1. Executive Summary: The Economics of Precision Manufacturing

If you are a purchasing manager, category buyer, or wholesale distributor, one of the most decisive factors in determining whether a product line becomes a long‑term profit generator or a costly liability is the method used to form its metal components. For B2B teams sourcing overseas, metal stamping is not merely a technical operation—it is a strategic, long‑term cost‑control mechanism that can reshape your unit economics across thousands or millions of parts.

In high‑volume programs, the right stamping process can stabilize quality, reduce scrap, and compress lead times. The ability to convert flat sheet metal into intricate, highly durable parts—often hundreds of components per minute—allows OEMs and wholesalers to keep per‑unit prices competitive while protecting margin. But effectiveness depends on understanding key cost drivers: tooling investment, material behavior, tonnage, and process capability.

Drawing from YISHANG’s 26+ years as a metal stamping manufacturer in China, exporting to 50+ countries, this guide provides a structured, ROI‑driven explanation of how metal stamping works from a sourcing perspective. For wholesale buyers searching for terms like “custom metal stamping parts supplier”, “sheet metal stamping for OEM” or “stamped steel parts manufacturer”, this guide helps you answer:

“How do I source stamped metal parts that meet global standards while maximizing profit margins and minimizing risk?”

What Is Metal Stamping in Manufacturing?

Metal stamping (also known as metal pressing or sheet metal pressing) is a manufacturing process that uses dies and high‑tonnage presses to cut, shape, or form flat sheet metal into specific geometries. It includes operations such as blanking, bending, piercing, coining, deep drawing, and more.

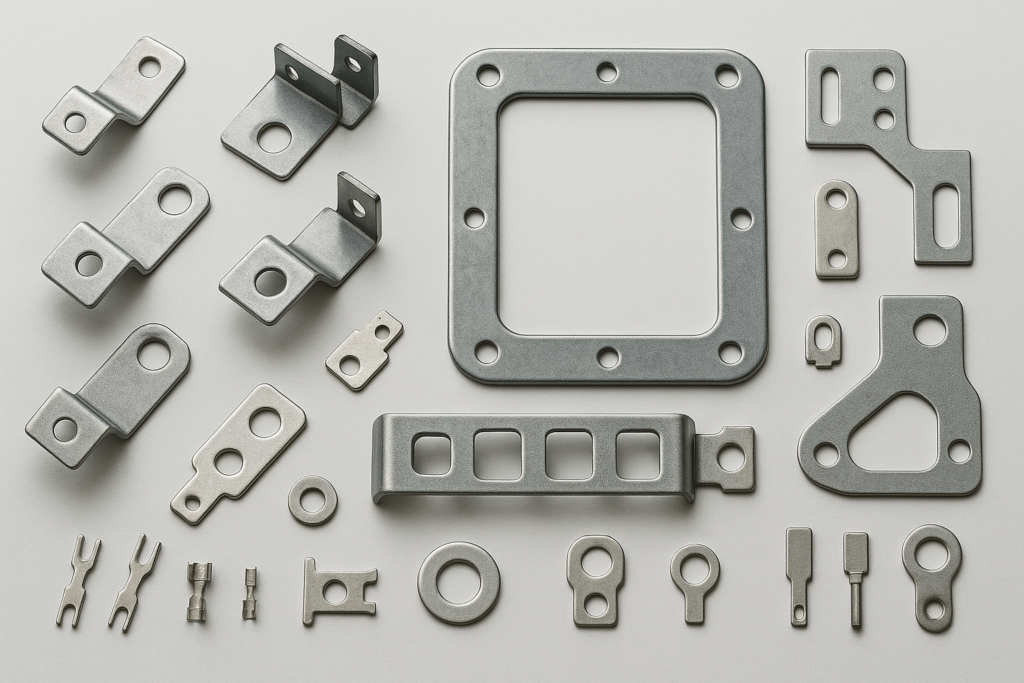

Metal stamping is widely used for:

- high‑volume production of consistent metal parts

- cost‑efficient fabrication once tooling is built

- manufacturing stamped steel brackets, frames, clips, terminals, enclosures, and structural components

This definition aligns directly with common searches such as “what is stamping in manufacturing”, “stamping process manufacturing”, and “sheet metal stamping process”.

