joins or precise fit—attributes that standard stamping often fails to achieve without costly secondary operations. If your component requires:

- Functional edges that serve as sealing or bearing surfaces,

- Aesthetically critical edge quality,

- Immediate fit into an assembly without deburring or machining,

…then fine blanking offers not just technical feasibility, but strategic efficiency.

Are Flatness and Dimensional Accuracy Mission-Critical?

Unlike conventional stamping, which can produce parts with edge roll, taper, and significant die break, fine blanking maintains parallelism, flatness, and tight dimensional control.

If your quality thresholds require minimal variation across large volumes—particularly for components that must interface with precision assemblies—fine blanking delivers measurable gains in yield and process capability (Cpk).

Are You Currently Adding Cost via Secondary Operations?

Ask yourself: Are you paying to mill, ream, or grind parts after stamping—just to meet edge, hole, or flatness specs? Every added operation introduces not only cost but also risk.

Fine blanking allows you to consolidate operations into a single stroke, reducing handling, inspection stages, and cross-departmental delays. The result: lower cost per part when total cost is considered.

Do You Require High Volume, High Repeatability?

Fine blanking tooling is more complex and capital-intensive, but its true payoff is seen over long runs where repeatability is paramount.

If you require hundreds of thousands—or millions—of identical parts with tight tolerances, the upfront tooling investment is amortized quickly. Fine blanking thrives in Tier 1 and Tier 2 automotive, appliance, and industrial supply chains.

Does Your Component Include Complex Geometries, Counterbores, or Coining?

Fine blanking tools can integrate additional forming actions within the stroke: countersinks, coining, embossing, and even minimal bending. This allows design engineers to rethink DFM (Design for Manufacturability), incorporating complex features that previously required multiple operations.

Procurement Takeaway:

If you answered “yes” to two or more of the above, your application likely aligns with the strengths of fine blanking. The goal is not just functional performance—but a procurement strategy that reduces lifecycle cost, variability, and time-to-market.

In the next section, we’ll explore why fine blanking is not just capable of achieving precision—but engineered specifically to do so, stroke after stroke.

Section 2: The Science Behind a Perfect Edge

Fine blanking doesn’t just produce clean edges by accident—it achieves them through a rigorously engineered sequence of physical mechanisms and press features. To appreciate why this matters, it’s worth briefly contrasting how standard stamping fails to deliver the same results.

Traditional Stamping vs. Fine Blanking: A Structural Difference

In standard stamping, the punch shears through material by exceeding its tensile strength, creating a fracture zone. This results in an uneven edge comprised of rollover, burnish, fracture, and die break—a jagged profile prone to burrs and dimensional inconsistency. The final edge often needs post-processing to meet functional or aesthetic requirements.

