A Practical Guide for Wholesale Buyers Seeking Precision Sheet Metal Solutions

Introduction

Aluminum remains a leading choice for OEMs and system integrators across automotive, medical, electronics, energy, and architectural sectors. Lightweight, corrosion-resistant, and easy to machine, it’s the backbone of many enclosure, panel, and bracket assemblies. But when you’re sourcing bending services for aluminum sheet or profiles, accuracy, repeatability, and finish quality become core decision factors.

This guide is crafted for global procurement teams, technical buyers, and supply chain managers who need reliable, production-grade aluminum sheet bending. Backed by over 26 years of experience, YISHANG shares insight into material selection, equipment compatibility, bending process planning, and risk control for scaling custom projects. Whether you’re pricing 90-degree folded housings or curved bended sheet panels, this is your blueprint.

Know Your Material: Which Aluminum Is Bendable, and Why?

The type of aluminum alloy and its temper state directly affect bendability. Poor choices here increase your risk of cracks, excessive scrap, and inconsistent outcomes.

Alloy Characteristics & Use Cases

| Alloy | Temper | Yield Strength (MPa) | Elongation (%) | Bendability | Common Applications |

|---|---|---|---|---|---|

| 3003 | H14 | 130 | 20 | Excellent | Ducts, signage, trims |

| 5052 | H32 | 193 | 12 | Good | Marine, cabinets |

| 6061 | T6 | 276 | 8 | Low (T6) | Frames, solar panels |

When preparing bending of sheet metal, 3003 and 5052 are preferred for tight radii and smooth edges. 6061-T6 is common in structural projects, but requires annealing to O or T4 before cold bending to avoid fracture.

Understanding Bend Radius & Grain Direction

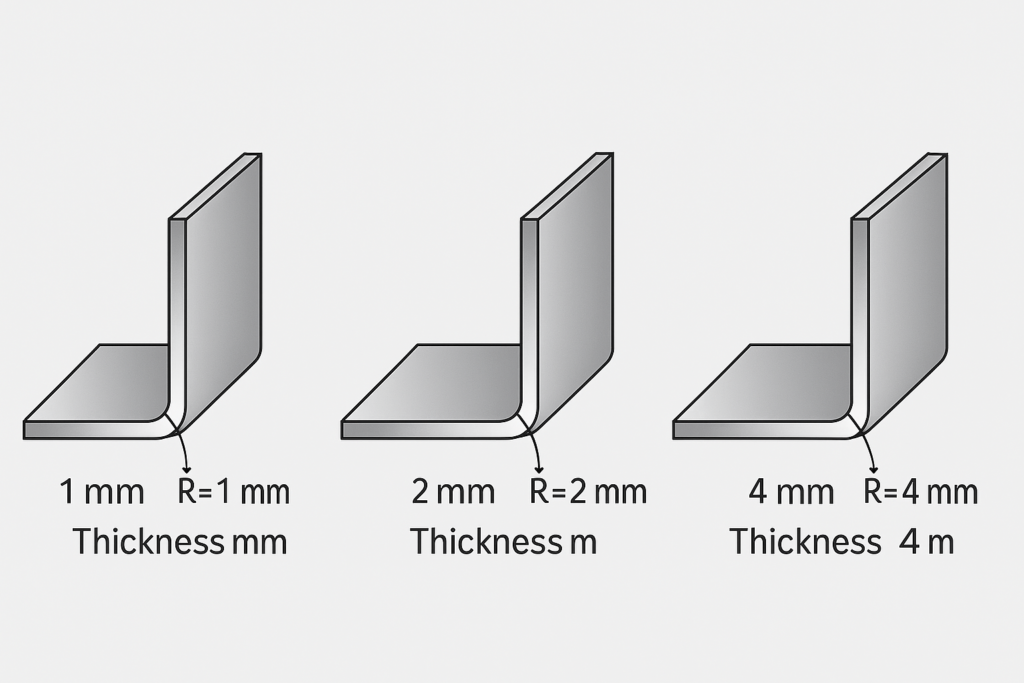

According to the bend radius chart for sheet metal, minimum bend radii must scale with thickness and temper:

5052-H32, 2mm → Radius ≥ 2.5mm

6061-O, 3mm → Radius ≥ 3.5mm

Always bend across the grain direction, not along it. At YISHANG, our laser alignment ensures fiber orientation is consistently controlled during production runs.

The Right Tools for Accurate Aluminum Bending

Tool selection matters just as much as alloy. Misaligned dies, low-grade press setups, or manual techniques can compromise dimensional control.

Manual vs CNC: When Each Applies

In early prototyping, manual bending of aluminum sheet with seamers or benchtop brakes suffices. But once your BOM hits thousands of units, only CNC aluminium bending machines can maintain precision:

±1° angle control (via live angle sensors)

±0.2mm part variance over 10,000+ pcs

Overbend values embedded into G-code (e.g., 3° for 5052)

YISHANG’s press brake cells are digitally managed to calibrate tool wear and offset springback automatically. We handle both air bending sheet metal and bottom bending depending on angle and batch specs.

