Introduction: Beyond the Flame—Oxy-Fuel Cutting’s Strategic Role in Modern Manufacturing

For heavy steel fabrication projects, selecting the most effective cutting method is critical to cost, safety, and efficiency. This guide is tailored for procurement engineers and manufacturing professionals evaluating whether oxy-fuel cutting is the optimal solution for thick plate steel applications.

Imagine a controlled, incandescent flame parting a 12-inch (300 mm) thick steel plate with surgical precision. This is the enduring power of oxy-fuel cutting. Born over a century ago from the ingenuity of French engineers, this foundational metal cutting technology remains an indispensable force in heavy industry. In an era dominated by high-definition plasma and fiber lasers, the brilliant glare of the oxy-fuel torch isn’t a relic of the past; it’s a testament to its unique capabilities, cost-effectiveness, and unparalleled prowess in severing thick sections of ferrous metal.

This oxy-fuel cutting guide is not a simple encyclopedia of facts. It is a strategic and practical manual crafted for engineers, project managers, and fabricators making critical decisions on the shop floor and in the field. Our objective is to move beyond the basics and provide a definitive resource that helps you determine precisely when oxy-fuel is the superior choice and how to master its application to achieve an optimal balance of cost, quality, and efficiency in your steel plate cutting operations.

Section 1: Executive Summary—The 30-Second Decision: Is Oxy-Fuel Right for Your Project?

In today’s fast-paced industrial environment, making the right process choice quickly is paramount. This section is designed for the busy decision-maker who needs immediate, actionable insights. Use this checklist to determine if oxy-fuel cutting aligns with your project’s core requirements.

Quick Assessment Checklist

- Your Material: Are you exclusively cutting mild steel or low-alloy steels? Oxy-fuel cutting is specifically designed for ferrous metals. It is chemically incompatible with stainless steel or aluminum under standard operation.

- Your Thickness: Is your material predominantly thicker than 2 inches (50 mm)? This is where oxy-fuel technology is not just viable but often the most economically efficient and technically superior method. For materials under 1 inch, plasma cutting generally offers a significant speed advantage.

- Your Budget: Is minimizing initial capital expenditure a key consideration? An oxy-fuel system represents one of the lowest entry costs for industrial thermal cutting, making it highly accessible.

- Your Work Environment: Do you require a portable cutting solution that operates without a high-amperage electrical supply? The independence of an oxy-fuel setup makes it the undisputed choice for on-site construction, demolition, and field repairs.

The Final Verdict

If your operations involve cutting thick carbon steel plates, especially where budget and portability are critical factors, oxy-fuel cutting is your optimal solution. For projects demanding high-speed cutting of thinner metals, material versatility (including non-ferrous metals), or the absolute highest precision, you should evaluate plasma or laser cutting as primary alternatives.

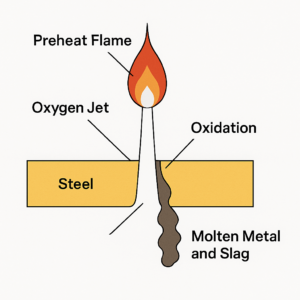

Section 2: Unveiling the Core Principle: It’s Not Melting, It’s Controlled Oxidation

A fundamental misunderstanding of the oxy-fuel cutting principle is that the torch simply melts its way through the metal. The reality is far more elegant and efficient, rooted in a powerful chemical reaction. The process is a carefully managed, high-speed oxidation that harnesses the chemistry of iron to achieve what brute thermal force alone could not.

Breaking Down the Myth: The Two-Stage Chemical Reaction

The oxy-fuel process is a sequential, two-stage event: preheating and oxidation. First, a preheat flame—a mixture of a fuel gas like acetylene or propane and oxygen—raises a localized area of the steel to its “kindling temperature,” approximately 1600–1800°F (870–980°C). At this point, the steel glows a bright cherry red but remains well below its melting point.

Once this critical temperature is reached, a separate, high-pressure jet of commercially pure oxygen (minimum 99.5% purity) is directed at the spot. This triggers a vigorous and highly exothermic reaction between the oxygen and the iron in the steel. This is not melting; it is a controlled, accelerated rusting process that generates immense heat, sustaining the cut as the torch moves forward. The product of this reaction, iron oxide (slag), has a lower melting point than the steel itself and is forcibly ejected from the cut path, or “kerf,” by the kinetic energy of the oxygen jet.

