Stainless Steel Manufacturing: Why It Matters for B2B Procurement

When sourcing stainless steel components in bulk, wholesale buyers aren’t just asking how to manufacture stainless steel—they’re assessing process consistency, delivery accuracy, and certification compliance. For brands like YISHANG, this means demonstrating not only manufacturing capability but also quality transparency and international compliance readiness.

Unlike primary steel production, stainless steel fabrication starts with processed forms like 304 or 316 stainless sheets, tubes, or coils. From there, precise forming, welding, and surface treatment shape the final product. Every decision impacts unit tolerances, anti-corrosion performance, and ease of integration for OEM clients.

Material Sourcing: What B2B Buyers Must Confirm Upfront

Every reliable fabrication process begins with material integrity. Stainless steel grades differ widely—304 for general use, 316L for marine or food-grade applications, and 430 for lower-cost interiors. For example, what is 316L stainless steel? It’s a low-carbon variant that improves weldability and prevents corrosion in chloride-rich settings.

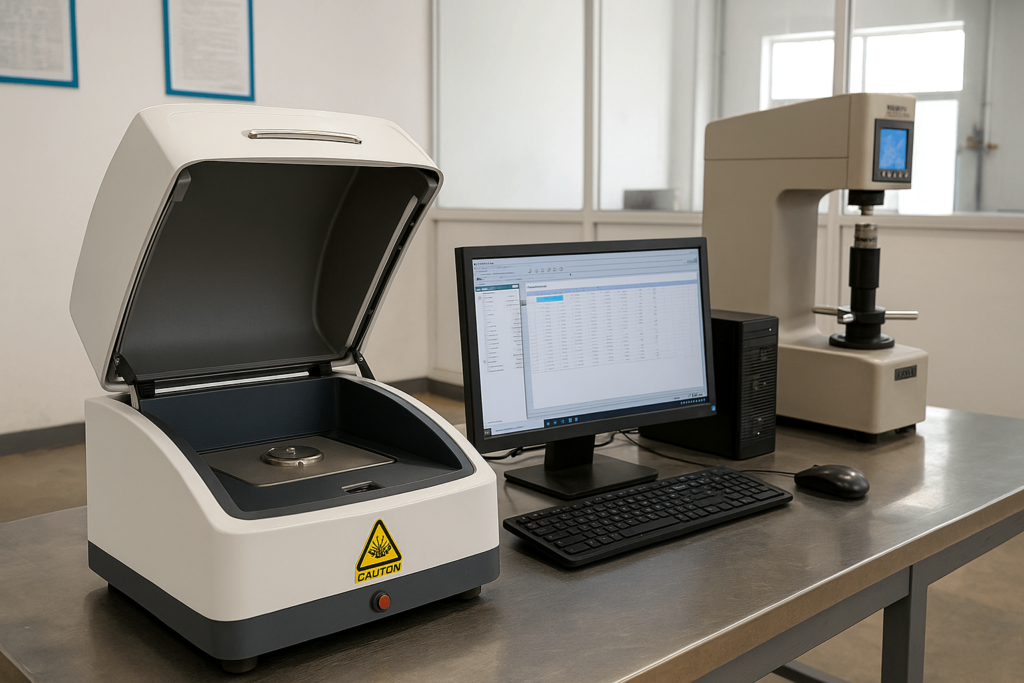

At YISHANG, inbound material is always verified via:

XRF and OES spectroscopy for grade validation

Hardness and tensile testing (ASTM-compliant)

Full traceability per EN 10204 3.1 certification

This level of input control prevents common sourcing errors—like receiving hot-rolled instead of cold-rolled coils—or incorrect alloys. Misuse of low alloy steel vs stainless steel materials can result in cost-heavy recalls. That’s why our clients value inspection logs tied to batch IDs.

