The First Cut: Why Precision is the Bedrock of Your Supply Chain

In high-volume manufacturing and fabrication, the initial cut on a piece of metal tubing is far more than a simple separation. It is a foundational step that dictates the quality, cost, and reliability of your entire product line.

An imprecise cut is a hidden liability that creates cascading issues down the assembly line—from misaligned fittings and weld failures to costly rework and project delays. For procurement managers, understanding the nuances of how to cut tubing is not about operating the machine; it’s about specifying a result that guarantees product integrity and protects your bottom line.

This guide provides a comprehensive view of the art and science of cutting metal tubing, framed specifically for sourcing professionals. It explores how different methods impact quality, cost, and production efficiency—empowering you to make informed purchasing decisions and evaluate fabrication partners with confidence.

Part I: Foundational Knowledge for Procurement: Defining a Quality Cut

Before issuing a Request for Quotation (RFQ), it’s crucial to understand the language of quality in metal fabrication. A clearly defined specification is the first step in mitigating risk and ensuring components meet your engineering and performance standards.

The Anatomy of a Quality Cut: Key Metrics for Your RFQ

When evaluating a supplier’s capability, focus on their ability to control these three critical metrics—benchmarks that distinguish a rough cut from a precision-engineered component:

- Squareness (Perpendicularity): A cut face that forms a perfect 90-degree angle to the tube’s axis is essential for welded joints or sealed fittings. Specifying a high degree of squareness (e.g., within ±0.002 inches) ensures consistent fit-up and prevents joint failures.

- Burr-Free Edge: Burrs are sharp, irregular projections of material left after cutting. A burr-free edge is critical for safe handling and system integrity. In hydraulic or pneumatic applications, internal burrs can detach and compromise system performance or damage seals.

- Minimal Heat-Affected Zone (HAZ): Thermal cutting can alter the microstructure of the metal near the cut edge. For high-stress parts or specialized alloys, specifying a minimal HAZ is vital to maintain mechanical strength and corrosion resistance.

The Procurement Matrix: Balancing Cost, Precision, and Lead Time

Choosing a metal cutting tool or process involves strategic trade-offs. As a buyer, recognizing this balance allows for more accurate evaluation of supplier quotes and alignment with your project’s technical needs.

- Cost: Consider the Total Cost of Ownership, not just price per part. A low-cost cut requiring secondary processes like deburring can result in a higher final cost than a clean, high-quality initial cut.

- Precision: Required tolerance control should match the application. Structural parts may tolerate more deviation than medical or aerospace components. Over-specifying tight tolerances can inflate costs unnecessarily.

- Lead Time (Speed): High-speed methods such as laser cutting suit large production volumes and tight timelines. Slower, manual methods may suffice for prototypes but may hinder scalability.

Part II: The Material-Centric Masterclass — Why Your Tubing Composition Dictates the Cut

Not all metals respond equally to cutting. Each alloy brings unique physical and chemical characteristics that influence tooling selection, cutting parameters, and edge quality. For procurement managers, understanding material behavior enables smarter sourcing decisions—especially when navigating multi-material assemblies or specifying surface finishes.

Stainless Steel Tubing: Precision, Work-Hardening, and Tool Wear

Stainless steel (304/316) is prized for its corrosion resistance and strength, but it presents notable challenges during cutting: For more on this material, see our stainless steel tubing guide.

- Work-Hardening Behavior: Stainless tends to harden as it’s cut, increasing tool wear and requiring controlled feed rates. This makes methods like abrasive sawing less desirable for tight-tolerance work.

- Heat Sensitivity: Excessive heat can cause discoloration or compromise corrosion resistance. Cold cutting methods such as rotary tube cutters or orbital saws help preserve surface integrity.

- Best Practices: Use of coolant, low cutting speeds, and negative rake angles on blades minimizes workpiece hardening and improves finish.

Aluminum Tubing: Burr Control, Vibration, and Speed Matching

Aluminum tubing is lightweight and ductile, making it easy to cut—but that softness brings its own set of concerns:

- Gummy Chips & Burr Formation: Ductile behavior means aluminum is prone to leaving burrs and clogging teeth on high-speed blades. Specialized blades with polished gullets and high rake angles help mitigate this.

