Why Inconel vs Titanium Matters to Industrial Buyers

In today’s precision-driven manufacturing landscape, selecting the right alloy is a strategic decision. For wholesale buyers sourcing components for high-temperature, high-stress, or corrosive environments, the comparison between Inconel and Titanium is more than material science—it’s about lifecycle cost, fabrication feasibility, and supply chain certainty.

This article provides an in-depth, non-generic evaluation of Inconel and Titanium, going beyond datasheets to offer insights rooted in real manufacturing environments. Whether you’re in aerospace, energy, or industrial equipment, understanding the differences will improve your sourcing decisions and reduce procurement risk.

What Is Inconel?

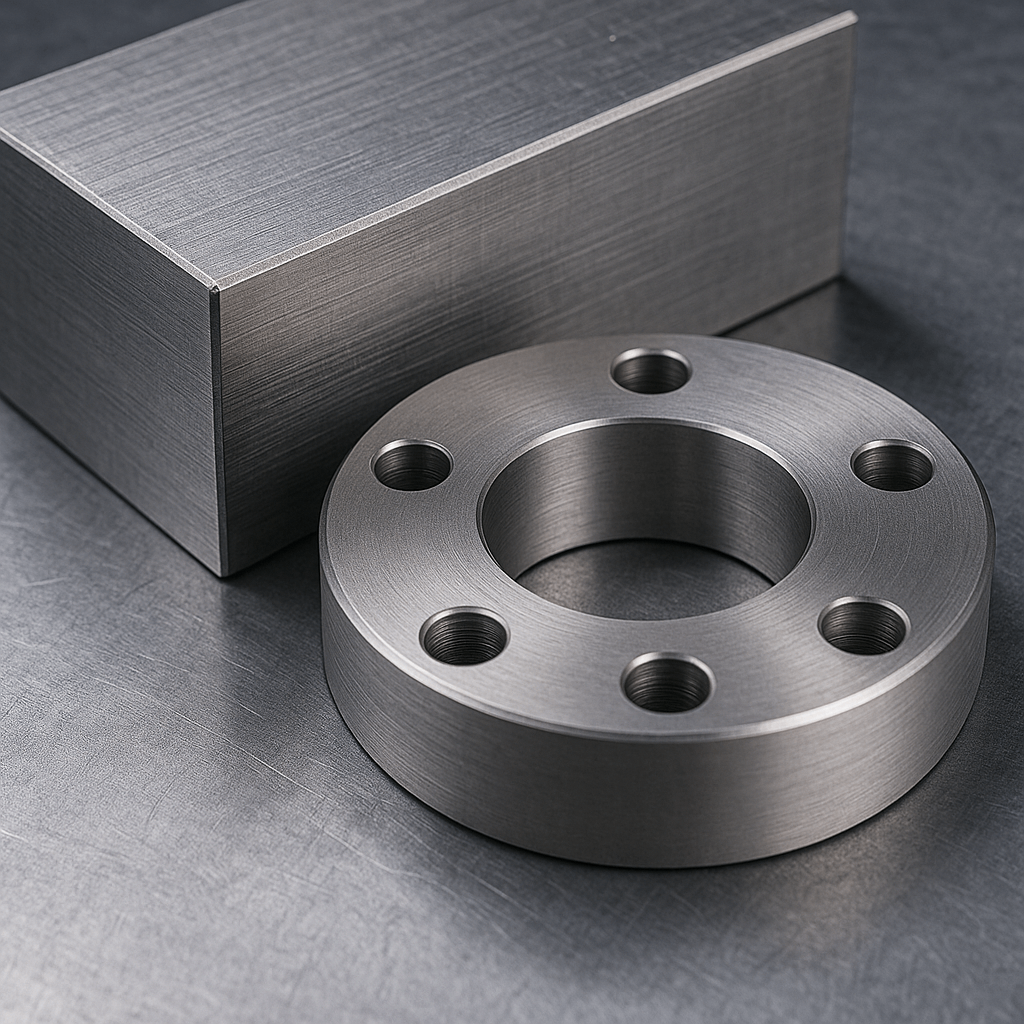

Inconel is a trademarked family of nickel-chromium-based superalloys developed for extreme heat and corrosive environments. The most commonly used grades are Inconel 625, 718, and 825, each offering high tensile strength and oxidation resistance.

