Introduction: Stop Thinking About Stamping as a Process. Start Thinking of It as a Supply Chain Strategy

In global sourcing and high-volume manufacturing, success is measured in unit cost, lead time stability, and parts-per-million (PPM) quality metrics. For decades, progressive die stamping has been a cornerstone for producing metal components. However, for a procurement manager, viewing it as merely a process is a critical oversight. The decision to specify progressive die stamping—and the partner you choose to execute it—is a fundamental supply chain strategy that directly impacts your profitability, product reliability, and speed-to-market.

This guide is engineered for the strategic buyer. It moves beyond textbook definitions to explore how to leverage this powerful technology as a competitive advantage. Not only will we explain how the stamping process works, but also how to align it with your sourcing goals. We’ll delve into the physics of precision that underpin its repeatability, the critical decision points that determine cost-efficiency, and the specific engineering problems it solves in mass production. Ultimately, this is a blueprint for transforming raw metal coil into a reliable, scalable, and strategic asset in your global procurement ecosystem.

To help clarify implementation, each section concludes with key insights framed from a buyer’s perspective—guiding sourcing managers toward more informed decisions. Whether you are in automotive, electronics, appliances, or another volume-driven sector, this guide is designed to connect the dots between technical feasibility and commercial viability. As an OEM precision metal stamping China factory, YISHANG brings this guide to support your sourcing success.

Part 1: The Physics of Precision – How a Single Die Guarantees Quality at Scale

Progressive die stamping is not just a metal forming method—it’s a repeatability system. A single progressive die, once dialed in, acts like a mechanical algorithm: feeding, aligning, forming, trimming, and ejecting with sub-millimeter consistency. Every stroke of the press delivers a part. This precision isn’t accidental; it’s engineered into the strip layout design, die components, and press calibration.

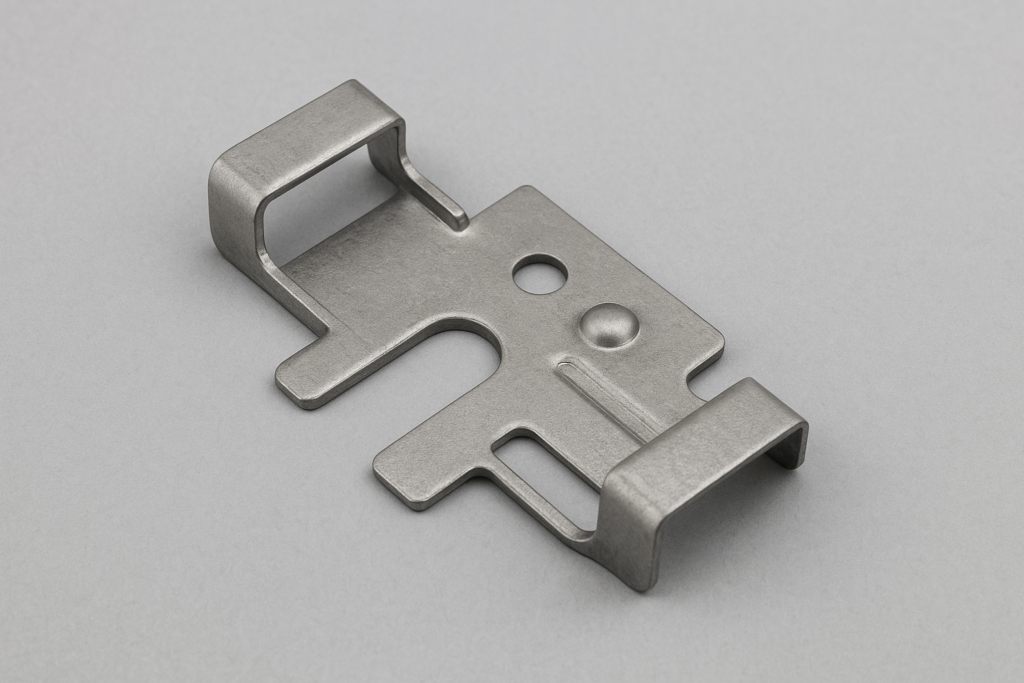

A progressive die is typically a multi-station tool mounted in a high-speed stamping press. As raw coil material advances through the die, each station performs a specific operation—such as piercing, bending, coining, or forming—building toward the final part geometry. Because all operations occur in a single setup, the need for multiple fixtures, setups, and handling steps is eliminated. That’s the secret to its high output and tight tolerances.

