For global procurement teams and wholesale buyers, understanding how to make a metal casting is not about becoming foundry engineers or trying metal casting at home. It is about evaluating whether a supplier can deliver consistent, specification‑accurate cast metal parts at scale. When a casting program fails, the root cause is rarely a single mistake — it is usually a mix of weak process control, unclear engineering decisions, or poor repeatability. All of these ultimately affect your cost, lead time, and downstream machining.

Buyers who search for terms such as how to make a metal casting, how to make a casting mold for metal, how to make a mold for metal, how to make a mould for metal casting, or making metal objects are usually trying to answer a more strategic question:

“How do I identify a casting supplier capable of stable, long‑term production?”

This article reframes the industrial metal casting process through the lens of procurement. Instead of giving a hobby‑style tutorial, it highlights the engineering and operational factors that matter most to buyers — quality stability, tooling predictability, process transparency, cost drivers, and long‑term partnership reliability.

The Industrial Logic Behind Reliable Casting Supply

Professional buyers should understand three engineering principles that determine casting reliability: controllability, predictability, and repeatability. These principles form a practical framework for evaluating supplier maturity and comparing metal casting suppliers.

Controllability: Whether the Supplier Truly “Owns the Process”

Controllability represents the supplier’s ability to keep critical production parameters within tight limits. In real‑world operations, even small deviations in furnace temperature, melt chemistry, mold moisture, or humidity can directly affect dimensional accuracy and internal soundness.

When controllability is weak, buyers encounter:

- fluctuating machining allowances,

- inconsistent mechanical properties,

- batch‑to‑batch variation and unpredictable scrap.

Competent suppliers show controllability through:

- documented furnace temperature curves,

- alloy composition checks and certificates,

- equipment calibration logs,

- mold and tooling maintenance routines.

These practices reduce uncertainty and help buyers forecast delivery quality more confidently.

Predictability: Turning Drawings Into Manufacturable Reality

Predictability reflects the supplier’s ability to understand metal flow, turbulence, shrinkage, and solidification patterns. When a supplier lacks this foundation, defects such as porosity, shrinkage cavities, misruns, and cold shuts become unavoidable — leading to delays, rework, or field failures.

Good suppliers invest in:

- gating and riser engineering based on part geometry,

- mold simulation (when available),

- alloy‑specific shrinkage planning,

- venting and air‑release strategies.

A supplier who can clearly explain why a mold is designed in a particular way demonstrates the engineering predictability buyers should prioritize.

Repeatability: The Most Valuable Indicator for Procurement

Repeatability determines whether the supplier can maintain quality across hundreds or thousands of parts, not just the first sample. It relies on:

- standardized work procedures,

- operator training and qualification,

- statistical monitoring of key dimensions and defects,

- consistent tooling and process maintenance.

For procurement teams handling recurring or multi‑year programs, repeatability is the clearest indicator of whether a casting supplier can scale without quality drift.

A Brief Overview of the Industrial Metal Casting Process

Before looking deeper at tooling, preparation, and inspection, it helps to align on what actually happens during an industrial metal casting process. At a high level, the workflow for most cast metal parts looks like this:

- Engineering and pattern design – translate the 3D model into a pattern with shrinkage allowance, draft, and machining stock.

- Mold making – prepare a sand mold, permanent mold, or die based on the chosen process.

- Melting and alloy control – melt the specified alloy and verify composition.

- Pouring – fill the mold with molten metal under controlled conditions.

- Cooling and solidification – allow the casting to cool in a controlled way.

- Shakeout and cleaning – remove the mold material and cut off runners and risers.

- Inspection and machining – verify dimensions and internal quality before finishing.

Many top‑ranking articles online reduce this to a simple step list. For industrial buyers, the value is not in memorizing the steps, but in understanding where risk is concentrated. In practice, the most critical stages for long‑term reliability are mold engineering, melt control, cooling strategy, and quality inspection. Those are also the stages where different suppliers can vary most in competence.

From Concept to Mold: Why Tooling Decisions Shape Most of the Quality

Mold Engineering: The Real Start of a Casting Program

When buyers search how to make a casting mold for metal, how to make a mold for metal, or how to make a mould for metal casting, the underlying concern is usually this: does the supplier have enough engineering capability to design tooling that produces sound castings, not just one‑off samples?

A casting mold is not simply a void that matches the final shape. It is an engineered system that controls metal flow, cooling paths, feeding, and air escape. Industry experience consistently shows that a high percentage of casting defects originate from decisions made at the mold design stage. Poor mold engineering cannot be fully compensated by “careful pouring” later.

