When Your Product Starts Failing—And It’s Not the Machine's Fault

In a metalworking facility, a batch of aluminum enclosures was recently returned due to misaligned holes. The issue wasn’t machine-related—it was caused by a poorly designed drill jig. Errors in jigs and fixtures often go unnoticed until product failure or costly rework occurs.

Understanding jig vs fixture differences isn’t just a technicality—it directly affects quality consistency, delivery assurance, and total production cost. For sourcing managers, tooling strategy reflects supplier capability and signals their reliability over repeat orders. A clear understanding of jigs vs fixtures helps prevent dimensional errors and builds a more resilient sourcing model.

For procurement teams sourcing custom metal parts, clarity on tooling function directly affects decisions about supplier reliability, quality control risks, and long-term manufacturing cost. Why does this matter to sourcing teams? Because better tooling means fewer dimensional errors, less scrap, and more consistent batches—especially in international trade where product returns are expensive.

What Really Separates a Jig from a Fixture?

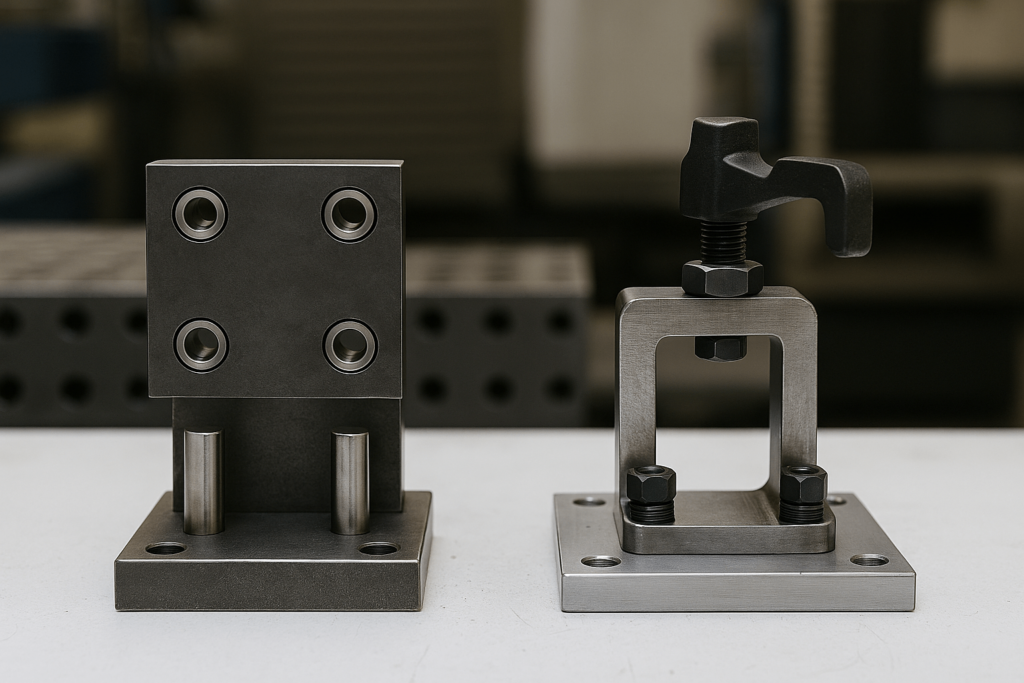

A jig and a fixture both improve precision, but their roles differ. A jig holds the workpiece and guides the tool. A fixture holds the workpiece securely but leaves the tool free.

If you’re drilling holes in sheet metal or aluminum panels, the jig ensures every hole lands where it should. What is a jig? It’s a repeatability tool. The drill doesn’t rely on an operator’s aim; it relies on the jig’s hardened bushings.

What is a fixture? It’s your foundation during milling, welding, or grinding. Fixtures prevent unwanted part movement during machining or assembly, especially under high torque or heat conditions.

CNC fixtures and CNC fixture clamps are vital in high-force setups, such as automated drilling stations or multi-axis milling operations. These tools create a stable base that ensures every pass or weld lands exactly where your engineering drawings specify.