Key Strengths: Maintains structural integrity at temperatures approaching 1000°C, ideal for gas turbines, marine exhausts, and heat exchangers.

Limitations: Expensive and notoriously difficult to machine.

Common Certifications: ASTM B443, AMS 5662, ISO 9001, RoHS compliance.

Buyers looking for Inconel parts for high temperature conditions must ensure supplier expertise in both heat treatment and corrosion protection.

What Is Titanium?

Titanium is a low-density, high-strength metal known for its excellent corrosion resistance and bio-compatibility. Commercially, Grade 2 and Grade 5 (Ti-6Al-4V) are the most frequently used.

Key Strengths: Lightweight, corrosion-resistant, non-magnetic, and weldable.

Limitations: Reactivity at high temperatures, prone to galling in mechanical joints.

Common Certifications: ASTM B348, AMS 4911, AS9100 for aerospace-grade suppliers.

In markets like medical, aerospace, and automotive, benefits of titanium include recyclability, strength-to-weight ratio, and support for anodized titanium finishes.

Inconel vs Titanium: Property-by-Property Comparison

Mechanical Strength and Temperature Tolerance

Inconel withstands higher operating temperatures (~980°C) compared to Titanium (~400°C).

Titanium exhibits superior fatigue resistance and higher strength-to-weight ratio.

Corrosion and Environmental Resistance

Inconel excels in oxidizing acids and saline high-temperature environments.

Titanium is unmatched in marine and chloride-rich conditions.

Weight and Density

Titanium’s density is ~4.43 g/cm³, nearly half of Inconel’s (~8.44 g/cm³).

For industries seeking lightweight assemblies, steel vs titanium weight favors Titanium.

Machinability and Weldability

Inconel hardens rapidly and requires advanced tooling.

Titanium, though not trivial, allows better thermal load management with proper tooling and cooling.

Cost and Availability

Inconel is more expensive and less commonly stocked.

Titanium is widely available but often sold with high MOQ.

Manufacturing Reality: From Blueprint to Production Floor

Inconel: Hard-to-Machine, High-Value Alloy

From a mass manufacturing standpoint, machining Inconel is labor-intensive and costly. It work-hardens rapidly and retains heat, accelerating tool wear. For wholesale buyers ordering large volumes, this translates into higher per-part fabrication costs and longer production lead times.

Titanium: Manageable but Demanding

Titanium requires sharp tools and controlled cooling systems but is generally more thermally manageable than Inconel during cutting. This improves cycle time consistency, making it suitable for high-volume production. Bead blast titanium finishes are easier to achieve consistently and afford tighter tolerance control.

Fabrication Partners and Procurement Caution

For buyers looking into custom titanium fabrication or titanium sheet metal processing, it’s essential to work with experienced partners who understand how to optimize cutting parameters to reduce scrap and extend tool life. For industries like aerospace or energy, it’s equally critical that CNC machining Inconel suppliers are well-equipped to handle thermal expansion, toolpath planning, and post-process inspections.

Material Failure Considerations: What Goes Wrong

Inconel, while extremely durable, is susceptible to stress corrosion cracking (SCC) under certain high-temperature, high-pressure environments, especially in the presence of chlorides. Improper heat treatment or poor design can exacerbate this.

Titanium can suffer from hydrogen embrittlement if exposed to improper surface treatments or welding environments without adequate shielding. Recognizing these failure risks helps procurement teams define proper fabrication protocols and select qualified suppliers.

Sourcing Pitfalls and Quoting Smarter

Common sourcing mistake: assuming a supplier that works with stainless steel can easily handle Inconel or Titanium. These metals demand distinct tooling, shielding, and inspection standards.

Inquiries tip: When requesting quotes, include questions about bulk order availability, MOQ, and whether the vendor provides export-ready Inconel parts with compliance documentation. Always confirm experience in delivering high performance metal components under international tolerance and certification requirements.

Use Case Spotlight: When to Choose Which

Aerospace: Inconel for engine parts; Titanium for airframe and brackets.

Energy: Inconel for high-pressure, high-temperature pipelines; Titanium for seawater heat exchangers.

Medical Devices: Titanium dominates due to bio-compatibility and formability.

Automotive EV Systems: Lightweight Titanium increasingly replaces steel or Inconel in structural components.

This section helps clarify titanium vs inconel for aerospace and other procurement-focused decision paths.