2. Step-by-Step: The Sheet Metal Stamping Process

Many high‑ranking articles include a clear step-by-step process, so this section improves SEO relevance for searches like “how does stamping work” and “stamping process steps”.

Step 1: Product & Tooling Design

Engineers define dimensions, tolerances, radii, hole spacing, and functional requirements. These decisions affect feasibility and tooling complexity.

Step 2: Material Selection

Determining thickness, grade, coating, strength, and corrosion resistance ensures compatibility with forming behavior.

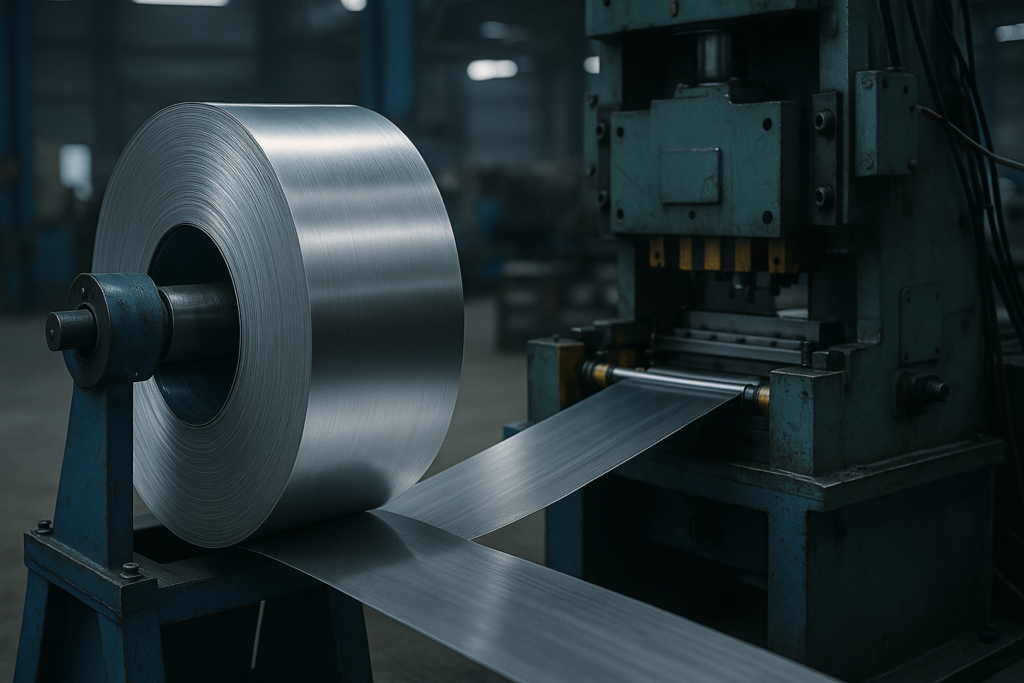

Step 3: Blanking / Coil Feeding

Sheet metal coils are fed into the press. Blanking or piercing produces the initial flat profile of the part.

Step 4: Forming (Bending / Drawing / Embossing)

Dies reshape the metal through bending, flanging, coining, or deep drawing. This is the core forming step.

Step 5: Trimming & Secondary Operations

Sharp edges are removed. Additional cutouts, embosses, or features may be added.

Step 6: Surface Finishing

Processes include powder coating, galvanizing, passivation, anodizing, or polishing.

Step 7: Inspection, QA, and Packaging

Finished stamped parts undergo dimensional checks, functional testing, and packaging for export.

This entire workflow supports keywords like metal stamping manufacturing, sheet metal pressing, and stamping process manufacturing.

