The Costly Misconception: When a “Waterproof” Rating Fails in the Real World

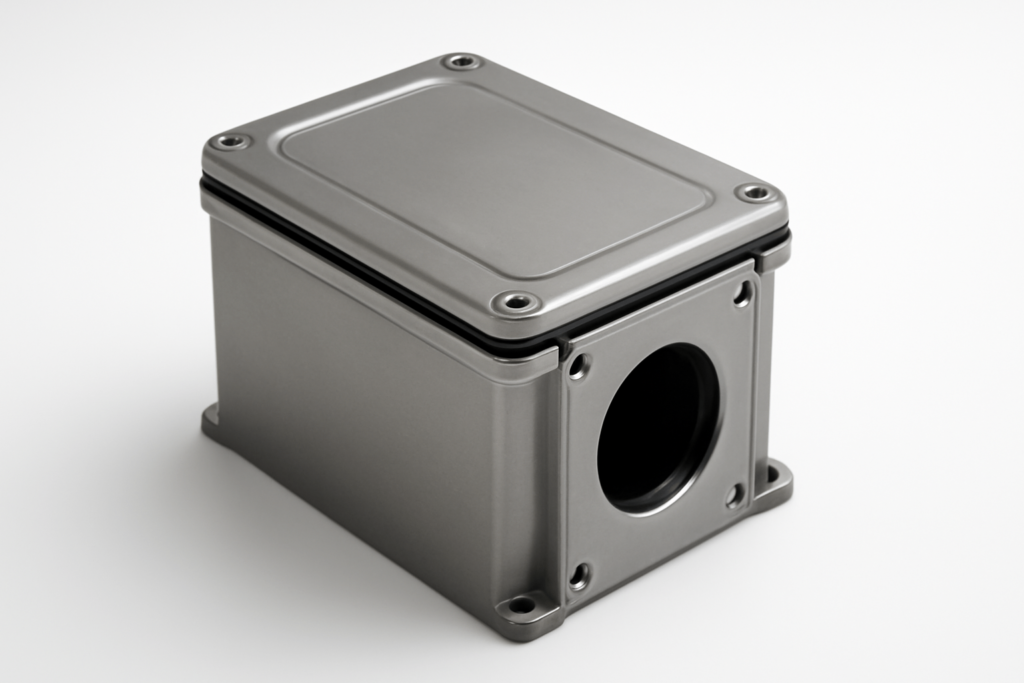

For wholesale procurement managers, product failure is more than an inconvenience—it’s a potential business catastrophe. Imagine launching a new line of outdoor equipment, specified with premium IP68-rated metal enclosures. However, months later, reports flood in from the field: system failures after heavy storms and malfunctions following routine industrial cleaning.

As a result, costly warranty claims, product recalls, and irreversible damage to your brand’s reputation occur. This scenario highlights a critical gap between the marketing promise of a “waterproof” rating and the complex engineering reality that governs long-term reliability and total cost of ownership.

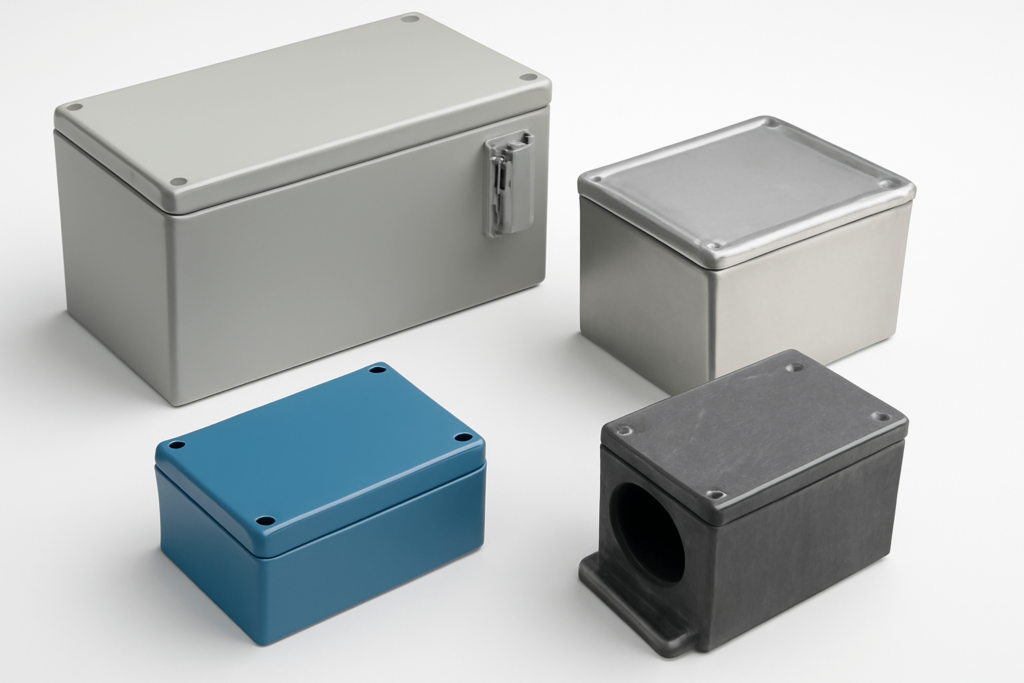

Thus, the question, “What is the best IP rating?” is flawed from a business perspective. It implies a simple scale where a higher number is always better. This oversimplification can lead to incorrect product specifications and significant financial risks. The optimal rating depends on various factors, such as the application, environmental hazards, and the material science of the enclosure itself.