Future-Proofing Your Material Strategy

Innovations and Real-World Alloy Replacements

Emerging Titanium alloys—such as Beta-C, Beta-21S, and 5553—offer improved formability and weldability. They’re ideal for AM (additive manufacturing), prototyping, and aerospace brackets. Inconel 740H and 939 are enabling power plants to operate at ultra-supercritical conditions with better creep strength.

For example, a leading aerospace supplier replaced Grade 5 Titanium with Inconel 625 in the manufacture of turbine rear frames to extend lifecycle durability and reduce part failure at high temperatures. Conversely, an automotive EV exhaust system was reengineered to swap Inconel for Beta-Titanium, reducing component weight by over 30% while maintaining fatigue resistance.

Sustainability and Digital Selection Tools

As sustainability becomes a procurement KPI, Titanium offers recyclability and a smaller carbon footprint. Inconel’s long service life offsets its energy-intensive production—especially in rotating machinery where replacement downtime incurs significant operational cost.

AI and digital twins are increasingly used in alloy selection. Procurement teams can model lifecycle costs, simulate stress loads, and digitally qualify suppliers based on material availability and certification history. Platforms such as Granta MI and Altair are helping companies reduce prototyping cycles by over 25% through predictive alloy matching.

For organizations selecting between Inconel and Titanium in new energy systems or aerospace, these AI tools now support data-driven answers to “how to choose Titanium vs Inconel” for custom manufacturing.

Property Table: Inconel 625 vs Titanium Grade 5 — Quick Technical Comparison

| Property | Inconel 625 | Titanium Grade 5 |

|---|---|---|

| Density (g/cm³) | 8.44 | 4.43 |

| Tensile Strength (MPa) | 827–1034 | 895–965 |

| Yield Strength (MPa) | 414–690 | 828–895 |

| Max Operating Temp (°C) | ~980 | ~400 |

| Corrosion Resistance | Excellent (oxidizing acids) | Excellent (seawater/chlorides) |

| Machinability | Low | Moderate |

| Weldability | Moderate | Good (requires shielding) |

| Common Applications | Turbines, chemical reactors | Aerospace structures, implants |

| Standards (typical) | ASTM B443, AMS 5662 | ASTM B348, AMS 4911 |

| Procurement Notes | Limited stock, niche alloy | Widely available, high MOQ |

| Related Long-Tail Keywords | inconel metal suppliers, CNC machining Inconel suppliers | custom titanium fabrication, titanium sheet metal processing |

FAQ: Answering Strategic Buyer Concerns

Q1: Is Inconel stronger than Titanium?

Yes—especially under high heat. Inconel maintains strength up to 980°C, whereas Titanium begins to lose structural stability beyond 400°C. However, in terms of strength-to-weight ratio, Titanium often performs better.

Q2: Which alloy offers better corrosion resistance?

Both excel but in different environments. Inconel resists oxidation and acid corrosion at elevated temperatures. Titanium excels in saltwater and chloride exposure, making it a strong candidate for marine applications.

Q3: Can Titanium replace Inconel in high-performance designs?

Yes, in some cases. For example, a German EV manufacturer replaced Inconel exhaust modules with Beta-Titanium to reduce weight while maintaining thermal fatigue strength. But for prolonged high-heat conditions, Inconel still outperforms.

Q4: What is the cost trade-off?

Titanium is generally more cost-effective in high-volume runs due to easier machining and wider availability. Inconel demands a higher upfront and processing cost but may offer longer component lifespan under extreme conditions.

Q5: What are some common sourcing mistakes?

Assuming all metal suppliers handle exotic alloys equally. Always verify experience in machining, welding, and post-treatment of specialty metals. Misinterpretation of certifications (e.g., thinking RoHS equals aerospace-grade) can also create compliance issues.

Match Material to Mission, Not Trend

Inconel and Titanium each have a strategic fit—not just technically, but economically and operationally. The decision should be driven by:

Functional requirements (e.g., high heat, chloride exposure, weight sensitivity)

Processing feasibility and partner capabilities

Total lifecycle cost, not just material price

Logistics and MOQ alignment with your sourcing model

YISHANG helps OEMs and industrial wholesalers make those decisions with confidence. Our expertise spans custom metal parts supply, precision sheet metal, and high-performance alloy fabrication.

Request a quote today to explore the best-fit alloy solution for your bulk order.