In the heart of a satellite’s guidance system, a surgeon’s robotic tool, or a high-frequency telecommunications switch, components smaller than a grain of sand perform flawlessly. These are not just miniaturized versions of larger parts; they are the products of a distinct and demanding discipline: micro precision metal manufacturing.

This is a world where the familiar rules of machining bend, the physics of metal changes, and the margin for error approaches zero. The relentless trend of miniaturization has created an insatiable demand for these infinitesimal components—especially among OEM CNC micro component buyers, medical equipment manufacturers, and aerospace precision sourcing managers.

However, creating them is not a simple matter of scaling down existing designs. It requires a fundamental shift in technology and a deep understanding of the challenges involved in micron tolerance manufacturing.

This guide is for the engineers, designers, and procurement professionals who operate at this edge of what’s possible. We will explore the principles, processes, materials, and formidable challenges that must be overcome to achieve perfection at the micron scale.

The Micron Mandate: Redefining “Precision” in Metal Manufacturing

The term “micro precision part” signifies much more than just a small component. It is a technical classification defined by a convergence of three core pillars: scale, tolerance, and complexity. For a wholesale purchaser, understanding these pillars is the first step in qualifying a supplier’s true capabilities.

What Truly Defines a “Micro Precision Part”?

These components are the result of a manufacturing philosophy where every variable is controlled to an extreme degree, impacting both performance and supply chain reliability.

- Pillar 1: The Scale (Microns, not Millimeters): The features of these parts are measured in micrometers (µm), or microns—one-millionth of a meter. To put this into perspective, an average human hair is approximately 70 µm wide. We are discussing the manufacturing of metal parts with features that are a fraction of that size.

- Pillar 2: The Tolerance (The Zero-Error Imperative): The most defining characteristic is the demand for ultra-tight dimensional accuracies. While conventional machining might hold tolerances of ±100 µm, micro-manufacturing routinely achieves accuracies within ±12.7 µm (±0.0005 inches), often reaching the single-micron range (±2-5 µm). This level of precision is critical, as even minor deviations can lead to assembly failure in high-value products.

- Pillar 3: The Complexity (Geometries that Defy Convention): These are not simple shapes. They frequently possess intricate geometries such as micro-threads, complex 3D contours, and ultra-thin walls. These features are designed to maximize functionality within a minimal footprint, a core requirement of modern electronics and medical devices.

The Great Divide: Why Conventional CNC Machining Fails at the Micro-Scale

Attempting to apply conventional machining principles to the micro-scale is a common sourcing pitfall. The difference is not merely about using smaller tools; it is a profound shift in the physics of material removal.

As the scale of machining shrinks, the fundamental behavior of metals changes. When the depth of a cut approaches the size of the material’s crystal grains, the metal no longer behaves as a uniform medium.

This phenomenon, known as the “size effect,” means the tool interacts with discrete grains, each with a different hardness. This leads to unpredictable cutting forces and inconsistent surface finishes, making process control a significant challenge. Consequently, a completely different playbook of specialized machinery and strategies is required for the successful manufacturing of metal parts at this scale.

The Architect’s Toolbox: A Decision Guide to Micro-Manufacturing Processes

The creation of high precision metal parts requires a departure from the familiar world of conventional manufacturing. For an engineer or procurement manager, understanding these micro-manufacturing processes is critical, as the part’s geometry, material, and required tolerances dictate the optimal and most cost-effective path to production.