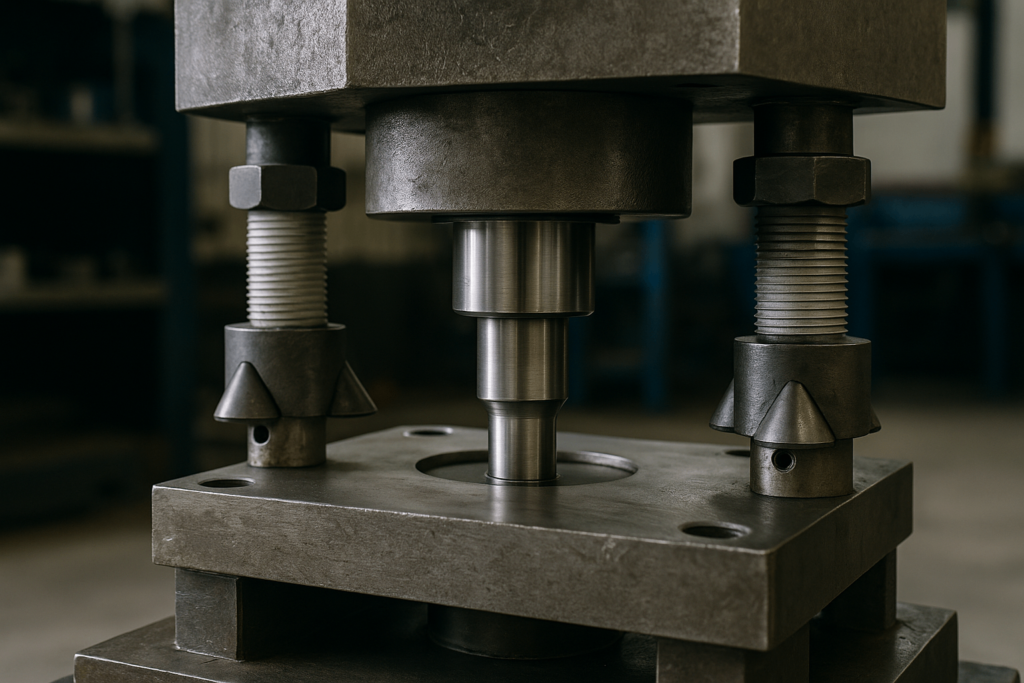

In contrast, fine blanking uses a triple-action press that applies clamping force from both the upper and lower dies while the punch shears. This minimizes material flow and lateral movement, creating a fully sheared edge that is perpendicular, smooth, and free of taper or break.

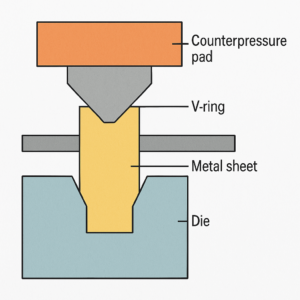

The Role of V-Ring and Counterpressure

Two unique mechanical features enable this process:

- V-Ring (stinger): This ring indents the periphery of the material just outside the cutting area, locking it in place during the punch stroke. This reduces radial displacement and supports edge integrity.

- Counterpressure Pad: Located beneath the workpiece, this component applies opposing force to the punch direction. It prevents downward extrusion, maintains part flatness, and supports surface quality throughout the stroke.

Together, these features allow the material to deform plastically rather than fracture—a key distinction. Instead of initiating a brittle break, the fine blanking press forces the material to flow in a controlled manner, producing edges that can meet surface roughness specs as tight as Ra ≤ 1.6 µm.

Edge Quality: Not Just Aesthetics, But Function

The output is more than cosmetic. Fine blanked edges are often functional surfaces:

- Sealing interfaces

- Gear tooth profiles

- Brake components

In such cases, the edge serves as a contact or load-bearing area. Surface roughness, perpendicularity, and uniformity become mission-critical—not just to aesthetics, but to product performance and longevity.

Dimensional Control and Parallelism

Fine blanking presses also maintain tight tolerances in flatness and parallelism, often eliminating the need for subsequent grinding. This is particularly valuable for:

- Multi-part stack-ups,

- Precision assemblies,

- Rotational components where balance is key.

The process yields less than 0.05 mm in flatness variation on many geometries, improving overall system efficiency.

Why This Matters for Procurement

For buyers and supply chain professionals, understanding this process isn’t just academic—it’s financial. Each burr eliminated, each micron of parallelism maintained, directly correlates to reduced assembly times, fewer rejects, and lower warranty costs.

In the next section, we’ll move from what fine blanking can do to what happens when it’s misunderstood or poorly executed—and what you can do to avoid those pitfalls.

Section 3: Failures, Misconceptions & Risk Mitigation in Fine Blanking

Fine blanking offers extraordinary precision—but only when executed within its process window. When misunderstood, it can introduce cost, tooling damage, or downstream failures that defeat its purpose.

This section outlines the most common missteps and how to preempt them in both design and procurement phases.

Mistake: Specifying Material Without Considering Ductility

Not all steels or non-ferrous alloys are suitable for fine blanking. A common error is selecting materials based solely on tensile strength or corrosion resistance, without considering formability.

Corrective Action: Work with suppliers to evaluate material ductility, anisotropy, and grain structure. Materials like cold-rolled steels with high elongation and low yield-to-tensile ratios typically perform better. Pre-processing steps such as spheroidizing anneal can improve formability.

Mistake: Overlooking Tooling Load During Feature Design

Fine blanking dies are subjected to high, concentrated forces—especially when integrating coined features, countersinks, or bend zones. Overloading the die can accelerate wear or lead to catastrophic failure.

Corrective Action: Involve tooling engineers early. Use FEA simulations to predict stress concentration. Design features with gradual transitions, and avoid sharp internal corners where stress risers can accumulate.

Mistake: Assuming Surface Finish is Always “Machined Quality”

While fine blanking edges are smooth and functional, they don’t replace all post-processing. Edge finish can vary based on material hardness, lubrication, and press tuning.

