Why the Difference Between NEMA 4 and 4X Actually Impacts Procurement

In enclosure sourcing, especially for global OEM or industrial distribution, overlooking the difference between NEMA 4 and NEMA 4X is more than a technical error—it can translate to warranty issues, shipment delays, and customer dissatisfaction.

Procurement professionals aren’t just choosing a code—they’re choosing long-term performance. A NEMA 4-rated enclosure might pass ingress tests, but fail within months if exposed to industrial solvents or salt spray. That’s where NEMA 4X provides the additional environmental tolerance needed for harsh conditions.

NEMA ratings must be understood in context. And for bulk buyers, this means asking the right questions up front: What environment will this operate in? What’s the failure cost if it’s the wrong spec? How can we avoid rework or replacement?

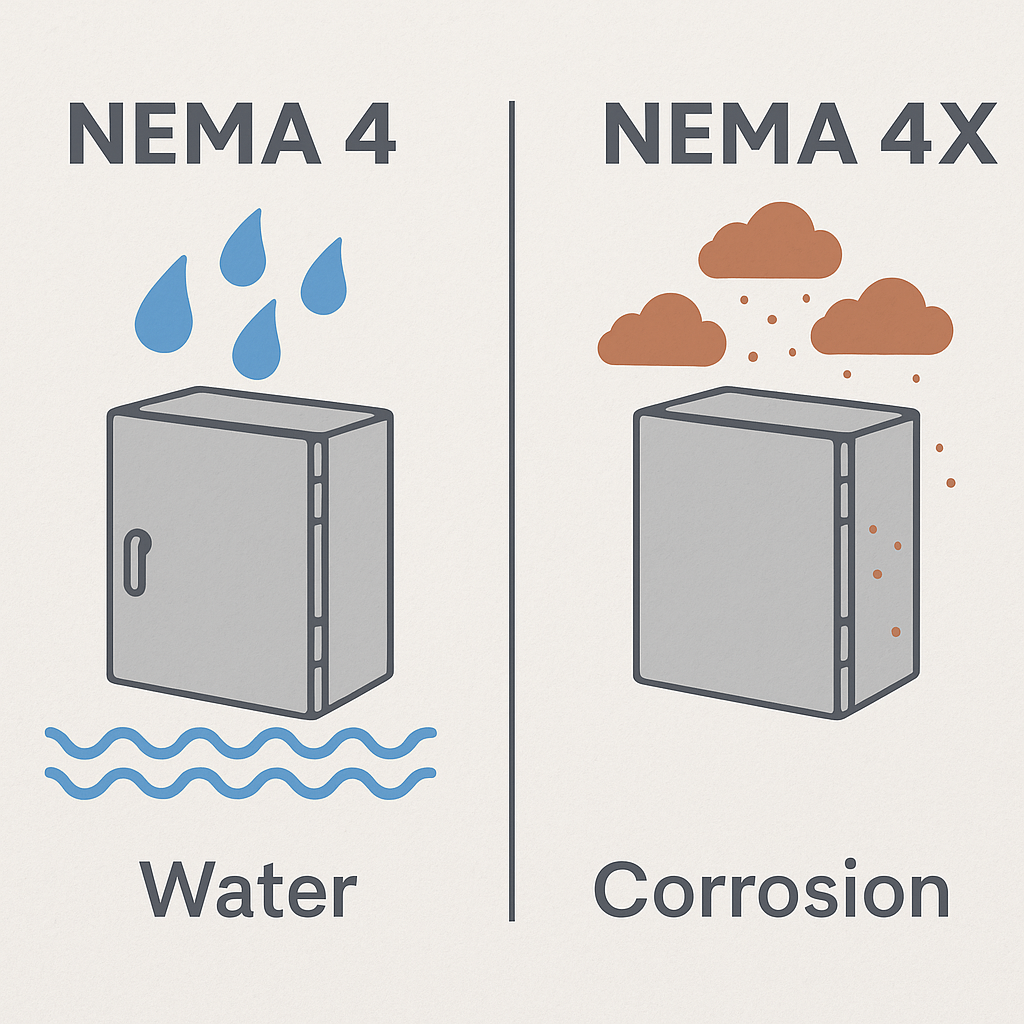

NEMA 4 vs. 4X: Technical Similarities, Procurement-Level Differences

Both NEMA 4 and 4X enclosures offer watertight protection. They handle hose-downs, sleet, and airborne dust with ease. They’re built for reliability in wet or dusty conditions.

