Introduction

For industrial procurement teams and wholesale buyers, surface finishing is more than a cosmetic decision—it’s a determinant of long-term performance, safety, and compliance. Hardcoat anodizing of aluminum, also referred to as Type III anodizing, delivers a durable, corrosion-resistant, and electrically insulating surface, especially vital for applications such as enclosures, chassis, and brackets in power distribution, telecom, and renewable energy systems.

This guide is tailored for sourcing professionals seeking to understand not only the fundamentals of hardcoat anodizing but also how to evaluate technical feasibility, quality consistency, and supplier capability. From alloy selection to quality certification, this in-depth resource provides a procurement-driven perspective for decision-makers.

What Is Hardcoat Anodizing?

Hardcoat anodizing is an electrochemical process that converts the surface of aluminum into a thick oxide layer. Unlike standard anodizing, which is often thin and decorative, hardcoat (Type III) builds an oxide layer typically between 25–100 µm in thickness, providing significant improvement in hardness, dielectric strength, and corrosion resistance.

The process operates under cold conditions (typically –2°C to 5°C) with high current densities (2–5 A/dm²), forming a dense, crystalline structure. The resulting surface reaches hardness levels up to 500–600 HV and provides electrical insulation up to 1500 volts.

From a sourcing perspective, this means fewer post-processing steps, lower defect rates, and reduced warranty claims for critical-use enclosures and components. Industries benefiting most include power electronics, solar infrastructure, medical equipment, and defense systems.

Technical Process Overview and What It Means for Buyers

Understanding the core steps of hardcoat anodizing empowers buyers to set realistic specifications, interpret supplier quotes, and assess QA reports effectively.

1. Surface Preparation

The aluminum is degreased and etched to remove oxides and surface contaminants. This phase determines the uniformity of the oxide layer. For suppliers, process control here affects yield and defect rates.

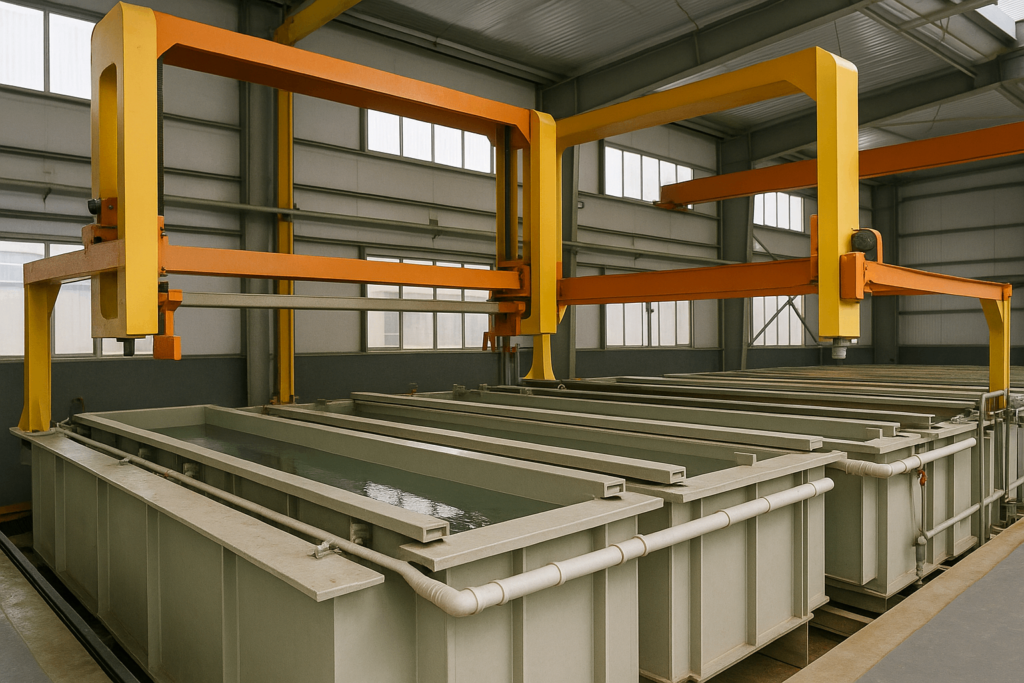

2. Electrolytic Oxidation

The aluminum part becomes the anode in a sulfuric acid bath. High current and low temperature cause rapid oxide formation. Key process controls include:

- Current density: 2–5 A/dm²

- Bath temperature: –2°C to 5°C

- Time: Typically 30–90 minutes

Buyers should look for suppliers who provide documented control parameters and SPC data to ensure coating consistency.

