At YISHANG, we operate in the same world you do. We understand the immense pressure to deliver flawless quality for large-volume orders against tight deadlines.

This pressure is compounded by one of the biggest challenges in the entire welding industry: the growing shortage of skilled labor. For wholesale buyers and their supply chains, this isn’t just an inconvenience—it’s a direct threat to production capacity and reliability.

This guide is our expert analysis of a specific solution we know intimately: the OTC DAIHEN FD-V6 robotic welding system. We move beyond the brochure to explore what this technology truly means for your workflow, your quality control, and your bottom line. From advanced seam tracking to real-time error correction, we dissect its most impactful features and what they translate to in a real manufacturing setting.

This is a deep dive for professionals, designed to help you determine if this is the right strategic investment to secure your production future.

The Core Challenge: Protecting Capacity and Ensuring Quality in a Demanding Market

The fundamental issue is a matter of supply and demand. The need for high-quality, consistent welds is rising, yet the number of expert welders is declining. For any company involved in manufacturing welding on a large scale, this creates a significant business risk.

Relying solely on manual labor for repetitive tasks ties up your most experienced technicians on jobs that don’t leverage their full expertise. This leads to production bottlenecks and increases the risk of human error, especially across long production runs.

The strategic solution is to view automation as a force multiplier. A system like the OTC FD-V6 empowers a single skilled welder to oversee the output of multiple automated cells.

Their role elevates to a higher level: programming, quality assurance, and handling the most complex fabrication challenges. This maximizes the value of your human assets and boosts your overall production capacity.

Deconstructing the System: What a Professional Buyer Needs to Know

Evaluating a robotic system goes beyond a simple spec sheet. For a professional buyer, every component must be assessed based on its impact on performance, reliability, and long-term maintenance costs.

The OTC FD-V6 is a fully integrated ecosystem. This reflects OTC DAIHEN’s “single-source solution” philosophy—they design and build the robot, controller, and power source. For a buyer, this unified approach simplifies post-installation troubleshooting and service, minimizing cross-vendor dependencies.

The Arm: The 6-Axis vs. 7-Axis Decision for Production Flexibility

The first key decision is the manipulator arm. The choice between a 6-axis and 7-axis robot directly impacts the complexity of the parts you can produce efficiently.

The standard FD-V6 is a 6-axis workhorse. It features a 6 kg payload and a 1402 mm reach, making it ideal for the vast majority of brackets, sub-assemblies, and other components in a high-density cell. Its precision is exceptional, with a positional repeatability of ±0.08 mm.

For more intricate welding assembly tasks, the FD-V6LS is a 7-axis variant. This is where the benefits of robotic welding become even more apparent.

Imagine welding a complex chassis with tight internal corners. A 6-axis robot might have to compromise its torch angle to avoid a fixture. The 7-axis robot, however, can articulate around obstacles while maintaining the perfect angle for a flawless weld—crucial for applications where the 5 basic weld joints must be executed with absolute precision.

| Model | Axes | Max Payload | Horizontal Reach | Positional Repeatability | Key Application Focus |

|---|---|---|---|---|---|

| FD-V6 | 6 | 6 kg | 1402 mm | ±0.08 mm | High-volume general fabrication |

| FD-V6L | 6 | 6 kg | 2006 mm | ±0.08 mm | Larger workpieces, extended reach |

| FD-V6LS | 7 | 6 kg | 2006 mm | ±0.08 mm | Complex geometries, interference avoidance |

The Controller & Pendant: An Interface Built for the Shop Floor

A robot’s power is useless if it’s too complex to program. The OTC FD11 controller is the system’s brain, and the teach pendant is the primary interface for your team.

OTC DAIHEN has clearly focused on usability. The pendant is lightweight and ergonomic, a crucial detail for reducing operator fatigue during the setup of new production runs.

The interface combines a color touchscreen with an intuitive physical jog dial. This allows for rapid, precise adjustments without navigating complex menus. The intuitive design significantly lowers the training barrier. Your existing welders can become proficient operators quickly—a key factor in managing operational costs and reducing onboarding time.