Shaping Stainless Steel: Forming and Fabrication Processes

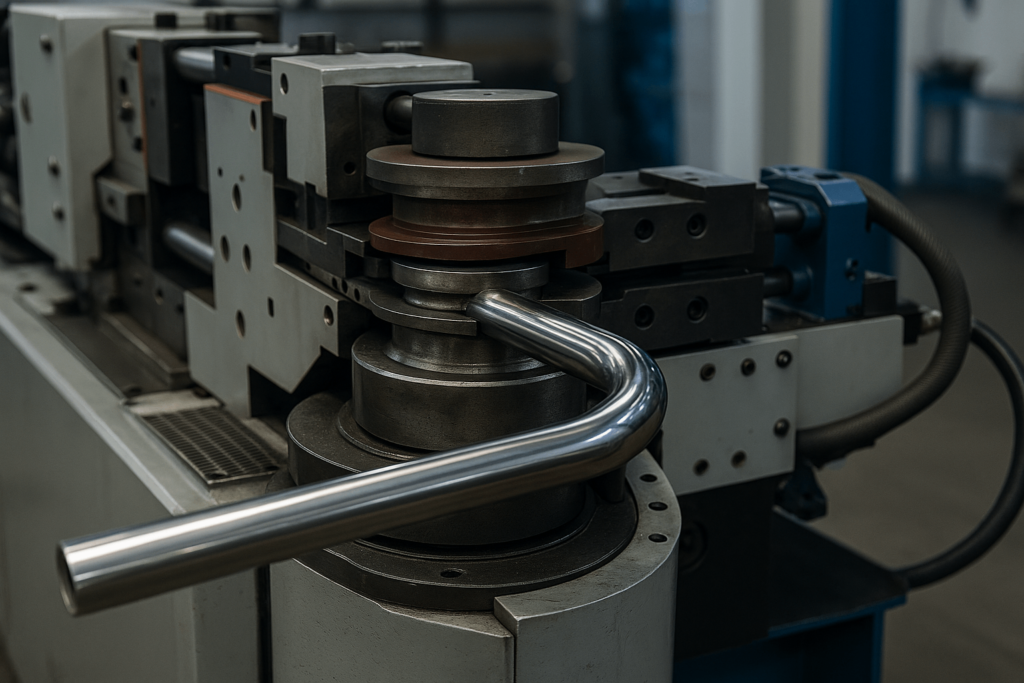

How to Bend Stainless Steel Without Compromise

Stainless steel has excellent strength but resists deformation. Proper bending—especially when clients ask how to bend stainless steel pipe or tubing—requires matching grain direction, selecting the right die radius, and compensating for springback.

Our CNC press brakes support ±0.5 mm accuracy. We regularly form:

430 stainless steel vs 304: softer vs tougher bendability

316 vs 304 stainless steel: 316 tends to allow smoother curves due to higher ductility

Understanding this helps buyers avoid costly mistakes—like cracking during post-fabrication fitting.

For post-bending stability and corrosion protection, see Section 4.

Precision Laser Cutting & CNC Shaping

Fiber laser systems at YISHANG achieve ±0.1 mm cutting tolerance on 304 or 316 stainless up to 10mm thick. Buyers searching how do you cut stainless steel sheets or how to cut stainless steel sheet metal typically want both smooth edges and no heat-affected discoloration.

To ensure that, nitrogen-assisted cutting is used to prevent oxide buildup. This enables clients in electronics, enclosures, and signage to receive clean, assembly-ready parts without secondary processing.

Deep Drawing, Stamping & Forming for High Volumes

In high-throughput projects—like sinks, pump housings, or casings—deep drawing and stamping reduce labor cost and maximize repeatability. With presses capable of 1500 strokes/min, YISHANG helps buyers scale up without sacrificing dimensional integrity.

Sheet metal must be matched to draw ratios and die design. This is where understanding the difference between steel and stainless steel becomes critical: stainless’s work-hardening behavior demands careful force balancing.

Stainless Steel Welding & Passivation: Preventing Failure

Joining stainless components isn’t complete without corrosion prevention. Welding affects chromium distribution at the heat-affected zone, weakening the passive layer.

That’s where passivation of stainless steel comes in—it restores corrosion resistance post-welding. For process details, see Section 4. We follow ASTM A967 passivation protocols and often provide documentation showing:

Weld maps

Filler metal origin

Also relevant: how to passivate stainless steel processes differ for 316L vs 430 parts, and we guide buyers accordingly.

Surface Engineering That Adds Value

Finishes aren’t just visual—they influence performance, cleanability, and client trust. Depending on the product application, we offer:

BA / 2B finish for kitchen or medical usage

No. 4 brushed for display or architectural installations

Electropolished for pharmaceuticals or biotech (Ra ≤ 0.2 μm)

Buyers comparing titanium vs stainless steel cookware, brass vs stainless steel, or chrome vs stainless steel often overlook that real differentiation lies in surface stability under use—not just initial appearance.

Also, inquiries like can stainless steel be powder coated or can you anodize stainless steel are common. The answer is yes—with proper surface pretreatment. This adds design flexibility without compromising corrosion protection.

Note: For Ra value applications, see surface finish guidelines in Section 3.4.