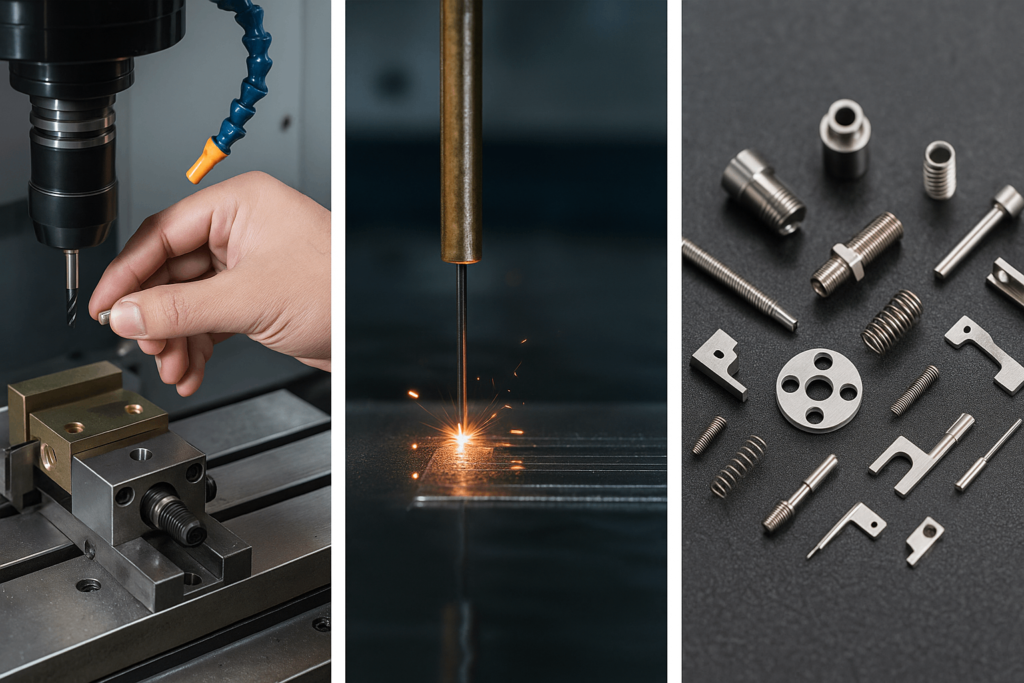

Precision Carving: Subtractive Methods for Metals

Subtractive processes create custom machined parts by meticulously removing material from a larger block. At the micro-scale, this involves a range of highly sophisticated techniques.

- The Workhorse (Versatility & 3D Shapes): Mechanical Micro-Milling & Turning. This process uses physical tools to cut material, analogous to its conventional counterparts but executed on a vastly different scale. Micro-milling sculpts complex 3D contours in materials like aluminum and stainless steel, while micro-turning creates cylindrical parts like pins and shafts. Success hinges on specialized machines, like Swiss-type CNC lathes, and ultra-high-speed spindles exceeding 60,000 RPM.

- The Specialist (Hard Metals & Sharp Corners): Micro-EDM (Electrical Discharge Machining). Micro-EDM is a non-contact, thermal erosion process that can shape any electrically conductive material, regardless of its hardness. It works by generating a series of rapid electrical sparks between an electrode and the workpiece, melting and vaporizing microscopic amounts of material. This force-free method is essential for hardened tool steels and titanium, creating sharp internal corners impossible with milling.

- The Universal Tool (Any Metal, No Heat Damage): Femtosecond Laser Micromachining. This advanced process uses an ultrashort pulse laser for material removal. Its power lies in “cold ablation,” where the laser pulse is so short it vaporizes the material before heat can spread. This creates a clean cut with a negligible Heat-Affected Zone (HAZ), eliminating the burrs and thermal distortion that can compromise part integrity. This is ideal for heat-sensitive alloys and critical medical components.

Building from the Ground Up: Additive & Hybrid Methods

While subtractive methods dominate, additive manufacturing plays a crucial indirect role in the metal parts fabrication ecosystem.

- For Molds & Prototypes: Two-Photon Polymerization (2PP). 2PP is the highest-resolution 3D printing process available, capable of creating polymer features with sub-micron accuracy. Its primary role in the metal industry is creating ultra-high-resolution polymer molds. These intricate molds can then be used in a secondary process like metal electroforming to produce custom metal parts with geometries that even micro-milling cannot achieve.

At-a-Glance Decision Matrix

| ProcessCore PrincipleBest For MetalsTypical ToleranceKey Advantage for Procurement | ||||

|---|---|---|---|---|

| Micro-Milling/Turning | Mechanical Cutting | Stainless Steel, Aluminum, Copper, Brass, Titanium | ±5-10 µm | High versatility for complex 3D shapes; mature and well-understood process. |

| Micro-EDM | Thermal Erosion (Sparks) | Hardened Steels, Titanium, Conductive Alloys | ±1-5 µm | Solves machinability issues with hard metals; enables designs with sharp internal corners. |

| Femtosecond Laser | “Cold” Ablation | All Metals, especially heat-sensitive alloys | ±1-5 µm | Burr-free parts with no thermal damage, reducing post-processing needs and ensuring material integrity. |

| 2PP + Electroforming | Additive Polymer Mold | Electroplatable Metals (Nickel, Copper, Gold) | <1-2 µm | Unlocks geometries impossible with other methods, offering maximum design freedom for specialized components. |