- Vibration Risk: Thin-walled aluminum tubing can vibrate or deform under pressure, affecting cut precision. Clamping and fixturing are essential.

- Tool Selection: Carbide-tipped cold saws or high-speed circular saws with non-ferrous-specific blades are ideal for production-grade cutting.

Copper & Brass Tubing: Clean Cuts and Deformation Risk

Copper and brass offer excellent conductivity and machinability but require attention to avoid deformation:

- Smearing & Blunting: Copper, in particular, can smear rather than shear cleanly. Sharp tools and steady feed rates are critical.

- Deformation Sensitivity: Brass is more rigid but still prone to end distortion. Using internal mandrels or backing plugs can help maintain roundness.

- Deburring Consideration: Despite excellent cut quality, both metals benefit from light deburring to ensure clean internal bores—especially for fluid or gas applications.

Mixed-Material Considerations in Assembly Procurement

In many industrial products, tubing assemblies may involve mixed alloys (e.g., stainless headers with aluminum branch lines). This introduces compatibility concerns in cutting operations:

- Different Cutting Parameters: Each metal requires distinct feeds, speeds, and blade types. A supplier must demonstrate capability to shift between materials without compromising quality.

- Cross-Contamination Risks: Especially in medical or food-grade environments, using the same tooling on carbon steel and stainless can introduce contamination. Ask vendors about tool segregation policies.

- Coating Awareness: Pre-coated or anodized tubes (common in decorative or architectural applications) require non-scarring cutting techniques such as rotary cutting or precision lasers.

Part III: Choosing the Right Tool for the Job — Matching Method to Application

Cutting metal tubing isn’t one-size-fits-all. The right tool depends on the tube’s material, wall thickness, required finish, production volume, and application context. This section breaks down the pros and cons of commonly used methods to help procurement teams align supplier capabilities with project demands.

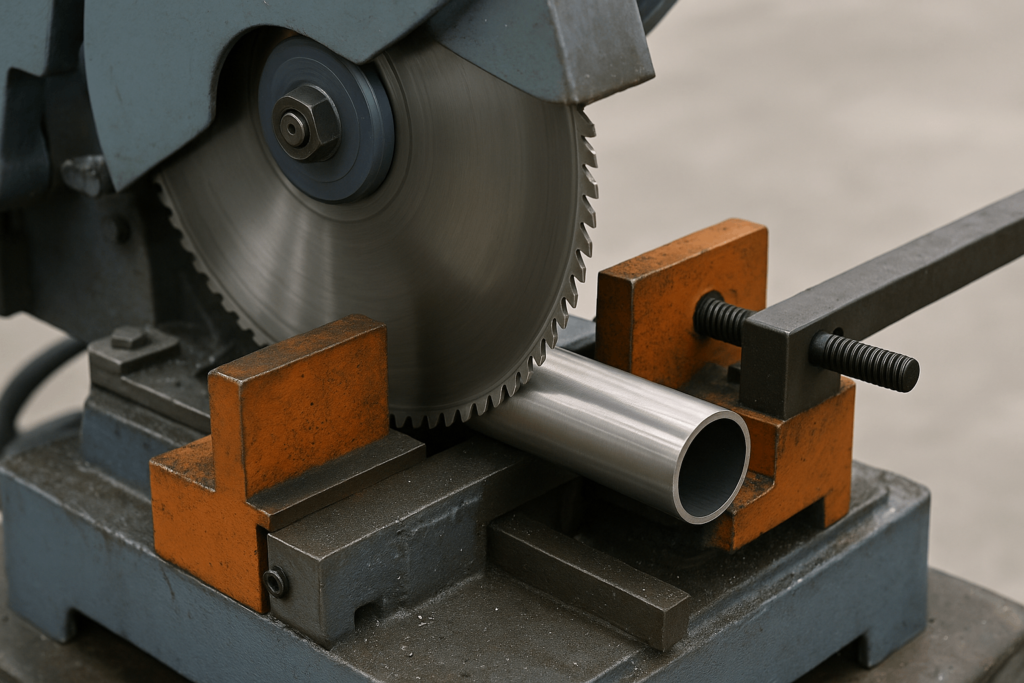

Cold Sawing: Clean, Square Cuts for Medium-Volume Runs

- How It Works: A toothed blade (often carbide-tipped) rotates at relatively low RPMs. Ideal for ferrous and non-ferrous metals alike.