3. Sealing and Finishing

After oxidation, the part is sealed—often in hot water or nickel acetate—to close the porous oxide structure. This step enhances corrosion resistance. Unlike decorative anodizing, hardcoat rarely requires coloring, though dark shades can be achieved with limited dye absorption.

Key Technical Attributes Buyers Should Prioritize

Hardcoat anodizing is not just a finish; it’s a functional enhancement. Key performance indicators include:

- Hardness: 400–600 HV. Look for parts tested to Vickers or Rockwell standards.

- Corrosion Resistance: Coated parts should exceed 336 hours in salt spray per ASTM B117.

- Dielectric Strength: Surface withstands up to 1500 V/mil, ideal for control panels and insulated enclosures.

- Thermal Stability: Maintains structure under –50°C to 200°C temperature cycles.

These properties are essential for products exposed to aggressive environments or requiring long-term reliability, such as:

- Outdoor battery housings

- High-frequency signal enclosures

- Marine-grade fixtures

For procurement teams, verifying these parameters in supplier QA documentation is critical.

Standards and Compliance: What Buyers Must Know

To ensure global supply chain consistency, sourcing teams should demand compliance with recognized anodizing standards:

- MIL-A-8625 Type III: U.S. military standard for thickness, process, and performance.

- ASTM B580: Defines coating class, testing procedures, and visual inspection criteria.

- ISO 10074: Common in Europe and Asia for anodized aluminum quality benchmarks.

Request a certificate of compliance (CoC) and third-party test reports for critical applications such as aviation, medical, or energy systems. Reputable suppliers should list these standards in quotes and data sheets.

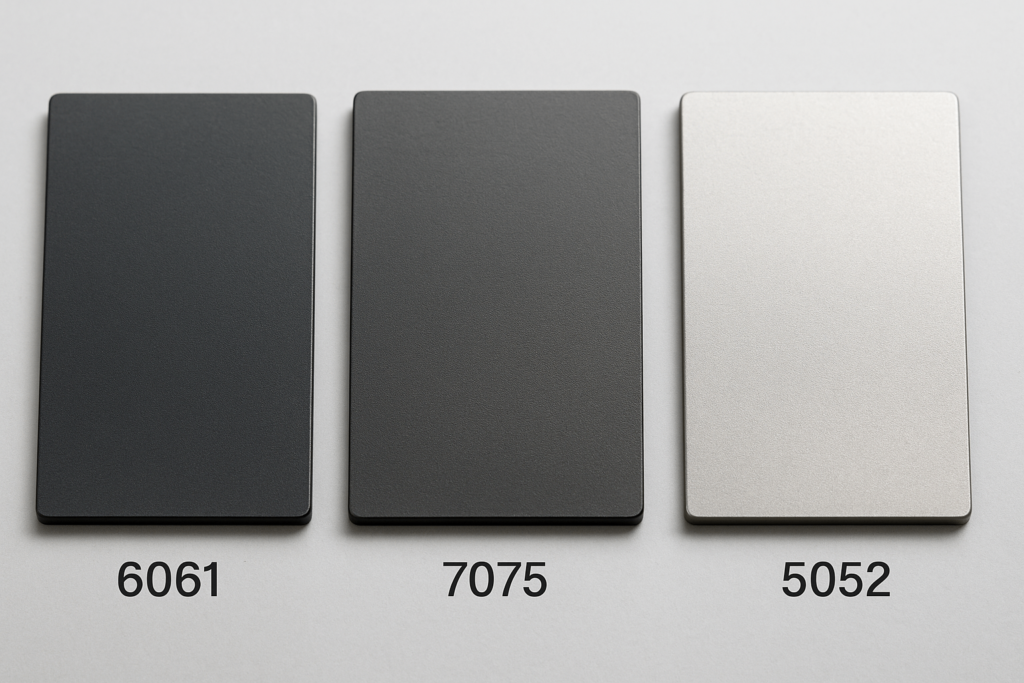

Alloy Selection: Impact on Finish and Quality

Not all aluminum alloys yield the same quality when hardcoat anodized. Each alloy has distinct oxide growth behavior, surface color variation, and finish response.