Corrective Action: Define surface finish tolerances explicitly (e.g., Ra ≤ 1.6 µm) and validate via sampling. Don’t assume all suppliers tune presses to the same level—auditing and standardization matter.

Mistake: Treating Fine Blanking as Plug-and-Play

Some procurement teams assume switching to fine blanking is simply a matter of ordering new dies. In reality, it requires rethinking part design, tolerance stack-ups, and supplier capability.

Corrective Action: Conduct DFM reviews with experienced fine blanking partners. Consider total value stream implications—from press tonnage to post-blanking handling to quality assurance protocols.

Procurement Risk Mitigation:

The best procurement teams treat fine blanking not as a process to buy, but as a system to co-engineer. Early engagement with capable suppliers, well-defined tolerances, and simulation-backed design reviews prevent most downstream issues.

In the next section, we look at where the fine blanking industry is headed—and how procurement can stay ahead of the curve.

Section 4: The Future of Fine Blanking — Smart Presses, Smarter Procurement

Fine blanking has long been associated with tight tolerances and repeatable quality—but it’s no longer just a mechanical advantage. The next generation of fine blanking integrates digital intelligence, simulation-driven design, and automation to further reduce cost, waste, and lead time. Forward-thinking procurement teams are already using these shifts to drive strategic gains.

Servo-Controlled Fine Blanking Presses

Traditionally, hydraulic presses have dominated fine blanking due to their precise force control. However, servo-driven presses are increasingly being adopted for their programmability and speed tuning.

- Benefit: Servo control allows precise modulation of punch velocity, enabling “slow-down-at-contact” profiles that reduce edge microcracks and extend tool life.

- Procurement Insight: Servo presses may come at a premium, but the longer tooling life, improved cycle time, and reduced reject rates often offset the capital cost in high-volume production environments.

FEA-Driven Die Design and Virtual Commissioning

Simulation tools like finite element analysis (FEA) now enable virtual die tryouts before cutting any steel.

- Benefit: Predicts material flow, punch loads, edge formation, and potential defect zones before fabrication begins.

- Procurement Insight: Early design validation reduces change orders, tooling delays, and misaligned expectations—particularly when sourcing from geographically distant suppliers.

Industry 4.0 and Real-Time Process Monitoring

Smart sensors embedded in fine blanking presses are enabling real-time monitoring of:

- Press tonnage curves,

- Lubrication distribution,

- Vibration signatures,

- Temperature shifts.

- Benefit: Allows predictive maintenance, instant feedback loops, and data-driven quality assurance.

- Procurement Insight: Suppliers with digital press monitoring capabilities offer traceable process control—critical for industries like automotive, aerospace, and medical.

