Why Surface Matters in Wholesale Metal 3D Printing

In the evolving world of industrial 3D printing, the conversation has shifted. Buyers are no longer satisfied with just functional prototypes — they demand surface quality that aligns with real-world performance and visual standards.

In B2B scenarios, surface finish is not just cosmetic. It directly affects product longevity, assembly precision, corrosion resistance, and coating adherence. Whether sourcing NEMA-rated electrical enclosures or custom-fabricated brackets, the “smoothness” of a part can influence your downstream assembly cost, customer perception, and regulatory compliance.

For wholesale buyers, especially those sourcing in volume, the challenge is twofold: how to secure functional surface quality without inflating cost, and how to assess that quality from early-stage drawings to delivered parts.

How Engineers Define “Smooth” — And Why It Matters

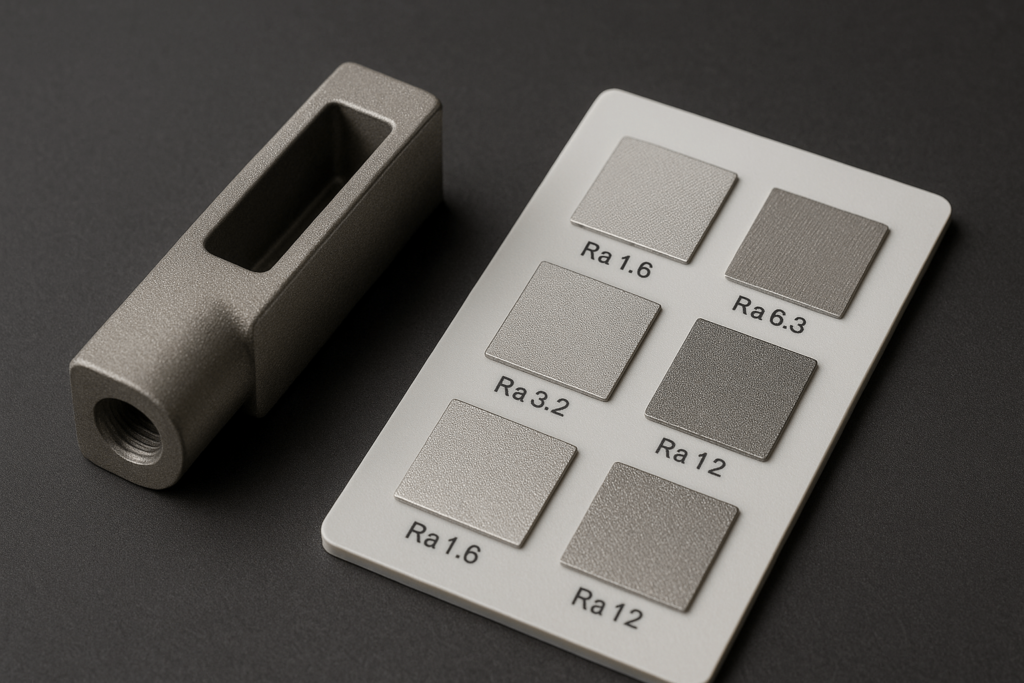

Ra, Rz & What Surface Quality Actually Means

In industrial terms, smoothness isn’t visual — it’s measurable. The most cited metric is Ra (average roughness), typically ranging from 0.8–12 µm in 3D metal printing. Lower Ra values mean finer surfaces. Other parameters like Rz (average peak-to-valley) provide additional insight into surface topography.

For sealing surfaces or components requiring precise contact — such as control panel housings or aluminum enclosures — even a few microns in Ra variation can affect sealing, fastening, or coating integrity. (Related keyword: “Ra value for sealing surfaces”)

Surface That Impacts Assembly, Function, or Compliance

A rough interior on a battery enclosure can hinder airflow and increase thermal risk. A poor finish on a stainless steel electrical cabinet may cause coating flake or early corrosion in outdoor environments.

Smoothness influences:

- Gasket sealing in IP66/IP67-rated enclosures

- Coating adhesion for outdoor telecom boxes

- Fit precision for hinge assemblies or fastener interfaces

B2B buyers should clarify these surface expectations during technical drawing review or RFQ stages.

Why Smooth Finishes Are a 3D Printing Challenge

Layer Lines Are Inherent to the Process

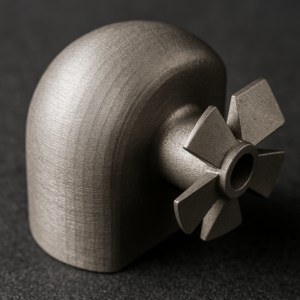

Unlike CNC machining, additive manufacturing builds parts layer by layer. In processes like SLM (Selective Laser Melting), this leads to stair-stepping on angled surfaces, micro-beading from partially melted powder, and even minor porosity. (Keyword: “selective laser melting surface”)

Standard as-printed Ra values can exceed 10 µm — unacceptable for mating surfaces or visible panels unless post-processed. That’s where wholesale buyers often face cost-control issues.