Key Engineering Decisions Buyers Should Notice

Shrinkage Allowance – Different metals shrink at different rates as they cool: aluminum roughly 1.3%, steel about 2%, many copper alloys around 1%. These values determine how the 3D model is scaled for pattern making and how much machining stock is left on critical surfaces.

Draft Angles – Proper draft reduces the risk of surface drag and distortion during pattern withdrawal or die opening. It also extends tooling life and helps maintain consistent surfaces and edges over many cycles.

Gating and Feeding Systems – The gating system controls how molten metal enters the mold; the feeding system ensures thicker sections remain sound as they cool. Poor gating design leads to turbulence, gas entrapment, and oxide inclusions. Poor feeding design leads to shrinkage porosity and internal voids.

Riser Positioning – Riser placement strongly affects internal soundness. A riser that feeds the wrong region or freezes too early cannot compensate for solidification shrinkage, even if the casting appears fine from the outside.

What a Competent Tooling Team Should Provide

When evaluating suppliers, buyers can reasonably expect:

- tooling drawings that show parting lines, gating, risers, and cores,

- a clear explanation of how shrinkage and feeding are handled,

- realistic estimates of tooling life and maintenance requirements,

- discussion of specific risk areas in the part geometry.

Suppliers able to speak in this level of detail show that they approach mold engineering as a technical discipline instead of pure trial and error.

Preparing for Casting: Material Behavior, Equipment Stability, and Environmental Control

Material Selection: Why It Influences Cost and Risk

Material choice affects far more than strength and appearance. It influences castability, tooling complexity, scrap rate, and machining cost. For industrial buyers placing orders for custom cast metal parts, understanding material behavior helps explain why quotes from different suppliers may vary.

Aluminum Alloys – Lightweight, easy to machine, and widely used for housings, brackets, and making metal objects that need good strength‑to‑weight ratio. However, aluminum is sensitive to hydrogen pickup, which can cause internal porosity if not controlled.

Steel and Iron – Suitable for high‑load and structural applications. Higher melting temperatures and greater shrinkage place more demands on mold design, melt control, and feeding systems.

Copper‑Based Alloys – Valuable for wear resistance, electrical conductivity, and aesthetics. However, they are more prone to gas absorption and may require specialized degassing and controlled cooling strategies.

Understanding these factors helps buyers interpret cost drivers in casting quotations and assess how well a supplier understands the trade‑offs between performance and manufacturability.

Equipment Control: Stability Buyers Can’t See but Always Feel

Casting quality is highly sensitive to equipment condition. Professional suppliers work to ensure that:

- induction furnaces follow calibrated temperature profiles,

- ladles and tools are thoroughly preheated,

- molds are properly dried and conditioned,

- ventilation and fume extraction keep the environment stable.

If any of these factors are neglected, defect rates, dimensional variation, and rework costs can increase. Buyers may not see the equipment directly, but they will see its impact in incoming inspection and field performance.

Environmental Control: A Hidden but Critical Factor

Humidity, sand moisture, dust, and ambient temperature all influence mold behavior and metal flow. Experienced casting suppliers monitor these variables and adjust sand recipes, binders, or process parameters to maintain stable performance.

When you ask a supplier about environmental control and they can describe specific monitoring and countermeasures, it is a strong sign that they understand process robustness beyond basic production.

The Casting Operation: Turning Metal and Tooling Into Real Parts

Melting and Alloy Control

Melting is both a thermal and metallurgical task. A reliable metal casting supplier controls:

- charge material composition,

- melt cleanliness and slag removal,

- target and minimum pouring temperatures.

Many industrial foundries perform spectrographic analysis or sampling to ensure the melt meets the specified alloy grade. For buyers, this means that mechanical property requirements and standards compliance are grounded in measured data, not assumptions.

Pouring Technique: A Controlled Balance of Flow and Temperature

The pouring operation may last only seconds, but it has long‑term consequences. If metal enters the mold too quickly, it can cause turbulence, erosion of the mold cavity, and oxide films. If it enters too slowly, parts of the mold may begin to freeze before the cavity is fully filled.

Mature suppliers use documented pouring procedures that define temperature ranges, typical pouring times, and handling practices. This reduces dependence on individual operator “feel” and supports repeatability from batch to batch.

Cooling and Solidification: The Silent Determinant of Internal Structure

Cooling behavior determines grain size, residual stresses, and the effectiveness of risers. Uncontrolled cooling can cause distortion, internal cracks, or shrinkage cavities in critical sections.