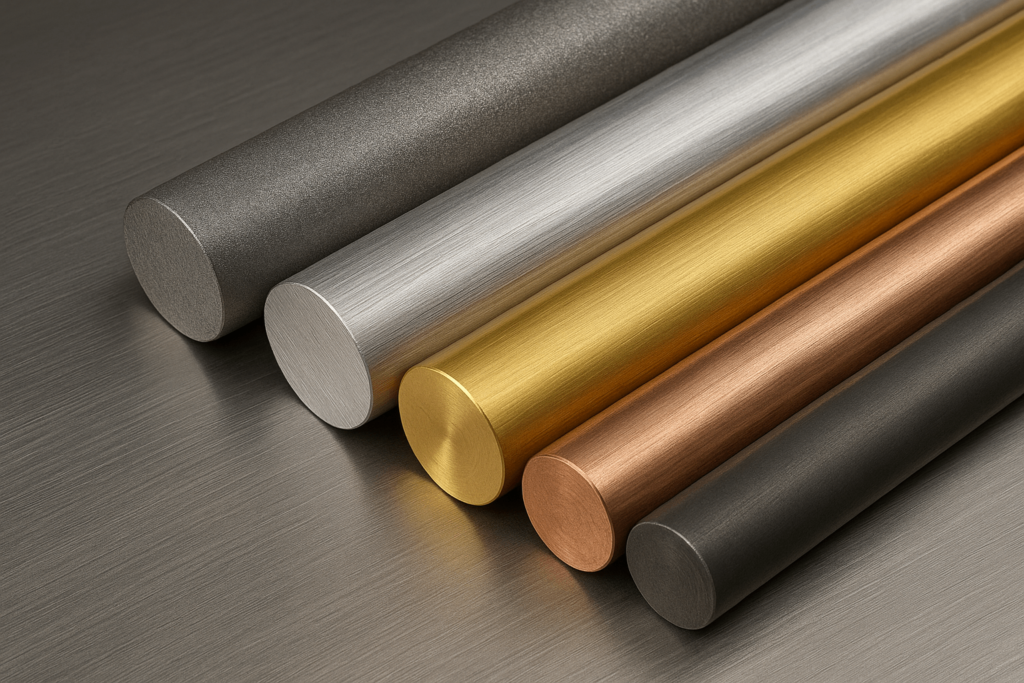

The Material Matrix: Balancing Performance vs. Machinability in Metals

In the world of micro precision parts, the ideal material for performance is often the most challenging to machine. This section explores the high-performance metals that define the industry, focusing on the critical trade-off between their desirable properties and the unique difficulties they present. This is crucial knowledge for sourcing professionals who must balance design requirements with manufacturing feasibility and cost.

Stainless Steel (304/316): The Durable All-Rounder

Stainless steel, especially grades 304 and 316, is widely used for its corrosion resistance, strength, and biocompatibility. These properties make it suitable for surgical instruments, aerospace connectors, and electronic sensor housings. However, its high toughness and work-hardening behavior significantly increase tool wear during micro-machining. Careful management of cutting parameters, coolant application, and tool material is essential.

Titanium: The Lightweight Champion

Titanium alloys such as Grade 5 (Ti-6Al-4V) provide high strength-to-weight ratios and exceptional corrosion resistance, particularly for aerospace and medical applications. Its low thermal conductivity, however, leads to rapid heat concentration at the cutting edge during machining, increasing the risk of tool failure and burr formation. Micro-EDM is often the preferred method for achieving high-precision features in titanium.

Copper & Brass: The Conductive Workhorses

Copper and brass excel in applications requiring high electrical and thermal conductivity, such as micro-connectors, RF components, and heat sinks. Brass, being easier to machine than pure copper, is often the economical choice. However, copper’s ductility and tendency to form built-up edges can lead to smearing and dimensional inaccuracies in micro-milling unless precise toolpath strategies are applied.

Aluminum: The Cost-Effective Lightweight Metal

Aluminum is prized for its machinability, weight-to-strength ratio, and cost-efficiency. Its widespread use spans medical housings, enclosures, and micro-mechanical components. However, due to its relatively low stiffness, thin-walled micro parts may deform under cutting forces, requiring specialized fixturing or hybrid approaches like laser ablation to maintain dimensional accuracy.