This guide goes beyond the numbers to empower procurement professionals and engineering teams with the expert knowledge required to select the correct level of protection. It ensures robust product performance, enhances customer satisfaction, and protects your bottom line from the costly consequences of enclosure failure.

The Language of Protection: Deconstructing the IP Code (IEC 60529)

To make informed sourcing decisions, you must first speak the language of the standard. The IP Code, or Ingress Protection, is defined in the international standard IEC 60529. This system replaces vague marketing terms with a precise, two-digit code, enabling accurate, data-driven comparisons based on rigorous, repeatable testing.

An IP rating consists of the letters “IP” followed by two numerals. The first digit relates to protection against solid objects (like dust), and the second digit relates to protection against liquids (water). The higher the number, the greater the protection in that specific category. Understanding this system is essential in mitigating risk.

First Digit (Solids): The Unsung Hero of Durability

While water resistance gets the spotlight, the first digit is the unsung hero of long-term durability. It quantifies protection against solid objects, from accidental contact to microscopic, abrasive dust. For sensitive electronics, this is a critical parameter on a scale from 0 (no protection) to 6 (complete protection).

An IP6X rating signifies the enclosure is “Dust Tight.” This is the non-negotiable baseline for any serious industrial or outdoor metal enclosure. It certifies that no dust can enter, thus protecting sensitive components from particulates that can cause short circuits, block cooling fans, and lead to premature failure.

Second Digit (Liquids): The Focus of Failure Analysis

The second numeral represents the enclosure’s ability to protect against harmful water ingress. This scale is the primary focus of failure analysis in wet or washdown environments and ranges from 0 (no protection) to a specialized 9K rating. Therefore, understanding the distinct challenges at each level is fundamental to specifying the correct component for your supply chain.

A Hierarchy of Hazards: Matching the Rating to the Application

The numbers in an IP rating are the direct results of highly specific, standardized laboratory tests. For procurement professionals, understanding the mechanics of these tests is crucial. It ensures that the rating is correctly translated into its real-world capabilities and that the supplier’s claims are valid.

Tier 1: Atmospheric & Incidental Exposure (IPX4, IPX5)

These ratings are designed for common, non-pressurized moisture encounters. An IPX4 rating certifies resistance to water splashing from any direction, making it suitable for environments with heavy rain. The test is conducted for 10 minutes, using a nozzle delivering 10 liters of water per minute.

A significant step up, the IPX5 rating signifies protection against low-pressure water jets, often referred to as the “garden hose test.” The IPX5 test uses a 6.3 mm nozzle to project water at 12.5 liters per minute at a pressure of 30 kPa from 3 meters for at least three minutes. This rating is ideal for enclosures in sheltered outdoor locations or indoor areas that undergo light cleaning.

Tier 2: The Industrial Washdown Standard (IPX6)

This category marks a critical escalation to the deliberate, pressurized streams of water common in industrial washdown procedures. An IPX6 rating certifies protection against powerful water jets and is essential for any equipment in factory or heavy machinery environments. The IPX6 test conditions are significantly more intense. The nozzle size increases to 12.5 mm, the flow rate jumps to 100 liters per minute, and the water pressure is increased to 100 kPa from 3 meters for at least three minutes. An enclosure that can withstand these conditions is truly prepared for the rigors of an industrial washdown.

Tier 3: The Immersion Myth (IP67 & IP68)

This is the category most associated with “waterproof,” yet it is also the source of significant misunderstandings. An IP67 rating provides a clearly defined benchmark: it certifies that an enclosure can withstand temporary immersion in 1 meter of still, fresh water for exactly 30 minutes. This is a safety net against accidental drops, not a certification for active use underwater.

The IP68 rating signifies protection beyond the IP67 standard, but its definition contains a critical ambiguity for buyers. The IEC standard only states that the conditions for IPX8 are agreed upon and specified by the manufacturer. This means there is no universal test for IP68. For a procurement manager, this means the IP68 label alone is insufficient. Therefore, you must demand the supplier’s specific test data to understand the actual performance limits.

A device rated for immersion (IP67 or IP68) is not automatically protected against powerful jets (IPX6). The engineering is different, which is why some rugged devices are dual-rated (e.g., IP65/IP68) to certify protection against both hazards.

The Industrial Frontier: Where Metal Enclosures Prove Their Worth (IP69K & NEMA 4X)

For the most demanding applications, standard IP ratings are insufficient. This is the industrial frontier where robust engineering, superior materials, and specialized certifications are required to ensure operational integrity and unlock lucrative markets.

