Introduction: How a Component Decision Impacts Project ROI

In large-scale industrial and infrastructure projects, choosing the right enclosure is more than a hardware decision—it’s a strategy for long-term success. The reliability of galvanized steel electrical enclosures directly affects asset performance, maintenance frequency, and lifecycle cost.

Corrosion remains a global challenge. According to industry estimates, corrosion-related failures cost the U.S. economy over $276 billion annually. For B2B procurement professionals, that translates to preventable downtime, unplanned replacement cycles, and reputational risk.

This guide offers a technical roadmap to mitigate such risks. It’s designed for engineers, supply chain managers, and industrial buyers seeking expert insight into galvanized steel enclosure selection—particularly for outdoor electrical boxes, industrial cabinets, and custom telecom enclosures.

We’ll go beyond surface-level comparisons to evaluate fabrication standards, HDG vs. EG processes, lifecycle value, and compliance factors such as NEMA and ASTM. Whether sourcing custom galvanized steel boxes from China or evaluating a vendor’s ability to meet IP66 or NEMA 4X, this guide helps you make informed, ROI-driven decisions.

Chapter 1: The Foundational Decision: How Galvanizing Process Dictates Asset Performance

For procurement, understanding that not all “galvanized steel” is created equal is the first step in risk mitigation. The choice between the two primary galvanizing methods directly impacts asset longevity, maintenance cycles, and TCO. This decision can mean the difference between an asset that performs for over 50 years and one that fails in under five.

The Core Distinction: Metallurgical Bond vs. Electrochemical Adhesion

The fundamental difference lies in how the protective zinc bonds to the steel.

Hot-dip galvanizing (HDG) is a total immersion process. A fully fabricated steel enclosure is submerged in a bath of molten zinc at approximately 850°F (460°C). This creates a series of zinc-iron alloy layers that are metallurgically bonded to the steel.

These intermetallic layers are harder than the base steel, providing a tough, abrasion-resistant coating typically ranging from 45 to over 100 micrometers (µm) thick. This becomes an integral part of the steel, not just a surface treatment. This makes it ideal for applications such as IP66-rated galvanized steel outdoor enclosures and galvanized electrical cabinets exposed to mechanical stress.

In contrast, electro-galvanizing (EG) is an electrochemical process. An electric current deposits a thin layer of pure zinc onto the steel’s surface from a cold electrolyte solution.

While this method provides a smooth finish, the coating is significantly thinner—generally 5 to 25 µm—and adheres through electrochemical attraction. It lacks the fused, hardened alloy layers of HDG, making it less resistant to abrasion and environmental stress. This makes EG-coated boxes better suited as indoor galvanized steel junction box enclosures or low-risk utility cabinets.

Consequences for Project Reliability and Field Performance

This distinction has real-world implications. For any outdoor electrical box, industrial control cabinet, or telecom enclosure, hot-dip galvanizing is the more durable and reliable engineering choice.

Its substantial coating provides a reservoir of zinc for robust sacrificial anode protection. When scratched, the zinc surrounding the breach corrodes first, protecting the exposed steel—essentially a “self-healing” feature. This key property ensures continued protection even after routine handling or field installation, especially for galvanized steel weatherproof enclosures in exposed installations.

Electro-galvanizing, while suitable for controlled indoor environments, poses greater risk in outdoor settings. Once its thin coating is compromised, corrosion of the steel substrate accelerates rapidly, potentially leading to avoidable failures and early equipment replacements, especially in high-humidity or coastal projects involving galvanized metal enclosures.

Chapter 2: Strategic Investment Analysis: A TCO Comparison of Metal Enclosures

A procurement professional’s role goes beyond unit pricing—it’s about maximizing lifecycle value. That means selecting enclosure materials that perform reliably in their specific environments while offering a favorable return over time.

Here, we analyze galvanized steel vs. stainless steel and galvanized steel vs. aluminum from the perspective of cost-effectiveness, performance, and project-specific suitability for galvanized steel control cabinets, wall-mounted boxes, and industrial electrical enclosures.

Round One: Corrosion Resistance—Matching Material to Environmental Risk

Environmental exposure dictates enclosure lifespan. In coastal or chemical-heavy environments, Type 316 stainless steel is the preferred option due to its resistance to chloride-induced corrosion.

Its passive oxide layer, enhanced by molybdenum, shields against pitting and degradation, making it indispensable for C5-CX corrosion zones.