Red & Yellow Metals: Aesthetics Meet Precision

Metals like bronze and red copper are used in precision instruments where aesthetics matter (e.g., optical devices, decorative medical tools). While they offer good machinability, they are sensitive to oxidation and surface finish inconsistencies. Post-processing such as electropolishing is often necessary.

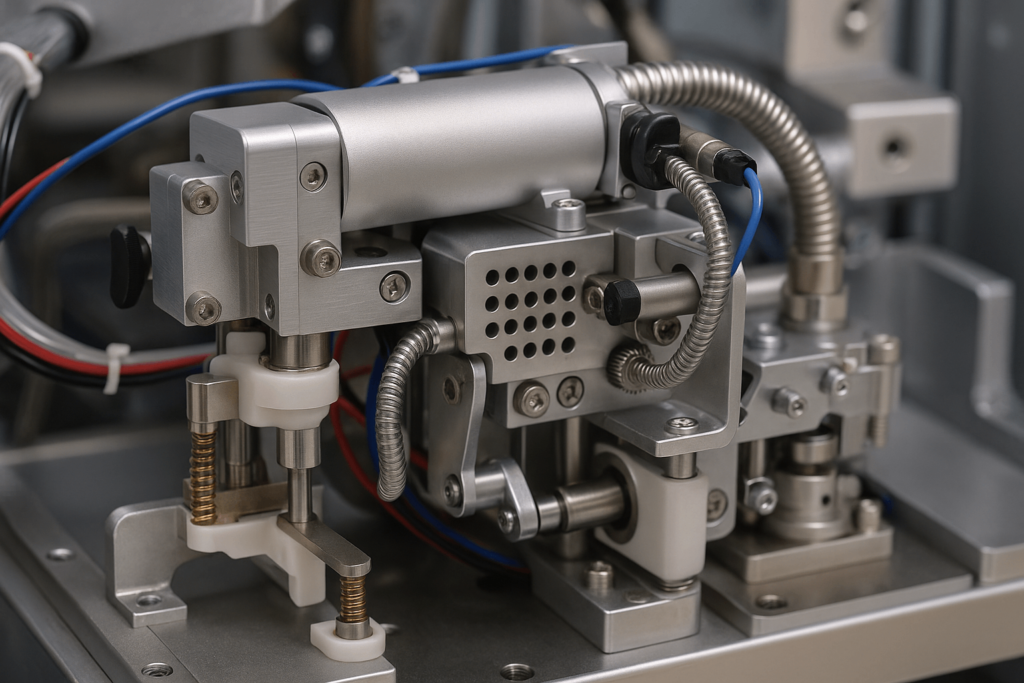

Engineering Applications: Where Micro Precision Matters Most

Understanding where these parts are used helps sourcing professionals gauge risk, performance priorities, and supply chain value. Here are key industries where micro precision metal parts make the difference between success and failure.

Medical Devices

In surgical robotics, endoscopic tools, and implantable devices, metal parts must meet extreme hygiene, dimensional, and biocompatibility standards. Micro-machined titanium or stainless steel components ensure sterile reliability without compromising strength or size. Tool paths must account for sharp transitions and eliminate burrs that could otherwise compromise tissue safety.

Aerospace & Defense

Aircraft sensor assemblies, satellite gyroscopes, and missile guidance systems require micron-level tolerances. Here, weight savings, electromagnetic shielding, and structural integrity are paramount. Micro-EDM and high-speed CNC turning of titanium and Inconel alloys enable components that endure vibration, heat, and G-forces.

Electronics & Optics

RF connectors, MEMS packaging, and camera gimbals rely on micro parts for signal fidelity and movement precision. Tighter packaging in 5G modules demands micro components that resist thermal expansion while allowing minimal assembly gaps. Electroformed nickel structures and copper inserts are common in this domain.

Energy Storage & Automation

Battery terminals, precision busbars, and micro-contactors in EVs or energy storage systems require low-resistance and high-reliability materials like copper and nickel alloys. Automation-driven assembly processes demand that these parts have burr-free edges and perfect flatness to avoid jamming or contact resistance.