Function-Driven Typologies: Tooling That Matches Application Demands

Forget generic classifications—here’s what matters when your production outcomes are on the line.

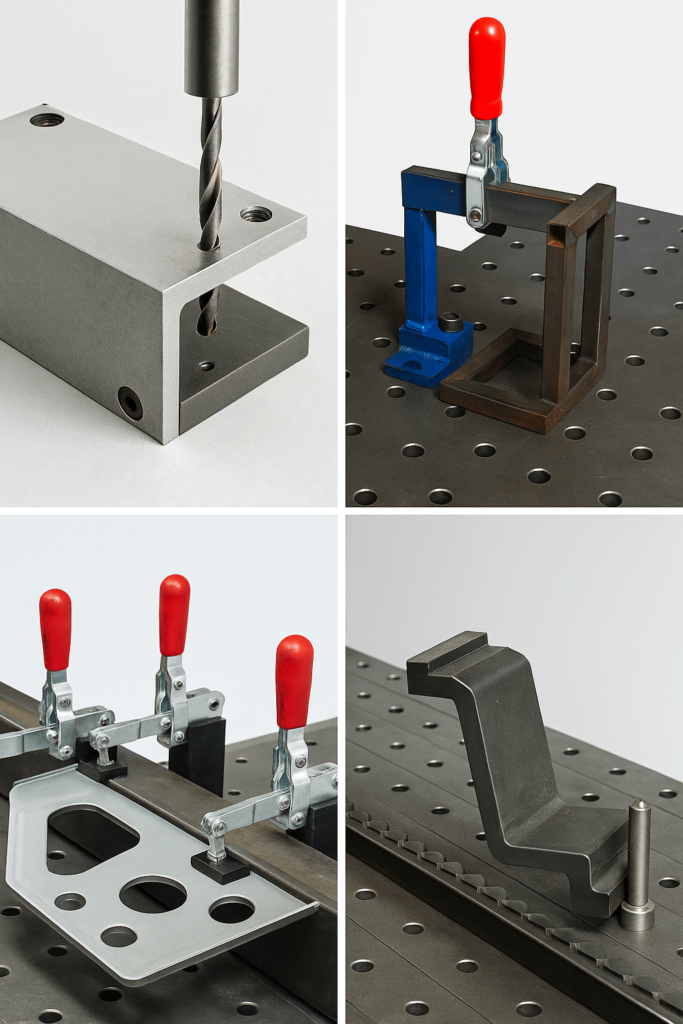

Drill jigs are vital in electronics housing and control panels where hole position matters. These jigs prevent cumulative hole misalignment in mass production runs.

Plate jigs work well for vending machine sides, while channel and box jigs align square tubular frames used in display structures or energy storage racks. These address both shape and weight challenges.

Fixtures vary by process:

Milling fixtures support multi-face CNC operations.

Welding fixtures in the automotive fixtures industry handle thermal expansion with floating clamps.

Modular fixtures enable reconfiguration across low-volume runs, saving tooling time and cost.

In these real-world contexts, jigs and fixtures are more than tools—they’re process enablers. Especially in the automotive fixtures industry and high-volume fabrication for vending, HVAC, or energy enclosures, well-designed tooling can cut cycle times by 15–20% and improve hole repeatability by ±0.1 mm, according to SME reports and customer feedback.

How Fixtures Control Precision, Process, and Cost

Fixtures often look static, but they silently control every micron of your production outcome. In CNC machining, even slight fixture misalignment results in dimensional error. That’s why high-precision industries invest in advanced CNC fixture systems with integrated referencing.

Welding aluminum frames? Poor fixture design causes thermal warping. A quality fixture accommodates expansion paths and keeps stress away from weld seams. This matters when sourcing box-type chassis or multi-panel assemblies.

Also, consider GD&T (Geometric Dimensioning & Tolerancing). A good fixture physically enforces your CAD-defined datums. This ensures part consistency—not just in one run, but across thousands of units.

