Why Precision Tubular Frames Matter to Global Buyers

For international wholesale buyers, sourcing stainless steel tubular frames goes far beyond aesthetics. It’s about consistency, dimensional accuracy, and assured supply. In markets like medical infrastructure, automated machinery, or public-facing equipment, structural failure means costly downtime and end-user dissatisfaction.

This guide provides actionable insights on how YISHANG delivers precision stainless steel tubular frames that meet industrial tolerances and scale requirements. You’ll discover how smart engineering, laser tube cutting, and quality assurance align with the procurement priorities of global OEM and ODM buyers.

Structural Performance Begins at Design

Stress-Resilient Design for High-Demand Applications

Frames in carts, robots, or kiosks face multi-directional forces: torsion, compression, and repetitive vibration. Without proper stress modeling, defects arise at joints or weld seams during transit or installation.

YISHANG integrates FEA simulation during early-stage design, simulating stress zones in alloy steel tubes or bent stainless tubing. This allows for proactive reinforcement and optimized bracing—reducing failure risk.

Matching Geometry with Functional Load

Wholesale buyers benefit most when the frame geometry matches end-use conditions. Round tubes distribute pressure evenly, while rectangular tubing resists lateral force—ideal for display systems.

Our builds use tube dimensions from 1.2mm to 3mm wall thickness, offering a balance between lightweight logistics and mechanical reliability. All assemblies conform to ISO 2768 standard tolerances, minimizing tolerance stacking in modular builds.

Fabrication Capabilities That Scale with You

Laser Tube Cutting: The Starting Point of Precision

YISHANG’s CNC laser cutting machines for tubes ensure repeatability and tight cutting tolerances (±0.2mm). Whether it’s for bent metal tubing or pre-slotted connections, laser cutting of tubes allows:

Precise bolt hole placements for assembly

Reduced manual post-processing labor

Smooth, burr-free joints ready for welding

We also support LSI configurations such as tube laser cut parts and tube laser services for multi-industry use cases.

Bending Tubes, Not Budgets: Controlled CNC Tube Forming

From bending stainless steel tubing in medical carts to shaping aluminum extrusion tubes for lighter frameworks, we offer:

Programmable angles for consistent production

Bend radius control for cintrage tube inox applications

Reduced welding points via formed joints

YISHANG’s ability to bend rectangular tubing and bent stainless tubing in complex geometries eliminates unnecessary joints while improving aesthetics and structural strength.

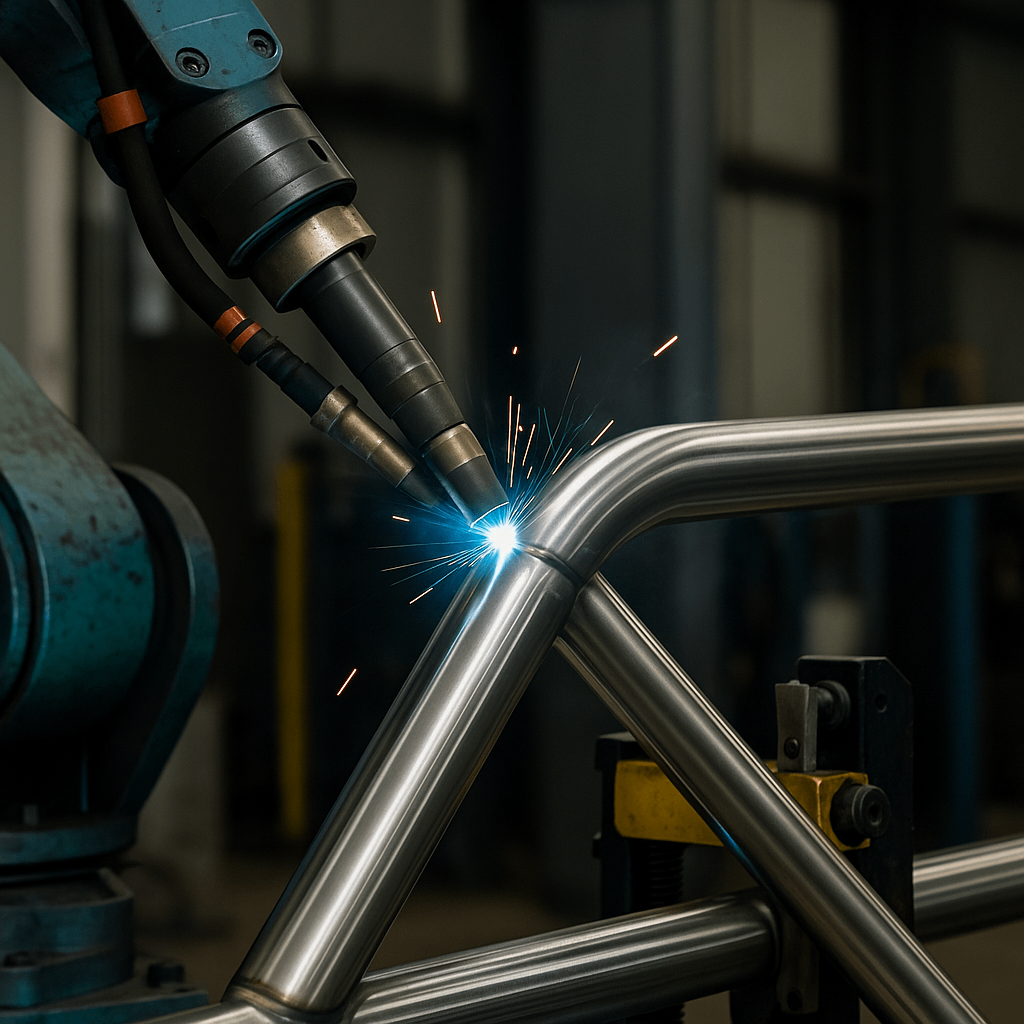

Weld Consistency for Long-Term Assembly Integrity

MIG and TIG welding are used based on weld location visibility and structural load. Robotic arms maintain weld width consistency and minimize human error.