But only NEMA 4X extends that protection to chemical, saline, and corrosive elements. Whether that’s from chlorine-based cleaners in food plants or salty air in port-side installations, this added resistance elevates operational lifespan and reduces service calls.

| Feature | NEMA 4 | NEMA 4X |

|---|---|---|

| Ingress Protection | Yes | Yes |

| Dust Resistant | Yes | Yes |

| Resistance to Harsh Agents | Limited | Enhanced |

| Typical Material Options | Painted Steel, Aluminum | Stainless Steel 304/316, FRP |

| Use in Marine/Chemical Areas | Not Recommended | Recommended |

If you’re supplying to environments with corrosive exposure, the higher-grade build of a 4X-rated unit minimizes field failure and increases your service credibility.

Deeper Insight: Why the NEMA 4X Rating Exists in the First Place

While NEMA 4 and 4X enclosures may appear similar in performance tests, they are validated under different long-term durability assumptions. NEMA 4X was introduced to meet the needs of industries facing consistent chemical exposure or salt-laden air — environments where painted steel or basic seals are simply not enough.

The inclusion of “X” signifies that the enclosure has been subjected to corrosion-specific evaluations, including ASTM B117 salt spray testing, which is not mandatory for NEMA 4 units. This makes a difference for buyers who must plan for asset longevity in high-risk zones. In short, NEMA 4 focuses on ingress protection; NEMA 4X extends that to material longevity.

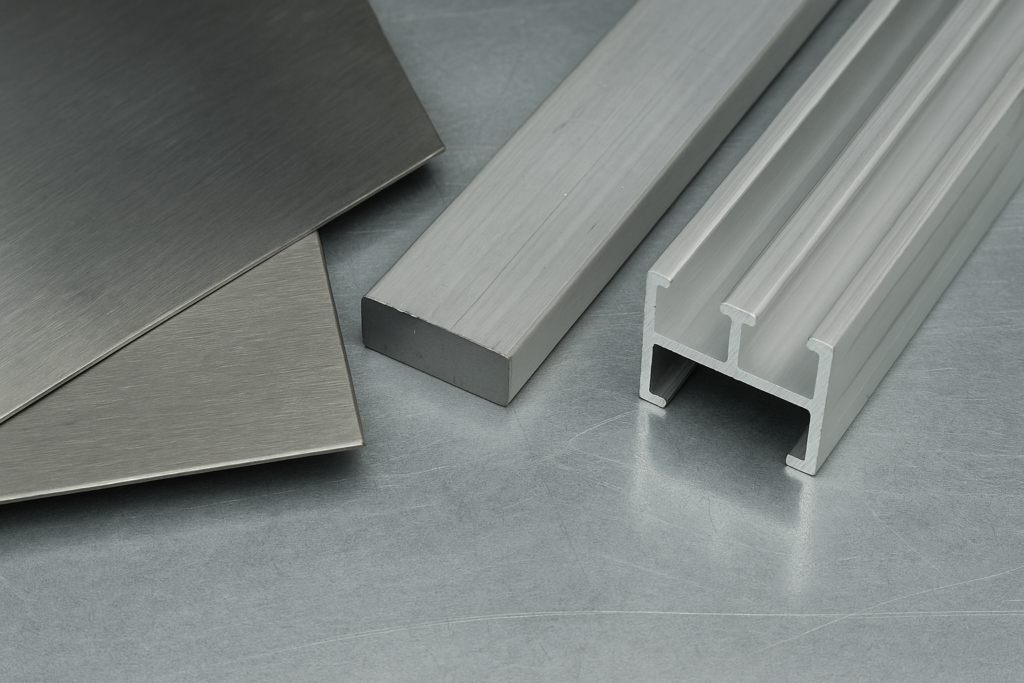

Material Drives Performance: Choosing What Lasts

The defining trait of a 4X-certified enclosure is material resilience. Coated carbon steel may handle water, but in corrosive or humid zones, degradation is rapid.

Buyers should seek enclosures using marine-grade 316 stainless steel, 304 stainless steel, FRP, or aluminum extrusion with certified sealing. These materials offer different strengths: weight reduction, chemical resistance, or strength-to-cost efficiency.