3. The Physics of “Cold Working”: Why It Matters for Your ROI

Successful procurement in metal stamping begins with understanding what happens to the metal inside the die. Cold working, the deformation of metal below its recrystallization temperature, is at the heart of the stamping process. While it may sound like a topic reserved for metallurgists, its implications are directly tied to your cost structure, tolerance feasibility, part reliability, and long‑term product performance.

When sheet metal undergoes stamping and pressing, the material is forced to flow into a new geometry under tremendous pressure. This interaction alters the internal grain structure, influencing strength, stiffness, and springback behavior. As a buyer or engineer, understanding these reactions equips you to make more informed decisions about material selection, part design, and tolerance expectations—ultimately reducing unnecessary design revisions and tooling modifications later.

From a sourcing angle, this means fewer unexpected quality issues, fewer rejected shipments, and less rework at your warehouse or at your customer’s assembly line. A supplier that truly understands the physics of cold working can help you balance material grade, thickness, and forming strategy so that the stamped parts perform reliably in real‑world applications, not just in drawings.

Work Hardening: Getting More Strength for Less Cost

During the metal stamping process, plastic deformation creates dislocations in the metal’s crystal lattice, increasing yield strength. This work hardening effect allows for cost savings that many buyers overlook. Because the final stamped steel part becomes stronger than the raw sheet material, you may be able to switch to thinner gauges—reducing raw material expenses and saving on shipping weight—without compromising durability.

For example, transitioning from a 2.0 mm stainless steel sheet to 1.5 mm may still achieve the required stiffness after forming due to work hardening. This is especially valuable in automotive, appliance, and equipment applications where every kilogram matters. For wholesale projects involving repeated orders over several years, improved strength and fatigue resistance translate to fewer warranty claims and a more predictable total cost of ownership.

The Springback Variable

After forming, metals naturally attempt to return to their original shape—a phenomenon known as springback. While all metals exhibit some degree of springback, high‑yield materials such as stainless steel (301/304) or high‑tensile steels display more pronounced deformation recovery. This behavior must be anticipated and compensated in tooling design.

Rather than simply increasing press force, experienced metal stamping manufacturers use simulation tools and past production data to predict springback and incorporate corrections directly into the die design. This may include over‑bending angles, adding draw beads, or adjusting tool geometry. For example, achieving a true 90° angle on 304 stainless steel may require designing tooling that forms to 88°–89° to counteract the rebound.

By understanding these physics‑based constraints early, you avoid unrealistic tolerance expectations and prevent costly tooling modifications that could slow projects and escalate budgets. When you evaluate quotes from different metal stamping suppliers, asking how they manage work hardening and springback is a quick way to assess technical depth and process maturity.

4. The “Make or Buy” Decision: Laser Cutting vs. Metal Stamping

One of the most common strategic questions in sourcing metal components is determining whether laser cutting or metal stamping is the more suitable manufacturing method. This decision directly affects cost, scalability, speed, and design flexibility. Although both processes are widely used in sheet metal manufacturing, their cost structures differ dramatically—especially for wholesalers who place repeated orders.

Laser cutting is a flexible, low‑commitment process ideal for prototypes or small batches, but its per‑unit cost remains relatively constant regardless of scale. Every part requires the laser head to trace the full geometry. Metal stamping and pressing, by contrast, requires a larger upfront tooling investment but achieves extremely low per‑unit costs at medium to high volumes. From a buyer’s perspective, the stamping tool behaves like a fixed asset: once the die is paid off, each additional stamped part becomes very economical.

The 3,000–5,000 Unit Threshold

For most sheet metal parts, the economic crossover between laser cutting and stamping typically falls within the 3,000–5,000 piece range. Below this output, tooling costs cannot be amortized effectively. Above this range, stamping’s speed and repeatability dramatically reduce cost.