The Power Source (Welbee): The Heart of Weld Quality

The quality of any weld ultimately comes down to the power source. This is where the system’s deep integration delivers its most significant advantage for a buyer concerned with final product quality.

The Welbee power source connects to the controller via a proprietary “seamless digital connection.” This enables instantaneous communication between the robot’s motion and the arc’s behavior, something unachievable with mixed-vendor systems.

This integration enables advanced processes like Synchro-Feed, an ultra-low spatter technology. For buyers who work with challenging materials, this is a critical feature.

It produces exceptionally clean welds on galvanized steel and is a game-changer for aluminium welding, minimizing defects and drastically reducing the need for costly post-weld cleanup. This makes it especially useful in applications that require high-strength, cosmetically clean welds—an important consideration when comparing welding versus soldering in metal fabrication.

Solving Production Hurdles That Impact Your Bottom Line

For a wholesale supplier, production stoppages and quality issues are not minor inconveniences—they are direct threats to profitability and client relationships.

The true value of an intelligent system like the FD-V6 is its ability to autonomously solve the common problems that cause these disruptions in high-volume production.

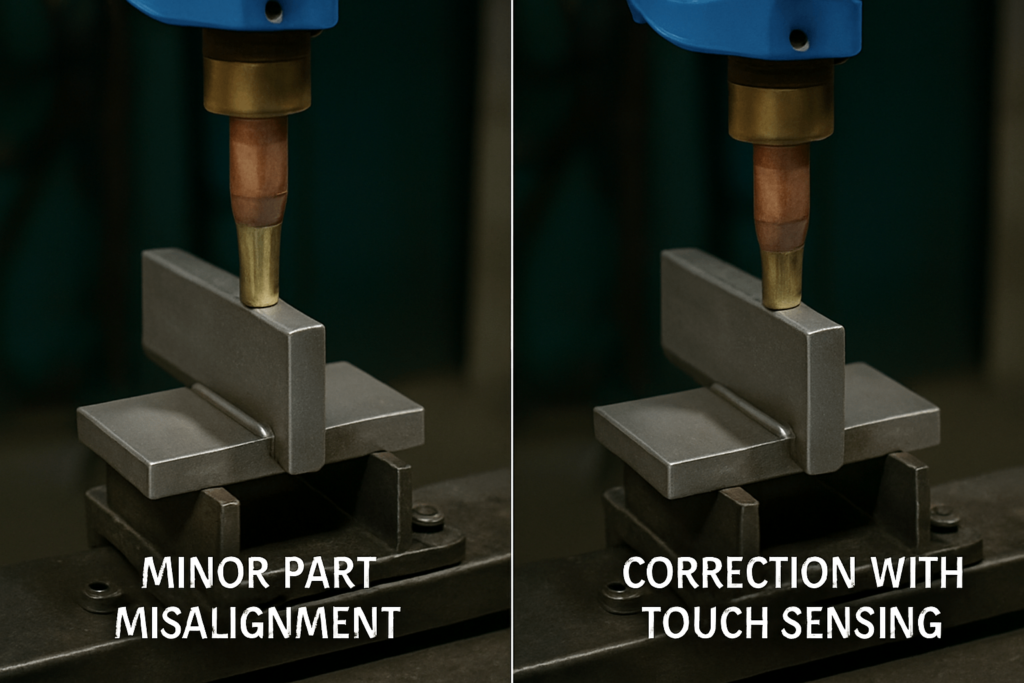

Hurdle #1: Minor Part Misalignment Causing Major Defects

In any real-world production, parts will never be placed in a jig with perfect, micron-level consistency. A basic robot will ignore this variance and weld where it was told, potentially missing the seam entirely.

The Solution: Touch Sensing. This function turns the welding wire into a smart probe. Before welding, the robot gently touches the part to detect the precise location of the joint.