Each project batch undergoes weld inspection using ultrasonic or dye-penetrant testing. This is especially useful in high-load points, such as automation machine legs or industrial shelf frames.

All welding processes align with EN ISO 3834-2 quality systems, providing procurement teams with weld specs and supporting documentation.

Functional Finishes that Protect and Present

Depending on climate, sanitation, or branding needs, our surface options include:

Ra < 0.8μm brushed stainless for hygiene equipment

Passivated finishes for medical-grade frames

Powder-coated tubes validated via ASTM B117 for 500-hour salt spray durability

These are not just visual treatments—they support corrosion resistance in outdoor kiosks, reduce microbial build-up in clinical equipment, and extend frame life.

From BOM to Batch: Collaborative Engineering for Procurement Clarity

Engineering Integration During RFQ and Drawing Exchange

Rather than quote passively on complex drawings, YISHANG engineers co-review BOMs to simplify design:

Replace welded joints with formed bent metal tubing

Advise on laser tube cutting patterns to reduce distortion

Flag overengineered tolerances that impact CNC time and cost

This early design alignment reduces revisions and supports a faster, smoother production handoff.

Prototyping That Validates Investment

To reduce PO risk, we run a complete validation process:

3D model simulation + tolerance verification (CMM)

First article approval for functional fit

Real-world strength tests aligned with weight class or usage cycle

All validations are documented for supplier audits and client-side QA use.

QA That’s Transparent, Trackable, and Trusted

Every Batch Has a Fingerprint

Each order is serialized, with process controls logged:

ID trace on laser cut tube parts

Weld station checks with jig alignment

Pre-packaging dimensional review by QC leads

Our QA team follows ISO 9001 workflows, and full inspection reports are available for customs, compliance, or internal recordkeeping.

Global Standards Built-In

We work with global clients who need adherence to:

RoHS (hazardous materials restrictions)

ASTM A554 (mechanical stainless tube standards)

EN ISO 3834 welding documentation

Our documentation kits support medical, EV, construction, and automation industries that operate under strict product liability expectations.

Application-Driven Precision: What Buyers Actually Get

Medical Equipment Frames That Meet Hygiene Compliance

In healthcare procurement, compliance and cleanability are top priorities. Buyers sourcing frames for IV poles, mobile diagnostic tables, or modular workstations need assurance on both corrosion resistance and sterility.

YISHANG delivers passivated and electro-polished frames using bent stainless tubing that supports medical-grade standards. Our welds are optimized to avoid micro-crevices where bacteria could collect—a key concern in regulatory audits. The use of precision tube laser technology also ensures dimensional control for compatible accessories.

Automation Frames That Fit Right Out of the Crate

For integrators in the automation industry, inconsistent dimensions mean lost time. We offer CNC-bent, laser cut tube frames that arrive bolt-on ready with clearly marked sections. This allows teams to reduce in-house jig setups and begin assembly immediately.

Dimensional tolerances are guaranteed to +/-0.5mm across length-critical features. Buyers benefit from reduced adjustment costs and fewer scrap components. Every laser cut tube is validated for its match with mating hardware, reducing trial-fit waste.

Weather-Resistant Frames for Public Infrastructure

Frames used in EV chargers, outdoor kiosks, or smart city structures face extreme environments. YISHANG fabricates outdoor-ready frames with minimized weld seams and anti-corrosion coatings validated via 500-hour salt spray tests (ASTM B117).

By combining tube laser cutting with environmental-grade powder coating, we provide builds that resist UV degradation, urban pollution, and freeze-thaw cycles. This helps procurement teams justify longer service cycles with reduced maintenance spend.

Confidence Beyond the Cut

Stainless steel frame sourcing is ultimately a trust decision. Global buyers need dimensional accuracy, logistics reliability, and vendor clarity. YISHANG brings precision tube laser fabrication, international QA systems, and decades of OEM insight to your next purchase order.

Let us help simplify your supply chain—start with a drawing, end with confidence.

FAQ | Common Questions from Global Procurement Teams

What is the standard tolerance range for stainless steel tubular frames?

YISHANG maintains a typical tolerance of ±0.5mm for critical length and width dimensions, with tighter tolerances available for precision applications. All tolerances are verified using calibrated CMM and inspection jigs.

Can you handle low-volume or pilot production runs?

Yes. We support low-MOQ projects for prototyping, market testing, or custom orders. Laser tube cutting and CNC tube bending allow us to deliver small batches efficiently while maintaining quality consistency.

What certifications and documentation do you provide for compliance?

We offer ISO 9001 inspection records, EN ISO 3834-2 welding documentation, RoHS declarations, and ASTM test reports (such as B117 salt spray). FAIR (First Article Inspection Report) is available upon request.

Do you support tube bending for materials other than stainless steel?

Absolutely. We work with alloy steel, aluminium extrusion tubes, and mild steel. Our CNC equipment adjusts bend radius and springback compensation per material type.

What’s the difference between pipe and tube in fabrication?

Pipes are generally measured by internal diameter and used for fluid transfer, while tubes are measured by external dimensions and are used for structural support. We focus on structural tube fabrication with precise outer dimensions.