For example, a standard 100 mm × 100 mm bracket cut via laser may cost a similar price per unit whether you buy 10 pieces or 10,000 pieces because the laser must process each part one at a time. Stamping, however, uses fixed tooling and can produce parts at 60+ strokes per minute—sometimes hundreds of stamped parts per minute—meaning labor, machine, and overhead costs per unit drop significantly.

In practice:

- < 3,000 units: Laser cutting is usually recommended for flexibility and lower upfront investment.

- 3,000–5,000 units: Evaluate both; consider future reorders, product lifecycle, and whether the item may become a long‑term catalog product.

- > 5,000 units: Stamping and pressing usually become significantly more cost‑effective for most geometries.

For buyers searching “laser cutting vs metal stamping cost” or “when to switch from laser cutting to stamping”, this rule‑of‑thumb offers a practical starting point. Once your forecasted annual demand passes this threshold, it is time to discuss progressive or transfer tooling.

The Hybrid Strategy (New Product Introduction)

A highly effective sourcing approach is the hybrid strategy, especially for new product introduction (NPI). Rather than committing to expensive tooling immediately, many manufacturers—including YISHANG—combine both processes strategically:

- Phase 1: Prototyping & Market Validation – Use laser cutting and basic forming for the first 200–1,000 pieces. This allows design refinement, real‑world testing, and market validation without risking expensive stamping tooling adjustments.

- Phase 2: Scaling to High Volume – Transition to progressive or transfer die stamping once the design is frozen and demand is proven. At this stage, stamped steel parts replace laser‑cut parts, dramatically reducing the cost per unit.

This hybrid model reduces risk while accelerating time‑to‑market. It also aligns with how many overseas wholesalers operate: start with smaller trial orders, validate local market demand, and then commit to large‑scale stamped production once sales channels are stable and predictable.

5. Decoding the Process: Progressive vs. Transfer vs. Deep Draw

Metal stamping is not a single technique—it is a family of stamping and pressing methods optimized for different geometries, thicknesses, and production volumes. Understanding these methods helps ensure accurate cost forecasting and avoids choosing a process incompatible with your part design. For anyone researching “how does metal stamping work” or “stamping process in manufacturing”, this section explains how the main processes differ.

Progressive Die Stamping (The Speed King)

Progressive die stamping is the fastest and most automated method for producing stamped parts. A coil‑fed strip of metal advances through multiple stations in a single die, where cutting, punching, bending, and coining occur. The part remains attached to a carrier strip until the final station.

This method excels in producing small, complex components such as terminals, brackets, connectors, or clips at high volumes—often exceeding 50,000 units or more. Its speed (up to hundreds of strokes per minute) and minimal labor involvement make it ideal for automotive electronics, appliances, and consumer hardware where consistent quality and low unit cost are critical.

The primary trade‑off is tooling complexity. Progressive dies require higher upfront investment and generate engineered scrap from the carrier strip. However, their lifetime output and speed typically outweigh these costs for high‑volume programs. When you are sourcing progressive die stamping parts, ask suppliers about expected tool life, maintenance plans, and material utilization rates.

Transfer Die Stamping (The Heavy Lifter)

Transfer die stamping separates parts from the metal strip at the first station. The part is then moved between forming stations by mechanical transfer fingers. Because the part is free from the strip, it can rotate or reposition between stations—an advantage for large, deep, or multi‑angle components.

Transfer processes are ideal for chassis parts, housings, structural frames, and medium‑to‑large stamped steel components where material utilization must be optimized. While slower than progressive stamping, transfer dies reduce scrap and allow more complex geometries without carrier limitations. For wholesalers dealing with heavy‑duty or structural applications, transfer stamping often provides the best balance between material cost and process flexibility.

Deep Drawing (The Geometry Master)

Deep drawing is used when part depth exceeds its opening diameter, allowing seamless cylindrical or box‑shaped parts such as fire extinguisher bodies, cookware, motor housings, or sealed containers.

