Introduction: A Mark of Quality is Not an Afterthought

In high-volume metal fabrication, the final mark on a product is a critical manufacturing step. It’s a declaration of quality, a guarantee of supply chain traceability, and a permanent symbol of your brand’s integrity.

For wholesale buyers, specifying the wrong marking method can lead to costly downstream failures: illegible serial numbers, compromised material integrity, or a brand image that fades under real-world conditions.

This guide is a strategic blueprint for engineers, designers, and procurement managers at industrial firms. It provides a practical framework for selecting the most suitable metal engraving process—backed by material science, real-world application scenarios, and total cost of ownership considerations. Whether you’re searching for custom metal engraving in China, evaluating bulk laser engraving suppliers, or comparing engraving solutions for OEM components, this article delivers what you need.

The Strategic Decision: Why Engrave in the First Place?

Before evaluating technical methods, it’s essential to clarify the strategic purpose behind the marking. The intent determines the best-fit process and its long-term ROI.

The decision to invest in a specific metal engraving method typically aligns with three core business needs:

Functional Imperatives: Traceability & Safety

In regulated industries like aerospace, automotive, and medical, permanent part identification is non-negotiable. Serial numbers, UDI codes, and data matrices ensure accountability and traceability throughout the supply chain.

In these sectors, the mark isn’t optional—it’s a built-in safety and compliance feature required by ISO, FDA, or MIL-STD standards. This is why engraving for OEM components must meet stringent criteria for permanence, readability, and durability.

Commercial Advantage: Branding & Perceived Value

Engraved logos, lot codes, or manufacturer marks communicate quality, precision, and durability. These markings enhance brand perception and offer long-term resistance to wear, chemicals, and environmental stress—key for OEMs seeking differentiation in competitive markets.

Many custom laser engraving manufacturers offer integrated branding solutions as part of their high-volume workflows.

Artistic & Customization Goals

For projects requiring visual appeal—such as control panels, architectural trims, or award plaques—engraving provides fine detail and customization potential. OEMs often integrate aesthetic elements into functional components for enhanced user experience.

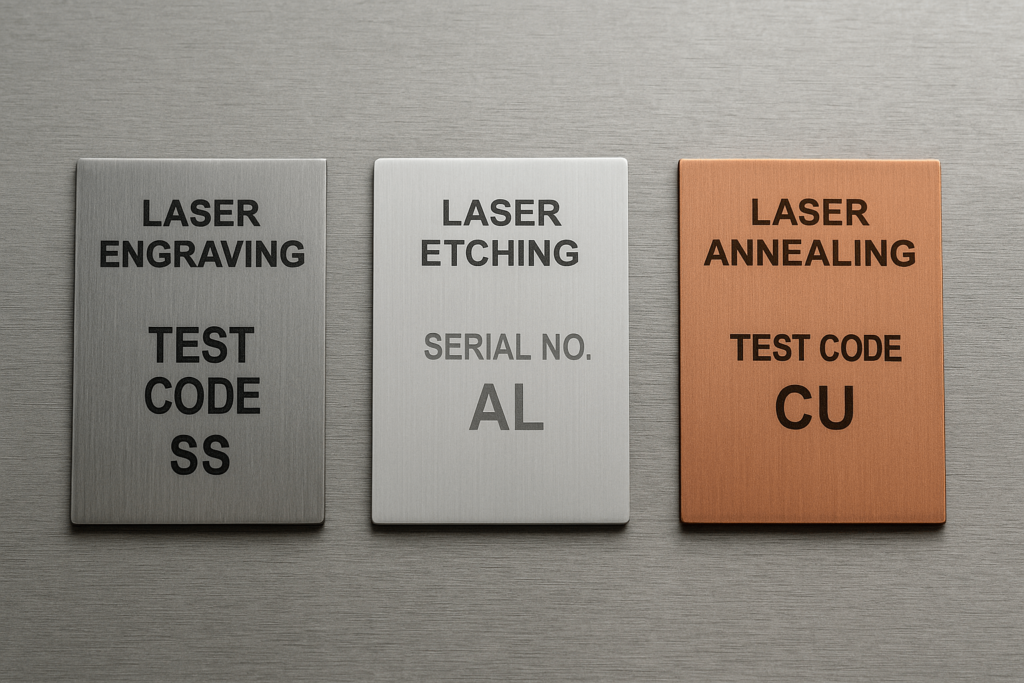

Decoding the Terminology: Engraving vs. Etching vs. Marking

In RFQs or CAD files, technical clarity matters. Understanding the differences between metal engraving, etching, and marking can prevent costly miscommunication—especially when sourcing industrial laser marking services.

Laser Engraving

A subtractive process where a high-powered laser beam vaporizes the metal surface, creating a permanent, tactile cavity. This method excels in harsh environments, offering superior abrasion resistance.

Laser Etching

A shallow, rapid process that melts the material surface to form a slightly raised mark. Though not as deep as engraving, it provides strong visual contrast and fast processing speeds.

