For procurement managers and engineers making critical material sourcing decisions, a polypropylene (PP) datasheet can be deceptively simple. The listed melting point, typically between 160°C and 170°C, only tells part of the story.

Understanding the nuances of this property is key to ensuring product quality, manufacturing efficiency, and supply chain reliability.

This guide moves beyond basic data to provide the actionable insights needed for strategic procurement. We will explore the critical difference between the ultimate polypropylene melting point and two other thermal benchmarks that dictate real-world performance:

Softening Temperature: The point where PP loses rigidity, often around 100°C to 120°C.

Continuous Use Temperature: The maximum safe temperature for prolonged use, which for standard PP is only around 82°C.

A clear grasp of this thermal hierarchy is essential for specifying the correct grade for demanding applications and avoiding costly production issues. These insights are especially valuable when sourcing high temperature resistant polypropylene, or PP intended for industrial molding and technical thermoplastics applications.

Quick Summary:

The melting point of polypropylene (PP) typically ranges between 160 °C and 170 °C (320–338 °F). However, this number alone doesn’t define its behavior in real manufacturing. The effective melting range, softening temperature, and processing window determine how PP performs in molding, extrusion, and thermal stability.

Chapter 1: The Molecular Code – Why Tacticity Dictates Everything

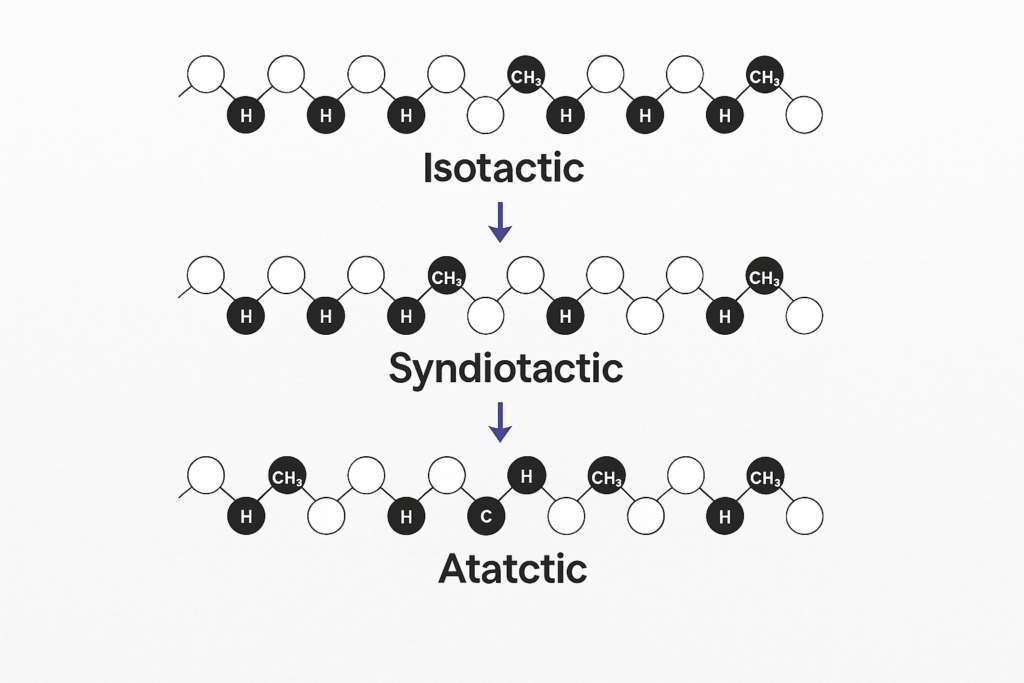

The foundation of polypropylene’s performance lies in its molecular architecture, a concept known as polypropylene tacticity—referring to the 3D arrangement of methyl (−CH3) groups along the polymer backbone. This orientation controls the material’s crystallinity, and thereby its core thermal and mechanical properties.

The Three Personalities of PP

This stereochemistry creates three distinct forms of polypropylene, each with a different performance profile:

Isotactic Polypropylene (iPP): All methyl groups aligned on one side of the chain. This regular structure enables dense packing and high crystallinity (up to 60%), resulting in the highest heat resistance and strength—ideal for structural applications.

Syndiotactic Polypropylene (sPP): Alternating methyl groups on both sides of the backbone. Less crystalline than iPP, sPP melts at a lower temperature (~130°C) and is suited for niche uses.