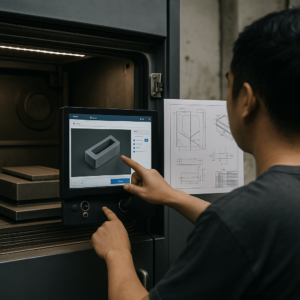

From CAD File to Printed Reality

Many buyers assume that a smooth CAD model guarantees a smooth part. But STL formats convert curved surfaces into faceted triangles. Low mesh resolution causes visible stair-stepping, while unsupported features may droop or distort. (Keyword: “STL mesh resolution impact”)

For complex parts — like an enclosure with embedded cooling channels — understanding the disconnect between CAD design and print output is critical to ensure realistic expectations and proper allowances.

Print Variables That Influence Surface Quality

Factors such as layer thickness (e.g., 20 vs 40 microns), laser scan strategy, and powder characteristics (including flow rate and particle shape) all have a direct impact on surface finish quality.

In addition, part orientation plays a surprisingly significant role. For example, orienting the visible face of an enclosure parallel to the build plate can reduce Ra by 30% — without requiring additional post-processing.

Designing for Better Surface Quality from the Start

Strategic Orientation = Less Post-Processing

By adjusting print orientation, critical surfaces (such as faceplates or flange edges) can be positioned to minimize stair-stepping. This reduces the need for sanding or CNC finishing.

YISHANG engineers often rotate carbon steel control panels 45 degrees in Z-axis printing to optimize finish and reduce powder entrapment. This one change can save 10–20% in finishing time per unit.

Modeling with Finish in Mind

If CNC finishing will follow printing, designers should build in machining allowances — typically +0.2 mm on key surfaces. This ensures proper tolerancing post-smoothing.

Additionally, edge rounding and chamfering help reduce print distortion, improve powder flow, and support uniform coating later. This matters for modular electrical enclosures and outdoor telecom cabinets, where assembly alignment is critical.

See our product range of Yishang stainless control cabinets.

Cost vs Smoothness: Know Where It Pays Off

Smoother parts require slower builds, more supports, and longer finishing — all of which increase unit cost. For example:

- A visible front panel may justify polishing

- Internal stiffeners or heat sinks may not

Wholesale buyers should define where finish contributes to function or customer experience — not everywhere.

Proven Finishing Techniques That Scale

Mechanical Options: Fast but Limited

Industrial buyers have access to:

| Method | Achievable Ra | Applications | Drawbacks |

|---|---|---|---|

| Belt Sanding | 1.2–2.5 µm | Flat panels, front enclosures | Labor-heavy |

| Tumbling | 2.5–5.0 µm | Small batches of modular parts | Inconsistent on fine edges |

| Abrasive Blasting | 3.0–6.5 µm | Large surface areas, powder cleanup | Alters surface hardness |

These are fast for external finishing but not suitable for internal geometries or tight tolerances.

CNC Machining for Functional Surfaces

Where Ra < 1.6 µm is needed (e.g., for gasket surfaces or bearing housings), subtractive finishing is still the standard. CNC finishing can be applied to:

- Mating flanges on aluminum enclosures

- Cable gland interfaces on stainless control boxes

- Fastener threads in modular brackets

Hybrid workflows (AM + machining) are widely used in high-value applications like aerospace, medical, and energy.

Chemical & Thermal Treatments

Techniques like electropolishing, acid dips, or heat-based smoothing can reduce Ra by up to 80%. Electropolishing is especially valuable for stainless steel enclosures used in washdown or cleanroom environments. (Keyword: “post-processing cost estimation”)

However, these processes must be tightly controlled to avoid dimensional loss or surface embrittlement.

The ROI of Smoothness — When and Where It Pays

Function-Driven Smoothing

A glossy part may look impressive but doesn’t always justify the cost. Instead, define smoothing needs by function:

- Required: sealing surfaces, sliding fits, or customer-facing panels

- Optional: interior ribs, heat sink fins, or hidden brackets

This approach helps suppliers focus labor and cost where they actually impact usage.

Finishing Costs: Budget by Surface Priority

Here’s an estimated breakdown based on different finishing expectations:

| Target Ra (µm) | Process Type | Added Cost/Unit ($) | Typical Use |

|---|---|---|---|

| < 1.0 | CNC + Electropolishing | 40–60 | Sealing gaskets, medical-grade parts |

| 1.5–2.5 | Sanding + Coating | 20–35 | Control stations, operator consoles |

| > 5.0 | As-printed + Deburr Only | 5–10 | Internal supports, non-visible structure |

For a 500-unit order, choosing the right finish for the right surface can save thousands.

The Practical Rule

If it doesn’t move, seal, or show — don’t polish it. This philosophy saves cost, reduces lead time, and improves consistency across production batches.

Sourcing Smooth 3D Metal Parts with Confidence

Ultimately, the goal isn’t perfect shine — it’s performance, reliability, and cost-efficiency.

Buyers sourcing from YISHANG know that our team aligns surface decisions with real-world applications. We help customers define functional surfaces, design for achievable finish quality, and apply appropriate post-processing techniques to meet those standards — all while controlling cost.

Whether you need carbon steel outdoor enclosures, IP-rated stainless cabinets, or custom aluminum interface panels — we offer scalable, finish-oriented metal 3D printing solutions tailored to your spec.

Need reliable surface finish in your next 3D printed metal parts? Contact YISHANG for expert-guided sourcing and competitive B2B pricing.

Learn more on Explore our full custom fabrication capabilities.