The Four Golden Rules of Cuttable Metals

The reason oxy-fuel cutting works flawlessly on mild steel but fails on other common metals is governed by a strict set of four fundamental requirements:

- Ignition Temperature Below Melting Point: The material must ignite in an oxygen-rich environment at a temperature lower than its melting point.

- Oxide Melting Point Below Material Melting Point: The oxide formed must melt at a lower temperature than the base metal. Stainless steel and aluminum form refractory oxides (chromium oxide and aluminum oxide) that hinder this process.

- Sustained Exothermic Reaction: The oxidation must generate enough heat to maintain preheat temperatures at the leading edge of the cut.

- Minimal Gaseous Byproducts: The reaction should avoid creating gases that disrupt oxygen purity or flame characteristics.

Section 3: Anatomy of the Oxy-Fuel Cutting System

An oxy-fuel setup appears deceptively simple but is a precise orchestration of components, each playing a critical role in maintaining safety and performance.

- Fuel Gas Cylinder: Acetylene is common for high heat output, but propane, propylene, and MAPP gas are also used depending on cost, availability, and desired flame characteristics.

- Oxygen Cylinder: High-purity oxygen (typically 99.5% or greater) is critical to maintain reaction efficiency.

- Pressure Regulators: These ensure consistent and safe gas delivery to the torch.

- Hoses: Color-coded and rated for flame resistance and specific pressure ranges.

- Torch Handle and Cutting Attachment: The control center of the operation—regulates gas flow and initiates the cutting stream.

- Cutting Tips: Sized according to plate thickness. A properly matched tip ensures a clean kerf and minimizes slag adhesion.

Understanding these components allows operators to better diagnose performance issues and fine-tune for different plate thicknesses and shop conditions.

Section 4: Mastering the Cut—Operational Techniques

Executing a quality oxy-fuel cut involves more than just lighting a torch and moving it across steel. Several operator-controlled variables influence cut quality:

- Preheat Time: Insufficient preheat leads to delayed ignition and poor kerf edges.

- Tip-to-Work Distance: Impacts flame shape and heat distribution. Too far causes heat loss; too close can oxidize tips.

- Travel Speed: Excessively fast speeds create drag lines and undercuts; too slow produces wide kerfs and heavy slag.

- Torch Angle: Generally perpendicular to the surface, but slight lead angles can help when initiating or exiting cuts.

Well-trained operators develop an intuitive rhythm based on flame color, sound, and slag behavior—hallmarks of seasoned fabrication shops.

Section 5: Diagnosing Cut Quality—What Your Kerf Is Telling You

A good cut leaves behind a clean, narrow kerf with minimal dross and vertical edges. Common quality indicators include:

- Top Edge Rounding: Indicates too much preheat or excessive stand-off distance.

- Excessive Dross: Suggests poor oxygen purity or incorrect travel speed.

- Drag Lines: Slight lines are normal; deep or curved ones point to unstable torch motion.

- Beveled Edges: Often caused by torch angle or uneven preheat.

Regularly inspecting these visual cues helps catch setup errors early and avoid material waste.