Atactic Polypropylene (aPP): Random methyl group orientation results in an amorphous, tacky material with no true melting point. It’s mainly used in adhesives and sealants.

| Feature | Isotactic PP (iPP) | Syndiotactic PP (sPP) | Atactic PP (aPP) |

|---|---|---|---|

| Methyl Group Arrangement | All on one side (Regular) | Alternating sides | Random |

| Ability to Crystallize | High | Moderate | None (Amorphous) |

| Typical Crystallinity | 40–60% | ~30% | ~0% |

| Melting Point (Tm) | 160–166°C | ~130°C | No sharp Tm |

| Commercial Relevance | Dominant commercial form (>90%) | Niche applications | Additive in blends |

As seen above, isotactic polypropylene exhibits the highest melting point (≈165 °C), while syndiotactic and atactic types melt or soften at significantly lower temperatures. This structural variation explains why data sheets often list different melting points for “polypropylene.”

Chapter 2: The Engineer’s Trade-Off – Choosing the Right PP Grade

Choosing the right PP grade is an engineering balancing act—stiffness and heat resistance vs. impact strength and flexibility.

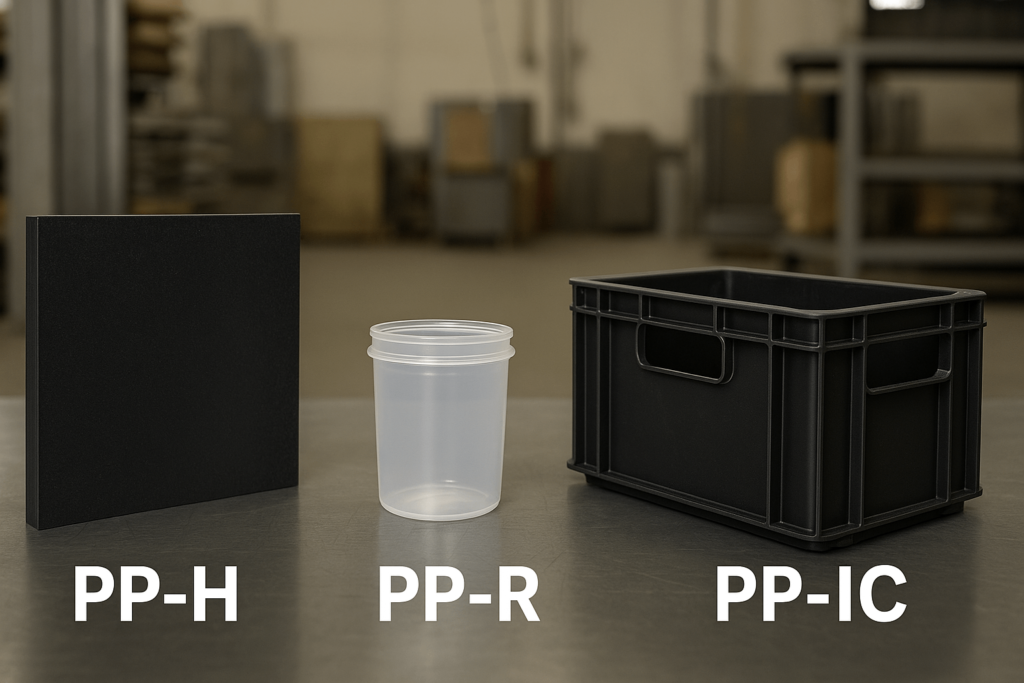

The Contenders in the PP Family

PP Homopolymer (PP-H): High crystallinity and rigidity, excellent thermal resistance, but poor cold impact strength.

PP Random Copolymer (PP-R): Contains ethylene for enhanced clarity and flexibility; melts at lower temperatures, ideal for packaging and medical use.

PP Impact Copolymer (PP-IC): Combines a stiff homopolymer matrix with rubber domains for superior impact resistance at low temps. These grades are commonly used in injection molding of crates, bins, and automotive trim components.

Data-Driven Comparison for Strategic Sourcing

| Property | PP Homopolymer (PP-H) | PP Random Copolymer (PP-R) | PP Impact Copolymer (PP-IC) |

| Melting Point (Tm) | 165–170°C | 135–160°C | 150–165°C |

| Stiffness (Flex Modulus) | 210–290 kpsi | 155–200 kpsi | 155–225 kpsi |

| Tensile Strength | 5000–5800 psi | 3600–4600 psi | 3000–4900 psi |

| Impact Strength (Notched Izod) | Poor (0.4–0.9 ft-lb/in) | Moderate (0.9–2 ft-lb/in) | Excellent (1.2 – no break) |

Melting Point Insight:

Homopolymer PP → Highest Tm (~170 °C), best heat resistance.

Random Copolymer PP → Lower Tm (~150 °C), improved clarity.

Impact Copolymer PP → Moderate Tm (~160 °C), best impact strength.

This variation explains why the “polypropylene melting point” is a range rather than a single temperature.