Visual Guide: Aluminum vs Stainless Steel Comparison

| Property | Aluminum | Stainless Steel |

|---|---|---|

| Weight | Lightweight | Heavier |

| Magnetism | Non-magnetic | Slightly magnetic (400 series) |

| Corrosion Resistance | Moderate (needs coating) | High (especially 316) |

| Surface Hardness | Softer | Harder |

| Thermal Conductivity | High | Lower |

| Cost per kg (avg.) | Lower | Higher |

This helps identify alloys during sourcing, especially for OEM buyers comparing alloy vs stainless steel components.

Quality Inspection for Global-Grade Deliverables

What matters to our B2B clients isn’t perfection—it’s repeatability. That’s why all stainless steel assemblies from YISHANG undergo:

CMM dimensional verification (±0.01 mm)

NDT tests: ultrasonic and dye penetrant on welds

Surface finish reports: confirming Ra targets relevant to function (see above)

These are logged against client POs, then packaged using:

VCI bags, to inhibit corrosion during sea freight

Shock-resistant crates, IPPC certified

QR labeling, enabling warehouse traceability

Whether the buyer is in logistics automation or custom fabrication, quality without documentation is a deal-breaker.

Environmental and Regulatory Compliance Isn’t Optional

For clients focused on ESG goals, YISHANG’s stainless steel manufacturing follows:

RoHS / REACH-compliant materials

Recycled-content coils (up to 60%)

Closed-loop acid treatment for passivation

This not only meets the standards—it supports branding efforts in sensitive industries like consumer appliances or medical devices. We document every batch’s carbon metrics where required.

What Smart Buyers Avoid—and How We Help

Misalignments between design and material are more common than expected. For instance:

Choosing 430 stainless steel for outdoor use

Requesting high-gloss finish on hot-rolled material

Skipping passivation on welded food contact parts

With experience serving 50+ countries, YISHANG helps buyers avoid these mistakes. Our team proactively reviews drawings for DFM flaws and material mismatches.

Matching Strategy to Specification

Successful buyers don’t just source parts—they match strategies to project specs. Here are three typical builds we produce:

Medical carts or enclosures:

Material: 316L stainless steel vs 316 (preferred for weldability)

Finish: Electropolished

Tolerance: Tight dimensional repeatability (±0.1 mm)

Power supply or server chassis:

Material: Cold-rolled 304

Process: CNC + Brushed finish

Public infrastructure panels:

Material: 316 + TIG welds + post-passivation

Finish: No. 4 brushed, Ra ≤ 0.8 μm

We explain every choice to the buyer—reinforcing not just feasibility, but alignment with industry norms and longevity expectations.

FAQ for B2B Procurement Managers

Q1: Which stainless steel is better, 304 or 316?

304 is cost-effective for indoor use. 316 offers higher resistance to corrosion, especially in marine or chemical environments. See Section 2 for sourcing criteria.

Q2: Can stainless steel rust over time?

Yes, if passivation is skipped or the surface is exposed to aggressive chemicals. Maintenance and correct finishing prevent it. See Section 3.4 and 4.

Q3: What rod is used to weld stainless steel to mild steel?

309L filler rods ensure proper adhesion and reduce cracking risk.

Q4: What is passivated stainless steel and why does it matter for food-grade products?

It refers to stainless steel that’s undergone chemical passivation to restore the chromium-rich oxide layer after fabrication. This enhances corrosion resistance—essential for hygiene-critical applications like food processing or medical use.

Q5: Is 316L stainless steel good for marine environments?

Yes, it has superior pitting resistance due to its low carbon and molybdenum content. That’s why it’s preferred in salt-exposed settings over standard 316.

Q6: Can stainless steel be powder coated?

Yes—with correct pre-treatment such as abrasive blasting and degreasing. Powder coating adds aesthetic flexibility and abrasion resistance while preserving the corrosion properties beneath.

Q7: What’s the difference between alloy vs stainless steel?

“Alloy steel” is a broader term—stainless is a specific corrosion-resistant alloy. Stainless contains at least 10.5% chromium, offering passive protection layers. Not all alloys are stainless.

Q8: How to tell the difference between aluminum and stainless steel?

See comparison chart in Section 4.

Conclusion: A Reliable Stainless Steel Supplier Is More Than a Vendor

Understanding how stainless steel is manufactured is just the first step. As a global B2B buyer, what you need is confidence in process control, documentation, and post-delivery performance.

YISHANG stands out not by volume—but by how well we translate technical capability into real-world deliverables. Ready to source 316L stainless steel parts or scale your next batch production with confidence? Let’s talk.