For an overseas wholesale purchaser, sourcing a product like a fire extinguisher cabinet seems straightforward. The focus is often on unit price, material specifications, and shipping costs. However, this narrow view overlooks a critical truth we’ve learned from over 26 years in precision metal fabrication: the most significant costs associated with this product are not on the initial invoice. They are the hidden risks that can erode your profit margins and damage your brand’s reputation.

These risks manifest as three distinct “hidden costs”: the liability of distributing non-compliant products into regulated markets, the financial drain of warranty claims and replacements due to premature material failure, and the catastrophic brand damage that occurs if a product fails in a life-or-death emergency.

This guide is not a product catalog—it is a strategic playbook crafted for procurement professionals. We will move beyond the spec sheet to dissect the critical decisions that separate a low-cost supplier from a high-value manufacturing partner, empowering you to build a more resilient and profitable supply chain.

We’ve organized this guide into three acts:

- Act I explores the environmental realities your cabinets will face, and how those should influence your material and design choices.

- Act II unpacks the technical capabilities your manufacturer must possess to deliver consistent, compliant, and durable products at scale.

- Act III puts it all together in a real-world case study, helping you simulate a smarter purchasing decision.

Whether you’re managing fire safety equipment distribution for hospitals, hotels, or industrial parks, this playbook will equip you with the insight to minimize hidden risks and maximize long-term value.

Why Fire Extinguisher Cabinets Incur Hidden Procurement Risks

For wholesale buyers sourcing fire extinguisher cabinets internationally, the unit price is only the surface of the equation. Beneath that surface lie hidden risks that can result in compliance violations, corrosion-related failures, and reputational damage. This playbook explores how procurement professionals can mitigate these risks by selecting the right manufacturing partner—one equipped with material expertise, compliant designs, and certified processes.

YISHANG, with over 26 years of experience in sheet metal fabrication and OEM manufacturing, serves clients across 50+ countries. We’ve built custom metal solutions for the fire safety industry with a strict focus on quality, consistency, and global compliance.

Act I: Environmental Diagnosis—Translating Location into a Profitable Product Strategy

Effective procurement begins with understanding where and how a cabinet will be used. This insight allows you to match material and design with application, ensuring long-term value and reduced risk. Let’s look at three typical environments:

1.1 High-Traffic Indoor Zones (Hospitals, Schools, Warehouses)

In environments with constant activity, such as educational and industrial settings, fire extinguisher cabinets face repeated impact. Using light materials like thin aluminum may save upfront costs, but it leads to dents, warping, and broken latches over time.

Here, carbon steel with a high-durability powder-coated finish becomes the optimal choice. It provides exceptional impact resistance and longer lifespan—reducing replacement frequency and reinforcing your reputation for quality.

1.2 Corrosive Outdoor Zones (Coastal Projects, Industrial Plants)

For seaside resorts, chemical storage areas, or facilities in snowy climates, corrosion is the enemy. This makes material selection non-negotiable. Grade 316 stainless steel, enriched with molybdenum, significantly outperforms 304-grade or carbon steel in resisting chloride-induced corrosion.

Buyers who educate their downstream customers about Total Cost of Ownership (TCO) often find they can justify the higher initial investment in 316-grade stainless cabinets through long-term savings and fewer warranty claims.

1.3 Regulated Public Areas (Offices, Transit Hubs, Commercial Buildings)

In North America and other regions, accessibility codes like the ADA impose specific design rules. Most important is the 4-inch protrusion limit for wall-mounted units between 27–80 inches from the floor. Surface-mounted cabinets often violate this.

The compliant solution? Recessed or semi-recessed cabinet designs. OEMs familiar with ADA and EU accessibility codes can design cabinets that maintain aesthetics while meeting legal standards—ensuring your product passes building inspections without issue.

Act II: Technical Deconstruction—Vetting a Partner’s True Capabilities

Not all manufacturers are created equal. Here’s how to verify whether a supplier can consistently meet your technical expectations for large orders:

2.1 CNC Laser Cutting vs. Stamping: Why Precision Matters

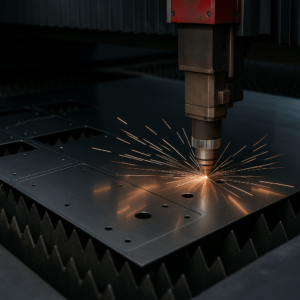

Poorly cut components create alignment issues, latch failures, and install frustration. That’s why precision CNC laser cutting should be your minimum standard. Unlike mechanical punching or shearing, laser cutting yields consistent tolerances across hundreds or thousands of units.