Engineers rely on parameters such as the Limiting Draw Ratio (LDR) to determine whether a part can be drawn successfully without tearing. Typically, a single forming stage cannot reduce blank diameter by more than ~50%. Understanding this ensures proper feasibility assessment during the design phase and prevents unrealistic geometry requests that could drive up tooling complexity or require intermediate annealing.

In practical terms, when sending RFQs for deep drawn stamping parts, it helps to share 3D files, target material, and annual volume. This allows the manufacturer to design an efficient draw sequence, select suitable lubricants, and advise whether the part is better suited to pure drawing or a combination of drawing, forming, and welding.

6. Material Selection: Balancing Cost and Performance

Choosing the right material is a critical decision that affects manufacturability, performance, corrosion resistance, and final cost. A material that performs well in one environment may fail prematurely in another. The following considerations help ensure selected materials align with both engineering requirements and stamping constraints.

For wholesale buyers, material choice also affects stock strategy and flexibility. Selecting a commonly used grade for your sheet metal stamping parts can shorten lead times and make it easier for your supplier to combine your orders with other customers’ coils, improving bargaining power on raw‑material pricing.

Stainless Steel (304 vs. 316)

304 stainless steel is widely used in enclosures, appliances, commercial equipment, and architectural components due to its excellent corrosion resistance and formability. It is a typical choice for many stamped steel parts exposed to indoor or mildly corrosive environments.

316 stainless steel, containing molybdenum, offers superior chemical and salt resistance—making it essential for coastal, marine, medical, and sanitation applications. However, 316 has higher strength and causes increased tool wear. Suppliers may need to use carbide tooling or adjust press settings, leading to slightly higher non‑recurring engineering (NRE) or tooling maintenance costs. Understanding these trade‑offs helps buyers anticipate quote differences and avoid surprises when comparing suppliers.

Pre‑Galvanized and Galvannealed Steel

Pre‑galvanized steel is popular for its corrosion resistance, but stamping friction may cause zinc flaking, affecting tool performance and leaving unprotected steel surfaces. To mitigate this, galvannealed steel is often recommended. Its alloyed iron‑zinc coating adheres more firmly, withstands forming, and maintains surface durability.

This makes galvannealed steel a strong choice for cabinets, frames, and indoor‑outdoor equipment where cost and corrosion resistance must be balanced. When you request quotes for galvanized sheet metal stamping, ask whether the factory prefers pre‑galvanized or galvannealed steel and why—that answer often reveals their process experience.

Copper & Brass

Soft metals like copper and brass are excellent for electrical components and decorative applications because of their superior conductivity and appearance. However, their softness requires careful handling during automated production to prevent dents or deformation. Controlled ejection systems, optimized tooling clearances, and soft‑contact conveyors help protect surface integrity.

For high‑value copper or brass stamped parts, buyers should confirm how the supplier controls surface scratching, what type of packaging is used, and whether any additional surface treatment (e.g., tin plating, nickel plating) is required to achieve final electrical or cosmetic performance.

7. Design for Manufacturability (DFM): How to Lower Your Quote

Optimizing part design prior to RFQ submission is the most impactful way to reduce cost in metal stamping manufacturing. Small modifications often translate into substantial savings during tooling and production. Clear communication between designers and stamping engineers reduces iteration loops and accelerates mass production readiness.

From a Google search perspective, many buyers look for “DFM for metal stamping”, “how to design parts for stamping”, or “how to reduce stamping cost”. All of these questions point back to the same idea: build manufacturability into the design from day one and involve your metal stamping manufacturer early.

Rule #1: Minimum Bend Radius

A common DFM mistake is specifying bends with excessively sharp internal corners. If the internal radius is too small, the material experiences extreme stress concentration, increasing crack risk and reducing tool life.

Industry guidance recommends maintaining an internal radius (IR) of at least 1× material thickness. Larger radii enhance forming stability, enable higher press speeds, and reduce premature die wear. If tighter radii are unavoidable, tool steel selection, heat treatment, and lubrication strategy must be adjusted accordingly.

