Table of Contents

隐藏

Short answer for procurement teams: For export‑grade finishes, powder coating rims typically requires 3–5 business days from receiving the wheels to final packing. The actual coating cycle per wheel is only 1–2 hours, but the complete industrial workflow—chemical stripping, neutralisation, blasting, outgassing, application, PMT‑based curing, cooling, inspection, and batch scheduling—defines the true lead time. For wholesalers and distributors, this timeframe directly impacts stocking plans, container consolidation, and downstream delivery commitments.

Most online results for how long does it take to powder coat rims or how long does it take to powder coat wheels target individual car owners. They often claim same‑day or 24‑hour service. These timelines rarely apply to export‑grade B2B production, especially when consistency, durability, and multi‑batch repeatability are required.

At YISHANG, with over 26 years of metal fabrication experience and clients in 50+ countries, we see a predictable pattern: buyers who clearly understand the technical timeline achieve better supply stability, lower defect rates, and stronger long‑term customer satisfaction. This article restructures the powder‑coating timeline specifically for B2B wholesale buyers, linking each technical step with procurement‑critical metrics such as reject‑rate control, warranty exposure, visual consistency, logistics planning, and supplier evaluation.

Lead Time as a Quality Indicator in B2B Sourcing

For wholesalers and brand owners, lead time is not simply an operational metric—it is a signal of process maturity and quality control. Consumer‑oriented workshops often promote same‑day wheel coating, but industrial operations cannot compress multi‑stage chemical, mechanical, and thermal treatments into a few hours without compromising coating integrity. B2B buyers also evaluate the indirect consequences of shortened processes. A batch that appears visually acceptable on arrival may still fail prematurely during transport, seasonal climate change, or regular field use. When coatings peel, bubble, or rust, the cost of remediation—returns, replacements, reputation loss—is far greater than the savings achieved by rushing production. A practical benchmark buyers often use is whether a supplier can clearly articulate the sequence: chemical stripping → neutralisation → blasting → outgassing → application → curing → cooling → inspection → packing. Suppliers who can explain each step usually maintain ISO‑aligned workflows, a stable performance record, and predictable repeat‑order results. For this reason, B2B buyers often consider 3–5 business days a realistic sign of a controlled, documented industrial process rather than inefficiency. Understanding this connection helps procurement teams compare offers, filter unrealistic claims, and avoid hidden quality risks that disrupt future shipments.Days 1–2: Foundation Work—Stripping, Neutralisation, Blasting and Outgassing

The first stages define the long‑term durability of powder‑coated rims. These steps require time to complete chemical reactions, stabilise the metal, and prepare a uniform surface. While individual durations vary by alloy, coating type, and contamination level, industrial buyers typically allocate one to two full days for this phase.

Full Chemical Stripping

OEM paint systems are engineered for corrosion resistance and mechanical durability. Removing them requires heated alkaline stripping or specialised chemical baths that fully dissolve multilayer coatings. This immersion process typically lasts 8–12 hours. It is not labour‑intensive, but it is time‑dependent; cutting it short leaves hidden coating residues that compromise adhesion. For B2B buyers distributing to multiple regions, incomplete stripping is especially problematic. Some wheels in a batch may perform well while others fail prematurely—an unacceptable outcome for brands relying on consistent quality across shipments.Neutralisation and Stabilising Rinse Cycles