Procurement teams benefit here. Better fixtures mean tighter part tolerances, reduced scrap, and fewer quality claims—particularly in high-mix or export-sensitive production lines.

Jig or Fixture? How Smart Buyers Make the Right Choice

Understanding when to use a jig vs fixture is essential for process efficiency and tooling investment.

| Process Requirement | Best Tooling Choice |

|---|---|

| Guided toolpath | Jig |

| Part restraint under load | Fixture |

| Drilling repeated holes | Drill Jig |

| Complex 3D surface referencing | CNC Fixture |

| Thin material with deformation risk | Fixture with support |

| Manual, high-accuracy operations | Jig |

| Quick tool changes | Modular Fixture |

If your part involves multi-hole patterns or thin-walled material, jigs deliver repeatability. But if your part requires multi-axis CNC machining or structural rigidity during welding, fixture systems with solid base and clamping are essential.

From a buyer’s standpoint, tooling strategy can expose a supplier’s level of production maturity. A jig may be faster to produce and ideal for short runs, but its long-term accuracy and operator dependence can lead to variability.

Fixtures, especially those tied to CNC fixture systems, generally offer tighter tolerances and are ideal for high-repeatability workflows. When evaluating CNC fixtures for sheet metal components, buyers should look for modularity, fixture rigidity, and quick-clamp designs that streamline assembly. Suppliers offering validated fixture design for repeatable tolerance—especially in laser-cut or thin-wall aluminum—reduce inspection cycles and increase line throughput.

Balancing upfront investment with process stability is a key procurement consideration—particularly when evaluating custom fabrication vendors for repeat contracts.

Common B2B Scenarios Where Tooling Matters Most

Let’s talk about situations buyers often face when sourcing precision metal parts:

Sheet metal boxes: Often used in kiosks, POS frames—need back-clamped fixtures to prevent corner lift during punching.

Enclosure panels with multiple cutouts: Require jigs with hardened sleeves to maintain hole-to-hole spacing.

Chassis frames for EV cabinets: Need distortion-controlled welding fixtures with floating location blocks.

In these cases, tooling isn’t optional. It determines whether your order arrives dimensionally correct or needs rework. Discussing tooling strategy with your supplier can reveal their production competence—especially when you’re evaluating fixture supplier capabilities for repeat orders, cross-site manufacturing, or vendor benchmarking.

Tooling ROI: What Buyers Need to Know

Jigs and fixtures don’t just guide tools—they guide your cost per part.