Chapter 3: The Performance Paradox – How Additives Drive Value

Additives enable tailored performance. Some even lower melting point intentionally to increase toughness and flexibility.

The Game Changer: Beta (β) Nucleating Agents

Beta-nucleating agents promote the formation of β-crystals (melting at ~147–155°C) which enhance impact strength. This is critical when toughness matters more than maximum heat resistance.

The Reinforcements: Fillers and HDT

HDT (Heat Deflection Temperature) is not the same as melting point. Fillers like glass fiber or talc raise HDT significantly—vital for structural parts operating near PP’s melting range, especially in polypropylene for high-heat applications.

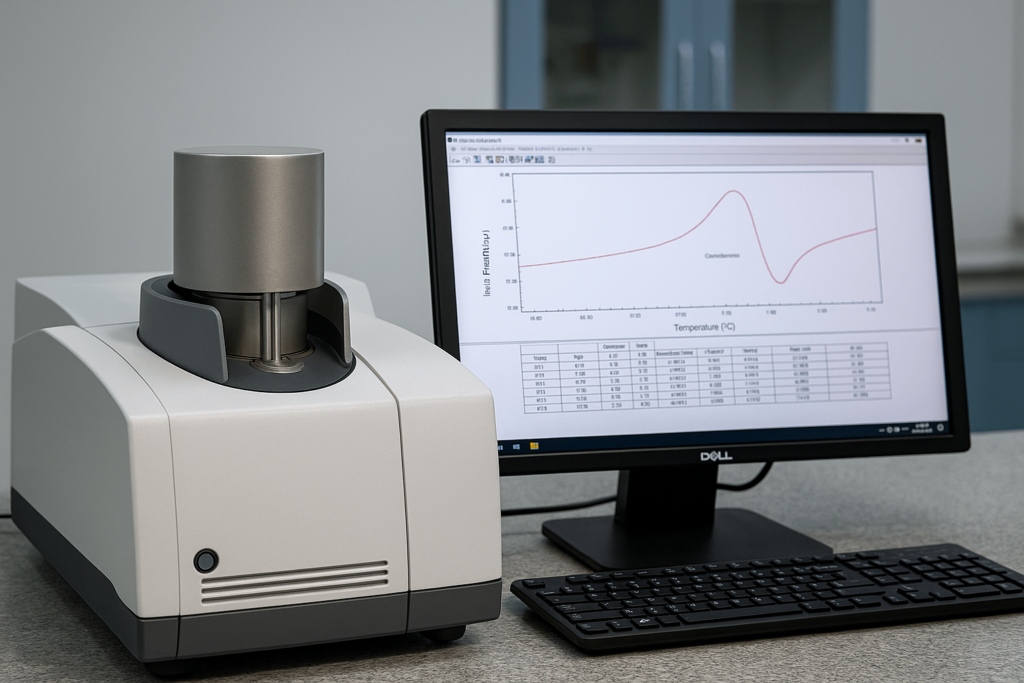

Chapter 4: Decoding the Thermal Fingerprint – DSC Analysis

Differential Scanning Calorimetry (DSC) is essential for verifying material consistency. A two-heat scan provides insight into both prior processing history and intrinsic properties.

Reading a DSC Curve

First vs. Second Heat: The second heat scan reveals standardized, stress-free behavior.

Multiple Melting Peaks: Indicates polymorphism, imperfect crystals, or recrystallization.

Crystallinity Calculation

%Xc = (ΔHf_sample / ΔHf°) × 100 — with ΔHf° for isotactic PP = 209 J/g.

Chapter 5: From Pellet to Part – Mastering the Processing Window

Melt temperature must balance flow and degradation risk.