This is especially important for ADA-compliant flush installations where even minor dimensional variance can cause regulatory violations. Suppliers using CNC laser systems demonstrate a long-term investment in scalable quality.

2.2 Powder Coating vs. Wet Paint: Surface Protection & Aesthetics

Aesthetic appeal matters—especially in commercial buildings. Powder coating produces a thicker, more uniform, chip-resistant surface compared to spray paint. When applied after chemical pre-treatment (like phosphate washing), it creates a sealed, rust-resistant barrier that lasts 3–5x longer.

It also allows color customization to match client interiors or safety color coding, supporting both design intent and safety visibility.

2.3 ISO 9001 Certification: Not Just a Badge

ISO 9001 certification means that every process from raw material inspection to final packaging follows documented standards. For bulk fire extinguisher cabinets, this consistency is vital to avoid batch variation, missed specs, or delivery delays.

Additionally, it gives procurement managers peace of mind that root cause analysis and preventive action systems are in place—reducing systemic risk throughout the supply chain.

Act III: Decision Simulation—Applying the Framework

Case Study: Hotel Chain in the Mediterranean Region

A European distributor is bidding on a hotel group’s fire safety fit-out across 10 resorts. Requirements include corrosion resistance outdoors, ADA compliance indoors, and aesthetic matching with luxury interiors.

- Material Strategy: Grade 316 stainless for poolside and beachfront; 304 stainless for interiors.

- Compliance Guarantee: Semi-recessed models that adhere to EU and ADA standards.

- Aesthetic Customization: Powder coating in custom RAL colors.

- Technical Vetting: Supplier must have CNC laser capability, ISO certification, and documented QMS.

YISHANG’s engineering and QC team collaborated to provide samples, drawings, and compliance test reports. The distributor won the bid by offering a long-life, regulatory-compliant, and visually integrated solution—backed by scalable manufacturing.

FAQ: Fire Extinguisher Cabinet Procurement

Q: What material is best for outdoor fire extinguisher cabinets?

A: Grade 316 stainless steel is ideal due to its superior resistance to salt, corrosion, and harsh marine conditions.

Q: Are fire extinguisher cabinets required to meet ADA standards?

A: Yes. In the U.S. and many global markets, cabinets installed in public buildings must comply with ADA regulations, including the 4-inch projection rule.

Q: What are the benefits of powder-coated finishes on cabinets?

A: Powder coating offers superior resistance to scratching, UV, and corrosion compared to traditional spray paints. It also increases cabinet longevity.

Q: Why choose ISO 9001 certified suppliers?

A: ISO 9001 certification ensures consistent quality, process control, and risk mitigation—essential for bulk OEM procurement.

✅ Key Certifications & Capabilities:

- ✔️ ISO 9001:2015 Certified Manufacturer

- ✔️ Exported to 50+ Countries (US, EU, Australia, Middle East)

- ✔️ OEM & ODM Metal Fabrication Expert

- ✔️ ADA Compliant Cabinet Engineering

- ✔️ CNC Laser Cutting & Powder Coating Facilities

🔗 Helpful References:

Conclusion: Your Supplier Choice Defines Your Business’s Resilience

For a wholesale purchaser, the process of selecting a fire extinguisher cabinet supplier is a microcosm of your entire sourcing strategy. A decision based solely on unit price exposes your business to hidden costs—compliance issues, premature corrosion, and costly replacements. These aren’t just line-item expenses; they are strategic vulnerabilities.

By contrast, sourcing from a technically competent, ISO-certified partner with a deep understanding of both compliance and environmental realities is an investment in long-term profitability. When you align your sourcing with lifecycle value, material performance, and technical capability, you don’t just mitigate risk—you differentiate your brand.

YISHANG has spent over two decades helping B2B partners reduce these hidden risks through engineering-led metal fabrication and compliance-ready cabinet design. We understand that in fire safety, failure is not an option. Your clients rely on you—and you can rely on us.

🔔 Ready to Build a Safer, Smarter Supply Chain?

Looking for a reliable, export-ready OEM fire extinguisher cabinet supplier with expertise in powder-coated finishes, ADA compliance, and stainless steel fabrication?

📩 [Request a Custom Quote Now] or 📞 Contact YISHANG’s Engineering Team Today.

We deliver scalable B2B solutions tailored for your global projects.