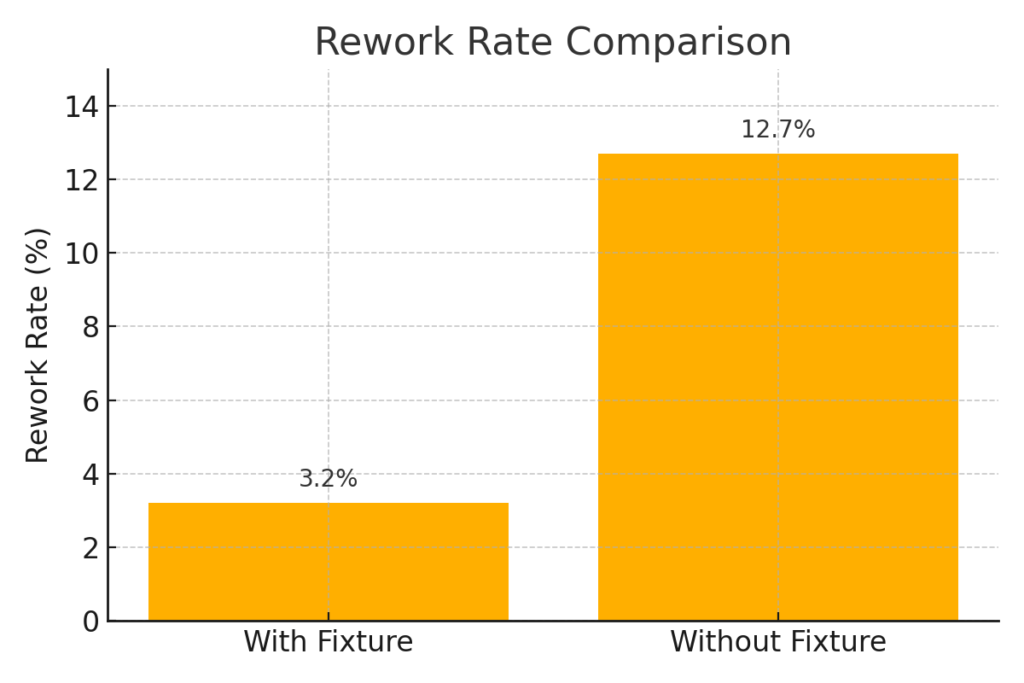

In YISHANG’s experience, optimized tooling design reduces rework rates by up to 30%. For mid-volume runs (500–2000 units), even minor improvements in fixturing deliver significant downstream savings. According to SME manufacturing benchmarks, optimized jig and fixture configurations can reduce scrap by over 20% in production environments with GD&T-critical tolerances.

A supplier that engineers process-specific fixturing builds more than just parts—they shape your brand’s consistency and customer satisfaction. The impact is measurable—in reduced field rework, shorter installation windows, and lower warranty-related logistics costs. Fewer line stoppages, lower inspection overhead, and fewer customer complaints all stem from this one hidden variable.

If you’re sourcing custom vending machine frames, POS enclosures, or display cabinets, precision tooling like a dedicated drill jig can improve hole alignment tolerance by ±0.1mm—critical when sourcing jigs for thin sheet aluminum. This level of precision aligns with ISO 2768-mK standards, ensuring consistent fits and mounting alignment for end-use assemblies in vending or medical equipment.

Hybrid Tooling Systems and Modular Solutions

Real-world production lines rarely rely on one type of fixture or jig. Hybrid approaches—mixing guided drill elements with positioning clamps—are now the norm.