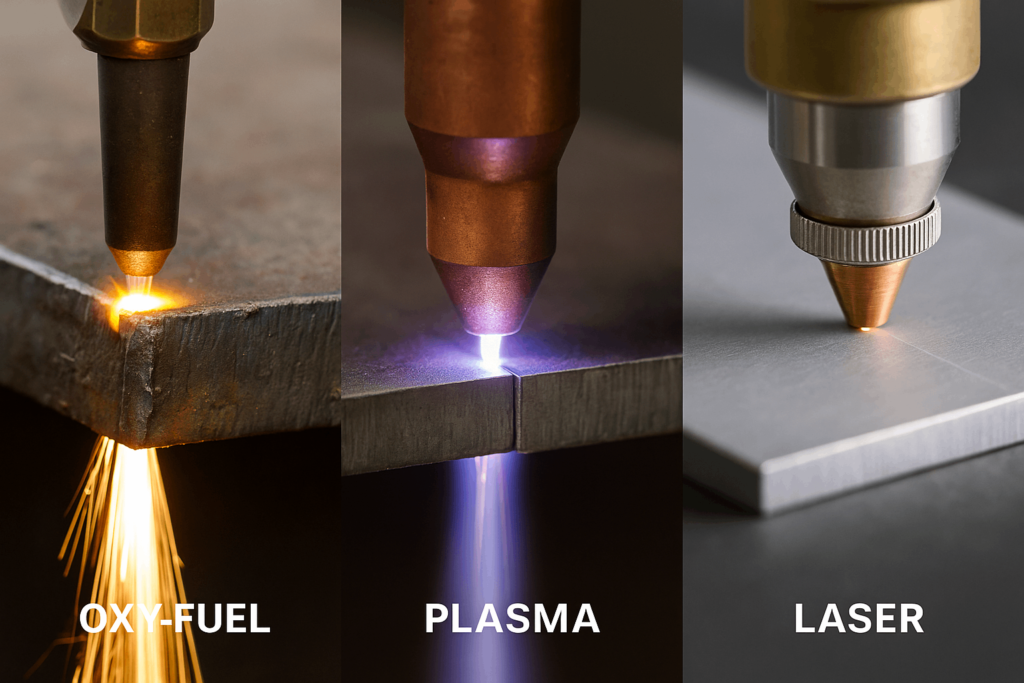

Section 6: Oxy-Fuel vs. Plasma vs. Laser—A Comparative Analysis

Each cutting method has unique advantages and trade-offs. This comparison table simplifies selection based on common industrial criteria:

| CriteriaOxy-Fuel CuttingPlasma CuttingLaser Cutting | |||

|---|---|---|---|

| Thickness Capability | Excellent for >2″ (50 mm) | Best for <2″ (50 mm) | Best for <1″ (25 mm) |

| Material Compatibility | Mild steel only | All conductive metals | All metals |

| Capital Investment | Low | Moderate | High |

| Cutting Speed | Slow | Fast | Very Fast |

| Edge Precision | Moderate | Good | Excellent |

| Portability | Excellent | Limited | Poor |

| Maintenance | Low | Moderate | High |

Oxy-fuel remains unmatched for thick steel cutting in terms of cost and simplicity, especially in field or repair scenarios.

Section 7: Innovations and the Future of Oxy-Fuel Cutting

While oxy-fuel is rooted in century-old principles, it’s not immune to innovation. Key trends include:

- Fuel Alternatives: Propylene and natural gas are replacing acetylene for cost and safety reasons.

- CNC Integration: Modern gantry systems offer automated motion control and nesting.

- Safety Enhancements: Flashback arrestors, check valves, and auto-ignition torches improve operator safety.

- Eco-Friendly Cutting: Low-emission fuel blends and fume extraction systems reduce environmental impact.

These enhancements ensure that oxy-fuel remains relevant—even in a landscape of rapid digital manufacturing adoption.

Section 8: Safety Protocols—Non-Negotiable for Industrial Use

Improper oxy-fuel handling can be catastrophic. Best practices include:

- Personal Protective Equipment (PPE): ANSI-approved goggles, flame-resistant clothing, gloves, and hearing protection.

- Cylinder Storage: Upright, secured, and in ventilated areas. Oxygen and fuel gas must be stored separately.

- Leak Testing: Regular soap-bubble testing at connections.

- Ignition Protocols: Never use matches or lighters. Spark igniters only.

Regulations such as OSHA 1910.253 and ANSI Z49.1 are not suggestions—they are enforceable standards that protect lives.

Section 9: Frequently Asked Questions (FAQ)

Can oxy-fuel cut aluminum or stainless steel?

No. These materials form refractory oxides that prevent the self-sustaining oxidation process necessary for oxy-fuel cutting.

How thick can oxy-fuel cut?

Industrial-grade systems can cut steel plates up to 24 inches (610 mm) thick with multi-torch configurations.

What’s the most cost-effective gas?

Propane often provides the best balance between cost, safety, and preheat performance.

Is oxy-fuel cutting outdated?

Not at all. For heavy plate fabrication, field cutting, and budget-sensitive operations, it remains highly competitive.

Conclusion: When Simplicity Meets Power

Oxy-fuel cutting may seem simple, but it’s a method forged from the intersection of chemistry, thermodynamics, and mechanical precision. In a world of lasers and automation, the flame torch holds its ground—not because it’s old, but because it works.

When cutting thick steel economically, safely, and reliably matters most, oxy-fuel cutting stands as a time-tested solution—and a core offering in the service portfolio of advanced metal fabrication partners like YISHANG.