The controller then instantly recalculates the entire weld path to match the actual position of the part. Over the course of a large batch order, this function ensures joint alignment remains within tolerance, significantly improving final pass rates and reducing rework.

Hurdle #2: Heat Distortion Compromising Weld Integrity

On long weld seams or thin materials, heat can cause the part to warp or pull away from its initial position mid-weld. This can lead to a critical defect known as lack of fusion in welding.

The Solution: Real-Time Seam Tracking. The FD-V6 actively compensates for this in real-time. Using Through-Arc Seam Tracking, it analyzes the electrical feedback from the arc itself to stay perfectly centered in the joint, even as it moves.

This adaptive capability is ideal for applications that demand consistent penetration across varied geometries, such as curved panels or bent tubes.

Hurdle #3: Arc Start Failures Halting the Production Line

One of the most frequent causes of downtime is a simple arc start failure. A small piece of spatter or contamination can prevent the arc from igniting, stopping the line until an operator intervenes.

The Solution: Arc Start Retry. This is an intelligent, autonomous recovery function. If the arc fails, the robot doesn’t just stop and wait.

It automatically retracts the wire, cleans the tip, and re-initiates the start sequence a set number of times. This feature ensures workflow continuity and significantly reduces production interruptions due to start anomalies.

Hurdle #4: Programming Errors Leading to Costly Collisions

A collision between the robot and a fixture can cause thousands of dollars in damage and days of unplanned downtime, jeopardizing delivery schedules.

The Solution: Built-in Collision Detection. The FD-V6 is equipped with a highly sensitive mechanical shock sensor. If an unexpected impact occurs, all motion is instantly halted.

This real-time safety measure protects high-value tooling and also allows for faster root cause analysis, helping teams refine future programming.

Building the Business Case: A Fabricator’s Guide to TCO and ROI

For a professional buyer, the decision to invest in automation is a financial one. It requires a clear analysis of the Total Cost of Ownership (TCO) and a realistic projection of the Return on Investment (ROI).

It’s crucial to understand that the robot arm is only part of the initial cost, typically about one-third of the total. The full investment includes safety systems, part fixtures, and integration. However, the returns are equally comprehensive.

Drastic Gains in Throughput and Uptime

This is the single largest financial driver. A manual welder’s true “arc-on” time, after factoring in breaks, setup, and fatigue, is roughly 25% per shift. A robotic cell, in contrast, can operate at up to 95% uptime, running continuously across multiple shifts.

This four-fold increase in efficiency means one robotic cell can often out-produce several manual stations. It fundamentally expands your capacity to handle large-volume contract welding & fabricating orders.

Reducing the Hidden Costs of Poor Quality

Inconsistent quality creates hidden costs that erode profit margins. These include scrap material, rework labor, and even warranty claims down the line.

The machine-like consistency of the FD-V6 drastically reduces defect rates. Its advanced arc controls reduce spatter, improving surface finish and eliminating the need for excessive grinding—thereby streamlining your process from weld to coating.

The Strategic Value of Long-Term Support

A key, often overlooked, factor in TCO is ongoing training. OTC DAIHEN offers a unique advantage with their “Free Training for Life” program.

This ensures that your team can remain proficient on the equipment for the life of the system—even with employee turnover. It eliminates a significant long-term operational expense and guarantees you can always leverage the system’s most advanced capabilities.

Conclusion: A Strategic Investment in Capacity and Reliability

The OTC DAIHEN FD-V6 is more than a piece of hardware; it is an integrated welding system engineered to solve the most pressing challenges in modern high-volume fabrication.

Its value lies not just in its speed, but in its intelligence—the ability to adapt to real-world imperfections and autonomously maintain quality, ensuring the final product meets the strictest standards.

For a wholesale buyer or a company managing a complex supply chain, this technology is not an expense. It is a strategic investment in predictable output, consistent quality, and the capacity to grow your business.

If you’re exploring how automation can secure and enhance your operations, the experts at YISHANG are ready to talk shop.