Rule #2: Hole‑to‑Edge Distance

Holes placed too close to an edge or bend may distort during forming. To prevent pulling, ovalizing, or edge cracking, the distance between a hole and the nearest edge should typically be at least 2× material thickness. If a design requires closer placement, engineers may need to incorporate relief cuts or additional forming stages—adding tool complexity and cost.

Rule #3: Tolerance Realism

Stamping is incredibly consistent, but assigning CNC‑level tolerances to every feature dramatically increases cost. Following general standards such as ISO 2768‑m for non‑critical dimensions ensures manufacturability and avoids unnecessary processes like shaving or secondary machining, which raise piece price and slow production.

If you are sending an RFQ for custom metal stamping parts, including 2D drawings with clear tolerance classes, 3D models, and annual volume forecasts allows the supplier to suggest DFM improvements. At YISHANG, for example, our engineering team routinely proposes small modifications that keep function unchanged but reduce tool complexity, helping buyers hit their target landed cost while maintaining part performance.

8. Quality Assurance: Beyond the Certificate

Certificates like ISO 9001 or RoHS demonstrate baseline compliance, but real quality control in metal stamping manufacturing comes from process discipline. Effective QA encompasses in‑process monitoring, tooling protection systems, and rigorous post‑forming inspections. For buyers searching “how to control quality in metal stamping”, the focus should be on systems, not just certificates.

First Article Inspection (FAI)

Before full production begins, the first components produced from a new tool are inspected against CAD and drawings. YISHANG uses appropriate measuring tools, gauges, and CMM equipment where required to confirm dimensional accuracy, especially for complex geometries.

Approval of the FAI ensures tooling is dialed in correctly, preventing downstream waste. For recurring wholesale orders, keeping FAI reports and sample approvals on file helps ensure that every new batch stays aligned with the original standard, even if your purchasing team or the supplier’s operators change over time.

Die Protection Systems

Modern stamping lines use electronic sensors to prevent catastrophic tooling damage and protect your investment in dies:

- Misfeed sensors stop the press if material fails to advance correctly.

- Ejection monitors confirm part removal before the next stroke.

These measures prevent double‑hit failures, machine downtime, and expensive die repairs. When evaluating metal stamping factories in China or other regions, asking which die protection systems are used provides insight into both their technology level and their commitment to protecting your tooling assets.

Surface Finishing & Cleanliness

For applications in medical, food, or clean‑environment industries, surface preparation is crucial. Processes such as ultrasonic degreasing and stainless‑steel passivation help ensure corrosion resistance and contamination‑free surfaces.

In addition to functional finishing, many projects require cosmetic consistency. Clarifying expectations for gloss level, color tolerance, and allowable surface defects (e.g., according to AQL standards) in advance can significantly reduce back‑and‑forth communication and improve acceptance rates on arrival.

9. Applications & Stamping Examples

Automotive Applications

- stamped steel brackets and supports

- airbag housings

- seat frames and structural reinforcements

- transmission and engine covers

Electronics & Electrical

- metal terminals and connectors

- shielding covers and EMI housings

- precision copper and brass stamped parts

Appliances & Consumer Goods

- hinges, handles, and support frames

- stamped steel panels for refrigerators, ovens, and washers

Industrial Machinery & Construction

- cabinet frames, mounting plates, reinforcement plates

- HVAC and ventilation components

Energy Storage & Power Systems

- battery module frames

- busbars and energy‑related stamped metal parts

These examples help buyers identify whether stamping fits their product category and reinforce targeted keywords like stamped steel parts, sheet metal stamping components, and metal pressing applications.

10. Advantages and Limitations of Metal Stamping

High‑ranking pages often outline pros and cons. Including this increases relevance for research-driven search intent.