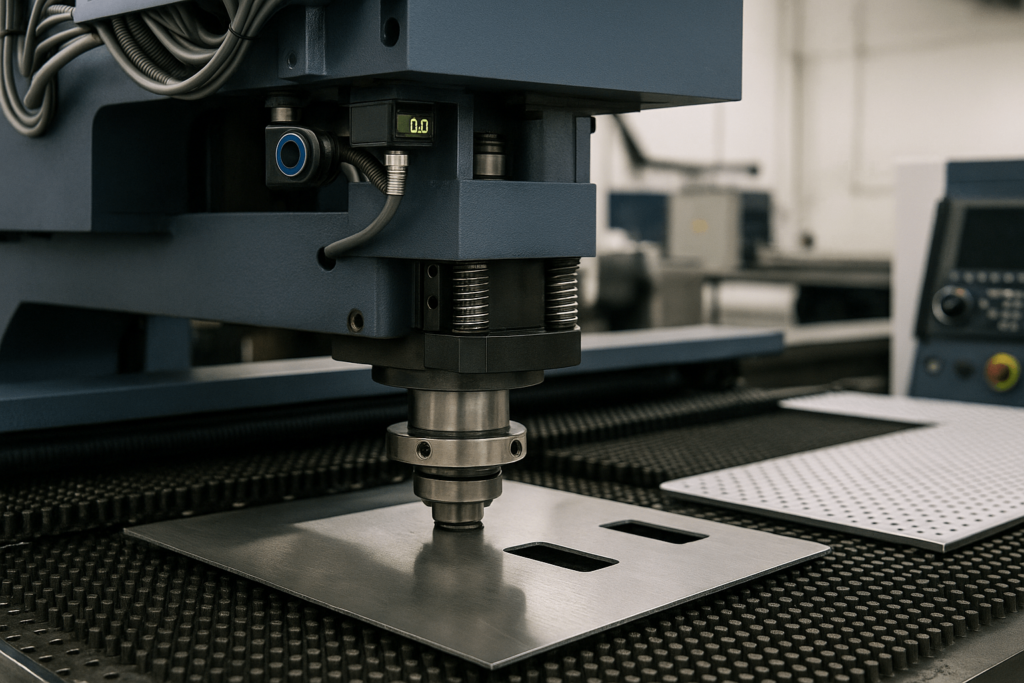

Automation, Robotic Transfer, and Post-Blanking Integration

Modern fine blanking lines integrate robotic part extraction, inline cleaning, deburring (if needed), and vision inspection in a seamless flow.

- Benefit: Reduces manual handling, labor cost, and cycle variation.

- Procurement Insight: Systems integrators or suppliers with end-to-end automation competence can reduce your vendor count and streamline production planning.

Sustainability and Material Efficiency

New developments in tooling coatings, low-friction lubricants, and scrap minimization techniques are aligning fine blanking with sustainability goals.

- Benefit: Lower environmental impact per part without sacrificing quality.

- Procurement Insight: Choosing suppliers who document scrap rates, energy use, and lubricant recovery helps meet ESG targets and respond to customer RFI audits.

Strategic Procurement Takeaway:

The future of fine blanking isn’t just smarter machines—it’s smarter supply chains. As presses become more intelligent and design becomes more predictive, procurement’s role shifts from sourcing parts to sourcing capability.

To stay competitive in precision manufacturing and metal part sourcing, aligning with suppliers that offer smart servo blanking presses, FEA-driven tooling design, and traceable quality systems is no longer optional—it’s strategic.

In the final section, we’ll tie these threads together with a practical summary and procurement-focused checklist for driving ROI through fine blanking.

Conclusion: From Precision to Profit — Turning Fine Blanking into a Strategic Advantage

Fine blanking is more than a process—it’s a precision manufacturing philosophy that, when fully understood and properly applied, becomes a tool for competitive differentiation.

For procurement leaders, adopting fine blanking isn’t about chasing the latest manufacturing trend. It’s about building a supply chain that:

- Reduces total cost of ownership (TCO),

- Eliminates redundant operations,

- Increases throughput and yield,

- Enhances part functionality,

- Enables faster time-to-market,

- Aligns with quality, traceability, and ESG compliance expectations.

In industries where cost, precision, and speed are non-negotiable, fine blanking delivers on all three—if approached with technical understanding and supply chain alignment.

Procurement isn’t just about quoting parts anymore. It’s about quoting the right process, for the right application, from the right supplier—with a clear grasp of cost vs. capability trade-offs.

Frequently Asked Questions (FAQ)

Q1: Is fine blanking only suitable for automotive components?

A: No. While automotive is a major user due to high volume and tight tolerance needs, fine blanking is ideal for industries like appliances, hardware, electronics, medical devices, and industrial machinery—anywhere repeatability, edge quality, and dimensional control matter.

Q2: How is fine blanking different from precision stamping?

A: Precision stamping improves dimensional control over standard stamping but still relies on fracture-based shearing. Fine blanking controls material flow through clamping, counterpressure, and V-ring support, achieving fully sheared edges with better surface finish and part flatness.

Q3: What tolerances can typically be achieved with fine blanking?

A: While it depends on part size and geometry, common tolerances are ±0.05 mm or better on critical dimensions. Edge quality can meet surface finish standards of Ra ≤ 1.6 µm without post-processing.

Q4: Is tooling for fine blanking more expensive?

A: Yes—but it’s more durable and provides significant ROI in high-volume scenarios by reducing secondary operations, improving part quality, and minimizing reject rates. Proper amortization planning is key.

Q5: Can fine blanked parts be welded or plated?

A: Absolutely. Fine blanked parts maintain high surface integrity, making them suitable for downstream processes like welding, plating, coating, and assembly without additional prep.

By understanding both the engineering behind fine blanking and the procurement levers that influence success, buyers and specifiers can unlock a new tier of precision and profitability in metal part sourcing.

For manufacturers ready to make the leap—from conventional to competitive—fine blanking isn’t just a better edge. It’s a better strategy.