However, in typical C1–C4 zones (urban outdoors, light industrial, telecommunications infrastructure), hot-dip galvanized steel offers an optimal balance of cost and durability. Its robust zinc coating protects against rain, UV exposure, and pollution without the higher cost of stainless steel, especially in large-scale deployments of galvanized steel outdoor cabinets.

Aluminum excels in moist environments and delivers excellent protection through its own oxide film. Its strength-to-weight ratio makes it ideal for wall- or pole-mounted applications. However, for load-bearing or impact-intensive use cases, it may fall short compared to steel—particularly when evaluating galvanized steel vs aluminum electrical enclosures in utility-grade contexts.

Round Two: Mechanical Strength—Ensuring Physical Asset Security

Enclosures don’t only face corrosion—they must also endure mechanical impacts and structural loads.

Stainless steel leads in tensile strength and is well-suited for high-security or mission-critical installations. Hot-dip galvanized steel combines the strength of carbon steel with its protective coating, making it a durable yet economical choice for most standard industrial use cases.

Aluminum’s value lies in its lightness and ease of fabrication. For telecom enclosures and rooftop installations, it reduces handling costs and structural stress. However, it may dent more easily or deform under heavy loads.

Round Three: The Total Cost of Ownership (TCO) Calculation

For decision-makers managing long-term infrastructure projects, TCO is the most actionable metric:

- Initial Investment: Galvanized steel presents the lowest upfront cost.

- Lifecycle Maintenance: With up to 50 years of performance in C1–C4 zones, HDG enclosures require virtually no maintenance.

- Return on Investment (ROI): The reduced risk of failure and minimized service interventions directly contribute to stronger ROI—especially in projects requiring a large number of galvanized steel enclosures for industrial facilities.

Chapter 3: The Specifier’s Guide to Mitigating Risk with Industry Standards

For procurement teams, compliance is critical. Misinterpreting certifications like NEMA, IP ratings, or ASTM standards can lead to costly rework or even regulatory failure—especially when dealing with export-grade galvanized electrical enclosures.

The Protection Rating Trap: NEMA 4X Delivers More Than IP66

IP66 focuses solely on ingress protection. NEMA 4X goes further—providing not just protection against water intrusion, but also certified corrosion resistance. For critical applications such as galvanized NEMA 4X outdoor enclosures, this added layer of protection ensures that both structural and functional longevity are addressed.

For corrosive or coastal environments, only NEMA 4X offers the comprehensive protection profile required to ensure enclosure longevity. IP66 on its own cannot validate corrosion performance, making it less ideal for rugged outdoor galvanized electrical boxes.

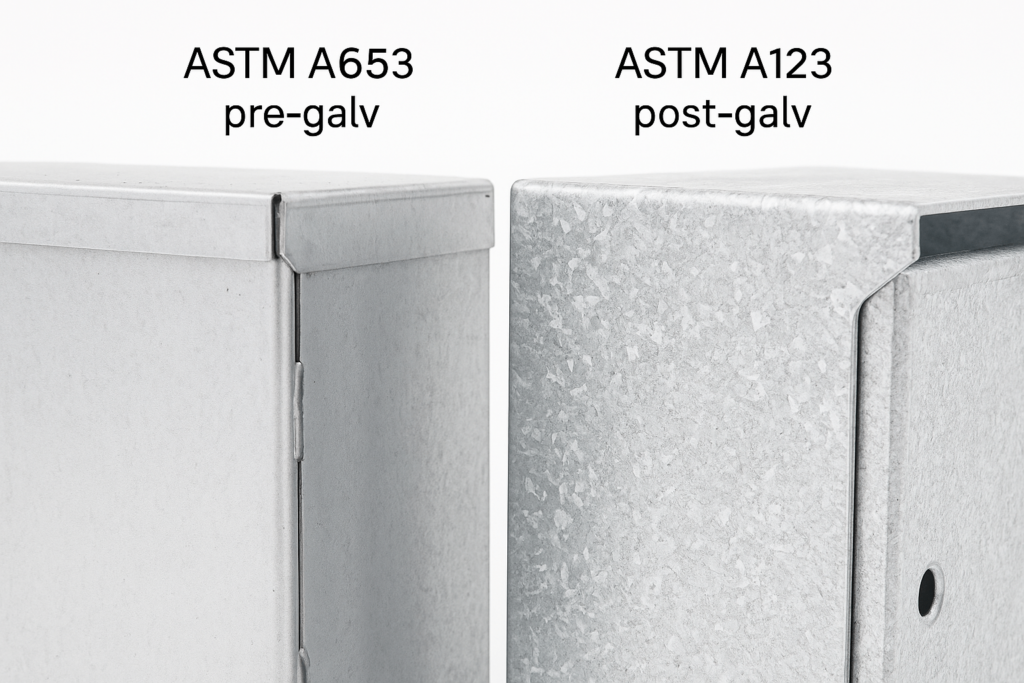

The Manufacturing Process Trap: The Critical Difference Between ASTM A653 and ASTM A123

Pre-galvanized steel (ASTM A653) is coated before fabrication. Every weld or cut exposes raw steel, compromising protection.