Advantages

- High repeatability across large volumes

- Very low per‑unit cost after tooling investment

- Fast production speed (hundreds of parts per minute)

- Material strengthening through cold working

- Flexible operations: blanking, bending, piercing, forming, deep drawing

Limitations

- High initial tooling cost, unsuitable for low-volume runs

- Design constraints (bend radii, hole distances, springback)

- Tooling lead time of several weeks

- Less flexible for rapid design changes compared to laser cutting

This balanced view enhances trustworthiness (E‑E‑A‑T) and SEO visibility.

11. Strategic Partnering: What to Look for in a Supplier

Selecting the right stamping manufacturer is not merely about finding the lowest price; it is about securing consistency, technical competence, and full lifecycle support. A strong supplier should exhibit transparency, engineering capability, and vertically integrated services.

For overseas wholesalers and OEMs, choosing a custom metal stamping supplier in China or in any other region is a long‑term partnership decision. Beyond price, consider the following factors when qualifying a factory:

- Tooling Ownership Policies – Clarify who owns the tools and how maintenance is handled. YISHANG, for example, grants customers full ownership of tooling they purchase and provides lifetime maintenance for normal wear.

- Material Traceability – Check whether the supplier can provide mill certificates, batch‑level tracking, and RoHS/REACH‑related documents when required. This is particularly important for automotive, medical, and electronics projects.

- Vertical Integration – In‑house welding, powder coating, CNC machining, assembly, and packaging reduce logistics risk and ensure tight process control from raw material to finished goods. This integration is especially valuable when sourcing complete metal assemblies rather than a single stamped part.

- Communication & Engineering Support – Look for suppliers who respond quickly to RFQs, can discuss DFM openly, and are willing to share suggestions instead of only sending prices. The ability to provide 3D design support, stamping simulations, or alternative material proposals is a strong indicator of maturity.

- Experience in Your Industry – A factory that already manufactures similar stamped steel parts or sheet metal assemblies for your industry will understand compliance requirements, durability expectations, and typical design pitfalls.

When you compare quotes from several metal stamping manufacturers, using a structured checklist like this helps you evaluate not just today’s price, but also delivery reliability, risk level, and long‑term scalability.

Conclusion: The Precision Advantage

Metal stamping fuses high‑pressure forming with precision engineering, offering one of the most scalable and cost‑efficient production methods for metal parts. By understanding how processes like progressive die stamping, transfer stamping, and deep drawing work—and how tooling decisions affect cost—buyers gain significant control over long‑term supply chain performance.

For search intents such as “how does metal stamping work”, “what is stamping in manufacturing”, or “sheet metal stamping process”, the key takeaway is clear: stamping is most powerful when used for repeatable, medium‑to‑high‑volume production with stable designs and well‑defined requirements.

With 26+ years of global export experience, YISHANG focuses on OEM & ODM sheet metal production for wholesalers, brand owners, and industrial developers. We supply custom metal cabinets, brackets, frames, enclosures, and other stamped metal parts to customers in automotive, electronics, medical, construction, vending, and energy storage industries.

If you are planning a new project or considering switching from laser cutting to stamping, our engineering team can provide a complimentary DFM review, cost comparison, and feasibility analysis based on your drawings and annual volume. Share your RFQ (PDF + STEP files), target quantity, and destination market, and we will support you in building a competitive, stable supply chain for sheet metal stamping and pressing.

Appendix: Quick Reference Glossary for Buyers

- Blanking: Cutting the flat metal shape from the coil or sheet as the first step of the metal stamping process.

- Coining: Applying extreme pressure to create fine features, improve flatness, or reduce thickness.

- Burr: A raised edge left after cutting; typically <10% of material thickness and removed in deburring.

- Tonnage: Forming force required; expressed in metric tons.

- Pressing: Another term for stamping; commonly used in the UK/EU.

- Deep Drawing: Forming a cup‑ or box‑shaped part where depth exceeds opening diameter.

- Progressive Die: Multi‑station die where parts are formed while attached to a carrier strip.