Surface Protection & Safety

Finish is critical, especially for commercial and medical-grade parts. We apply PET or polyfilm during processing and use mirror-polished dies. Staff adhere to RoHS and ISO standards for safe, contamination-free handling.

How We Bend Aluminum—And Avoid Errors

Bending is more than just a force application. It’s a calibrated system. Here’s how our bend machine shop controls each stage.

Step 1: Clean, Align, and Mark

We start by degreasing sheets and checking fiber direction. Laser marking ensures consistent line placement, accurate to ±0.1mm.

Step 2: Position and Clamp

Sheets are clamped using CNC-controlled backgauges, eliminating misalignment. Multi-stop systems maintain accuracy across panels exceeding 1m in width.

Step 3: Execute the Bend

Our bending process uses controlled force and programmed speed ramps. Sensors measure real-time angles and halt production if drift occurs.

By contrast, suppliers relying on manual force or inconsistent pressure settings often face inconsistent angles, material fatigue, and even part warpage—especially in bending stainless steel or harder aluminum grades. This increases defect rates and delivery risk.

Step 4: Verify and Document

First-article inspection uses digital inclinometers and height gauges. CMM reports are included upon request. Data is traceable, supporting compliance checks.

Avoiding Common Pitfalls in Sheet Metal Bending

Buyers often ask: how do we avoid post-delivery issues like rejections or stress cracks? Here’s how we mitigate risks upfront.

Springback Compensation

Aluminum’s elasticity leads to springback. Our bending software pre-compensates:

5052-H32 → Overbend ~3°

6061-O → Overbend ~5°

When tight angles are needed, bottom bending is used with hardened dies to minimize variance.

Cracking & Breakage

If a part is failing at the bend line, likely causes include:

Bending along grain (wrong direction)

Insufficient bend radius (per bend radius sheet metal charts)

Skipping pre-heating in 6061-T6 parts

We document and simulate all critical bends, and optional annealing is used where design risk is high.

Surface Marks & Distortion

Common on customer-facing parts. We avoid them via:

Surface film application

Polished dies and regulated pressure

Anti-scuff buffers during ejecting and stacking

In addition, we apply quality control tools such as gloss meters to monitor reflectivity and surface finish, and surface roughness testers to measure Ra values on cosmetic parts.

Advanced Bending Techniques for Industrial Designs

Complex parts require more than one bend. For bending of manufactured parts, here’s how we ensure repeatability.

Multi-Bend & Sequenced Operations

For box-style enclosures or bending rectangular tubing, we simulate interference using CAD before programming sequential tool paths. This prevents collision and angle deformation.

K-Factor & Pattern Accuracy

Using a K-factor of 0.35 (5052) or 0.42 (6061), we optimize flat pattern layouts—important for reducing offcuts during laser prep. This improves yield for wholesale projects.

Tighter Tolerances with Bottoming

When your project specifies angles within ±0.5°, bottoming offers high repeatability by eliminating most springback. While it requires dedicated tooling, this method is applied for precision-intensive parts across aerospace and electronics projects.

How YISHANG Helps Global Buyers Hit Specs

Whether you’re sourcing bending metal sheet brackets or bending of metal tubing, here’s how YISHANG supports buyers in real-world projects:

Case: 5052-H32 Medical Frame (EU Buyer)

Spec: ±0.2mm, film-protected, RoHS compliant

Volume: 12,000 pcs

Result: Zero claims, no secondary QA needed by client

Case: 6061 Energy Battery Box (USA Client)

Spec: 3mm, 8 folds, complex geometry

Process: Pre-heat + sequenced CNC bending + CMM report

Outcome: Passed UL test, repeat reorder placed

We focus on solving issues before they happen—because your reputation depends on parts arriving right.

FAQs: Answers for Technical Buyers

Can I bend 6061-T6 without heat? Only with cracking risk. Always anneal first or order in O/T4 state.

Do you use the 90 degree bend deduction chart? Yes, and it’s integrated into our CAM software with validated values for each alloy.

What’s better: air or bottom bending? Depends. Air bending is flexible, bottom bending ensures higher precision. We apply both where appropriate.

Can you do custom tooling for bended sheet metal? Yes, for high-volume projects (MOQ applies). We also stock universal dies for common radii.

Do you bend steel or stainless too? Yes. We offer bending stainless steel sheet, bend stainless steel tube, and bending steel tubing services alongside aluminum.

Conclusion

Whether it’s a bend aluminum flat bar for solar panels or a 4-side enclosure for electronics, getting aluminum bending right is about design, preparation, and execution. For overseas B2B buyers, minimizing deviation, scrap, and delay is non-negotiable.

With high-volume press brake cells, in-house QC, and English-speaking engineers, YISHANG ensures your project is not only manufacturable—but scalable. Our clients return because we understand one thing well: precision matters.

Need accurate, consistent aluminum bending at scale? Contact YISHANG today to get a fast quote or request a free sample and design suggestion.

Your CAD files and specifications are handled with full confidentiality. We use encrypted file transfer systems and guarantee NDA protection upon request. Secure, seamless, and buyer-friendly ordering is our standard.