- Strengths: Produces burr-free, accurate cuts with minimal HAZ. Excellent for 90-degree precision cuts on structural tubing.

- Limitations: Slower cycle times than laser or rotary cutting. Blade life can be a concern with work-hardened materials like stainless.

- Best Use Case: Medium-volume runs requiring clean, weld-ready ends with no thermal distortion.

Laser Cutting: Speed, Precision, and Intricate Geometry

- How It Works: Focused light beam melts or vaporizes material with high precision. Can be CNC-programmed for complex shapes.

- Strengths: Fast, contactless, and highly accurate. Excellent edge quality and minimal mechanical stress.

- Limitations: Creates a HAZ, especially in thick-walled tubing. Not ideal for highly reflective metals (e.g., copper, brass) without specialized lasers.

- Best Use Case: High-volume projects with detailed profiles or tight tolerances, especially in stainless or mild steel.

Rotary Cutting: Deformation-Free and Cost-Efficient for Thin Walls

- How It Works: A hardened wheel scores the tube’s circumference until separation occurs via break or snap.

- Strengths: No heat generation. Maintains roundness in thin-walled tubing. Quick and quiet operation.

- Limitations: Not suitable for thicker tubing. May require post-processing for perfectly flat ends.

- Best Use Case: HVAC, appliance, and instrumentation tubing with small diameters and thin walls.

Abrasive Sawing: Fast but Crude — Use with Caution

- How It Works: A resin-bonded abrasive disc grinds through the tubing with high-speed rotation.

- Strengths: Cuts through tough materials quickly. Low upfront equipment cost.

- Limitations: Generates heat, burrs, and wide kerfs. Poor surface finish. Risk of operator error or inconsistent length.

- Best Use Case: Limited prototyping or low-spec applications where post-processing is expected.

Bandsawing: Low Cost, Low Precision

- How It Works: A continuous band blade slices through tubing with downfeed pressure.

- Strengths: Economical and widely available. Can handle larger diameters. It may also be suitable for basic CNC machining services when dimensional tolerance isn’t critical.

- Limitations: Rough finish, slower speeds, inconsistent tolerance control.

- Best Use Case: Simple structural cuts where finish quality and precision are not priorities.

Part IV: Beyond the Cut — Add-On Services That Save Time and Money

While cutting is a critical operation, it’s rarely the final step in the tubing fabrication process. Add-on services—such as deburring, chamfering, cleaning, and kitting—can significantly improve downstream efficiency and reduce your Total Cost of Ownership (TCO). For procurement managers, understanding these options allows for holistic cost evaluations and better supplier negotiations.

Deburring and Edge Conditioning: The Hidden Cost Saver

A cut tube may meet dimensional specs but still fail in assembly due to rough edges or residual burrs. Especially in high-pressure systems, unconditioned edges can compromise O-ring seating or scratch mating components.

- Why It Matters: Deburring eliminates metal fragments that could damage seals, cause leaks, or lead to rejections during incoming inspection.

- Techniques Used: Mechanical brushing, tumbling, or precision grinding. For tight-tolerance parts, electropolishing or abrasive flow machining may be applied.

- Procurement Tip: Always clarify whether “burr-free” in the quote includes post-cut edge conditioning, or just a clean shear. The difference affects unit cost and quality yield.

Cleaning and Particle Control: Especially for Fluid or Medical Applications

Residual oils, chips, and particulate matter from the cutting process can cause contamination or clogging in downstream systems—particularly in fluid delivery, pneumatic, or medical-grade applications.

- Why It Matters: Cleanliness requirements can range from simple degreasing to ISO Class 7 cleanroom packaging. Unclean tubes can create warranty claims or regulatory compliance failures.

- Cleaning Methods: Ultrasonic washing, vapor degreasing, high-pressure rinsing, or alcohol swabbing are commonly applied based on industry standards.

- When to Specify: For any tubing used in instrumentation, biotech, semiconductor, or aerospace systems, specify cleaning level in your RFQ.

Chamfering, Slotting, and End-Forming: Reducing Assembly Time

Many suppliers can integrate end-processing features into the cutting workflow. This eliminates additional subcontracting and ensures tighter dimensional alignment. It’s often combined with other custom sheet metal fabrication processes to achieve greater efficiency.