ASTM A123, by contrast, governs post-fabrication hot-dip galvanizing. The entire finished unit—seams, welds, and joints—is coated uniformly. This distinction is vital for ensuring long-term durability in the field, especially for heavy-duty galvanized steel control enclosures exposed to industrial contaminants.

For any enclosure project where environmental reliability matters, always specify “HDG to ASTM A123” or equivalent ISO 1461 for galvanized enclosure manufacturing.

The Latent Risk: Galvanic Corrosion from Dissimilar Metals

Galvanic corrosion can silently compromise performance. For example, mounting a copper lug directly onto a galvanized enclosure without isolation will cause localized zinc loss.

Experienced fabricators—such as OEM/ODM suppliers of galvanized steel enclosures in China—will proactively recommend insulating washers or compatible alloys to prevent such failures in telecom or utility-grade installations.

Chapter 4: From Specification to Solution: The Value of a True Fabrication Partner

Beyond material choice, supplier capabilities determine the success of your deployment. An experienced supplier does more than manufacture boxes—they solve system-level challenges in large-scale rollouts of custom galvanized steel enclosures for industrial use.

Functional Customization for Optimal Performance

Your supplier should offer CNC or laser-cut precision for ports, HMIs, and cable entries tailored to your specific equipment.

Thermal management is another often-overlooked requirement. Engineered venting and airflow solutions must be integrated without compromising NEMA ratings—especially for sealed galvanized electrical housings with sensitive electronics.

This is where an experienced metal fabrication partner adds value—not only through precision, but through compliance-aware design.

Structural Customization and Supply Chain Integration

A true OEM/ODM supplier should provide options such as:

- Pre-installed mounting hardware (DIN rails, grounding studs)

- Modular panel configurations

- Duplex Systems (powder coat over HDG) for extended outdoor life

These features reduce integration time and ensure repeatability across production runs, particularly for contract manufacturing of galvanized electrical enclosures for energy or telecom clients.

Chapter 5: Asset Lifecycle Management: Maintenance and Future-Proofing

Strategic procurement is about future-proofing. That includes specifying enclosures that are both durable and adaptable to future expansion or sensor integration.

Best Practices for In-Service Maintenance and Repair

Even the most durable coatings can be damaged during handling or operation. Per ASTM A780, authorized repair methods include:

- Zinc-rich epoxy paint

- Zinc-bearing solders

- Thermal zinc spray (metallization)

These restore not just surface coverage, but also the crucial galvanic protection—an essential task for maintaining galvanized steel junction enclosures in field environments.

The Future of Protection: Advanced Materials and Smart Technology

Modern innovations include ZAM coatings (Zinc-Aluminum-Magnesium), which offer exceptional edge corrosion resistance and are gaining adoption for advanced galvanized enclosure applications.

Meanwhile, smart enclosures equipped with IoT sensors can monitor internal temperature, humidity, or vibration—enabling predictive maintenance and improving system uptime. These intelligent galvanized steel enclosures are especially relevant in smart grid, renewable energy, and remote communication deployments.

Conclusion: A Procurement Framework for Choosing a Partner

The right galvanized steel enclosure delivers much more than protection—it’s an investment in operational continuity.

Use this checklist to guide your vendor selection:

- Environmental Risk Assessment: Is the enclosure material suited to project conditions?

- Standards Compliance: Are NEMA/IP/ASTM certifications aligned with your regulatory needs?

- Customization Capabilities: Can the supplier offer design and engineering flexibility?

- Lifecycle Value: Does the material choice minimize TCO and downtime?

When these criteria are met, your supplier becomes more than a vendor—they become a partner in long-term performance.

Looking for a reliable galvanized enclosure supplier for industrial, telecom, or infrastructure applications? Our team at YISHANG is here to support your next project with engineering-backed solutions tailored for global deployment.