To manage this, suppliers may:

- adjust gating to balance filling and cooling,

- introduce chills to control local solidification,

- choose mold materials with appropriate thermal properties.

For buyers, consistent dimensional results and stable machining behavior are signs that the supplier has cooling and solidification under control.

How Engineers Interpret Castings — And What Buyers Can Learn from That

Surface Indicators: Quick Clues to Process Stability

Surface flow lines, cold shut marks, blowholes, and sand inclusions provide immediate feedback on process performance. For example:

- smooth flow lines indicate controlled filling,

- cold shuts suggest low metal temperature or poor gating,

- clustered gas pores point to venting or moisture issues.

Understanding these clues helps buyers make more informed comments during first‑article evaluations instead of relying only on “good/bad” judgments.

Dimensional Stability: Evidence of Tooling and Process Control

Warping, uneven wall thickness, or systematic dimensional shifts often originate from tooling rigidity or cooling patterns. When a supplier monitors and trends dimensional data, then adjusts tooling or process settings based on that data, it demonstrates a closed‑loop approach rather than a reactive one.

For buyers, this means fewer surprises during machining and assembly and a lower risk of unexpected fit‑up issues in production.

Internal Soundness: What Really Determines Service Life

Internal defects, even in small numbers, can shorten fatigue life or reduce safety margins. X‑ray, ultrasonic, and other non‑destructive testing methods reveal these hidden issues.

Industrial buyers should be comfortable asking:

- which NDT methods are available,

- how often they are applied,

- what acceptance criteria or standards are followed.

Suppliers able to answer these questions clearly are more likely to deliver castings that perform reliably in the field.

Quality Control: The Core of Supplier Reliability and Buyer Confidence

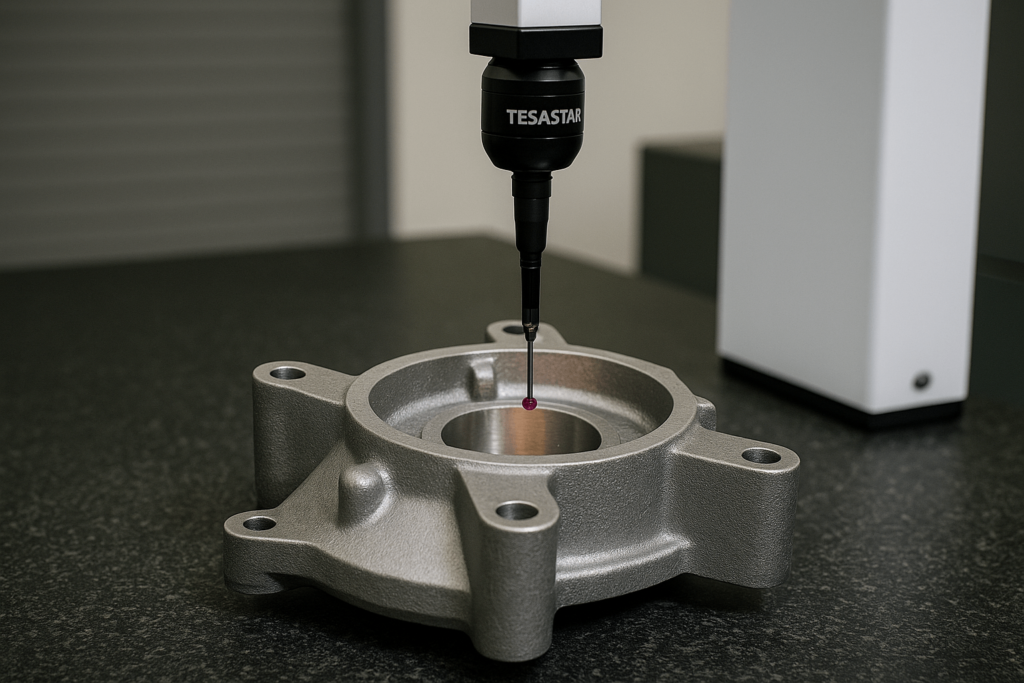

Dimensional and Tolerance Assurance

Dimensional consistency directly affects machining cost and assembly fit. A capable metal casting supplier will typically:

- provide first‑article inspection reports on request,

- use CMMs for complex or multi‑datum parts,

- track key dimensions over time to detect drift.

For buyers, this information helps distinguish between suppliers who simply “meet drawings” once and those who manage dimensional quality continuously.