IP69K: The Ultimate Washdown Rating

The IP69K rating represents the pinnacle of protection against high-pressure, high-temperature water jets. This rating originates from the ISO 20653 standard, initially developed for road vehicles requiring intensive cleaning. Its application is now essential in any industry where rigorous sanitation is paramount.

The IP69K test is a trial by fire and water, simulating a close-range steam cleaning. The enclosure is sprayed with water heated to 80°C (176°F) at an extremely high pressure of 80–100 bar (1160–1450 psi) from a nozzle held a mere 10-15 cm away. This level of protection is non-negotiable in industries like food and beverage processing, where compliance with hygiene regulations is critical.

NEMA 4X: The Corrosion Killer

In North America, the NEMA rating system often runs parallel to the IP code. While there are approximate equivalencies, a discussion of NEMA vs IP rating reveals that NEMA’s scope is significantly broader. The most critical distinction for high-value applications is the NEMA 4X rating.

While a NEMA 4X enclosure is roughly equivalent to IP66 in terms of dust and water jet protection, the crucial difference is the “X,” which designates certified corrosion resistance. The IP standard has no equivalent for this. This rating necessitates the use of specific materials, such as 316 stainless steel. For a buyer, specifying NEMA 4X is essential for products destined for marine environments, chemical plants, or any application where salt spray would rapidly degrade a standard enclosure.

Beyond the Rating: Critical Failure Points for Metal Enclosures

An IP rating is a certification of a new product under ideal laboratory conditions. At YISHANG, our experience fabricating and testing enclosures shows that the difference between a product that simply passes a test and one that performs reliably for years comes down to mitigating real-world failure points.

The Corrosion Factor (Saltwater & Chemicals)

The single most critical limitation of IP waterproof tests is that they are all conducted using fresh, pure water. Saltwater is far more destructive. It is highly conductive, increasing the risk of short circuits, and extremely corrosive. When it evaporates, it leaves behind salt crystals that aggressively attack metal components and abrade seals. This is why material specification—like choosing 316 over 304 stainless steel for marine applications—is as important as the IP rating itself.

Seal Integrity & Gasket Failure

A metal enclosure is only as good as its seal. The long-term reliability of an IP rating depends entirely on the quality and design of its gaskets. The choice of material is critical: silicone offers excellent performance across a wide temperature range, while EPDM rubber provides superior resistance to weathering and UV exposure. A common failure point we observe is an improperly designed flange or the use of low-quality gasket material that experiences “compression set” (permanent deformation) over time.

The Physics of Pressure (Static vs. Dynamic)

IP immersion ratings (IPX7 and IPX8) are tests of static pressure—the pressure exerted by a column of still water. The moment a fluid moves past an object (like waves hitting a ship), it is subjected to dynamic pressure. This additional pressure, created by the kinetic energy of the fluid’s motion, can far exceed the certified static depth rating and force water past seals. This is a critical consideration for specifying enclosures for transportation or mobile equipment.

Physical Damage & Thermal Cycling

An IP rating applies to a pristine enclosure as it leaves the factory. The rating can be instantly compromised by physical damage. A single drop or impact can create a microscopic crack in a weld or slightly deform the frame, compromising the seal flange. Furthermore, metal enclosures are subject to thermal cycling—the constant expansion and contraction from temperature changes. Over thousands of cycles, this movement can stress seals and fasteners.

The Engineer’s Decision Matrix: Specifying the Right Enclosure

Choosing the correct enclosure requires moving beyond a simple quest for the highest number and instead engaging in a risk-based analysis of the operating environment. This decision matrix provides a practical framework for matching the environment to the appropriate level of protection.

| Operating Environment | Primary Threat | Minimum IP Rating | Strongly Consider NEMA 4X If… |

|---|---|---|---|

| Indoor Factory Floor | Circulating Dust, Splashes | IP54 | Caustic cleaning chemicals are used. |

| Outdoor (General Use) | Rain, Windblown Dust | IP65 | Located in a coastal/salty air environment. |

| Food Processing Plant | High-Pressure Washdowns | IP66 / IP69K | High-temperature steam and sanitizers are used. |

| Marine / Coastal | Salt Spray, Waves | IP66 | This is the baseline requirement. |

| Chemical Plant | Corrosive Vapors, Spills | IP66 | This is the baseline requirement. |

Conclusion: Engineering for Reality, Not Just for a Rating

The journey through the intricate world of Ingress Protection ratings leads back to a profound conclusion for anyone responsible for product reliability and procurement: the IP rating is a starting point, not the finish line. True, long-term performance is not achieved by simply selecting the highest number on a chart.

As we have demonstrated, the “best” rating is relative and application-specific. An IP68-rated enclosure is superior for static submersion, but an IP66-rated enclosure is far better suited to withstand a daily industrial washdown. True protection lies in matching the engineering to the reality of the environment.

Ultimately, the long-term integrity of your equipment and the reputation of your brand depend on more than just a rating. They depend on the quality of the enclosure’s construction, the resilience of its seals, and the inherent properties of the materials used. Partnering with a metal fabrication expert who understands these critical nuances is the most effective way to mitigate risk.

If you have questions about specifying the right enclosure for your application, our team at YISHANG is here to help.