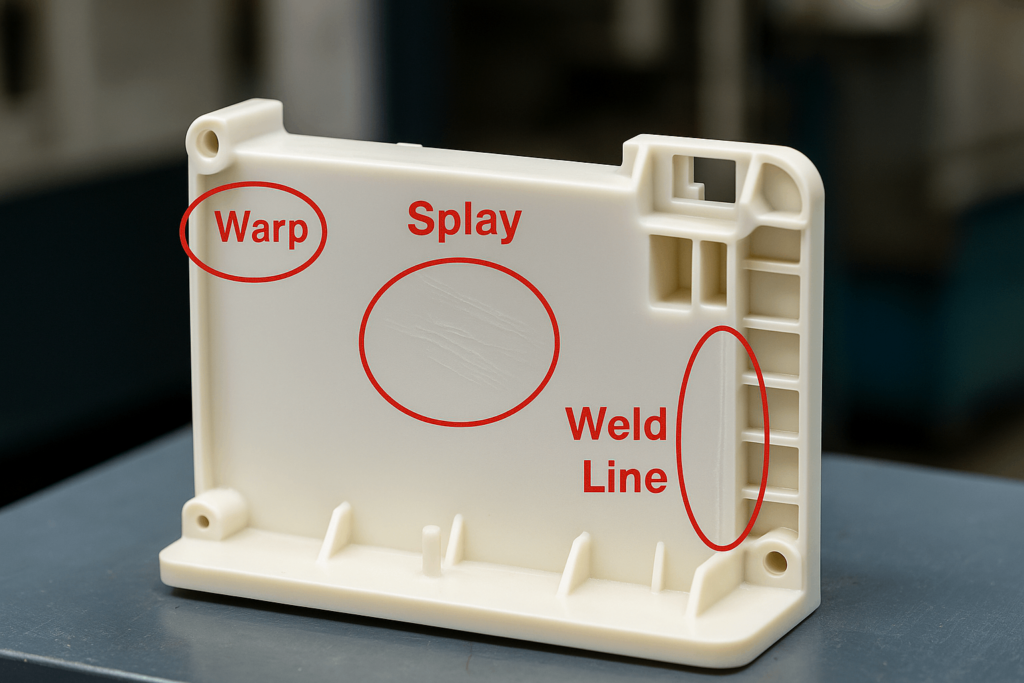

Troubleshooting by Temperature Symptom

For most PP grades, recommended melt temperatures are about 30–70 °C above their melting point, typically 190–240 °C. Keeping within this range prevents thermal degradation while ensuring full mold filling.

| Defect | Likely Cause | Solution |

| Sink Marks | Overheated melt, insufficient cooling | Reduce melt temp; extend cooling cycle |

| Warpage | Uneven cooling, high melt temp | Improve cooling balance; lower temp |

| Flash | Low viscosity from overheating | Reduce melt temp; clamp tighter |

| Short Shot | Cold melt, poor fill | Raise melt temp; check venting |

| Weld Lines | Melt too cool at junction | Increase melt/mold temp; faster injection |

| Burn Marks | Degradation or trapped air | Vent mold; lower melt temp |

Temperature Cheat Sheet

| PP Grade | Melt Temp (°C) | Mold Temp (°C) |

| Neat Homopolymer/Copolymer | 190–210 | 30–80 |

| Talc-Filled | 210–225 | 30–50 |

| Glass-Filled | 230–240 | 40–80 |

Chapter 6: PP in the Hot Seat – Real-World Applications

Case 1: Automotive Under-the-Hood

Reinforced PP replaces metal in high-temp zones—fan shrouds, HVAC housings, battery cases—thanks to talc/glass-filled grades with HDT up to 160°C.

Case 2: Medical Sterilization

Steam autoclave (132–134°C) requires PP copolymers that survive sterilization without melting—ideal for syringes, trays, bottles. Selecting the correct polypropylene grade for medical molding ensures safety and durability.

Chapter 7: PP vs. Alternatives – Thermal Snapshot

| Material | Melting Point (°C) | Max Use Temp (°C) | Notes |

| PP | 160–170 | ~82 | Best value-performance tradeoff |

| HDPE | 130–137 | ~60 | Lower cost, flexible |

| PET | ~250–260 | ~150 | Strong, transparent, barrier properties |

| PC | ~250 | ~140 | Impact-resistant, clear, dimensionally stable |

| Nylon 6 | ~220 | Varies | Strong, moisture-absorbing |

Beyond melting point, polypropylene’s softening temperature (100–120 °C) and continuous use limit (~80 °C) determine its real-world durability. Designers should evaluate all three to ensure dimensional stability and long-term performance.

Conclusion: Turn Data into Strategy

PP’s melting point is more than a number—it’s a strategic lever. Understanding how tacticity, additives, crystallinity, and processing interact empowers better material selection and quality control.

Whether you’re sourcing injection-grade polypropylene or comparing thermal resistance across polymers, a deeper understanding translates to better decisions.

For expert sourcing assistance or material compatibility review, contact the YISHANG team.

FAQs

What is the melting point of PP?

160°C to 170°C depending on grade.

Does crystallinity impact melting point?

Yes. More crystalline = higher melting temp.

Do additives affect melting point?

Yes—beta-nucleants lower it for toughness.

Why is PP’s melting point important in molding?

It defines the bottom end of the processing window.

Does molecular weight affect melting point?

Slightly. Higher weight = stronger chain interactions = higher Tm.

What are typical processing temps?

190°C to 290°C depending on reinforcement.

What applications rely on PP’s thermal behavior?

Automotive engine bay parts; medical items needing sterilization; high-temperature-resistant molded products.