YISHANG delivers these options through automated processes—CNC laser cutting, TIG welding, and powder coating. Our engineers review use-case specs and propose the optimal material blend for cost and durability.

Real Use Scenarios: When 4X Is the Reliable Choice

In some environments, 4X is not a preference—it’s a prerequisite. Areas like bakery production lines, sea transport hubs, or agricultural pump stations demand advanced corrosion defense.

For example, one client operating in Southeast Asia saw a 40% reduction in repair costs after switching to YISHANG 4X stainless enclosures, avoiding repainting and sealing failures common in humid environments.

NEMA 4X enclosures are particularly suited for:

Food processing (washdown zones)

Seaside communications infrastructure

Pharmaceutical equipment enclosures

High-fertilizer agriculture zones

Beyond performance, this compliance readiness smooths UL, CE, and ISO inspections.

Price vs. Lifecycle: What Sourcing Teams Really Track

Upfront pricing doesn’t tell the full story. Factoring in field reliability, replacement shipping, and brand reputation shows why 4X enclosures are often the smarter purchase.

| Application | Upfront Cost | Corrosion Risk | Service Disruption Cost | Ideal Rating |

| Indoor Offices | Low | Minimal | Low | NEMA 4 |

| Industrial Kitchens | Medium | High | High | NEMA 4X |

| Port Terminal Equipment | Medium | Very High | Very High | NEMA 4X |

When scaled across hundreds of units, field reliability becomes a key metric in project profitability.

Global Relevance: Export Readiness and Certification Alignment

Global buyers often ask: “Is IP66 the same as NEMA 4X?” Technically, both prevent water ingress. But IP66 lacks corrosion test requirements like ASTM B117, which is central to NEMA 4X validation.

| Rating | Corrosion Resistance | IP Equivalent | Required Materials | Export-Friendly |

| NEMA 4 | No | IP66 | Coated Steel | Limited |

| NEMA 4X | Yes (ASTM B117) | IP66 + | SS304/316, FRP, Aluminum | Preferred |

For clients serving regulated markets or harsh climates, NEMA 4X simplifies import approvals and long-term warranty control.

Making the Right Choice: A Procurement Decision Guide

Smart sourcing teams apply environmental, regulatory, and ROI filters:

Operational Zone: Humid, dry, corrosive?

Chemical/Fertilizer Proximity: Yes or no?

Expected Unit Lifespan: Months or multiple years?

Client Quality Expectation: Budget or premium?

YISHANG helps simplify these choices with quick-spec reviews and CAD support during quotation, ideal for large or recurring orders.

What Quality Buyers Also Verify: Pre-Shipment QC Guidance

When dealing with bulk shipments, relying solely on a product label is risky. High-volume buyers benefit from structured quality checks:

Visual Inspection: Check seals, coating uniformity, welding consistency

Random Sampling: 10% physical test verification against spec

Label & Documentation Matching: Ensure NEMA, material, and CE/UL claims are reflected in shipping documents

Salt Spray Certificate: For 4X claims, request ASTM B117 report

YISHANG supports third-party QC processes and provides batch-level test summaries to give importers peace of mind before containers ship.

Summary: The 'X' That Reduces Field Failures

Procurement isn’t about the cheapest SKU—it’s about the lowest project risk. And NEMA 4X is the enclosure grade that consistently prevents avoidable field issues in challenging environments.

At YISHANG, we’ve supported hundreds of OEM and global buyers with NEMA 4X-certified enclosures, optimized for performance and logistics. With support for aluminum extrusion, SS316, polycarbonate, and FRP fabrication, we tailor solutions to meet bulk order specs without compromising timelines.

Ready to reduce replacement costs and inspection headaches? Choose 4X where it matters.

FAQs for Sourcing Teams

Q: What’s the difference between NEMA 4 and 4X in field use?

A: NEMA 4 shields against water and dust; 4X adds materials and sealing techniques to handle chemicals and saline exposure.

Q: Can aluminum enclosures qualify for 4X?

A: Yes, with corrosion-resistant coating and passed ASTM testing. Ask your supplier for proof.

Q: Do you offer spec sheets and pre-export support?

A: Yes. YISHANG supplies RoHS/ISO files, test reports, and standard international shipping docs.

Q: Is polycarbonate suitable for harsh conditions?

A: Only for low-abrasion areas. For industrial zones, FRP or stainless is safer.