| Alloy | Application Fit | Anodizing Quality | Notes |

|---|---|---|---|

| 6061 | Enclosures, panels | Excellent | Balanced strength and finish |

| 7075 | Aerospace, frames | Moderate | High strength but color variation |

| 2024 | Structural, aerospace | Low | Poor corrosion unless sealed |

| 5052 | Marine, outdoor | Good | Needs tighter bath control |

When placing RFQs, specify both alloy and target thickness (e.g., ≥ 50 µm). Ask suppliers to provide prior examples on matching alloys or sample coupons.

Factors Affecting Quality and Functional Output

Several upstream and process-level factors influence anodizing consistency and performance:

- Electrolyte Chemistry: Deviations in acid concentration can cause soft coatings or color defects.

- Temperature Drift: Even 1–2°C fluctuation can shift coating hardness or thickness.

- Current Overload: Leads to pitting, discoloration, or microcracking.

- Alloy Contamination: Traces of silicon or copper affect oxide adhesion and color.

- Sealing Integrity: Incomplete sealing degrades corrosion protection.

Buyers should request:

- Electrolyte monitoring logs

- Thickness data per ISO 2360 (eddy current)

- QA photos or micrographs of coating structure

Testing and Quality Assurance: What to Ask For

Sourcing teams should build a checklist of post-processing QA requirements to reduce disputes and ensure fit-for-purpose parts:

- Thickness Verification: ISO 2360 (eddy current) or cross-sectional SEM analysis

- Hardness Tests: Vickers (HV) or Rockwell (HR15T), performed on every lot

- Salt Spray Results: 336+ hours, per ASTM B117, for corrosion resistance

- Dielectric Breakdown Test: For parts requiring electrical insulation

- Batch Traceability & QC Documentation: Required for certified supply chains

Request pre-shipment QA reports and, where possible, video inspections or third-party QA certificates.

How It Compares: Other Finishes vs. Hardcoat Anodizing

Hardcoat anodizing is one of several aluminum finishing options. Buyers must evaluate based on performance needs:

| Finish Type | Wear Resistance | Insulation | Corrosion | Appearance |

|---|---|---|---|---|

| Hardcoat Anodize | Excellent | Excellent | Excellent | Limited |

| Powder Coating | Good | Poor | Good | High |

| Chromate (Alodine) | Low | Fair | Moderate | Low |

| Clear Anodize | Moderate | Moderate | Moderate | High |

If function outweighs form—particularly in outdoor, high-voltage, or high-cycle applications—hardcoat is the preferred finish.

Supplier Evaluation: A Checklist for B2B Buyers

When selecting anodizing service providers, prioritize:

- MIL-A-8625 Type III capability

- Alloy compatibility track record

- Documented bath control procedures

- Batch QA reports with verifiable test methods

- Willingness to provide samples or coupons

- In-house fabrication + anodizing integration

YISHANG, for instance, combines CNC sheet metal production with certified anodizing lines, allowing for tight control over tolerances and visual consistency.

Applications in the Field: Where Hardcoat Anodizing Delivers

Real-world examples of successful applications include:

- Solar Charge Controllers: Require insulation + thermal durability

- Utility Meter Enclosures: Long-term corrosion protection in harsh climates

- Aerospace Connectors: Lightweight, electrically insulated components

- Industrial Machinery Frames: High cycle wear resistance

These illustrate why OEMs in energy, automation, and telecom rely on properly anodized parts for mission-critical equipment.

Conclusion: Making Informed Decisions

Hardcoat anodizing is not just a technical process—it’s a strategic sourcing choice. For procurement professionals, knowing how to define specs, evaluate supplier claims, and validate quality through testing is key to successful partnerships.

Choose suppliers who demonstrate process control, certification, and field-tested experience. By aligning technical requirements with supply capabilities, you’ll ensure long-term product performance and reduced lifecycle cost.

Start your inquiry today to discuss alloy compatibility, coating specs, and sample testing. Our team is ready to support your project.