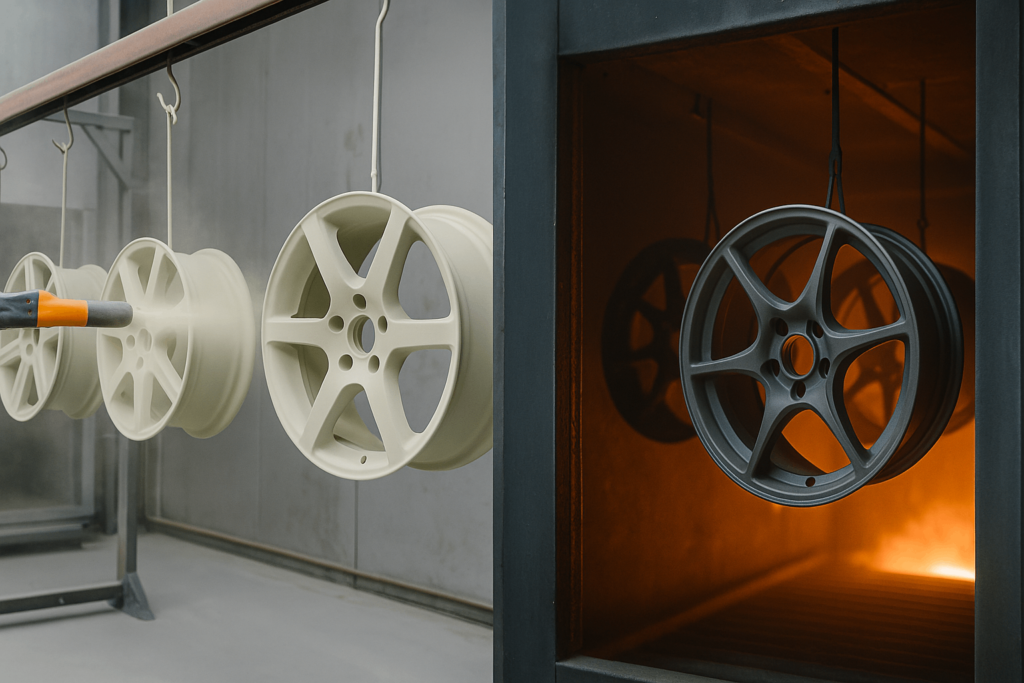

Once stripped, wheels must be neutralised to eliminate alkaline residues. Without proper pH balancing, chemical activity can continue beneath the coating, causing blistering or under‑film corrosion months after installation. Multiple rinse cycles ensure chemical stability before mechanical preparation. This is a small part of total labour time but a major contributor to long‑term coating reliability—critical for buyers shipping through varied humidity and temperature conditions.Media Blasting for Mechanical Anchoring

Blasting with aluminium oxide creates microscopic surface peaks and valleys, increasing surface area and ensuring strong mechanical bonding. This step is essential for rims used in demanding applications—fleet vehicles, off‑road equipment, agriculture hardware, and other sectors requiring shock and abrasion resistance. The quality of blasting directly influences film uniformity and edge retention. B2B buyers should verify the blasting media, pressure standard, and inspection method to evaluate a supplier’s preparation quality.Outgassing (Pre‑Bake Treatment)

Aluminium castings often trap moisture and gases. When rims heat up during curing, trapped volatiles expand and can cause pinholes or bubbles. Outgassing cycles—typically 1–3 hours—release these internal contaminants before coating begins. For buyers focused on warranty stability, outgassing is one of the clearest indicators of industrial‑grade process control.Days 3–4: Application, Multi‑Coat Systems and PMT‑Controlled Curing

The third and fourth days concentrate on coating application, curing profiles, and handling. This is where shortcuts create the most visible and functional defects, and where professional powder‑coating turnaround time diverges sharply from express consumer services.

Managing the Faraday Cage Effect

Rims feature deep pockets and complex geometries, making uniform coverage challenging. Powder tends to repel from tight recesses, requiring technicians to adjust KV (kilovolt settings), change nozzles, adapt spray angles, or modify grounding. For complex models—mesh, split‑spoke, deep‑dish—this may involve multiple controlled passes. Correct handling improves film‑thickness consistency and reduces reject rates across large batches, which directly affects procurement cost stability.Single‑Coat vs Multi‑Coat Production Cycles

Higher‑value markets increasingly demand two‑coat or three‑coat systems. A typical custom finish might include:- a metallic base layer,

- a tinted translucent layer,

- and a final protective clear coat.