In industries like automotive or electronics, dimensional drift can cause costly downstream failures. Progressive stamping mitigates this risk by embedding precision into the tooling itself. Guide pins ensure alignment. Pilots control pitch accuracy. Strip carriers stabilize lateral movement. The result? Every part matches the CAD.

Unlike other stamping methods, progressive dies are inherently stable across long production runs. Once optimized, they operate with minimal human intervention. This allows sourcing teams to lock in predictable part costs over millions of cycles.

High-speed presses (ranging from 100 to 1,500 strokes per minute) and automatic feeding systems elevate efficiency further. Sophisticated lubrication systems and in-die sensors prevent jams and detect tool wear in real time. These upgrades make progressive stamping ideal not just for mass production, but for smart production.

Buyer Insight: Always ask your supplier whether they use piloting systems, strip layout design, and precision-ground tooling for progressive dies. These components are the silent guarantors of dimensional consistency from a custom progressive die stamping parts supplier.

Part 2: The Volume Threshold – When Progressive Die Stamping Becomes Cost-Effective

Progressive die stamping requires upfront investment in tooling, which can range from a few thousand to over $100,000 depending on part complexity. This cost is amortized over the life of the tool—meaning per-part pricing drops significantly with volume.

So when does it make economic sense? Typically, at production volumes exceeding 20,000–50,000 units annually. For parts with complex geometries or multiple features, progressive dies consolidate operations that would otherwise require multiple tools and setups. This alone can offset initial costs within the first production cycle.

The real cost savings come from reduced labor, lower scrap rates, and faster production speeds. Traditional stamping methods like single-stage dies or compound dies require manual handling between operations, which adds labor cost, increases risk of defects, and elongates lead times.

By contrast, progressive stamping automates the entire forming sequence. Material utilization improves because the die design is optimized for feed progression and nest arrangement. Less material waste translates directly to cost savings—particularly important for high-value alloys like stainless steel, brass, or copper.

Modern tooling software now allows simulation of progressive die setups before fabrication, further improving ROI. Engineers can detect and resolve forming challenges, strip deflection, or potential interferences early in the design stage. This avoids costly rework and downtime.

Buyer Insight: If your product forecasts exceed 20,000 units annually, always model a progressive die ROI—even if your part seems simple. The hidden savings in yield and automation often justify the tooling faster than expected. For early-stage product decisions, a progressive die vs compound die cost comparison can reveal long-term savings.

Part 3: Real-World Engineering Problems That Progressive Dies Solve Better Than Anything Else

Progressive dies shine in solving complex manufacturing challenges—especially those involving multi-step forming or stringent part-to-part repeatability.

Take parts requiring multiple bends, offset forms, embosses, or deep drawn features. In conventional stamping, each feature demands a dedicated setup or tool, increasing handling time and alignment errors. Progressive dies combine these steps in one flow, using staged tooling and pilot alignment to ensure cumulative accuracy.

Another common challenge is tight positional tolerances between holes, cutouts, or tabs. In die-punched parts, even slight misalignment between operations can cause downstream assembly issues. Progressive dies eliminate this variability by creating all features in a single die set, under the same registration control.

Progressive stamping also solves flatness issues in thin-gauge materials. Using contoured pressure pads and stripper plates, dies can flatten or control springback during forming. This is critical in applications like battery contacts, EMI shields, or enclosure gaskets.

Beyond the geometry itself, progressive dies improve consistency of surface finish—since parts remain nested in the strip until the final cut-off station. This prevents nicks, scratches, and handling marks.

Buyer Insight: If your team faces rework, dimensional drift, or inconsistent surface quality in formed parts—progressive stamping isn’t just an upgrade, it’s a solution. Always ask suppliers how they engineer for flatness, springback, and part-to-part repeatability, especially in high volume stamping for automotive components.

Part 4: The Tyranny of Tooling – What Most Sourcing Teams Fail to Account For

Tooling isn’t just a technical issue—it’s a supply chain liability if mishandled. Progressive dies are complex assets that require design approval, maintenance schedules, and ownership terms.

One common mistake is assuming the die belongs to the buyer once paid for. But without clear contractual language, suppliers may restrict access, refuse to release tooling, or charge storage fees. Always define tooling ownership, maintenance responsibilities, and transfer clauses upfront.

Tool life varies depending on part material, press speed, and maintenance discipline. High-quality tools can exceed 1 million strokes. But dies exposed to high-strength steel, or lacking proper lubrication, can wear prematurely—leading to burrs, misalignment, or fracture.