Laser Marking

A non-contact method that induces surface color changes through heat (annealing). Common in medical and aerospace applications where surface integrity must remain intact.

| Feature | Laser Engraving | Laser Etching | Laser Marking (Annealing) |

|---|---|---|---|

| Process Type | Vaporizes material to form deep grooves | Melts surface to create slight raised texture | Oxidizes sub-surface layer to induce color shift |

| Material Removal | Yes | Minimal | None |

| Use Case Examples | Serial codes on industrial tools, deep branding | Rapid batch part labeling, temporary lot codes | UDI for medical components, smooth-surface aerospace parts |

| Best For | Harsh environments, deep identification | Fast visual marks with moderate durability | Smooth surface applications requiring zero structural disturbance |

The Business Case: Comparing Methods on Cost, Speed, and Precision

For B2B buyers managing large-scale production, cost-efficiency and repeatability are essential. Let’s examine each method through a procurement lens.

Cost Implications: Beyond Price-Per-Piece

Mechanical engraving: Lower initial machine cost, but recurring expenses due to tool wear, calibration, and maintenance.

Laser engraving: Higher capital investment, but minimal wear and consistent output. Ideal for mid to high-volume orders where TCO matters. This makes it the preferred solution for buyers seeking bulk metal engraving services.

Chemical etching: Low tooling costs (especially for design changes), but chemical disposal and regulatory handling add operational complexity.

Production Speed: Matching Process to Output Volume

- Mechanical: Slowest due to physical toolpath movement.

- Laser: Fastest for variable data and automation. Galvo systems mark within seconds.

- Etching: High parallel throughput. Best for batch processing hundreds of parts at once.

Precision and Tolerances: Meeting Engineering Standards

Laser engraving and chemical etching offer the tightest tolerances and excellent repeatability. Mechanical engraving may introduce variation due to tool degradation.

Material Matters: How Composition Affects Marking Outcomes

Understanding how specific metals respond to different marking methods helps avoid production errors and rework.

| Material | Fiber Laser | CO2 Laser | Recommended Process |

|---|---|---|---|

| Stainless Steel | ✅ Excellent | ❌ Poor | Deep engraving or annealing |

| Aluminum | ✅ Moderate | ❌ Poor | Etching + post-treatment |

| Brass | ✅ Good | ❌ Poor | Engraving |

| Titanium | ✅ Excellent | ❌ Poor | Color marking or annealing |

| Copper | ⚠️ Moderate | ❌ Poor | High-power engraving |

| Mild Steel | ✅ Excellent | ⚠️ Limited | Engraving |

Coated surfaces (e.g., anodized aluminum) respond well to etching with excellent contrast. However, for applications requiring long-term durability (marine/automotive), direct engraving into the base metal is preferred. We recommend working with suppliers experienced in engraving anodized aluminum parts to ensure optimal results.

From Blueprint to Production: Workflow Integration

Efficient execution requires collaboration between design and manufacturing teams.

- Submit vector-based formats like DXF or SVG.

- Indicate engraving depth using layer properties or line weights.

- For serialization, prepare CSV/XML files with variable data.

In automated environments, ERP-integrated engraving allows on-the-fly part marking—ideal for OEM traceability and logistics.

Implement visual QC systems to inspect mark contrast, scan rate, and depth, especially for regulatory parts (e.g., UDI, CE). For clients in need of engraving solutions for industrial applications, this automated traceability support is critical.

Safety and Compliance Considerations

Ensure your supplier complies with:

- Laser system class certifications (especially Class 3B/4 enclosures)

- RoHS and ISO 9001 process standards

- Industry-specific standards: FDA UDI, AS9100, etc.

Protective eyewear, fume extraction, and chemical waste protocols are non-optional in high-volume settings.

Choosing the Right Partner: YISHANG’s Precision Advantage

At YISHANG, we support global OEMs and wholesale buyers with:

- CNC & mechanical engraving for deep marks

- Fiber laser engraving for flat or curved metal parts

- Engraving-compatible finishes (anodizing, powder coat, brushing)

- Full DFM guidance, prototyping, and large-batch QC support

We’re a trusted custom metal engraving manufacturer in China with 26+ years of experience. Our RoHS-compliant and ISO 9001-certified processes serve buyers in automotive, electronics, medical device, vending, and display fixture industries.

Whether you need bulk laser engraving for stainless steel, custom branding on aluminum components, or engraving for OEM serialization, our team delivers durability, traceability, and branding in one integrated workflow.

Final Thoughts: Engraving as Strategic Differentiator

Metal engraving isn’t just about product identification—it’s a critical element of your brand’s credibility, compliance, and customer perception.

When applied thoughtfully, engraving enhances not just the product, but the entire buyer experience.

📩 Contact YISHANG today to discuss your next engraved component project or submit your RFQ for industrial laser marking, OEM metal engraving, or custom part serialization.