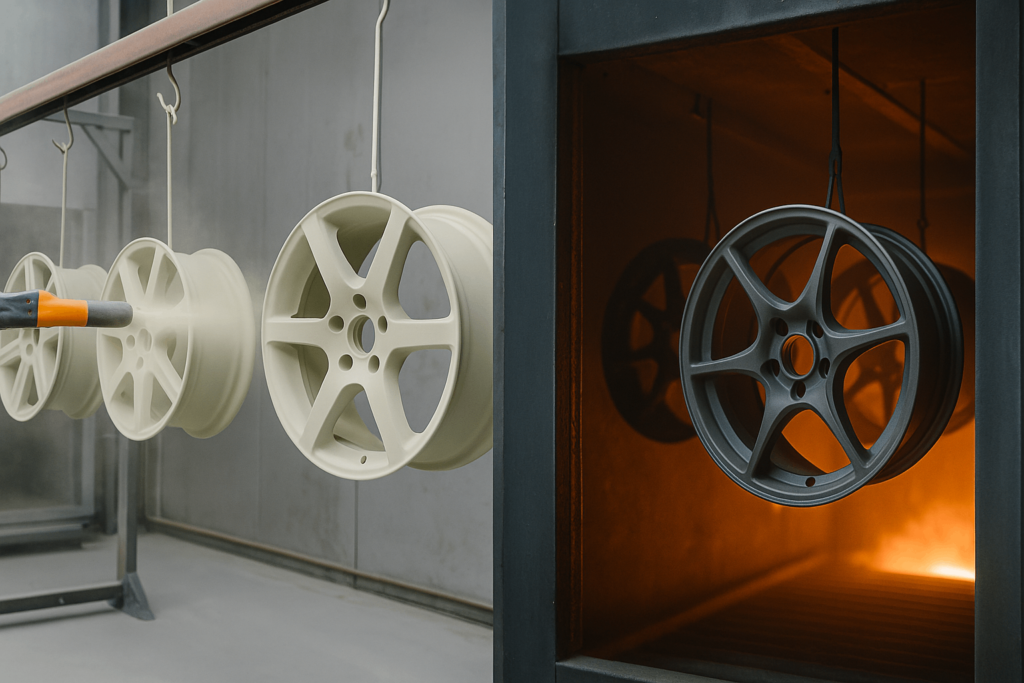

PMT (Part Metal Temperature) and Accurate Curing

Powder coatings cure based on metal temperature, not oven air temperature. Thick alloy wheels may require 20–30 minutes just to reach curing temperature. Only then can the oven‑hold timer begin. A single curing cycle, including ramp‑up and cool‑down, typically spans 40–60 minutes. Multi‑coat systems multiply this timeframe. Under‑curing reduces hardness and chemical resistance, while over‑curing can cause brittleness. Buyers should confirm whether suppliers use thermocouples or data loggers to monitor PMT—an essential sign of process consistency.Controlled Cooling for Dimensional and Visual Stability

Cooling periods between coats ensure the coating stabilises without imprinting or thermal distortion. Rapid cooling may accelerate handling but increases internal stress. In container‑level orders, consistent cooling procedures support uniform colour tone and gloss across hundreds of units.Day 5: Batch Scheduling, Colour Management and Export‑Ready Preparation

Even when technical steps are completed efficiently, industrial workflows require structured scheduling. Many online articles overlook this stage entirely, yet it has a profound impact on B2B delivery reliability.Colour Batching for Consistency and Cost Control

Colour changes require intensive cleaning of booths, hoses, and recovery systems. To avoid contamination, facilities group similar colours together. Rims enter the production queue when the booth is set up for their specific colour. This batching method benefits buyers by improving colour consistency and reducing setup‑related costs. Reorders processed within similar batching patterns produce better visual alignment across shipments.Capacity Planning for Small vs Large Orders

Small orders may be slotted between larger batches, while pallet‑ or container‑level volumes require reserved capacity. Buyers planning quarterly or monthly orders can secure dedicated slots and stabilise freight timelines. Strategic forecasting also allows suppliers to pre‑order powders and adjust labour, reducing delays during peak seasons.Final Inspection, Packing and Export Preparation

Post‑coating inspection evaluates thickness, edge coverage, gloss level, and surface defects. Nonconforming units undergo rework. Finished wheels are then packed using foam layers, separators, protective films, or custom cartons. For long‑distance shipping, proper packing is essential to reduce freight‑related defects. A structured packing protocol is a strong indicator of a supplier capable of supporting international buyers.Why DIY and Same‑Day Services Do Not Meet B2B Requirements

Some buyers ask whether small workshops or DIY services can support low‑volume procurement. These setups can be suitable for consumer repairs but rarely meet the requirements of industrial buyers.Equipment Limitations Create Inconsistent Results

DIY ovens lack thermal stability, and consumer spray guns offer limited voltage and flow control. This results in uneven film thickness, overspray, or colour variation—issues unacceptable in retail or branded batches. B2B buyers must prioritise suppliers with industrial ovens, calibrated systems, and documented QC processes.Preparation Shortcuts Reduce Coating Lifespan

Without chemical stripping, controlled neutralisation, or structured outgassing, adhesion becomes unpredictable. Some units may last years while others fail quickly. Such variability creates downstream warranty and brand‑perception challenges.Lack of Traceability and Compliance

Industries such as automotive, energy storage, vending, or construction often require RoHS compliance and ISO‑aligned workflows. DIY coaters typically lack process records, batch tracking, or corrective‑action systems. For importers and brand owners, traceability is not optional—it is a key risk‑management requirement.Practical Summary: Realistic Timelines for Industrial Buyers

When combined, all stages form a reliable timeline of 3–5 business days for export‑grade powder‑coated rims. The steps include:- Days 1–2: stripping, rinsing, neutralisation, blasting, outgassing;

- Days 3–4: application, PMT‑controlled curing, cooling, multi‑coat cycles;

- Day 5: batching, inspection, packing, logistics preparation.