Structural Verification Through NDT

For pressure‑bearing parts, rotating components, or safety‑critical structures, non‑destructive testing is essential. X‑ray and ultrasonic inspection help ensure that internal soundness aligns with design assumptions.

Suppliers who can explain the typical defect types they look for, and how they adjust processes to prevent recurrence, show a deeper level of control than those who only present pass/fail results.

Traceability and Process Documentation

Robust traceability links each batch of castings to:

- raw material heats,

- melt parameters,

- tooling and mold identifiers,

- inspection results and any deviations.

Such tracking demonstrates that the supplier not only produces parts but also manages risk systematically — a key consideration for OEM programs and long‑term supply relationships.

| Defect Type | Likely Cause | Engineering Response |

|---|---|---|

| Porosity | Gas entrapment, turbulence | Improve gating/venting and melt practice |

| Shrinkage | Poor feeding | Optimize riser design and hot spot management |

| Warping | Uneven cooling | Adjust cooling path or increase mold rigidity |

| Cold shut | Low temperature or slow fill | Raise melt temperature, refine gating |

Integrating Casting Into Broader Manufacturing and Supply Chains

Casting delivers the most value when it is integrated into a complete manufacturing and logistics strategy. For industrial buyers, key considerations include:

- whether machining allowances align with downstream CNC strategies,

- whether surface specifications match planned coatings or plating,

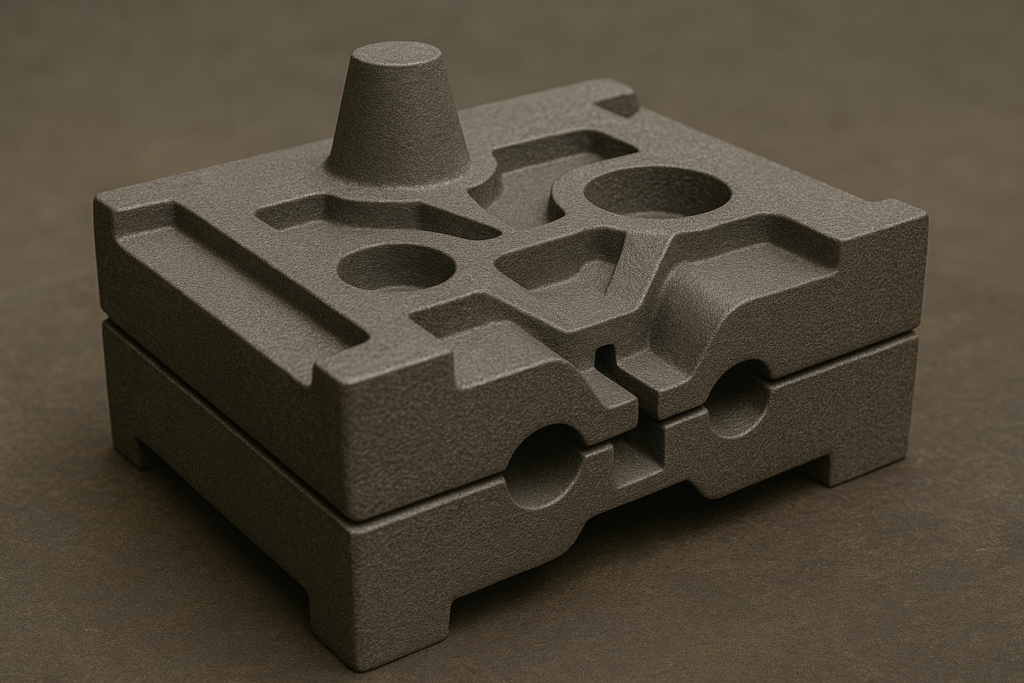

- whether packaging protects critical surfaces and geometries in transit,

- whether the supplier can manage engineering change notices (ECNs) without disrupting shipments.

A supplier who can discuss these topics in practical terms is more likely to support you as a long‑term partner rather than just a part vendor.

Final Evaluation Criteria for Casting Suppliers

Understanding how to make a metal casting and how to make a casting mold for metal gives buyers a clearer lens through which to judge suppliers. The most reliable casting partners usually demonstrate:

- strong mold and tooling engineering capability,

- disciplined control over materials, equipment, and environment,

- measurable repeatability across batches,

- transparent inspection and traceability systems.

If your project requires engineered, stable, and batch‑repeatable cast metal parts rather than hobby‑level metal casting at home, YISHANG is ready to support your drawings and technical requirements. You are welcome to share your specifications for a technical review or quotation.