Choose suppliers who implement predictive maintenance and store tools in climate-controlled environments. Request die set maintenance program documentation, including sharpening logs, component replacement history, and calibration reports.

Also evaluate toolmaker capability. The best suppliers use CNC-machined die components, EDM-cut features, and in-die sensors for feedback. Some offer modular tool design, enabling faster insert replacement or geometry changes.

Buyer Insight: Push beyond unit cost. Always request a tooling maintenance schedule, ownership terms, and expected tool life in writing before issuing a PO. Also confirm their die set maintenance program and tool steel selection strategy. It pays off.

Part 5: Smart Dies and Servo Presses – The Quiet Revolution in Precision Metalforming

Servo presses and in-die sensors are redefining what’s possible in progressive stamping. Unlike traditional mechanical presses with fixed motion curves, servo presses allow programmable ram speeds, dwell times, and stroke profiles.

This flexibility enables smoother forming of complex geometries and reduces shock load on tooling—extending die life. In-die threading, tapping, and nut insertion are now possible at production speed.

Smart dies incorporate sensors that detect strip position, punch force, part ejection, and more. These signals feed into PLCs or SCADA systems for real-time monitoring. If a defect is detected, the system halts the press to prevent further scrap.

The result is a stamping line that’s not only faster but smarter—capable of SPC, auto-correction, and integration with MES systems. This is essential for sectors requiring traceability, such as automotive, aerospace, or medical.

Buyer Insight: If your end-users demand zero-defect delivery or lot traceability, smart tooling and servo presses can help you achieve that standard while reducing total inspection costs. Partnering with a servo press metal stamping expert helps future-proof your supply chain.

Part 6: Due Diligence – What to Look for When Choosing a Progressive Die Stamping Partner

Great tooling can’t overcome poor project management. That’s why supplier selection is critical in progressive stamping projects.

Start by evaluating vertical integration. Does the supplier offer in-house tool design and fabrication, or do they outsource? Internal capability speeds up iterations, protects IP, and improves accountability.

Review their press capacity and tonnage range. Progressive dies may require presses from 25T to over 600T depending on part size and material. Look for suppliers with modern servo or mechanical presses, and quick-change tooling systems.

Assess quality systems. ISO 9001 certification is a baseline. Look for FMEA, APQP, PPAP documentation if you’re in automotive. Medical and aerospace parts may require NADCAP or ISO 13485.

Ask for samples from similar projects—ideally with matching material, geometry, and volume. Inspect dimensional reports, surface finish, and edge quality. A good partner will also help you optimize part design for manufacturability.

YISHANG has delivered progressive stamping components to over 50 countries in industries including automotive, medical, vending machines, and energy storage.

Buyer Insight: Choose suppliers who speak engineering fluently, not just logistics. Great stamping partners don’t just hit tolerances—they help you build better, faster, and more economically. As an ISO 9001 certified metal stamping manufacturer, YISHANG backs every tool with accountability.

Conclusion: From Press to Profit – Why Strategic Buyers Choose Progressive Die Stamping

Progressive die stamping isn’t just another process in your sourcing toolkit—it’s a strategic enabler. When applied correctly, it reduces cost-per-part, shortens lead time, improves product quality, and enhances supply chain predictability.

For global sourcing professionals, it unlocks a world of high-performance parts that scale. But its full potential is only realized when matched with the right supplier—one who understands not just metallurgy and mechanics, but also your business drivers.

At YISHANG, we don’t just provide a service. We offer a partnership built on expertise, transparency, and a shared commitment to long-term success. Whether you’re launching a new product line or optimizing an existing component, we invite you to explore how YISHANG can support your next project—combining precision engineering with reliable global fulfillment.

Request a free tooling evaluation or design-for-manufacturability consultation today.

Explore More: For detailed specifications, RFQs, or to download our stamping capabilities datasheet, visit https://zsyishang.com or email sales@metal-display.com.

Frequently Asked Questions (FAQ)

Q1: Is progressive die stamping suitable for low-volume production?

A: Typically, it is more cost-effective for medium to high production volumes due to tooling costs. However, for certain precision parts requiring high consistency, the investment may still be worthwhile even at moderate volumes.

Q2: What’s the difference between progressive die and compound die stamping?

A: Progressive dies perform multiple operations across sequential stations in one stroke, ideal for complex parts at high speed. Compound dies combine operations in a single station, typically used for simpler geometries.

Q3: Can progressive die stamping be used for stainless steel parts?

A: Yes, it is highly effective for stainless steel, including thin-gauge materials used in EMI shielding and enclosures.