Barriers to Entry: The Real Challenges in Manufacturing Micro Parts

From an engineering and procurement standpoint, micro metal part manufacturing is a battlefield of extreme constraints. Understanding these challenges is key to making informed sourcing decisions.

Tool Wear is Exponential

At micro scale, tools are typically smaller than a sewing needle and made from expensive materials like polycrystalline diamond or coated carbide. Even microscopic wear can translate into dimensional drift. Tool life may be measured in minutes, not hours.

Material Microstructure Becomes Unpredictable

At micron-level cuts, you’re machining individual grains in metal. That inconsistency makes every cut a potential risk. Specialized CAM software must adjust feeds and speeds dynamically.

Metrology Becomes a Bottleneck

You can’t inspect a 2 µm feature with a caliper. Non-contact inspection tools like white-light interferometers or SEMs (Scanning Electron Microscopes) are required, which adds time and cost.

Burrs and Debris = Catastrophic Failure

Even a 10 µm burr on a part surface can destroy a micro actuator or short an electrical signal. Deburring and ultrasonic cleaning are essential post-processes.

Process Repeatability is Fragile

High-mix, low-volume orders with tight tolerances often require multiple machine setups. Even thermal expansion of a spindle can throw off the result.

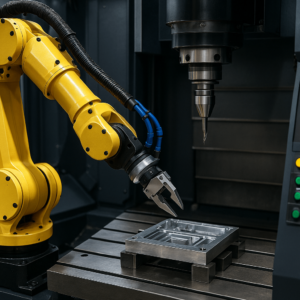

Future Trends: AI, Nanotech & the Next Frontier of Micro Manufacturing

For procurement leaders looking ahead, knowing what’s next can define your supplier partnerships.

AI-Enhanced Machining

AI-assisted CAM tools are enabling dynamic feedrate and spindle optimization based on real-time tool condition. This increases part yield and reduces waste.

Adaptive Fixturing

Fixtures embedded with sensors detect micromovements and adjust part position automatically. This ensures positional accuracy during long cycle times.

Digital Twins in Micro Manufacturing

Suppliers are increasingly using digital twin models to simulate micro part performance and manufacturability before cutting begins. This reduces iteration time and improves design-for-manufacture outcomes.

Nanomaterials & Surface Structuring

New alloys and nanostructured coatings offer better wear resistance, lower friction, and even antimicrobial properties—especially valuable in medical and aerospace applications.

What to Ask Your Supplier Before Placing a Micro Precision Parts Order

- What is your proven tolerance range in µm, and how is it verified?

- Do you use SEM or other non-contact inspection tools?

- Can you provide a sample part with full metrology data?

- What experience do you have with my target industry’s materials (e.g., Inconel, Ti-6Al-4V)?

- How do you control tool wear during long runs?

- Is there in-house cleaning, deburring, or electropolishing capability?

These questions separate shops that truly specialize in micro-manufacturing from those that simply accept small parts jobs.

FAQ: Common Questions from Micro Component Buyers

Q1: Can you produce both prototypes and full-scale production runs?

Yes. Many shops have separate cells for R&D versus high-volume. Prototyping enables design iteration and validation.

Q2: Are off-the-shelf tools used, or is everything custom?

For micro features under 100 µm, custom tooling is the norm. Off-the-shelf cutters simply aren’t rigid or sharp enough.

Q3: Can micro parts be integrated with plastic assemblies?

Yes, many medical and consumer devices combine injection-molded plastics with press-fit or insert-mounted metal components.

Q4: What’s the average lead time for micro precision parts?

Typical production lead time is 3–5 weeks after prototype approval, depending on complexity and volume.

Q5: What industries are most reliant on these parts?

Medical, aerospace, defense, telecommunications, optics, and energy storage are the top sectors.

About YISHANG

With over 26 years of expertise in precision metal fabrication, YISHANG serves industrial buyers and OEMs across more than 50 countries. From micro CNC components to intricate custom metal housings, our ISO 9001 and RoHS-certified facilities produce quality at scale. We specialize in stainless steel, aluminum, copper, titanium, and more—with support for laser cutting, CNC machining, EDM, deburring, surface treatment, and custom assembly.

YISHANG supports both OEM and ODM production. All orders are custom manufactured to client specs, and we offer fast prototyping, design validation, and scalable mass production.

Want to discuss your micro precision part requirements?

👉 Request a Quote or email us directly to explore how YISHANG can support your next project.