- Examples:

- Chamfering: Tapered edges to ease insertion into mating parts.

- Beading or Flaring: Common in automotive or HVAC fluid lines to secure hose fittings.

- Slotting: Allows for clamp flexibility or alignment in mechanical assemblies.

- Procurement Impact: Consolidating forming operations with cutting reduces handling time, improves tolerances, and simplifies your logistics.

Kitting, Labeling, and Packaging: Value-Added Logistics for Scale

Beyond cutting and forming, value-added services like kitting and labeling can further reduce your internal labor costs. These packaging and labeling solutions enhance traceability and simplify final assembly.

- Kitting: Pre-sorted bundles of various tube sizes per assembly line or station.

- Labeling: Barcode tagging, part number etching, or color coding for fast visual identification.

- Packaging: Custom separators, bagging, or foam inserts to prevent surface damage during transit.

- RFQ Consideration: Define packaging and labeling expectations clearly in procurement documentation—especially for overseas shipments or sterile environments.

Conclusion: Strategic Sourcing Begins at the Cut

The process of cutting metal tubing may seem simple on the surface, but for procurement professionals, it’s a high-leverage decision point. The selected cutting method, tooling approach, and auxiliary services have a direct impact on your product’s quality, assembly time, and long-term cost structure.

A clean, burr-free cut eliminates rework. Material-specific techniques improve surface integrity. Tooling selection dictates scalability and lead time. Value-added operations like deburring, cleaning, and kitting streamline your supply chain. These aren’t just technical preferences—they’re procurement strategies.

When sourcing a tubing supplier, it pays to go beyond asking, “Can they cut this?” and instead evaluate:

- Can they consistently hit tight tolerances on the specified material?

- Do they offer edge finishing, cleaning, and forming in-house?

- Are their processes traceable, repeatable, and suitable for scale?

- Can they adapt tooling setups based on batch size or material shifts?

By shifting the conversation from unit price to delivered performance, you gain leverage in both negotiations and long-term vendor partnerships.

Final Takeaway for Procurement Teams

Before your next RFQ goes out, consider adding a dedicated section on tubing specifications:

- Material and wall thickness

- Required dimensional tolerances

- Surface finish expectations

- Secondary processing needs (deburring, cleaning, forming)

- Packaging, labeling, or kitting preferences

This not only filters out underqualified suppliers, but sets the foundation for true value-added collaboration.

At YISHANG, we understand that cutting metal tubing isn’t just a task—it’s a strategic process. With over 26 years of experience serving global industrial buyers, we bring precision, scalability, and engineering insight to every order. Our cutting capabilities span stainless, aluminum, and copper tubing, and we offer in-house support for forming, labeling, packaging, and more.

🔹 Ready to streamline your supply chain with precision tubing solutions? Contact our engineering team to discuss your requirements or request a customized quote.

FAQ: Cutting Metal Tubing — What Procurement Managers Need to Know

❓ What is the best method for cutting stainless steel tubing?

The best method depends on your application and volume. For high-precision, clean cuts with minimal burrs, cold sawing or laser cutting are preferred. For thin-walled stainless, rotary cutting may be used to reduce heat and deformation.

❓ Can I specify deburring and cleaning in the RFQ?

Yes—and you should. Deburring, ultrasonic cleaning, and alcohol wiping can be critical in fluid, pneumatic, or cleanroom applications. Be clear about whether you need a “clean shear” or a burr-free, processed edge.

❓ Is laser cutting safe for all types of tubing?

Laser cutting is excellent for many metals, especially stainless and mild steel. However, highly reflective materials like copper or polished aluminum may require fiber lasers or alternate methods to avoid beam deflection.

❓ What’s the difference between a clean cut and a burr-free cut?

A clean cut typically refers to straight, accurate geometry, while burr-free refers to edge condition. A part can look dimensionally perfect but still require edge processing to meet functional or safety standards.

❓ Can tubing be cut, formed, and labeled in one operation?

Yes, many advanced suppliers offer inline forming, chamfering, and labeling to streamline your production. This reduces handling time, improves quality, and lowers overall costs—ideal for high-volume OEM supply.