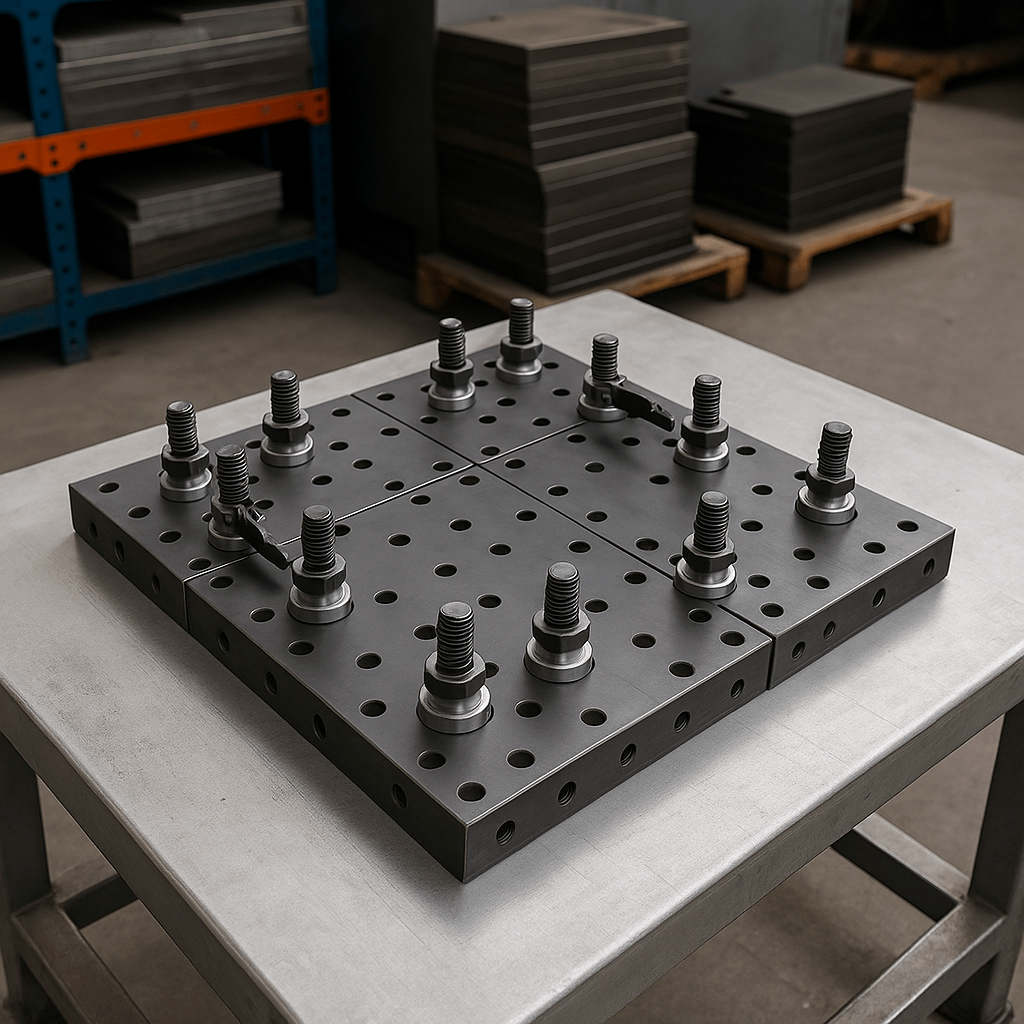

For instance, YISHANG often integrates modular base plates with quick-swap jig inserts. This allows high-mix orders to be processed with minimal changeover time, a must-have in seasonal or project-based supply chains.

Modular CNC fixtures also support complex sheet-and-frame assemblies. If you’re managing high-mix manufacturing with frequent setup changes, modular fixture for high-mix manufacturing reduces downtime and improves flexibility across your product SKUs., especially when paired with CAM-driven positioning systems.

In short, tooling isn’t static. If your supplier uses hybrid or reconfigurable solutions, your cost per unit—and lead time—benefits.

Engineering Considerations Buyers Should Expect from Fixture Designers

Experienced suppliers approach jigs and fixtures as engineering assets, not just mechanical clamps.

Key considerations include:

3-2-1 principle: Locking all degrees of movement

Material compatibility: Steel vs aluminum based on wear resistance

Clamp path clearance: Ensuring no toolpath interference

Inspection integration: Fixtures aligned to QC gauges or vision systems

Suppliers using CAD-integrated FEA can simulate stress paths, identify clamp-induced distortion, and optimize holding force—before any metal is cut. That’s where design meets production.

A procurement manager looking for supplier reliability should ask: “How is your tooling validated?”

Smart Fixtures, AI, and 3D Printed Jigs: What's Next?

In Industry 4.0 workflows, smart fixtures are no longer a novelty. Sensor-enabled clamps now feed live alignment data to MES dashboards. AI-generated jig geometry reduces weight while maintaining rigidity.

Additive manufacturing is making rapid jig prototyping a reality—especially for validation or short-run batches. These printed tools cut lead time from 2 weeks to 48 hours in YISHANG’s testing cycles.

For buyers, that means faster onboarding of new SKUs, better project delivery compliance, and easier design validation—especially in rapid-change industries like vending, advertising structures, or mobility enclosures.

Conclusion: The Tool Behind the Tolerance

When comparing jigs vs fixtures, the decision is about more than functionality—it’s about cost, quality, and speed. Buyers don’t just need parts that fit; they need parts that repeat—and that starts with the right tooling system.

Whether you’re sourcing CNC fixtures for tight-tolerance assemblies or lightweight jigs for manual drilling, a smart tooling strategy delivers measurable ROI.

With over 26 years of experience in metal tooling design and OEM fabrication, the YISHANG team supports procurement teams worldwide with custom-engineered jigs and fixtures. Our tooling systems are optimized for medium-volume, high-mix production environments—delivering dimensional reliability, repeatability, and reduced setup delays across vending, medical, EV frames, and advertising structure applications.

Need help improving your fixturing strategy? Reach out to our team to discuss your application.